- DL manuals

- Bunn

- Coffee Maker

- U3A

- Operating & Service Manual

Bunn U3A Operating & Service Manual

Summary of U3A

Page 1

Operating & service manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 www.Bunnomatic.Com u3a bunn ® 10060.0003a 07/02 ©2002 bunn-o-matic corporation.

Page 2

Page 2 introduction this brewer will brew a three gallon batch of coffee into each reservoir (one at a time). Each reservoir has its own dispensing faucet(s).The brewer also has a hot water faucet(s) for allied beverage use. It is only for indoor use on a sturdy counter. 10060.3 070102 bunn-o-matic ...

Page 3

Page 3 #00831.0000 #00656.0000 user notices carefully read and follow all notices on the brewer and in this manual. They were written for your protection. All notices on the brewer are to be kept in good condition. Replace any unreadable or damaged labels. #00878.0000 #12593.0000 #03408.0000 #03409....

Page 4

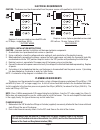

Page 4 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. Electrical installation instructions caution – improper electrical installation will damage electronic components. 1. An electrician must provide electrical service as sp...

Page 5

Page 5 initial setup caution - the brewer must be disconnected from the power source throughout the initial setup , except when specified in the instructions. Important: brewer must be level and installed on a sturdy structure. Electrician's and plumber's instructions are provided. These instruction...

Page 6

Page 6 adjusting brew volumes caution - disconnect the power source from the brewer prior to the removal of any panel for the replacement or adjustment of any component. Note: prior to setting or modifying batch sizes, check that the brewer is connected to water supply, the tank is properly filled, ...

Page 7

Page 7 coffee brewing 1. Brew cycles may be started whenever water temperature is correct. This condition is indicated by the dial thermometer on front of the brewer. Whenever the pointer is in the green, brewer is ready for brewing. 2. Insert a bunn ® filter in funnel and add desired amount of coff...

Page 8

Page 8 problem brew cycle will not start probable cause 1. No water 2. No power or incorrect voltage to the brewer 3. Water level below pump housing. (water level in the hot water gauge glass should be approximately half full). 4. Swing arm switch 5. On/off switch remedy water lines and valves to th...

Page 9

Page 9 troubleshooting (cont.) problem brew cycle will not start (cont.) tank not filling probable cause 6. Start switch 7. Timer 8. Pump 9. Solenoid valve 10. Strainer 1.On/off switch (this switch must be in the "on" position for the refill circuit to operate.) 2. No water 3. Solenoid valve 4. Prob...

Page 10

Page 10 troubleshooting (cont.) problem water running out of the overflow water is not hot probable cause 1. Brewer not level 2. Solenoid valve 3. Liquid level board 4. Probe 5. Manual fill and drain valve un- derneath brewer open. 1. Limit thermostat caution - do not eliminate or bypass limit therm...

Page 11

Page 11 probable cause 1. Fuse 2. Tank heater(s) 1. Timer 2. Start switch 1. Timer 2. Solenoid valve 3. Lime build-up in swing spout and pump tubing. 1. Filters 2. Hole in bottom of funnel ob- structed. 3. Pump - flow rate 4. Soft water troubleshooting (cont.) problem fuse opening water keeps runnin...

Page 12

Page 12 troubleshooting (cont.) coffee reservoir overflows brewer is making unusal noises probable cause remedy 1. Coffee reservoir not completely empty before a brew cycle was started. 2. Timer 3. Pump - flow rate 1. Plumbing lines 2. Water supply 3. Tank heater(s) be sure coffee reservoir is empty...

Page 13

Page 13 p2178.60 fig. 2 contactor location: the contactor is located on the left front of the component bracket service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in ...

Page 14

Page 14 service (cont.) test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the red wire from the limit thermostat to the contactor coil and the black wire from the main harness to the contactor coil. 3. Connect the brewer to the power source. 4. Check the voltage across t...

Page 15

Page 15 service (cont.) control thermostat fig. 4 control thermostat p2178.60 location: the control thermostat is mounted on the right front of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Locate the thermostat and check for 230 volts between the red wir...

Page 16

Page 16 service (cont.) location: the fuse and fuse holder are located on the right rear of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Remove the cap and fuse from the fuse holder. 3. Remove fuse from the cap. 4. Check for continuity through the fuse. ...

Page 17

Page 17 limit thermostat service (cont.) fig. 9 limit thermostat terminals fig. 8 limit thermostat p2178.55 location: the limit thermostat is located on the center front of the component bracket behind the timer mounting bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Di...

Page 18

Page 18 t1 blu to solenoid valve t2 red to on/off switch t3 blk to main harness t4 pnk to level probe fig.11 liquid level board terminals p1733.50 service (cont.) liquid level board and level probe (cont.) touching the frame. Repeat these several times. Keep in mind there is an approximate five seco...

Page 19

Page 19 service (cont.) on/off switch fig.12 on/off switch p2104.25 location : the on/off switch is located on the left side of the switch mounting bracket. The switch mounting bracket is mounted on the front of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. ...

Page 20

Page 20 service (cont.) pump assembly fig.14 pump assembly p2178.55 location: the pump is located on the center rear of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the black wire from the black lead on the pump and the red wire from the black...

Page 21

Page 21 service (cont.) selector switch (half batch option) fig. 16 selector switch (half batch) p2104.25 location: the selector switch is located in the upper center of the switch mounting panel. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the wires from the switc...

Page 22

Page 22 blu from liquid level board t1 fig. 19 solenoid terminals p2110.50 service (cont.) solenoid fig. 18 solenoid p2178.55 location: the solenoid is mounted on the upper left rear of the component bracket. Test procedures: 1. Drain 1/2 gallon of water from the faucet in order to activate the prob...

Page 23

Page 23 service (cont.) start switch (brew) fig. 20 start switch (brew) p2104.25 location: the brew start switch is located on the upper right side of the brewer component housing. Test procedures: 1. Disconnect the brewer from the power source. 2. Remove the wires from the start switch terminals. 3...

Page 24

Page 24 service (cont.) swing arm switch fig. 22 swing arm switch location: the swing arm switch is attached to the cupola cover. Test procedures: 1. Disconnect the brewer from the power source. 2. Remove the cupola cover end caps, swing spout and cupola cover. 3. Disconnect the two black wires conn...

Page 25

Page 25 blk (thermal fuse) to terminal block blu (thermal fuse) to ter- minal block blk (thermal fuse) to contactor lower left ter- minal red (thermal fuse) to contactor lower right ter- minal service (cont.) tank heaters fig. 25 tank heater terminals p1746.71 left right fig. 24 tank heater p2178.55...

Page 26

Page 26 service (cont.) thermal fuses fig. 26 thermal fuses p2179.65 location: the thermal fuses are mounted between the tank heater terminals and contactor terminals or terminal block. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the thermal fuses from the tank hea...

Page 27

Page 27 service (cont.) timer (early models)old style(cont.) if voltage is present as described, proceed to #8. If voltage is not present as described, refer to the wiring diagram and check the brewer wiring harness. 8. Disconnect the black and white wires to the swing arm switch and pump leads. 9. ...

Page 28

Page 28 digital timer (late models) fig. 29 digital timer p2212.55 service (cont.) location: the timer is located on the front center of the component bracket. Test procedure. Note: do not remove or install wires while timer board is installed. Pressure applied to one side may cause damage to the bo...

Page 29

Page 29 service (cont.) digital timer (late models) blu/blk wire from tl5 to p1 whi/grn wire from tl4 to (red) pump whi/blu wire from tl3 to swing arm switch whi wire from tl2 to p2 blk wire from tl1 to p3 j2 - three pin connector from half/full batch switch p2037 fig. 30 digital timer terminals 1. ...

Page 30

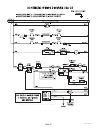

Page 30 10493.0004a 07/02 © 2002 bunn-o-matic corporation 10060.3 070102.