Summary of EOS

Page 1

Operator's manual eos1 label printer.

Page 2: Operator'S Manual

2 23 operator's manual for the following products family type eos eos1 / 200 eos1 / 300 eos1 / 200 c eos1 / 300 c eos1 / 200 pc eos1 / 300 pc edition: 07/2011 - art.-no. 9009088 copyright this documentation as well as translation hereof are property of cab produkttechnik gmbh & co. Kg. The replicati...

Page 3: Table of Contents

2 3 3 table of contents 1 introduction ....................................................................................5 1.1 product description .........................................................................5 1.2 instructions ..............................................................

Page 4: Table of Contents

4 45 table of contents 9 licences .......................................................................................33 9.1 ec declaration of conformity ........................................................33 9.2 fcc ...............................................................................

Page 5: 1.1 Product Description

4 5 5 1.1 product description the device is an industrial thermal transfer printer for printing labels and continuous media. 1.2 instructions important information and instructions in this documentation are designated as follows: danger! Draws your attention to an exceptionally grave, impending dang...

Page 6: 1.3 Intended Use

6 67 1.3 intended use • the device is manufactured in accordance with the current technological status and the recognized safety rules. However, danger to the life and limb of the user or third parties and/or damage to the device and other tangible assets can arise during use. • the device may only ...

Page 7: Danger!

6 7 7 • unauthorized interference with electronic modules or their software can cause malfunctions. • other unauthorized work on or modifications to the device can also endanger operational safety. • always have service work done in a qualified workshop, where the personnel have the technical knowle...

Page 8: 2.1 Device Overview

8 89 2.1 device overview 1 2 3 4 5 6 7 8 1 cover 2 margin stops 3 roll retainer 4 ribbon supply hub 5 ribbon take-up hub 6 belt roller 7 print mechanics 8 touchscreen display fig. 1 device with tear-off plate 9 9 cutter or perforation cutter fig. 2 device with cutter or perforation cutter 2 installa...

Page 9: Attention!

8 9 9 13 15 12 10 11 16 17 14 10 label sensor 11 printhead retainer with printhead 12 guides 13 knob for adjusting the guides 14 knob for adjusting the label sensor 15 lever for locking the printhead 16 tear-off plate 17 print roller fig. 3 print mechanics 2.2 unpacking and setting-up the printer li...

Page 10: Installation

10 10 11 2 installation 2.3 connecting the device 2 3 4 5 1 1 power switch 2 usb master ports for keyboard, scanner, memory stick or service key 3 usb high-speed slave port 4 ethernet 10/100 base-t 5 power connection jack fig. 4 connections 2.3.1 connecting to the power supply the printer is equippe...

Page 11: Installation

10 11 11 2.4 switching on the device when all connections have been made: switch the printer on at the power switch (1). The printer performs a system test, and then shows the system status ready in the display. If an error occurs during the system test, the symbol , critical fault and type of error...

Page 12: Control Panel

12 12 13 3.1 structure of the touchscreen display i notice! It is advantageous, whenever possible, to make adaptations to various print jobs in the software. 2 1 ready the touchscreen display (1) indicates the current status of the printer and the print job, indicates faults and shows the printer se...

Page 13: Control Panel

12 13 13 3 control panel 3.3 symbols on the start display symbol status function ready to offline menu ready feeds a blank label ready after the end of a print job, reprint the last label printing label interrupt print job, printer goes into "pause" state pause continue the print job, printer goes i...

Page 14: Control Panel

14 14 15 3 control panel 3.4 printer states state display description ready ready the printer is in the ready state and can receive data. Printing label printing label and the number of the printed label in the print job. The printer is currently processing an active print job. Data can be transmitt...

Page 15: Attention!

14 15 15 4.1 loading media from roll 5 7 8 6 9 2 1 3 4 fig. 7 loading media from roll 1. Turn ring (2) counterclockwise, so that the arrows points to the symbol , and thus release the margin stop (1) from the roll retainer (4). 2. Load label roll (3) on the roll retainer (4) in such a way that the p...

Page 16: Loading Material

16 16 17 4 loading material 4.2 loading fanfold labels 2 6 3 4 5 7 1 fig. 8 loading fanfold labels 1. Position label stack (2) behind the printer. 2. Guide material below the roll retainer (1) to the printing unit. Ensure that the printing side of the labels is visible from above. 3. Turn lever (6) ...

Page 17: Loading Material

16 17 17 4 loading material 4.3 adjusting the label sensor i notice! When the printer is delivered the label sensor is positioned in the middle of the paper feed. Thus, the label sensor must only be adjusted if: • material with reflex or cut-out marks, which are not in the middle, • multi-strip mate...

Page 18: Loading Material

18 18 19 4 loading material 4.4 loading transfer ribbon 6 5 2 4 3 1 1 7 fig. 10 transfer ribbon feed path c a b 1 fig. 11 guide adjustment i notice! With direct thermal printing, do not load a transfer ribbon; if one has already been loaded, remove it. 1. Clean the printhead before loading the trans...

Page 19: Loading Material

18 19 19 4 loading material ! Attention! Guide transfer ribbon over the label sensor (7). 7. Secure starting end of the transfer ribbon to the ribbon core (3) using adhesive tape. Ensure counterclockwise rotation direction of the transfer ribbon take-up hub. 8. Turn transfer ribbon take-up hub (2) c...

Page 20: Option

20 20 21 5 option 5.1 cutter/perforation cutter the cutter /perforation cutter contained in the contents of delivery must be mounted to the printer during the initial start-up. 1 4 5 1 3 2 fig. 13 mount cutter or perforation cutter 1. Put snap arm (5) of the cutter with the groove (4) first into the...

Page 21: Option

20 21 21 5 option 5.2 external supply hub 2 1 3 4 5 7 6 fig. 14 load material to external supply hub mount external supply hub 1. Position external supply hub behind the printer. 2. Lift printer slightly and position ground plate (7) on both hooks (6) of the external supply hub. Load material 1. Tur...

Page 22: Printing Operation

22 22 23 6 printing operation ! Attention! Printhead damage caused by improper handling! Do not touch the underside of the printhead with the fingers or sharp objects. Ensure that the labels are clean. The printer is ready for operation when all connections have been made and labels and the transfer...

Page 23: Maintenance

22 23 23 7 maintenance 7.1 cleaning instructions danger! Risk of death via electric shock! Disconnect the printer from the power supply before performing any maintenance work. It is important to clean the thermal printhead regularly. This guarantees a consistently good printed image and reduces wear...

Page 24: Maintenance

24 24 25 1 fig. 15 printhead line 1. Lift the printhead. 2. Remove labels and transfer ribbon from the printer. 3. Clean printhead line (1) with rubbing alcohol and a soft cloth. 4. Allow printhead to dry for 2–3 minutes before commissioning the printer. 7.3 changing the printhead 2 6 7 1 5 8 3 4 2 ...

Page 25: Attention!

24 25 25 7.4 cleaning or replacing the print roller accumulations of dirt on the print roller may impair the media transport and the print quality. ! Attention! Damage of the print roller. Do not use sharp objects (knives, screwdrivers, etc.) to clean the printhead. 1 2 4 3 3 5 fig. 17 print roller ...

Page 26: Maintenance

26 26 27 7 maintenance 7.5 cleaning cutter/perforation cutter and replace blades ! Warning! Disconnect printer from electrical outlet to prevent accidental blade movement. ! Warning! Risk of injury! The cutter blades are sharp! I notice! When cutting through the label material instead of the label g...

Page 27: Maintenance

26 27 27 7 maintenance 9 10 11 5 8 7 8 7 5 6 fig. 19 replace blades 13 12 fig. 20 springs 4. If the blades are very dirty with residues of adhesive or if they are worn, change blades: turn shaft (6) clockwise using a torx wrench tx10 until the gear racks (7) cannot engage anymore. Pull upper blade (...

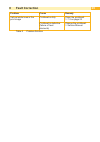

Page 28: 8.1 Types Of Errors

28 28 29 8.1 types of errors the diagnostic system indicates on the touchscreen display if an error has occurred. The printer is set into one of the three possible error states according to the type of error. State display button correctable error continue , cancel display flashes red irrecoverable ...

Page 29: Fault Correction

28 29 29 problem cause remedy vertical white lines in the print image printhead is dirty clean the printhead. 7.2 on page 23 printhead is defective (failure of heat elements) change the printhead. Service manual. Table 4 problem solution 8 fault correction.

Page 30: Fault Correction

30 30 31 8 fault correction 8.3 error messages and fault correction error message cause remedy barcode too big the barcode is too big for the allocated area of the label reduce the size of the barcode or move it. Barcode error invalid barcode content, e.G. Alphanumeric characters in a numerical barc...

Page 31: Fault Correction

30 31 31 8 fault correction error message cause remedy memory overflow current print job contains too much information, e.G. Selected font, large graphics cancel current print job. Reduce amount of data to be printed. Name exists duplicate usage of field name in the direct programming correct progra...

Page 32: Fault Correction

32 32 33 error message cause remedy protocol error printer has received an unknown or invalid command from the computer, e.G. The command to perform a cut although a cutter is not mounted select continue to skip the command or select cancel to cancel the print job. Read error read error when reading...

Page 33: Ec Declaration of Conformity

32 33 33 9.1 ec declaration of conformity gesellschaft für computer- und automations- bausteine mbh & co kg wilhelm-schickard-str. 14 d-76131 karlsruhe, germany ec declaration of conformity we declare herewith that as a result of the manner in which the device designated below was designed, the type...

Page 34: 9.2 Fcc

34 34 35 9.2 fcc note : this equipment has been tested and found to comply with the limits for a class a digital device, pursuant to part 15 of the fcc rules. These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial enviro...

Page 35: 10 Index

34 35 35 10 index c cleaning ............................26 cutter ..........................26 printhead .....................23 print roller ..................25 cleaning instructions .........23 connecting ........................10 contents of delivery ............9 correctable error ..............

Page 36

36 36 this page was intentionally left blank..