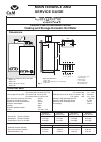

C&M Calyadra comfort Maintenance and service manual

MAINTENANCE AND

SERVICE GUIDE

Fanned Flue Combination Boiler

Heating and Storage Domestic Hot Water

Dimensions

Technical data

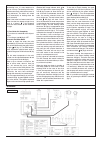

Heat input C/H & DHW

Cal. comfort 80 : 11.73 to 28.70 kW

Cal. comfort 100 : 15.43 to 31.57 kW

Heat output C/H & DHW Cal. comfort 80 : 9.5 to 24 kW

Cal. comfort 100 : 12.5 to 28,2 kW

Max. operating pressure C/H circuit

: 2.5 bar

Expansion vessel net capacity

: 5.44 l

Expansion vessel initial pressure

: 0.7 bar

Electrical consumption

: 150 w

Voltage

: 230 v

Electrical protection index

: IP44

Fuses

: 2 A and 1.25 A

DHW flow rate at @ AT 30 K Cal. comfort 80 :

12.1 l/min

Cal. comfort 100 :

14.1 l/min

DHW flow rate at @ AT 35 K Cal. comfort 80 :

10.4 l/min

Cal. comfort 100 : 12.1 l/min

Minimum DHW operating flow rate

:

2.00 l/min

Minimum DHW working pressure

:

0.5 bar

Maximum DHW working pressure

:

10 bar

Gas category

:

II 2H 3+

Nominal gas flow rate at 15°C and 1013 mbar

Calydra. comfort 80

Calydra. comfort 100

Maximum Minimum Maximum Minimum

power 25,9 kW

power 9.5 kW

power 31,1 kW

power 9,5 kW

- Natural gas ( G 20) at 20 mbar

2.74 m

3

/h

1.00 m

3

/h

3.29 m

3

/h

1.00 m

3

/h

- Butane gas ( G 30) at 28 mbar

2.04 kg/h

0.74 kg/h

2.45 kg/h

0.74 kg/h

- Propane gas ( G 31) at 37 mbar

2.00 kg/h

0.72 kg/h

2.42 kg/h

0.72 kg/h

Injectors and gas valves seat diameter

Calydra. comfort 80

Calydra. comfort 100

Natural gas

Butane or Propane

Natural gas

Butane or Propane

- Solenoid restrictor diameter

2.60 mm

1.75 mm

2.90 mm

2.00 mm

- Gas valve restrictor diameter

6.70 mm

4.90 mm

no resrictor required

6.70 mm

- Manifold injectors (16)

1.23 mm

0.70 mm

1.28 mm

0.76 mm

JK L M N

I

54 54 54 54 68

360

260

5050

738

850

380

212

I

Safety valve outlet

J Heating flow

K D.H.W. flow

L Gas supply

M Cold water inlet

N Heating return

1

2

3

0

4

bar

1

2

3

0

4

bar

c

The boiler is suitable for the 4 flue types:

• type C 12

• type C 22

• type C 32 xx or C 32 xy

• type C 52

Outer case dimensions :

- Height : 850

- Width : 440 (minimum space required 450)

- Depth : 380

All dimensions in mm

Fig. 1

c

C