- DL manuals

- CAB

- Printer

- XC Series

- Service Manual

CAB XC Series Service Manual

Summary of XC Series

Page 1

Service manual label printer xc series.

Page 2

2 2 family type xc xc4/300 xc6/300 edition: 11/2012 - part no. 9009285 copyright this documentation as well as translation hereof are property of cab produkttechnik gmbh & co. Kg. The replication, conversion, duplication or divulgement of the whole manual or parts of it for other intentions than its...

Page 3

2 3 table of contents 1 important information ............................................................................................................................ 4 1.1 instructions .................................................................................................................

Page 4

4 4 1.1 instructions important information and instructions in this documentation are designated as follows: danger! Draws your attention to an exceptionally grave, impending danger to your health or life. ! Warning! Indicates a hazardous situation that could lead to injuries or material damage. ! A...

Page 5

4 5 1 important information 1.3 protective devices ! Warning! There is a risk of injury if protective devices are missing or defective. Replace all protective devices (covers, safety notices, grounding cables etc) after maintenance work has been completed. Replace parts that have become defective or...

Page 6

6 6 2 preparation 2.1 tools do not use any worn of damaged tools. Only use tools and testing devices that are suitable for the task at hand. Cab special tools: • test collar for transfer ribbon winder (cab item number: 5534199) • distance caliber 0,1 mm (cab item number: 5961064) standard tools: • t...

Page 7

6 7 3 cleaning 3.1 cleaning by the operator the following cleaning work is described in the “operator's manual“: • cleaning the device • cleaning the printhead • cleaning the print roller 3.2 cleaning the label sensor 1 2 3 4 5 6 fig. 2 cleaning the label sensor danger! Risk of death via electric sh...

Page 8

8 8 4 replacing assembly units 4.1 replacing the printhead 4.1.1 replacing the printhead xc4 the printhead of the label printer can be replaced without the need for fine adjustment. The printhead must be replaced if worn. 1 2 3 4 6 4 6 5 1 printhead 2 plug connection 3 plug connection 4 screw 5 prin...

Page 9

8 9 i notice! The printhead replacement will be described for the upper printhead. The procedure applies for the lower printhead in the same manner. Removing the printhead 1. Lift the printhead. 2. Remove labels and transfer ribbon from the printer. 3. Lightly keep printhead mounting bracket (8) on ...

Page 10

10 10 4 replacing assembly units 4.1.2 replacing the printhead xc6 2 3 5 4 1 4 1 printhead 2 plug connection 3 plug connection 4 threaded hole 5 printing line fig. 5 structure of the printhead xc6 ! Attention! The printhead can be damaged by static electricity discharges and impacts! Ground your bod...

Page 11

10 11 4 replacing assembly units 6. For replacing the lower printhead remove the lower print roller 4.2 on page 12 and guide the printhead downward between the print units (8,9). 7. Loosen both plug connections (2, 3) on the printhead. 1 2 3 9 8 fig. 7 replacing the lower printhead xc6 installing th...

Page 12

12 12 4.2 replacing the print roller 1 6a 8 2 3 6c 6b 5 7c 7b 7a 9 4 10 11 fig. 9 replacing the print rollers 1. Unlock the levers (10,11) and lift the printheads. 2. Loosen the screws (6,7) and remove the plates (5,9). 3. Remove the print rollers (2,3). 4. Slide new rollers (2,3) onto their shafts ...

Page 13

12 13 4 replacing assembly units 4.3 replacing the slipping clutches the rewinders for the transfer ribbon are coupled to slipping clutches (1) in the main drive. The supply hubs of the transfer ribbon are braked with a slipping clutches (2) during printing. Change a slipping clutch when it can no l...

Page 14

14 14 4 replacing assembly units installing the slipping clutches on the rewinders 1 2 3 4 5 fig. 11 slipping clutch on the rewinder 1. Slide coupling (2) onto the winder axis (4). 2. Align grooves in the coupling disks (3) with the guides in the collar of the belt wheel (5). 3. Slide coupling furth...

Page 15

14 15 4.4 replacing the brake block on the roll retainer 3 4 5 6 1 2 8 10 9/4x 7 fig. 13 brake on the roll retainer 1. Turn knob (7) clockwise to release the roll retainer and remove the margin stop (10) from the roll retainer. 2. Loosen 4 screws (9) an remove wall spacer (8). 3. Remove snap ring (6...

Page 16

16 16 4 replacing assembly units 4.5 replacing the label sensor i notice! Soiling of the label sensor can also cause malfunctions. Before replacing the label sensor, check whether it is soiled and clean it if necessary 3.2 on page 7. Danger! Risk of death via electric shock! Before opening the rear ...

Page 17

16 17 4 replacing assembly units 4.6 replacing the cpu danger! Risk of death via electric shock! Before opening the rear cover, disconnect the device from the mains supply and wait at lease one minute until the power supply unit has discharged. 1 2 2 2 2 3 3 3 3 removing the cpu 1. If possible, save...

Page 18

18 18 4 replacing assembly units 4.7 replacing the power supply unit danger! Risk of death via electric shock! Before opening the rear cover, disconnect the device from the mains supply and wait at lease one minute until the power supply unit has discharged. 1 2 3 3 4 4 5 6 removing the power supply...

Page 19

18 19 5 adjustments 5.1 measuring and adjusting the winding torques the rewinders for the transfer ribbon are coupled to slipping clutches in the main drive. The supply hubs of the transfer ribbon are braked with a slipping clutches during printing. The correct setting of the torques of these slippi...

Page 20

20 20 5 adjustments the set values for the winding torque and the resulting pulling force at the test collar are: slipping clutch on direction of rotation winding torque m pulling force f ribbon take up hub against the winding direction 7,5 - 10,5 ncm 2,5 - 3,5 n ribbon supply hub any 3,6 - 4,5 ncm ...

Page 21

20 21 5 adjustments 5.1.2 adjusting the slipping clutches the winding torque of a winder can be changed at the knurled ring of the respective slipping clutch. The numbers on the knurled ring stand for the value of the winding torque: • 1: lowest winding torque • 7: highest winding torque the current...

Page 22

22 22 5 adjustments 5.2 adjusting the printing mechanism major adjustment of the printing mechanism beyond format-based settings is only required if the printhead assembly has been removed or parts in this area have been replaced. Excluded from this is the replacement of the printhead, after which r...

Page 23

22 23 5.2.2 adjusting the printhead position in order to achieve the best possible print image the following printhead settings are necessary: • align the heating line with the highest point of the print roller. Density of the print image is the greatest at this point. • set the parallelism of horiz...

Page 24

24 24 5 adjustments 5.2.3 adjusting the printhead pressure the printhead pressure can be changed with the screws (1a) and (1b) at the inside and outside of the printhead. Increasing the head contact pressure leads to an improvement of the print image density on the corresponding side and to a shifti...

Page 25

24 25 5 adjustments 5.2.4 adjusting the transfer ribbon feed path you can adjust the transfer ribbon feed path by changing the head contact pressure and adjusting the transfer ribbon deflection (2). Increasing the head contact pressure with the screws (3a) and (3b) shifts the ribbon feed path in the...

Page 26

26 26 5 adjustments 5.3 adjusting the label feed path you can adjust the label feed path by skewing the roller below the lower print unit. If a clear lateral drift of the labels occurs the label feed path can be adjusted by turning the eccentric (2). 4 1 2 3a 4 1 2 3b fig. 24 adjusting the label fee...

Page 27

26 27 5 adjustments 5.4 adjusting the belt tension danger! Risk of death via electric shock! Before opening the rear cover, disconnect the device from the mains supply and wait at lease one minute until the power supply unit has discharged. Up to sn 120132 3 1 2 6 4 5 7 8 9 fig. 25 adjusting the bel...

Page 28

28 28 from sn 120133 3 1 2 6 4 5 fig. 26 adjusting the belt tension (from sn 120133) 1. Unplug the printer from the electrical outlet. 2. Remove the cover 2.2 on page 6. 3. For adjusting the ribbon rewinder drive belt (3) : • loosen screws (1). • push the tension bracket (2) in such a way that the b...

Page 29

28 29 5 adjustments 5.5 adjusting the head switch the head switches prevent printing from occurring when a printhead is open. Adjust the head switches if the error message head open appears in the display even though the printheads are locked. Danger! Risk of death via electric shock! Before opening...

Page 30

30 30 5.6 adjusting the magnetic clutch a misaligned magnetic clutch can cause a very high and not adjustable torque at the ribbon supply hub of the lower print unit. The distance between chassis of the magnetic clutch (2) and the armature disk (1) must be 0.1 mm . Danger! Risk of death via electric...

Page 31

30 31 5.7 adjusting the ribbon saver mechanics the lower print unit is equipped with a ribbon saver. The saver automatic reduced the consumption of color ribbon, because in case of the saver mode the movement will interrupted by lifting the printhead. This is operated by a eccentric, which is contro...

Page 32

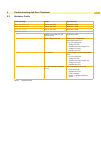

32 32 6 troubleshooting and error treatment 6.1 failure of device functions functional error possible remedy medium is not transported check electrical connections between cpu and stepper motor media transport check drive mechanism replace the cpu replace the stepper motor media transport no print i...

Page 33

32 33 6 troubleshooting and error treatment 6.2 hardware faults error message cause fault recovery adc malfunction fault on the cpu replace the cpu fpga malfunction fault on the cpu replace the cpu invalid setup fault on the cpu replace the cpu voltage error v bat voltage of the battery on the cpu i...

Page 34

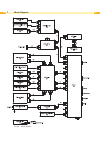

34 34 7 block diagram fig. 32 block diagram.

Page 35

34 35 8 layout diagram cpu fig. 33 layout diagram cpu - components side.

Page 36

36 36 8 layout diagram cpu fig. 34 layout diagram cpu - soldering side with measuring points.

Page 37

36 37 9 index a accidents ............................................5 b belt tension .......................................27 block diagram ...................................34 brake block roll retainer ....................15 c cleaning .............................................7 cpu replacem...