Vp17a operating & service manual bunn-o-matic corporation post office box 3227 springfield, illinois 62708-3227 phone: (217) 529-6601 fax: (217) 529-6644 www.Bunnomatic.Com 10860.0001d 04/07 ©1997 bunn-o-matic corporation to obtain the illustrated parts catalog, visit the bunn-o-matic website, at ww...

Page 2 introduction this equipment will brew a half-gallon batch of coffee into an awaiting dispenser. It is only for indoor use on a sturdy counter or shelf. Warranty bunn-o-matic corp. (“bunn”) warrants the equipment manufactured by it to be commercially free from de- fects in material and workman...

Page 3 10860.1 040407 user notices (cont.) # 00831.0000 # 00658.0000 #02763.0000 warning ! Fill water tank before turning - on - thermostat or connecting appliance to power source. Use only on a properly protected circuit capable of the rated load. Electrically ground the chassis. Follow national/lo...

Page 4 electrical requirements caution - the brewer must be disconnected from the power source until specified in initial set-up. Electrical hook-up caution – improper electrical installation will damage electronic components. 1. An electrician must provide electrical service as specified. 2. Using ...

Page 5 coffee brewing 1. Insert a bunn ® filter into the funnel. 2. Pour the fresh coffee into the filter and level the bed of grounds by gently shaking. 3. Slide the funnel into the funnel rails. 4. Place an empty dispenser beneath the funnel. 5. Pour one pitcher of tap water into the screened area...

Page 6 troubleshooting a troubleshooting guide is provided to suggest probable causes and remedies for the most likely problems encountered. If the problem remains after exhausting the troubleshooting steps, contact the bunn-o-matic technical service department. • inspection, testing, and repair of ...

Page 7 troubleshooting (cont.) problem spitting or excessive steaming dripping from sprayhead beverage overflows dispenser weak beverage probable cause remedy 1. Lime build-up caution - tank and tank compo- nents should be delimed regularly depending on local water condi- tions. Excessive mineral bu...

Page 8 troubleshooting (cont.) problem weak beverage (cont.) dry coffee grounds remain in the funnel brewer is making unusal noises cool beverage serving tempera- ture probable cause remedy 4. Funnel loading 5. Water temperature 1. Funnel loading 1. Tank heater 1. On/off warmer switch(s) 2. Warmer e...

Page 9 service this section provides procedures for testing and replacing various major components used in this brewer should service become necessary. Refer to troubleshooting for assistance in determining the cause of any problem. Warning - inspection, testing, and repair of electri- cal equipment...

Page 10 fig. 3 control thermostat terminals p1263 control thermostat location: the control thermostat is located inside the trunk on the upper left side of the component bracket. Test procedures: 1. Disconnect the brewer from the power source. 2. With a voltmeter, check the voltage across the blue w...

Page 11 on/off warmer switch p1166.45 fig. 4 on/off warmer switch service (cont.) location: the on/off warmer switch(s) are located on the front of the hood. Test procedure: 1. Disconnect the brewer from the power source. 2. Viewing the switch from the back, remove the red wire from the upper termin...

Page 12 tank heater location: the tank heater is located inside the tank and secured to the tank lid. Test procedures: 1. Disconnect the brewer from the power supply. 2. With a voltmeter, check the voltage across the black and red wire. Connect the brew to the power source. The indication must be 22...

Page 13 service (cont.) 10860.1 071598 thermal cut-offs fig. 8 thermal cut-offs p1262 location: the thermal cut-offs are located inside the hood connected to the tank heater terminals. Test procedures: 1. Disconnect the brewer from the power source. 2. Disconnect the thermal cut-off from the termina...

Page 14 p1167 fig. 11 warmer element terminals warmer element(s) location: the warmer element(s) is located under the warmer plate. Test procedures: 1. Disconnect the brewer from the power source. 2. With a voltmeter, check voltage across the red wire to the terminal block and white/red, brown/black...

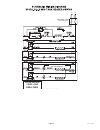

Page 15 2 top or side warmers not used on late models with side warmers 10862.0001l 01/07 ©1995 bunn-o-matic corporation 220-240 volts ac 2 wire + gnd single phase blk l1 l2 blk red main on/off switch (late models only) 10860.1 040407.

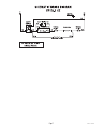

Page 16 10860.1 091300

Page 17 10860.1 091300