- DL manuals

- CAB

- Printer

- e4

- Operator's manual

CAB e4 Operator's manual

Summary of e4

Page 1

Barcode/label printer operator's manual e4 the economy class..

Page 2

2 2 contents 1 introduction ............................................................. 3 1.1 instructions ................................................................ 3 1.3 intended use of the printer ....................................... 3 1.4 safety instructions .............................

Page 3

3 1 introduction 1.1 instructions important information and instructions in this documentation are designated as follows: danger danger! Draws your attention to an exceptionally grave, impending danger to your health or life. Warning ! Warning! Indicates a hazardous situation that could lead to inju...

Page 4

4 4 2 product description 2.1 technical data standard option 1. Printhead e4 printing method thermal/thermal transfer printhead resolution dpi 203 300 print speed up to mm/s 100 75 print width up to mm 108 106 2. Labels material labels, continuous material on rolls or leporello, thermal and stan...

Page 5

5 2 product description 2.2 device overview 60 40 100 ready ribbon media pa u s e feed cancel 100 80 40 60 80 100 ready ribbon media pa u se feed cancel 100 80 60 40 40 60 80 2 1 13 7 9 8 3 4 5 6 10 11 14 15 16 17 18 19 20 12 1 control panel 2 cover 3 ribbon unwinding unit 4 printhead 5 printhead ho...

Page 6

6 6 3 getting started i when unpacking the device, check that the delivery is complete and that there has been no transport damage. ! Warning! Risk of material damage. Please ensure the following before starting up the printer: set up the printer in a place where there is adequate space available fo...

Page 7

7 3 getting started 3.3 the label designing software elabel each e4 printer is supplied with elabel, a high-performance label designing software application. I the printer driver has to be installed before elabel can be installed. The software is on the supplied cd rom. Updates can be downloaded fro...

Page 8

8 8 3 getting started 3.5 positioning the media sensor ready ribbon media p a use feed cancel 100 100 80 60 40 40 60 80 2 1 1 3 4 1 3 4 1 media sensor 2 media sensor cover 3 media 4 spaces between labels release the printhead module and swing it up. Take the cover (2) off the media sensor (1). Posit...

Page 9

9 3 getting started 3.6 loading the transfer ribbon ! Warning! Risk of material damage. When inserting the transfer ribbon ensure that the coated side faces the labels, as otherwise the printhead can become soiled. Ensure that the media is winding in the same direction as shown in the illustration. ...

Page 10

10 10 4 operation 4.1 operator controls power switch the power switch is located on the left-hand side of the printer. Position 0: off position i: on dip switches i switch off the printer before setting the dip switches. Dip switch functions remarks 12345678 dip o ni on off 1 on: direct thermal prin...

Page 11

11 4 operation 4.2 operating functions normal mode feed a label is fed forward. Pause the current print job has paused, media fl ashing. Paused print job resumed. Cancel the current print job has been stopped. Continue printing after rectifying fault. System mode i in system mode, the printer cannot...

Page 12

12 12 5 cleaning danger! Danger from electric shock! Switch off the printer before starting any maintenance work. ! Warning! Risk of damage! Only use cleansers approved by the manufacturer. The manufacturer shall not be liable for damage caused by the use of other cleansers. Remove dust and paper fl...

Page 13

13 6 troubleshooting 6.1 error messages a fault is indicated by one or two of the three leds fl ashing. Possible cause recommended solutions remarks ready and media leds fl ashing simultaneously failure to detect gap between labels or refl ective marks check media path check the software setting if ...

Page 14

14 14 7 interfaces 7.1 rs 232 serial baud rate: 9600, 19200, 38400, 57600 (setting by dip switches 7 - 8) data format: always 8 data bits, 1 start bit and 1 stop bit parity: always non parity flow control: rts/cts (hardware fl ow control), if you are using software or drivers under the windows ® env...

Page 15

15 7 interfaces 7.3 ethernet interface handshake: tcp/ip connector type: rj45 standard ip address: 199.9.9.196. I only connect the printer if the standard ip address has not been assigned elsewhere, change the other assignment if necessary. Confi gure the ip address of the printer switch off printer...

Page 16

16 16 7 interfaces 9. Confi rm with close. 10. Switch off printer. 11. Set dip switch 6 to off. I the ip address of the printer can be checked by a self-test printout. Setting up the printer driver select the cab printer driver in the operating system under "start" -> "settings" -> "printers and fax...

Page 17

17 7 interfaces 2. Enter the ip address of the printer in the wizard to add a tcp/ip connection. 3. Enter standard as the device type, and follow the further instructions of the wizard. 7.4 ascii table 0 1 2 3 4 5 6 7 0 nul 0 @ p ´ p 1 soh xon ! 1 a q a q 2 stx “ 2 b r b r 3 xoff # 3 c s c s 4 $ 4 d...

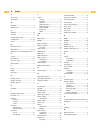

Page 18

18 18 8 index a accessories ........................................ 5 ascii table ....................................... 17 b barcodes ............................................ 4 bottom case........................................ 5 c cancel ........................................... 10 cleani...