- DL manuals

- Bunn

- Coffee Maker

- VLPF

- Operating & Service Manual

Bunn VLPF Operating & Service Manual

Summary of VLPF

Page 1

Bunn ® vlpf operating & service manual bunn-o-matic corporation of canada 280 industrial parkway south, aurora, ontario, l4g 3t9. Phone: (905) 841-2866 fax: (905) 841-2775 10179.7000h 02/07 ©1987 bunn-o-matic corporation.

Page 2

392, autopod, axiom, brewlogic, brewmeter, brew better not bitter, brewwise, brewwizard, bunn espress, bunn family gourmet, bunn gourmet, bunn pour-o-matic, bunn, bunn with the stylized red line, bunnlink, bunn-omatic, bunn-o-matic, bunnserve, bunnserve with the stylized wrench design, cool froth, d...

Page 3: Warning

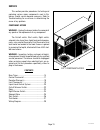

Page 3 user notices carefully read and follow all notices on the equipment and in this manual. They were written for your pro- tection. All notices on the equipment should be kept in good condition. Replace any unreadable or damaged labels. #00656.0000 #00658.7000 #00882.7000 warning ! Fill water ta...

Page 4

Page 4 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. The brewer has an attached cordset and requires 2-wire, grounded service rated 120 volts ac, 15 amp, single phase, 60 hz. Plumbing requirements this brewer must be connect...

Page 5

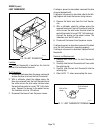

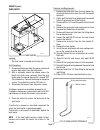

Page 5 10179 060100 initial set-up caution - the brewer must be unplugged throughout the initial set-up, except when specified in the instruc- tions. 1. Remove the top lid from the brewer. 2. Rotate the control thermostat knob fully counterclockwise to the “off” position and replace the top lid. 3. I...

Page 6

Page 6 2. Setting batch sizes. To set a batch volume, first check that the set/lock switch is in the “set” position on the circuit board. Press and hold the start or brew switch until three distinct clicks are heard, and then release the switch. (failure to release the switch within two seconds after...

Page 7

Page 7 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical services department. • • •inspection, testing, and repair...

Page 8

Page 8 troubleshooting (cont.) problem equipment will not operate brew cycle will not start automatic refill will not operate after drawing hot water. Probable cause 1. No power or incorrect voltage 1. No water 2. Water strainer/flow control 3. On/left switch 4. Start switch 5. Brew timer 6. Relay 7....

Page 9

Page 9 troubleshooting (cont.) problem automatic refill will not operate after drawing hot water.(cont.) water flows into tank continuously (on/left switch “off”) water flows into tank continuously (on/left switch “on”) water is not hot. Probable cause 2. Liquid level control system 3. Relay 4. Solenoi...

Page 10

Page 10 troubleshooting (cont.) problem decanter warmer is not hot spitting or unusual steaming from sprayhead inconsistent beverage level in decanter probable cause 1. Warmer switches 2. Decanter warmers 1. Control thermostat 2. Lime build-up caution: tank and tank compo- nents should be delimed re...

Page 11

Page 11 troubleshooting (cont.) problem inconsistent beverage level in decanter (cont.) consistently high or low beverage level in decanter. Dripping from sprayhead beverage overflows decanter. Weak beverage probable cause 3. Syphon system 1. Brew timer adjustment 1. Syphon system 2. Solenoid valve 1...

Page 12

Page 12 troubleshooting (cont.) problem weak beverage (cont.) brewer is making unusual noises probable cause 4. Funnel loading 5. Water temperature 1. Solenoid valve 2. Plumbing lines 3. Water supply remedy the bunn ® paper filter should be centered in the funnel and the bed of ground coffee leveled ...

Page 13

Page 13 service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Component access warning - unplug the brewer before the removal of...

Page 14

Page 14 brew timer (early models) service (cont.) location: the brew timer is located in the hood, to the right of the tank. Test procedure: 1. Disconnect the brewer from the power source and separate the polarized, three-pin connectors between the timer and brewer wiring harness and rotate the brew...

Page 15

Page 15 brew timer (cont.)(late models) 10179 121704 p2172.80 service (cont.) location: the brew timer is located in the hood, to the right of the tank. Test procedures: 1. Disconnect the brewer from the power source and remove the top cover. 2. With a voltmeter, check the voltage across termi- nals...

Page 16

Page 16 1. Modifying brew volumes. To modify a brew vol- ume, first check that the set/lock switch is in the “set” position on the circuit board. To increase a brew volume, place the on/off switch in the “on” position, press and hold the start switch until three clicks are heard. Release the switch a...

Page 17

Page 17 bunn off hi service (cont.) location: the control thermostat is located on the rear of the hood to the right of the tank. Test procedure: 1. Disconnect the brewer from the power source and remove the black wire from the control thermo- stat. 2. With a voltmeter, check the voltage across the ...

Page 18

Page 18 service (cont.) decanter warmers fig. 8 decanter warmers p1956.40 left warmer right warmer whi/vio to on/left switch whi to right warmer whi to cordset brn/blk to right switch whi to on/left switch whi to left warmer fig. 9 warmer element terminals p1982 location: the decanter warmers are lo...

Page 19

Page 19 service (cont.) limit thermostat location: the limit thermostat is located on the tank lid between the tank heater terminals. Test procedure: 1. Disconnect the brewer from the power source and remove the blue wire from the limit thermostat. 2. With a voltmeter, check the voltage across the b...

Page 20

Page 20 liquid level control system location: the liquid level control system is composed of the circuit board in the right front corner of the hood and the probe in the tank lid. Test procedure: 1. Disconnect the brewer from the power source and remove the wires from terminals 1 & 4 of the circuit ...

Page 21

Page 21 service (cont.) liquid level control system (cont.) removal and replacement: 1. Remove all wires from the liquid level control board terminals. 2. Remove the two #8-32 slotted-head screws hold- ing the circuit board to the brewer hood. 3. Install the new circuit board to the hood, making sur...

Page 22

Page 22 if continuity is not present as described, replace the switch. Removal and replacement: 1. Remove all wires from the switch terminals. 2. Compress the clips inside the hood and gently push the switch through the opening. 3. Push the new switch into the opening and spread the clips to hold th...

Page 23

Page 23 service (cont.) relay fig. 16 relay p2172.80 location: the relay is located in the right rear corner of the hood. Test procedures 1. Disconnect the brewer from the power source. 2. With a voltmeter, check the voltage across termi- nals a & b in the lower corners of the relay when the on/left...

Page 24

Page 24 location: the right switch is located in the front of the hood, above and to the right of the brew funnel. Test procedure: 1. Disconnect the brewer from the power source and remove the wires from all three terminals of the right switch. 2. With a voltmeter, check the voltage across the black...

Page 25

Page 25 service (cont.) solenoid valve pn : 65 8 bunn off hi fig. 20 solenoid valve p2173.80 10179 060100 location: the solenoid valve is located in the left rear corner of the hood. Test procedures: 1. Disconnect the brewer from the power source and remove both wires from the solenoid valve coil te...

Page 26

Page 26 start switch fig. 22 start switch p2172.80 blu to timer whi/ red to on/ left switch whi/ red to liquid level control board p1987 fig. 23 start switch terminal service (cont.) 10179 060100 location: the start switch is located in front of the hood, centered above the brew funnel. Test procedu...

Page 27

Page 27 service (cont.) pn: 65 8 p1983.40 fig. 24 tank heater 10179 060100 tank heater location: the tank heater is located on the tank lid. Test procedure: 1. Disconnect the brewer from the power source and remove both wires from the tank heater. 2. With a voltmeter, check the voltage across the bl...

Page 28

Page 28 10179 121704.