Summary of A Series

Page 1

Service manual a+ the premium class. Label printer.

Page 2

Family type a+ a2+ a4+ a4.3+ a6+ a8+ a4+m edition: 6/2008 - part no. 9008508 copyright this documentation as well as translation hereof are property of cab produkttechnik gmbh & co. Kg. The replication, conversion, duplication or divulgement of the whole manual or parts of it for other intentions th...

Page 3

Table of contents 1 important information ............................................................................................................................ 4 1.1 general safety instructions ......................................................................................................

Page 4

4 4 1 important information 1.1 general safety instructions this service manual is intended for use by qualified service and maintenance personnel. For more operation and configuration information, refer to the user or configuration manual. Follow the general safety rules below: keep the area around...

Page 5

4 5 1 important information 1. Handling electricity the following work may only be done by trained and qualified electricians: work on electrical components. Work on an open device still connected to the mains supply. General precautions before starting maintenance work: find out where the emergency...

Page 6

6 6 cleaning .1 cleaning by the operator the following cleaning work is described in the “operator's manual“: cleaning the device cleaning the printhead cleaning the print roller cleaning the label sensor a2+ a4+ . Cleaning the label sensor a6+, a8+ 2 1 3 5 7 6 4 fig. 1 cleaning the label sensor a6+...

Page 7

6 7 . Cleaning the label sensor a4+m 1 5 2 4 2 3 fig. 2 cleaning the label sensor a4+m danger! Risk of death via electric shock! Before opening the housing cover, disconnect the device from the mains supply and wait at lease one minute until the power supply unit has discharged. Remove media from th...

Page 8

8 8 replacing assembly units .1 tools do not use any worn of damaged tools. Only use tools and testing devices that are suitable for the task at hand. Cab special tools: test collar for transfer ribbon winder (cab item number: 5534199) standard tools: phillips-head screwdriver, size 1 allen key 1,5 ...

Page 9

8 9 replacing assembly units . Replacing the printhead ..1 replacing the printhead a+, a4+, a4.+, a4+m the printhead of the label printer can be replaced without the need for fine adjustment. The printhead must be replaced if worn or when switching to a printhead with higher or lower resolution. For...

Page 10

10 10 replacing assembly units removing the printhead turn lever (10) counterclockwise to lift the printhead. Remove labels and transfer ribbon from the printer. Remove allen key (11) from its retainer. Lightly keep printhead mounting bracket (9) on the print roller with one finger and screw out scr...

Page 11

10 11 8 9 6 6 7 5 4 3 4 1 2 fig. 7 removing and installing the printhead a6+, a8+ removing the printhead turn lever (8) counterclockwise to lift the printhead. Remove labels and transfer ribbon from the printer. Remove allen key (9) from its retainer. Lightly keep printhead mounting bracket (7) on t...

Page 12

1 1 .4 replacing the print roller and rewind assist roller 1 3a 3b 2 3c 4 5 6 removing the side plate turn lever (1) counterclockwise to lift the printhead. Lift the pinch roller (5) off the rewind assist roller. Remove labels and transfer ribbon from the printer. Loosen screws (4) on plate (6) with...

Page 13

1 1 .5 replacing the slipping clutches the rewinder for the transfer ribbon and the internal rewinder are coupled to slipping clutches in the main drive. The supply hub of the transfer ribbon is braked with a slipping clutch during printing. Change the slipping clutch when it can no longer be set 4....

Page 14

14 14 installing the slipping clutch on the rewinders 8 7 6 5 4 4 snap ring 5 slipping clutch 6 coupling disks 7 winder axis 8 collar of the belt wheel fig. 12 slipping clutch on the rewinders slide coupling (5) onto the winder axis (7). Align grooves in the coupling disks (6) with the guides in the...

Page 15

14 15 .6 replacing the label sensor i notice! Soiling of the label sensor can also cause malfunctions. Before replacing the label sensor, check whether it is soiled and clean it if necessary.. For a+, a4+, a4.+ operator's manual, for a6+, a8+ . On page 6. Danger! Risk of death via electric shock! Be...

Page 16

16 16 .6. Replacing label sensor a4+m 1 5 2 4 2 3 fig. 15 replacing the label sensor a4+m danger! Risk of death via electric shock! Before opening the housing cover, disconnect the device from the mains supply and wait at lease one minute until the power supply unit has discharged. Removing the labe...

Page 17

16 17 .7 replacing the pcb cpu danger! Risk of death via electric shock! Before opening the housing cover, disconnect the device from the mains supply and wait at lease one minute until the power supply unit has discharged. 3 1 2 1 removing the pcb cpu if possible, save the printer configuration to ...

Page 18

18 18 .8 replacing the power supply unit danger! Risk of death via electric shock! Before opening the housing cover, disconnect the device from the mains supply and wait at lease one minute until the power supply unit has discharged. 1 2 3 2 6 7 5 4 removing the power supply unit unplug the printer ...

Page 19

18 19 4 adjustments 4.1 measuring and adjusting the winding torques the rewinder for the transfer ribbon and the internal rewinder are coupled to slipping clutches in the main drive. The supply hub of the transfer ribbon is braked with a slipping clutch during printing. The correct setting of the to...

Page 20

0 0 4 adjustments the set values for the winding torque and the resulting pulling force at the test collar are: slipping clutch on direction of rotation printer winding torque m pulling force f ribbon take up hub clockwise a2+ a4+, a4.3+, a6+ a8+ 10.2 - 10.8 ncm 13.5 - 14.4 ncm 17.7 - 18.1 ncm 3.4 -...

Page 21

0 1 4 adjustments internal rewinder measurement of the winding torque at the internal rewinder occurs by determining the pulling forces with a cord wrapped around the rewinder. The physical relation between the torque and the pulling force is: f= m / r f: pulling force [n], m: winding torque [ncm], ...

Page 22

4 adjustments 4.1. Adjusting the winding torques the winding torque of a winder can be changed at the knurled ring of the respective slipping clutch. The numbers on the knurled ring stand for the value of the winding torque: 1: lowest winding torque 7: highest winding torque the current value is ind...

Page 23

4 adjustments 4. Adjusting the printing mechanism major adjustment of the printing mechanism beyond format-based settings is only required if the printhead assembly has been removed or parts in this area have been replaced. Excluded from this is the replacement of the printhead, after which readjust...

Page 24

4 4 4 adjustments 4.. Adjusting the printhead position in order to achieve the best possible print image the following printhead settings are necessary: align the heating line with the highest point of the print roller. Density of the print image is the greatest at this point. Set the parallelism of...

Page 25

4 5 4 adjustments 4.. Adjusting the printhead pressure the printhead pressure can be changed with the screws (1a) and (1b) at the inside and outside of the printhead. Increasing the head contact pressure leads to an improvement of the print image density on the corresponding side and to a shifting o...

Page 26

6 6 4 adjustments 4..4 adjusting the transfer ribbon feed path you can adjust the transfer ribbon feed path by changing the head contact pressure and adjusting the transfer ribbon deflection. Increasing the head contact pressure with the screws (3a) and (3b) shifts the ribbon feed path in the corres...

Page 27

6 7 4 adjustments 4. Adjusting the belt tension at the main drive motor danger! Risk of death via electric shock! Before opening the housing cover, disconnect the device from the mains supply and wait at lease one minute until the power supply unit has discharged. ! Attention! The toothed belt could...

Page 28

8 8 4 adjustments 4.4 adjusting the head switch the head switch prevents printing from occurring when the printhead is open. Adjust the head switch if the error message head open appears in the display even though the printhead is locked. Danger! Risk of death via electric shock! Before opening the ...

Page 29

8 9 5 troubleshooting and error treatment 5.1 failure of device functions functional error possible remedy medium is not transported check electrical connections between pcb cpu and motor check drive mechanism replace the pcb cpu replace the motor no print image with medium transport check plug conn...

Page 30

0 0 5 troubleshooting and error treatment 5. Hardware faults error message cause fault recovery adc malfunction fault on the pcb cpu replace the pcb cpu fpga malfunction fault on the pcb cpu replace the pcb cpu invalid setup fault on the pcb cpu replace the pcb cpu voltage error v bat voltage of the...

Page 31

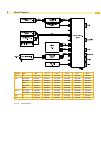

0 1 6 block diagram printer type nr. 1 nr. Nr. Nr. 4 nr. 5 nr. 6 a2+ all 5954105 5954293 5954292 5946203 5954098 5954090 a4+ 200, 200p 5954081 5954067 5954066 5946206 5954098 5954090 300, 300p 5954072 5954067 5954066 5946206 5954098 5954090 300m 5954072 5954067 5954066 5946208 5954099 5958670 600, 6...

Page 32

7 layout diagram pcb cpu fig. 29 layout diagram pcb cpu - components side.

Page 33

7 layout diagram pcb cpu fig. 30 layout diagram pcb cpu - soldering side.

Page 34

4 4 8 index a adjusting the belt tension ................. 27 adjusting the head switch ................. 28 adjusting the printhead position ....... 24 adjusting the printhead pressure ...... 25 adjusting the printing mechanism..... 23 adjusting the ribbon feed path .......... 26 b block diagram .....