- DL manuals

- Bunn

- Coffee Maker

- TWF-EZ

- Operating & Service Manual

Bunn TWF-EZ Operating & Service Manual

Summary of TWF-EZ

Page 1

Bunn-o-matic corporation twf-ez post office box 3227 springfield, illinois 62708-3227 telephone: (217) 529-6601 fax: (217) 529-6644 29466.0000c 8/00 © 1999 bunn-o-matic corporation operating & service manual bunn ®.

Page 2

Page 2 contents introduction .............................................................. 2 warranty ................................................................... 2 user notices ............................................................. 3 electrical requirements .............................

Page 3

Page 3 #00831.0000 #00656.0000 #03408.0000 #03409.0000 user notices carefully read and follow all notices on the equipment and in this manual. They were written for your protec- tion. All notices on the equipment should be kept in good condition. Replace any unreadable or damaged labels. 29466 06159...

Page 4

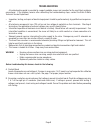

Page 4 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. 120v model brewers require 2-wire, grounded service rated 120 volts ac, 15 amp, single phase, 60 hz. Proceed as follows: electrical hook-up caution – improper electrical ...

Page 5

Page 5 initial set-up 1. Insert the funnel (empty) into the funnel rails. 2. Place an empty tea dispenser on the brewer base. Be prepared to empty the dispenser a few times. 3. Plug in the brewer, place the tea/off/coffee switch in the “coffee” position, and momentarily press the start switch. When ...

Page 6

Page 6 operating controls a. Tea/off/coffee switch tea- placing the switch in the full left position allows the start switch to activate a timed brew cycle for a 0.5 gallon of tea concentrate and 2.5 gallons of dillution water into the dispenser. Coffee- placing the switch in the full right position...

Page 7

Page 7 twf-ez adjustments & optional settings adjusting brew volumes brew volume set-up: use the following steps when setting up the brewer for the first time. 1. Place an empty funnel in the funnel rails and an empty decanter (when switch is in "coffee" position) or 3- gallon dispenser (when switch...

Page 8

Page 8 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 9

Page 9 troubleshooting (cont.) brew circuit problem probable cause remedy ready light flashing brew cycle will not start 1. Brewer has shut down due to malfunction. 1. No water 2. No power or incorrect voltage to the brewer 3. Tea/off/coffee switch 4. Start switch 5. Low water temperature (brew lock...

Page 10

Page 10 troubleshooting (cont.) brew circuit problem probable cause remedy refer to adjustments and optional settings to set brew volume. See page 7. Using a stop watch or sec- ond hand, time the length of the brew cycle. Record this time inside the top lid. If service is ever needed again, use the ...

Page 11

Page 11 troubleshooting (cont.) brew circuit problem probable cause remedy dripping from sprayhead weak beverage drip out time too long 1. Lime build up 2. Brew solenoid valves 1. Sprayhead 2. Water temperature 3. Filter type 4. Funnel loading 1. Funnel tip (tea brewing) inspect the tank assembly fo...

Page 12

Page 12 troubleshooting (cont.) brew circuit problem probable cause remedy dry tea leaves or coffee grounds re- main in the funnel 1. Sprayhead 2. Funnel loading make sure sprayhead is present and holes are clear and unobstructed. There should be seven separate streams of water coming out of the spr...

Page 13

Page 13 troubleshooting (cont.) heating circuit problem probable cause remedy 29466 082200 water does not heat to proper temperature important: make sure no tem- perature tests are taken before the ready light is "on". Tank tempera- ture must be stabilized before read- ings are taken. Spitting or ex...

Page 14

Page 14 diagnostics intermittent flashing of the ready indicator indicates that a fault exists. Count the number of flashes between pauses and use this chart as a guide to investigating the fault. Flashes cause things to check 1 dry plug - in fault - water pressure (is water shut off?) sheath of tem...

Page 15

Page 15 service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal equipmen...

Page 16

Page 16 location: viewing the brewer from the rear the hot coffee brew solenoid valve is mounted on the left side of the mounting bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the white/red and white wires from the hot coffee solenoid valve. With the tea/off...

Page 17

Page 17 p1960.60 fig. 4 iced tea brew solenoid valve location: viewing the brewer from the rear the iced tea brew solenoid valve is mounted in the center of the mount- ing bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the white/blue and white wires from the ...

Page 18

Page 18 service (cont.) dilution solenoid valve fig. 6 dilution solenoid valve p1960.60 location: viewing the brewer from the rear the dilution so- lenoid is mounted on the right side of the solenoid mounting bracket. Test procedure: 1. Disconnect the brewer from the power source. 2. Disconnect the ...

Page 19

Page 19 service (cont.) limit thermostat fig. 8 limit thermostat p1960.60 location: the limit thermostat is located inside the hood on the tank lid. Test procedure: 1. Disconnect the brewer from the power source and remove the blue wire from the limit thermostat. 2. With a voltmeter, check the volta...

Page 20

Page 20 fig.11 tea/off/coffee switch terminals p1525 service (cont.) tea/off/coffee switch fig. 10 tea/off/coffee switch p1808.40 location: the tea/off/coffee switch is located in the front of the hood, above and to the left of the brew funnel. Test procedure: 1. Disconnect the brewer from the power...

Page 21

Page 21 service (cont.) start switch fig. 12 start switch p1808.40 location: the start switch is located in the front of the hood, above and to the right of the brew funnel. Test procedure: 1. Disconnect the brewer from the power source. 2. Remove white/yellow and white/orange wires from the start s...

Page 22

Page 22 fig. 14 tank heater location: the tank heater is located inside the tank and se- cured to the tank lid. Test procedures: 1. Disconnect the brewer from the power supply. 2. With a voltmeter, check the voltage across the black and white wires. Connect the brewer to the power source. The indica...

Page 23

Page 23 service (cont.) temperature probe fig. 16 temperature probe p1960.60 location: the temperature probe is located on the tank lid, to the rear and left of the sprayhead tube. Test procedures: 1. Disconnect the brewer from the power source. 2. Remove the temperature probe from the grom- met. 3....

Page 24

Page 24 service (cont.) thermal fuse fig. 18 thermal fuse p1960.60 location: the thermal fuse is located inside the hood con- nected to the right tank heater terminal. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the thermal fuse from the tank heater terminal and th...

Page 25

Page 25 service (cont.) control board fig. 20 control board p1960.50 trm1 tr m2 j6 j7 j3 j1 j4 j2 j5 location: the control board is located inside the hood on the right front behind the start switch. Test procedure: the test procedures for the control board will vary depending upon the problems expe...

Page 26

Page 26 29466 082200