- DL manuals

- CAB

- Printer

- M4

- Operator's Manual

CAB M4 Operator's Manual

Summary of M4

Page 1

Edition 5/04 thermal transfer printer operator's manual.

Page 2

2 cab produkttechnik gmbh & co kg m4 copyright by cab / 9008331 / o20 / 1 all specifications about delivery, design, performance and weight are given to the best of our current knowledge and are subject to change without prior notice. Gesellschaft für computer- und automations- bausteine mbh & co kg...

Page 3

3 cab produkttechnik gmbh & co kg m4 all rights reserved, including those of the translations. No part of this manual nor any translation may be reproduced or transmitted in any form or by any means, for any purpose other than the purchaser's personal use, without the express written permission of c...

Page 4

4 cab produkttechnik gmbh & co kg m4 table of contents trademarks .................................................................................................................................... 6 a general guide to the documentation .................................................................

Page 5

5 cab produkttechnik gmbh & co kg m4 table of contents loading labels ........................................................................................................................ 42 loading labels from roll ....................................................................................

Page 6

6 cab produkttechnik gmbh & co kg m4 table of contents / trademarks trademarks centronics ® is a registered trademark owned by centronics data computer corporation. Macintosh-computer is a product of apple computer, inc. Microsoft ® is a registered trademark owned by microsoft corporation. Bitstream...

Page 7

7 cab produkttechnik gmbh & co kg m4 a general guide to the documentation a general guide to the documentation this manual contains the description and usage instructions for the m4 printer. For detailed technical information on programming of the m4, a separate programming guide is available on req...

Page 8

8 cab produkttechnik gmbh & co kg m4 printer types m4/200 : with 203dpi printhead m4/200r : with 203dpi printhead and internal rewinder m4/200p : with 203dpi printhead, internal rewinder and present sensor m4/300 : with 300dpi printhead m4/300r : with 300dpi printhead and internal rewinder m4/300p :...

Page 9

9 cab produkttechnik gmbh & co kg m4 characteristics of the thermal printhead caution ! The thermal printhead is the most sensitive part of your printer. Please pay special attention to the following guidelines: 1) the glass cover on the printhead must not be touched with the hand. Also, do not use ...

Page 10

10 cab produkttechnik gmbh & co kg m4 1. Product description compliances the device complies with the following safety regulations : ce : the printer complies with the following safety requirements - ec low voltage directive (73/23/eec) - ec machinery directive (98/37/eec) - ec electromagnetic compa...

Page 11

11 cab produkttechnik gmbh & co kg m4 technical specifications printhead printhead type : direct thermal or thermal transfer printhead model : thick film transfer printhead printhead resolution : m4/200 : 203 dpi = 8 dots / mm m4/300 : 300 dpi = 11.8 dots / mm number of dots/line : m4/200 : 832 m4/3...

Page 12

12 cab produkttechnik gmbh & co kg m4 media edge sensor distance to paper edge : .16-2.3 in (4-57,5 mm) material recognition : gap sensor ("see-through"), bottom-reflective sensor electronics processor : 32 bit motorola coldfire / 64 mhz internal memory (ram) : 8 mb slot for memory card : compactfla...

Page 13

13 cab produkttechnik gmbh & co kg m4 barcodes linear codes : code 39, code 93, code 128 a,b,c, codabar, ean 8, ean 13, ean 128, ean/ucc 128, ean/upc anhang 2, ean/upc anhang 5, fim, hibc, interleaved 2/5, ident-/leitcode der deutschen post ag, jan 8, jan 13, msi, plessey, postnet, rss14, upc a, upc...

Page 14

14 cab produkttechnik gmbh & co kg m4 options external media unwinder/rewinder for operating large print jobs, external unwinders and rewinders are available to handle big label rolls. The external rewinder er1 can be used for label rolls with a diameter up to 8.3 in (200mm). The external rewinder e...

Page 15

15 cab produkttechnik gmbh & co kg m4 1. Product description print media the m4 printers can be run in a direct thermal or thermal transfer mode. For direct thermal mode, the label material must be specifically designed for this use. The printout is created directly on the paper, as the paper reacts...

Page 16

16 cab produkttechnik gmbh & co kg m4 1. Product description print media for direct thermal printing the material to be printed must comply with certain important specifications to ensure a quality print image and to avoid damage or extra wear to the printhead. Using the label stock which we have te...

Page 17

17 cab produkttechnik gmbh & co kg m4 item min. Max. A label width .5 (12) 4.6 (116) peel-off mode 1 (25) 4.6 (116) b backing width 1 (25) 4.7 (120) c label length .2 (5) 39 (1000) peel-off mode .5 (12) 7.9 (200) d gap between labels .08 (2) 39 (1000) e label thickness .003 (0.07) .12 (0.3) f thickn...

Page 18

18 cab produkttechnik gmbh & co kg m4 1. Product description transfer ribbon the choice of transfer ribbon plays an important role in the quality of print image that can be produced, and it also directly affects the longevity of the printhead. Caution ! Poor quality transfer ribbon can lead to prema...

Page 19

19 cab produkttechnik gmbh & co kg m4 1. Product description software there are several methods to create formats and to send them to the printer. Below, a short explanation of the most common methods is given. Direct programming the printer is equipped with an internal command set. The command set ...

Page 20

20 cab produkttechnik gmbh & co kg m4 2. General safety instructions caution ! - the printer is built exclusively to print die-cut labels, continuous media, and similar materials as listed in technical specifications in chapter 1. - connect the printer to an outlet with the correct voltage! The prin...

Page 21

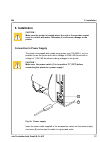

21 cab produkttechnik gmbh & co kg m4 3. Unpacking fig. 3 removing the securing devices removing the securing devices 1. Place the printer on a solid flat surface. 2. Open the cover. 3. Remove the securing devices (1, 2). 1 2.

Page 22

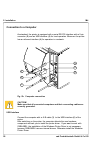

22 cab produkttechnik gmbh & co kg m4 fig. 4a general view 1 - warning label ''end of ribbon'' 2 - navigator pad 3 - present sensor ps8 (option for m4/200p and m4/300p) 4 - print mechanism 5 - internal rewinder (not at m4/200 and m4/300) 6 - ribbon take up hub 7 - ribbon supply hub 8 - media hub 9 -...

Page 23

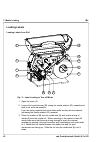

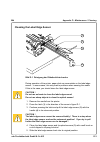

23 cab produkttechnik gmbh & co kg m4 4. Printer component location fig. 4b print mechanism m4/200, m4/300 with printhead open 1 - printhead locking screw 2 - ribbon shield 3 - label edge sensor 4 - media feed roller 5 - tear-off plate 6 - printhead support 7 - screw to adjust the printhead support ...

Page 24

24 cab produkttechnik gmbh & co kg m4 4. Printer component location fig. 4c print mechanism m4/200r, m4/300r with printhead open 1 - printhead locking screw 2 - ribbon shield 3 - label edge sensor 4 - media feed roller 5 - rewind guide plate 6 - printhead support 7 - screw to adjust the printhead su...

Page 25

25 cab produkttechnik gmbh & co kg m4 4. Printer component location fig. 4d print mechanism m4/200p, m4/300p with printhead open 1 - printhead locking screw 2 - ribbon shield 3 - label edge sensor 4 - media feed roller 5 - dispense plate 6 - rewind assist roller 7 - locking system 8 - printhead supp...

Page 26

26 cab produkttechnik gmbh & co kg m4 1 2 3 4 5 fig. 4e back view 1 - memory card slot 2 - ethernet interface 3 - rs-232 interface 4 - usb slave interface 5 - power switch 6 - power supply connector 6 4. Printer component location.

Page 27

27 cab produkttechnik gmbh & co kg m4 5. Installation caution ! Make sure the printer is located where the unit or the operator cannot come in contact with water. Otherwise it could cause damage to the printer. 1 2 5. Installation connection to power supply the printer is equipped with a wide range ...

Page 28

28 cab produkttechnik gmbh & co kg m4 1 2 connection to a computer as standard, the printer is equipped with a serial rs-232-interface with a 9 pin connector (5) and an usb interface (6) for local operation. Moreover the printer has an ethernet interface (4) for operation in a network. Caution ! Mak...

Page 29

29 cab produkttechnik gmbh & co kg m4 5. Installation serial rs-232 interface connect the computer and the printer with a suitable cable and secure the cable connections with screws provided on the connectors. Cables for the serial connection (2) are described in appendix b. There you can also find ...

Page 30

30 cab produkttechnik gmbh & co kg m4 5. Installation switch on the printer fig. 5c switch on the printer after making all connections, power on the printer using the power switch (1). The printer will perform a short system test, then key lights up on the navigator pad. If a hardware failure occurs...

Page 31

31 cab produkttechnik gmbh & co kg m4 windows driver installation ther are different driver installation methods, depending on the interface connection and the windows version. Usb interface notice ! Windows 95 and windows nt4.0 do not support usb interfaces ! Windows 98/me 1. Make sure that the pri...

Page 32

32 cab produkttechnik gmbh & co kg m4 5. Turn on the printer. Windows displays, that a new hardware was found and that the "found new hardware wizard" installs a driver for that device. Click "next". 6. The message "search for a suitable driver for my device appears. Click "next. 7. Click the boxe...

Page 33

33 cab produkttechnik gmbh & co kg m4 5. Installation serial rs-232 interface windows 95/98/me 1. Turn on the computer. 2. Quit any open applications. 3. Insert the "printer accessories cd a-series/m-series" into the cd-rom drive. 4. From the start menu, select settings, printers, add printer. 5. Th...

Page 34

34 cab produkttechnik gmbh & co kg m4 5. Installation windows 2000/xp 1. Turn on the computer. 2. Quit any open applications. 3. Insert the "printer accessories cd a-series/m-series" into the cd-rom drive. 4. From the start menu, select settings, printers, add printer. 5. The add printer wizard box ...

Page 35

35 cab produkttechnik gmbh & co kg m4 5. Installation ethernet interface notice ! M4 supports the network print protocols lpd and raw-ip. Under the windows 95/98/me operating system, there is no built-in support for raw-ip and lpd. Under windows nt4.0 raw-ip is not supported. But there are third-par...

Page 36

36 cab produkttechnik gmbh & co kg m4 5. Installation windows 2000/xp 1. Turn on the computer. 2. Quit any open applications. 3. Insert the "printer accessories cd a-series/m-series" into the cd-rom drive. 4. From the start menu, select settings, printers, add printer. 5. The add printer wizard box ...

Page 37

37 cab produkttechnik gmbh & co kg m4 6. Navigator pad fig. 6a navigator pad 6. Navigator pad the navigator pad allows the operator the ability to control the most important functions directly on the printer, e.G. To pause and continue or to cancel print jobs on demand. During printing the keys on t...

Page 38

38 cab produkttechnik gmbh & co kg m4 system mode print the printer is currently processing an active print job. In this mode, the transfer of data is possible. New print jobs will be carried out immediately following the completion of the previous job. Key/ state function lettering on interrupts th...

Page 39

39 cab produkttechnik gmbh & co kg m4 system mode fault-correctable the printer has encountered a fault during printing which is easily corrected by the operator (e.G. "out of paper"). Once the fault has been corrected, the printing process may be continued. Key/ state function lettering on indicate...

Page 40

40 cab produkttechnik gmbh & co kg m4 1. Pay attention to the specifications of the material indicated in chapter 1 . 2. When using the printer for the first time or using label media with a different width, make sure to adjust the printhead support as well as the position of the label edge sensor. ...

Page 41

41 cab produkttechnik gmbh & co kg m4 preparation for tear-off mode / rewind mode m4/200r and m4/300r are delivered with the rewind guide plate (1) mounted for operation in rewind mode. With the optional tear-off plate the printers also may be operated in tear-off mode. For this purpose the rewind g...

Page 42

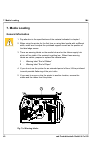

42 cab produkttechnik gmbh & co kg m4 loading labels fig. 7c label loading in tear-off mode 1. Open the cover (1). 2. Loosen the knurled screw (10), swing the media retainer (11) upwards and slide it out as far as possible. If you are using material that is the same width as the previous material, j...

Page 43

43 cab produkttechnik gmbh & co kg m4 4. Swing the media retainer (11) downwards until it touches the media hub (9). Push the media retainer against the supply role until it rests against the label media. Tighten the knurled screw (10). 5. Raise the printhead assembly (2) by rotating the lever (7) c...

Page 44

44 cab produkttechnik gmbh & co kg m4 7. Media loading 9. To accommodate a variety of print jobs, the position of the label edge sensor (3) can be adjusted until it is at the proper sensing position. It is important to ensure that the sensor (14) itself (the position of which is indicated by a notch...

Page 45

45 cab produkttechnik gmbh & co kg m4 7. Media loading fig. 7f loading labels from roll in rewind mode 12. In rewind mode, the rewind guide plate (16) must be mounted. Remove the labels from the first 4 in (100mm) of the label strip. Then, slide the media strip (4) around the rewind guide plate (16)...

Page 46

46 cab produkttechnik gmbh & co kg m4 7. Media loading fig. 7g loading labels from roll in peel-off mode 13. For peel-off mode swing the locking system (21) away from the rewind assist roller (23). 14. Remove all labels from the media strip hangig out of the printer. Then, slide the strip (25) aroun...

Page 47

47 cab produkttechnik gmbh & co kg m4 7. Media loading when printing narrow label stock (width less than 60% of the maximum print width), it is possible that the printhead will come into direct contact with the printing roller in the area where there is no media. Caution ! The printhead touching the...

Page 48

48 cab produkttechnik gmbh & co kg m4 7. Media loading loading fanfold labels 1. Open the cover. 2. Loosen the knurled screw (7) and slide the media guide (6) to its outermost position. Rotate the media guide (6) downwards past the media retainer (5). 3. Place the stack of media (4) behind the print...

Page 49

49 cab produkttechnik gmbh & co kg m4 7. Media loading 9. Slide the media guide ring (3) inward until it lightly touches the side of the media strip. 10. Lower the printhead by rotating the lever (1) counter-clockwise until it stops. Notice ! When printing narrow label stock please activate the prin...

Page 50

50 cab produkttechnik gmbh & co kg m4 7. Media loading notice ! For direct thermal printing no transfer ribbon is needed ! 1. Rotate the printhead lever (7) clockwise until it stops to raise the printhead. 2. Slide the roll of transfer ribbon (4) as far as possible onto the ribbon supply hub (5). No...

Page 51

51 cab produkttechnik gmbh & co kg m4 7. Media loading 4. Slide a cardboard core (1) onto the ribbon take up hub (2). Clamp the core by rotating the knurled knob (3) counter-clockwise. 5. Feed the transfer ribbon along the path as shown in figure 7l and attach it to the cardboard core (1) using a pi...

Page 52

52 cab produkttechnik gmbh & co kg m4 7. Media loading fig. 7m adjustment of the transfer ribbon in the event that wrinkles appear in the transfer ribbon (1), which cause an inconsistent print image, the transfer ribbon shield (2) can be adjusted to remove the wrinkles. The adjustment should be done...

Page 53

53 cab produkttechnik gmbh & co kg m4 7. Media loading this page is intentionally left blank..

Page 54

54 cab produkttechnik gmbh & co kg m4 8. Printer configuration overview there are a variety of parameters that can be set to configure the printer to specific requirements. The configuration of the parameters should be performed when operating the printer for the first time and also when basic chang...

Page 55

55 cab produkttechnik gmbh & co kg m4 8. Printer configuration printer configuration using the cab setup utility if the printer is connected to a serial or usb interface of the computer, the settings can be made using the "cab setup utility", wich is accessible after the windows driver installation....

Page 56

56 cab produkttechnik gmbh & co kg m4 8. Printer configuration 8. Printer configuration - click "read settings". - the current settings of the parameters are downloaded from the printer. Then the parameters are shown in a tree. - to open and close the different folders click on the [+] or [-] button...

Page 57

57 cab produkttechnik gmbh & co kg m4 8. Printer configuration - click on the parameter you want to change. In the right part of the window the current setting is shown. Click on that area. - depending on the parameter type you can select the new setting from a list or enter the new setting directly...

Page 58

58 cab produkttechnik gmbh & co kg m4 8. Printer configuration printer configuration using cablabel if the printer is connected to the serial interface of the computer, the settings of the configuration parameters can be made using the cablabel software. The cablabel lite version is delivered with e...

Page 59

59 cab produkttechnik gmbh & co kg m4 8. Printer configuration - the "printer settings" window will be opened. Click on the "m series" tab. - the current settings of the parameters will be downloaded from the printer. Then the "printer settings" window shows the parameters in a tree. - to open and c...

Page 60

60 cab produkttechnik gmbh & co kg m4 8. Printer configuration - click on the parameter you want to change. In the lower part of the window the current setting is shown. Click on that area. - depending on the parameter type you can select the new setting from a list or enter the new setting directly...

Page 61

61 cab produkttechnik gmbh & co kg m4 8. Printer configuration printer configuration using the printer webpage the firmware of the printer contains an internal webserver which can be accessed via ethernet interface using a java enabled browser (i.E. Microsoft internet explorer 4.X, netscape navigato...

Page 62

62 cab produkttechnik gmbh & co kg m4 8. Printer configuration assignment of the ip address in a network without dhcp server : if no dhcp server is available, you must manually assign the ip address. That can be done in different ways : a) ip assignment using the serial interface if you can connect ...

Page 63

63 cab produkttechnik gmbh & co kg m4 8. Printer configuration fig. 8i printer web-page "status" tab access to the printer web-page - start the internet browser. - access the printer's web-page by entering the printer's ip address in the internet browser : example : http://192.168.100.208 - the prin...

Page 64

64 cab produkttechnik gmbh & co kg m4 8. Printer configuration pin activation - change to the "info" tab. In this tab, all configuration parameters can be set. - in the top window, open the folder "security" and click on "pin". Fig. 8g printer web-page "info" - pin activation - in the lower window s...

Page 65

65 cab produkttechnik gmbh & co kg m4 setup local settings country time zone daylight saving set date set time machine param. Printhead pos. X printhead pos. Y tear-off pos. [demand sensor] [cutter] time powersave debug mode print parameters heat level print speed transfer print warn level ribbon la...

Page 66

66 cab produkttechnik gmbh & co kg m4 parameter meaning land set the language for the printer configuratiom, the printer webpage, self-test printouts and the date and time format for the country default setting: usa time zone set the time zone using utc (universal time coordinated) default : utc +1 ...

Page 67

67 cab produkttechnik gmbh & co kg m4 country the "country" parameter allows to set the language for the printer configuration, the printer webpage and self-test printouts as well as the date and time format used for printing. The formats for time and date can be configured with software, but will n...

Page 68

68 cab produkttechnik gmbh & co kg m4 parameter meaning printhead pos. Shift the print image on the label x left to right. Default : 0.0 mm printhead pos. Shift the print image on the label y top to bottom. Default : 0.0 mm tear-off pos. Shift the tear-off position default : 0.0 mm demand sensor (on...

Page 69

69 cab produkttechnik gmbh & co kg m4 printhead position x using this setting will shift the entire print image to the left on the label. This parameter should only be altered if you are printing the same format on several printers, and the printed image is not consistent on each printer. Notice ! T...

Page 70

70 cab produkttechnik gmbh & co kg m4 demand sensor - peel position this parameter allows for adjustment of the presentation position of the printed label on the dispense plate. Peel position with the initial offset value of 0 causes the printed label to be peeled off from the liner leaving approx...

Page 71

71 cab produkttechnik gmbh & co kg m4 cutter when the optional cutter is attached, the "cutter" menu appears in the "machine parameters" menu. The menu contains all of the parameters for the cut function. Detailed information is available in the cutter documentation. Time powersave if the printer do...

Page 72

72 cab produkttechnik gmbh & co kg m4 parameter meaning heat level basic adjustment of the heat intensity default : 0 print speed basic adjustment of the print speed default : 100 mm/s transfer print basic selection of thermal transfer mode / direct thermal mode default : on warn level setting the t...

Page 73

73 cab produkttechnik gmbh & co kg m4 parameter meaning barcode error selection, if the printer should handle invalid barcode data as errors default : on pause reprint allows you to print additional labels after finishing a print job by pressing the key default : off width setting the print width fo...

Page 74

74 cab produkttechnik gmbh & co kg m4 warn level ribbon that parameter allows to define a threshold diameter of the ribbon supply roll. As soon as the diameter of the roll falls below this threshold a snmp or e-mail warning message is sent via ethernet interface. So the operator is already asked to ...

Page 75

75 cab produkttechnik gmbh & co kg m4 backfeed in cut and peel-off mode, the material will be stopped in a position where the leading edge of the following label has already been forwarded beyond the printhead. The printer will then backfeed the label material from its cut/ dispense position to the ...

Page 76

76 cab produkttechnik gmbh & co kg m4 interfaces 8. Printer configuration table 8e overview of the "interfaces" folder parameter meaning character set select the character set table default : windows 1252 rs232 baud rate set the baud rate default : automatic handshake set the handshake default : rts...

Page 77

77 cab produkttechnik gmbh & co kg m4 character set the parameter defines how different characters (symbols, letters, special characters) will be translated to the interface. Before operating the printer, the "character set" of the printer should be adapted to match the character set of the computer...

Page 78

78 cab produkttechnik gmbh & co kg m4 rs-232 / handshake using this parameter it is possible to select, if the serial interface should be operated with the hardware protocol "rts/cts", the software protocol "xon/ xoff" or without protocol (setting "---"). Ethernet / dhcp in order to use the printer ...

Page 79

79 cab produkttechnik gmbh & co kg m4 lpd lpd is a network printing service. The service is available under windows nt4.0, windows 2000 and windows xp. To use the printing service, the "lpd parameter must be set to "on". Snmp snmp (simple network management protocol) is a query and command language...

Page 80

80 cab produkttechnik gmbh & co kg m4 parameter meaning pin set, erase, change a pin number to protect certain functions default : off security setup security selection off on change pin with this menu it is possible to set, erase or change a four-digit code number (pin). Notice ! If you want to cha...

Page 81

81 cab produkttechnik gmbh & co kg m4 9. Test options 9. Test options overview the printer is equipped with several test options. These options make it possible for the user to understand something about : - important configuration parameters - the fonts available in the printer - important hardware...

Page 82

82 cab produkttechnik gmbh & co kg m4 9. Test options fig. 9a status print status print a b d c e f.

Page 83

83 cab produkttechnik gmbh & co kg m4 9. Test options the status print contains : a) the type of printer as well as the version and date of the printer's firmware. B) the values of selected configuration parameters. C) cumulative operating time of the printer, amount of printed labels as well as cum...

Page 84

84 cab produkttechnik gmbh & co kg m4 device list the hardware components installed in the printer and the optional devices connected to the printer are displayed in this list. Fig. 9c device list the meaning of the details printed on the device list are as follows: cpu : type and serial number of t...

Page 85

85 cab produkttechnik gmbh & co kg m4 ascii dump (monitor) mode the ascii dump mode provides a method to print the control sequences sent to the interface. In this mode the data received will be printed in text format depending on the selected character set. Error messages will be printed directly b...

Page 86

86 cab produkttechnik gmbh & co kg m4 code druck code druck code druck code druck dec hex dec hex dec hex dec hex 00 00 08 08 16 10 24 18 01 01 09 09 17 11 25 19 02 02 10 0a 18 12 26 1a 03 03 11 0b 19 13 27 1b 04 04 12 0c 20 14 28 1c 05 05 13 0d 21 15 29 1d 06 06 14 0e 22 16 30 1e 07 07 15 0f 23 17 ...

Page 87

87 cab produkttechnik gmbh & co kg m4 10. Network printer functions 10. Network printer functions m4 is equipped with an ethernet interface. Therefore it is possible to connect the printers to a network using a 10 base t / 100 base t network connector and tcp/ip protocol. Using the ethernet interfac...

Page 88

88 cab produkttechnik gmbh & co kg m4 10. Network printer functions printer web-page the firmware of the printer contains an internal web-page that can be accessed using ethernet and an internet browser with java applets enabled. 1. Start the internet browser. 2. Access the printer's web-page by ent...

Page 89

89 cab produkttechnik gmbh & co kg m4 the lower area of the display you will find a list of the error conditions, which occured since powering on the printer. The list will display the last eight events. If the printer is currently in an error condition, the error will appear bold and will be indica...

Page 90

90 cab produkttechnik gmbh & co kg m4 "info" tab fig. 10c printer web-page - "info" tab the "info tab allows configuration of the parameters which are also accessible using cablabel or the cab setup utility. Notice ! If you want to change parameter settings using the printers internal webpage, the...

Page 91

91 cab produkttechnik gmbh & co kg m4 "ealert" tab when using the ethernet interface it is possible for printer to send error messages by email to selected email addresses. Notice ! For the use of this function, it is necessary to have an smtp server configured. (see chapter "printer configuration")...

Page 92

92 cab produkttechnik gmbh & co kg m4 "snmp" tab snmp (simple network management protocol) is a query and command language between managing stations on the one hand and managed units (the printer) on the other hand. For snmp communication between printer and managing station the parameter "snmp agen...

Page 93

93 cab produkttechnik gmbh & co kg m4 ip ip setting for two managing stations, which may communicate with printer via snmp. Community several snmp managing stations can be put together as a community. The membership to a community the managigng station declares with the snmp community string (a kind...

Page 94

94 cab produkttechnik gmbh & co kg m4 "fonts" tab in the "fonts tab, the parameters of the character fonts available are listed. The table contains both printer internal fonts and the character fonts which have been downloaded to the printer. Fig. 10e printer web-page - "fonts" tab the parameters o...

Page 95

95 cab produkttechnik gmbh & co kg m4 "devices" tab the "devices tab displays the hardware components of the printer, as well as the devices that are attached to the printer. Fig. 10f printer web-page - "devices" tab the parameters in the "devices" tab are defined as follows : cpu : type and serial...

Page 96

96 cab produkttechnik gmbh & co kg m4 printing on a network the printer can be operated on a network using the printing protocols "raw-ip and "lpd. Availability and installation of the printing protocols under windows under windows nt4.0 and windows 2000 the protocols are available, but lpd is not...

Page 97

97 cab produkttechnik gmbh & co kg m4 ftp printer administration using the file transfer protocol (ftp) you can send files over the network. For the handling of files, you can use most common ftp programs (ftp-clients), with which files from a local computer or server can uploaded or downloaded, del...

Page 98

98 cab produkttechnik gmbh & co kg m4 structure of the ftp server administration of the memory card notice ! Make sure before accessing the memory card that the printer is in the online mode. You can check the status of the printer by using the "status" tab on the printer's web-page. Download a down...

Page 99

99 cab produkttechnik gmbh & co kg m4 ftp fimware update notice ! Make sure the printer is in the online mode before attempting a firmware update. You can check the printer's status by using the printer's web- page under the "status" tab. In order to upload the firmware update, you must be logged-in...

Page 100

100 cab produkttechnik gmbh & co kg m4 ********************************************************************************************************** copyright 1988, 1989 by carnegie mellon university all rights reserved permission to use, copy, modify, and distribute this software and its documentation...

Page 101

101 cab produkttechnik gmbh & co kg m4 11. Memory cards the m4 printer offers the ability to use memory cards to permanently save formats, graphics, fonts and database information on the memory card. Data is sent to the memory card using the printer's interface and stored on the memory card. Althoug...

Page 102

102 cab produkttechnik gmbh & co kg m4 installation and removing the memory card with the compactflash card contacts facing the slot (1), insert the card (2) into the slot (1). Notice ! There are guides on the sides of the memory card which make it impossible to insert the card incorrectly. For remo...

Page 103

103 cab produkttechnik gmbh & co kg m4 preparing the memory card in order to use the memory card the first time, the card must be formatted for the printer to read and write data. Often the cards are preformatted for use with the printer. If you try to access a card, which is not formatted, the prin...

Page 104

104 cab produkttechnik gmbh & co kg m4 10. Memory cards this page is intentionally left blank..

Page 105

A-1 cab produkttechnik gmbh & co kg m4 appendix a - operation in peel-off mode components for the peel-off mode the printer types m4/200p and m4/300p are specificly developed for operation in the peel-off mode and they are equipped with dispense plate (7). Additionally the optional present sensor ps...

Page 106

A-2 cab produkttechnik gmbh & co kg m4 appendix a - operation in peel-off mode prelimininary tests the media width and height given in the technical specifications are suggested values for media when using the present sensor : label width : 1 to 4.6 in (25-116 mm) label height : .5 to 7.9 in (12-200...

Page 107

A-3 cab produkttechnik gmbh & co kg m4 appendix a - operation in peel-off mode loading labels loading of labels for peel-off mode is described in the chapter "media loading". Operation the printer is ready for operation if all connections have been made and all materials are loaded correctly. Notice...

Page 108

A-4 cab produkttechnik gmbh & co kg m4 appendix a - operation in peel-off mode this page is intentionally left blank..

Page 109

B-1 cab produkttechnik gmbh & co kg m4 appendix b - pin assignment of the interface connectors pin assignment of the rs-232 interface the printer is equipped with a 9 pin sub-d connector for the serial rs-232 interface. Fig. B-1 rs-232 interface connector (rear of the printer) table b-1 pin assignme...

Page 110

B-2 cab produkttechnik gmbh & co kg m4 interface cable for rs-232 to communicate with the printer, a standard rs-232 interface cable is used. If you have any problems interfacing with the printer, contact the manufacturer of your computer on the pin assignments of the interface. Use the pin assignme...

Page 111

C-1 cab produkttechnik gmbh & co kg m4 appendix c - error messages / problem solution error messages the printer is equipped with a self diagnostic system that will indicate errors switching on the letterings , or on the navigator pad. Recoverable errors while processing a print job, errors can occu...

Page 112

C-2 cab produkttechnik gmbh & co kg m4 non-recoverable errors during printing, an error has occured which cannot be cleared without canceling the print job (e.G. Hardware error). Appendix c - error messages / problem solution indications on the navigator pad lettering status on flashes table c-3 ind...

Page 113

C-3 cab produkttechnik gmbh & co kg m4 possible cause requested file is not on the card. There are labels missing on the media. The label size defined in the format sent to the printer does not match the actual media size. Printer is loaded with continuous media, the software is configured for die-c...

Page 114

C-4 cab produkttechnik gmbh & co kg m4 error protocol error solution depending on the type of error, the command can be skipped by pressing the key or the print job must be canceled by pressing the key. Switch the printer off. Correct the interface settings in printer setup (see chapter 8). Possible...

Page 115

C-5 cab produkttechnik gmbh & co kg m4 appendix c - error messages / problem solution cause and solution shield for the transfer ribbon is not correctly adjusted. Make the adjustment according to chapter 7. Printhead support is not correctly adjusted. Make the adjustment according to chapter 7. Tran...

Page 116

C-6 cab produkttechnik gmbh & co kg m4 appendix c - error messages / problem solution cause and solution printhead is dirty, clean the printhead (appendix d). Printhead is defective (failure of heating elements), replace the printhead. Printer is being used with backfeed set to "smart" in cut or dis...

Page 117

D-1 cab produkttechnik gmbh & co kg m4 appendix d - maintenance / cleaning the printer requires very little maintenance. Most important, clean the printhead on a regular basis. This will ensure a high quality printed image. It also reduces the amount of wear of the printhead. Aside from that, the on...

Page 118

D-2 cab produkttechnik gmbh & co kg m4 cleaning the printhead during printing, the thermal printhead will accumulate dirt such as paper dust or particles of color from the ribbon. This accumulation can caused a deterioration of the print quality (contrast difference of the label, appearance of clear...

Page 119

D-3 cab produkttechnik gmbh & co kg m4 cleaning the label edge sensor during operation of the printer, paper dust can accumulate on the label edge sensor. In some cases, this may lead to problems when sensing the media. If this is the case, you should clean the label edge sensor. Caution ! Do not us...

Page 120

D-4 cab produkttechnik gmbh & co kg m4 appendix d - maintenance / cleaning this page is intentionally left blank..

Page 121

E-1 cab produkttechnik gmbh & co kg m4 the printers are designed so the printhead replacement can be completed without making any adjustments. On m4 cannot be switched between printheads with 203 dpi and 300 dpi print resolution. Caution ! The printhead (1) is attached and aligned on a head plate (2...

Page 122

E-2 cab produkttechnik gmbh & co kg m4 fig. E-2 changing printhead i warning ! Unplug the power cord from the power source before starting! Caution ! Protect the printhead against damage by electrostatic dischargement ! - put the printer on to a grounded conductive surface ! - ground yourself during...

Page 123

E-3 cab produkttechnik gmbh & co kg m4 6. Carefully unplug the printhead (1) from the connectors of the printhead cables (9 and 10). 7. Connect the new printhead to the cables. 8. Place the printhead into the assembly and insert the holes (8) onto the pins (11). 9. Tighten the locking screw (5) by h...

Page 124

E-4 cab produkttechnik gmbh & co kg m4 replacing the print roller and the rewind assist roller fig. E-4 changing print roller and rewind assist roller (i) 1. Lift the printhead up and swing the locking system (5) away from the rewind assist roller (4). Remove the media from the printer. 2. Take the ...

Page 125

E-5 cab produkttechnik gmbh & co kg m4 fig. E-5 changing print roller and rewind assist roller (ii) 5. Remove the print roller (1) or the rewind assist roller from the respective shafts (11, 12). Caution ! Before assembling the new roller check if the keys (10, 13) are placed correctly in the shafts...

Page 126

E-6 cab produkttechnik gmbh & co kg m4 appendix e - replacing assembly units this page is intentionally left blank..

Page 127

F-1 cab produkttechnik gmbh & co kg m4 appendix f - firmware updates general information over a period of time, the printer's firmware is subject to constant development and revisions to allow for new features, easier error correction, etc. The firmware is stored in a flash-eprom, which represents a...

Page 128

F-2 cab produkttechnik gmbh & co kg m4 appendix f - firmware updates firmware update using the ethernet interface for firmware update using the ethernet interface you must use a ftp client that has binary data transfer available. Moreover a pin must be activated on the printer (see "printer configur...

Page 129

Cab produkttechnik gmbh & co kg m4 index a adjustment of the label edge sensor 44 adjustment of the printhead support 47 ascii dump mode 85f. B backfeed 72,75 backfeed delay 68,70 bar codes 13 barcode error 65,73,75 baud rate 76f. Bottom-reflect 72,74 c cab setup utility 54ff.,62 cablabel 19f.,28,30...

Page 130

Cab produkttechnik gmbh & co kg m4 index j java-applet 88ff. K keys 37ff. L label edge sensor 23ff. Label edge sensor, adjustment 44 label edge sensor, cleaning d-3 label formats 17 label sensor 72,74 labels from roll 42ff. Label software 19 limit peel-off speed 9,68,70, a-2 loading labels 42ff. Loa...

Page 131

Cab produkttechnik gmbh & co kg m4 index rewind mode 41,45 ribbon shield 23ff.,52 ribbon supply hub22 ribbon take up hub 22 rs-232 interface 26,28f.,33f.,54,76ff., b-1f., f-1 s safety precautions 20 securing devices 21 security 65,80 set date 66f. Set time 66f. Switch on 30 smtp-server 77,79,91 snmp...

Page 132

Cab produkttechnik gmbh & co kg m4 eu - conformity declaration we declare herewith that as a result of the manner in which the machine designated below was designed, the type of construction and the machines which, as a result have been brought on to the general market comply with the relevant funda...