- DL manuals

- C&H

- Air Conditioner

- GKH18K3BI

- Owner's Manual

C&H GKH18K3BI Owner's Manual

O W N E R ' S M A N U A L

M A N U A L

C & H A IR C O N D I T I O N E R S

Air Conditioner

FLOOR-TO-CEILING SERIES

MODELS:

indoor unit / outdoor unit

GTH18K3BI / GUHN24NK3AO

GTH24K3BI / GUHN24NK3AO

GTH36K3BI / GUHN36NM3AO

GTH48K3BI / GUHN48NM3AO

Thanks for your selection of our Air-Conditioning Unit. Before use, please read this instruction

manual carefully and keep it properly to ensure correct use of this machine.

Summary of GKH18K3BI

Page 1

O w n e r ' s m a n u a l m a n u a l c & h a ir c o n d i t i o n e r s air conditioner floor-to-ceiling series models: indoor unit / outdoor unit gth18k3bi / guhn24nk3ao gth24k3bi / guhn24nk3ao gth36k3bi / guhn36nm3ao gth48k3bi / guhn48nm3ao thanks for your selection of our air-conditioning unit. ...

Page 2

Safety considerations please read this manual carefully before use and operate correctly as instructed in the manual. 1 you are specially warned to note the two symbols below.: warning! A symbol indicating that improper operation might cause human death or severe injuries. A symbol indicating that i...

Page 3

9 failure st atus display 10 sleep st atus display 11 mode key 12 se t temperatur e incr ease key 13 se t temperatur e decr ease key 14 fan speed key (fresh air setting) 15 sleep key (outdoor environment temperatur e check) 16 timing key 17 on/off key wire controller (standard fitting) swing swing t...

Page 4

Operating instructions of wire controller turning on/off unit press the on/off key, then the unit shall start up. Press the on/off key again, then the unit shall shut off. Swing timer fan control (the figures show the relevant display areas) if the fan control key is pressed consecutively, the fan s...

Page 5

Swing function setting swing press swing button then the swing mode will be operated by the air conditioner. Repress swing button once to stop swing mode. Note: there is no swing mode for duct type indoor unit swing timer sleep function setting swing timer when under the cooling or dehumidifying mod...

Page 6

Operating mode setting swing timer this key is pressed consecutively, the operating mode shall change as per the following sequence: cooling dehumidifying fan heating auto when the unit operates under “cooling” mode, “cool” shall be displayed. Now the set temperature must be lower than the ambient t...

Page 7

Timer setting swing timer when the unit is shut off, timing start can be set; after the unit is started up, timing shutoff can be set. After the "timer" key is pressed, the unit enters the timing set status and the word "timer" flashes on the display. Now user can press ( ) or( ) key to increase or ...

Page 8

Display outdoor temperature under normal conditions, the “out env” column shall only display the indoor temperature. Press the “sleep” key for 5 consecutive seconds when the unit is shut off or start up, the lcd shall display “out env”. After the outdoor temperature is displayed for 10 seconds, the ...

Page 9

Failure display swing when there is failure in the unit operation, “error” will flash on the lcd of the wire controller and the code of failure will also be displayed. When there are multiple failures at the same time, the codes of failures will be displayed one after one on the wire controller. The...

Page 10

9 unit off display 10 clock display 11 confirm button 12 increase button 13 decrease button 14 cacel/delete button 15 single/group button 16 timer/time button 17 on/off button unit function • 7dp - seven days programmer (accessory not supplied) centralized control and week timer functions: the centr...

Page 11

Note: 1. For upper unit checks 16 lower units consecutively, there will be no more than 16 seconds delay when setting works till unit responds. 2. Please let us know your requirement before your placing the order, for this weekly timer will only be prepared when customer orders (communication joint ...

Page 12

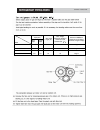

Wire controller (with week timer functions) warning! ● never install the wired controller where there is water leakage. ● never knock, throw or frequently open the wired controller. Fig.1 each part of wired controller 1 timing display 11 swing status display 2 ambient temperature display 12 timer in...

Page 13

1) on/off(fig.2) press the “on/off” button, the unit will start running. Press the “on/off” button again, the unit will stop running. 2) fan control (fig.3 is about display region and the same as following figures.) when press fan button once, the fan speed will be changed as follow: in dry mode: th...

Page 14

Setting temperature range under each mode: heat -------- 16℃~30℃ cool -------- 16℃~30℃ dry -------- 16℃~30℃ fan -------- can not be set auto mode is divides into new auto mode and old auto mode. New auto mode --------------16 ℃~30℃ old auto mode ---------- can not be set 4) swing setting (fig.5) pre...

Page 15

The outdoor unit will be frosted resulting in low efficiency of heating, in which case, the controller will automatically start to defrost with defrost displayed. Note: no heating for cooling-only unit and auto mode will be shielded after setting energy saving. 6) timer setting (fig.7, 8, 9) timer f...

Page 16

In timing setting mode, press mode button to select any desired setting object: week (1-7), timer interval (1-4), timing (timer on or timer off time), min. Part or hour part of time, and then press ▲ or ▼ button to adjust this object, which is fixed by pressing timer button or can be canceled by pre...

Page 17

In deleting timing status, press ▲ or ▼ button to select one day of a week, and then press timer button to confirm, in which case, ”dd” is displayed .The day also can be canceled by pressing timer butto n without “dd” displayed. At last, press on/off button to quit the setting after finish.(fig.13) ...

Page 18

Blinking. Press ▲ and ▼ to set lower-limit cooling temp (setting range is16 -30) and then press on/off to fix .Press ▲ and ▼ to set upper-limit cooling temp, which will be displayed where ambient temp is displayed (setting range is 16-30), and then press on/off to fix. Note: upper- limit temp can no...

Page 19

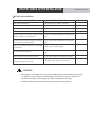

Fig.17 codes malfunction e0 water pump malfunction e1 compressor high-pressure protection e2 indoor anti-freezing protection e3 compressor low-pressure protection e4 compressor high-temp. Exhaust protection e5 compressor overload protection e6 communication malfunction e8 indoor fan protection e9 wa...

Page 20: Checking Before Cont

Checking before cont problem act the service man operation instructions causes re contact the service man c ca au us se es s p pr ro ob bl le em m problem causes checking before contact the service man operation instructions check if breaker switch is still on.

Page 21: Indoor Unit Installation

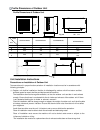

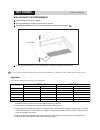

Indoor unit installation installation instructions installation dimensions of the indoor unit when installing the indoor unit, you can refer the paper pattern for installation, and make sure that the drainage side must be 10mm lower than the other side in order to drain the condensation water fluent...

Page 22: Indoor Unit Installation

Indoor unit installation installation instructions selection of installation location. Such a place where cool air can be distributed through out the room. Such a place where is condensation water is easily drained out. Such a place that can handle the weight of indoor unit. Such a place which has e...

Page 23: Indoor Unit Installation

Fig.25 indoor unit installation installation instructions set the suspension bolt.(use w3/8 or m10 size suspension bolts) adjust the distance from the unit to the ceiling slab beforehand (refer to fig.25) 27 28 26 26 29 30 40mm or less fig.25 fig.2 fig.27 fig.2 fig.29 fig.3.

Page 24: Outdoor Unit Installation

Outdoor unit installation installation instructions fig.31 fig.32 caution.

Page 25

Outdoor unit installation ins tallation ins t r uc t ions electric wiring connection guhn18nk3ao guhn24nk3ao guhn36nk3ao guhn48nm3ao or c a u t i o n wrong wiring ma y c a us e fire of electric s hock. D o not pull the wire when fixing it with wire clamp and clasp. Do not let the wire too loose all ...

Page 26

Profile dimensions of outdoor unit profile dimensions of outdoor unit fig. 30 uni t mm model item a guhn18nk3ao 848 guhn24nk3ao 1018 guhn36nm3ao 1018 guhn48nm3ao 950 b 320 412 c 540 700 d 540 572 e 286 300 412 840 572 378 412 1250 572 378 unit installation instructions precautions on installation of...

Page 27

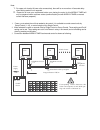

Schematic diagram of unit line connection installation instructions electric wiring connection the section area of cables selected by users must not be smaller than the specifications show diagram. The signal wire between indoor and outdoor unit shall be installed in the shielded bushing, and the un...

Page 28

Schematic diagram of unit line connection installation instructions guhn18nk3ao guhn24nk3ao guhn36nm3ao guhn48nm3ao all the indoor units.

Page 29

Position and method of installing wire controller installation instructions installation instructions position and method of installing wire controller position and method of installing wire controller 1. One end of the control wire of the manual controller is connected with main board of electric b...

Page 30

Position and method of installing wire controller installation instructions installation instructions position and method of installing wire controller electric box cover sketch map for indoor unit communication wire wire clamp control wire cable-cross loop communication wire metallic pipe metallic ...

Page 31

Position and method of installing wire controller installation instructions caution: before installing the electrical equipment, please pay attention to the following matters which have been specially pointed out by our designers: (1) check to see if the power supply used conforms to the rated power...

Page 32: Pipe Preparation

Pipe preparation operation instructions.

Page 33: Refrigerant Piping Work

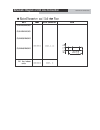

Refrigerant piping work operation instructions item model size of fitting pipe (mm) max. Pipe length (m) max. Height difference between indoor unit and outdoor unit m amount of additional refrigerant to be filled (for extra length of pipe) gas pipe liquid pipe gth18k3bi 1/2” 1/4" 20 15 30g/m gth24k3...

Page 34

Air purging and check of pipe leakage operation instructions.

Page 35

Liquid pipe and drain pipe operation instructions.

Page 36: Drain Piping Work

Drain piping work operation instructions45.

Page 37

Routine check after installation operation instructions check after installation items to be checked possible malfunction situation has it been fixed firmly? The unit may drop, shake or emit noise. Have you done the refrigerant leakage test? It may cause insufficient refrigerating capacity. Is heat ...

Page 38: Test Running

Test condition indoor side outdoor side db(c) wb(c) db(c) wb(c) nominal cooling 27 19 35 24 nominal heating 20 -- 7 6 rated cooling 32 23 43 26 low temp. Cooling 21 15 18(-7) -- rated heating 27 -- 24 18 low temp. Heating 20 -- -7 -8 test running operation instructions evaluation of the performance ...

Page 39

This product must not be disposed together with the domestic waste. This product has to be disposed at an authorized place for recycling of electrical and electronic appliances. 66129904712.