- DL manuals

- CAC / BDP

- Portable Generator

- 10kW

- Owner's Manual

CAC / BDP 10kW Owner's Manual

Summary of 10kW

Page 1

Study guide s e r v i c e t r a i n i n g air-cooled training.

Page 3: Owner’S Manual

Owner’s manual 8, 10, 12, 14, 16, 17 & 20kw air-cooled, automatic standby generators danger deadly exhaust fumes. Outdoor installation only! Not intended for use as primary power in place of utility or in life-support applications. Listed c us do not lift unit by roof!.

Page 4: Introduction

Introduction thank you for purchasing this compact, high per- formance, air-cooled, engine-driven generator. It is designed to automatically supply electrical power to operate critical loads during a utility power failure. This unit is factory installed in an all-weather, metal enclosure that is int...

Page 5

Table of contents air-cooled generators 1 introduction ........................Inside front cover read this manual thoroughly ........................ Ifc contents .......................................................... Ifc operation and maintenance ............................ Ifc how to obtain ...

Page 6: Warning:

2 study these safety rules carefully before install- ing, operating or servicing this equipment. Become familiar with this owner’s manual and with the unit. The generator can operate safely, efficiently and reliably only if it is properly installed, operated and maintained. Many accidents are caused...

Page 7

3 electrical hazards all generators covered by this manual produce • dangerous electrical voltages and can cause fatal electrical shock. Utility power delivers extremely high and dangerous voltages to the transfer switch as does the standby generator when it is in opera- tion. Avoid contact with bar...

Page 8: 1.1 Unpacking/inspection

Danger only qualified electricians or contractors should attempt such installations, which must comply strictly with applicable codes, standards and regu- lations. 1.1 unpacking/inspection after unpacking, carefully inspect the contents for damage. This standby generator set is ready for installa- •...

Page 9: 1.4 Emission

Section 1 — general information air-cooled generators 5 if during the installation of the home standby system the decision is made to provide back up power to a bedroom branch circuit, then the circuit breaker in the transfer switch should be replaced with an arc fault circuit interrupter. It is mos...

Page 10: 1.5 The

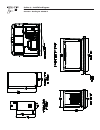

6 section 1 — general information air-cooled generators 1.5 the generator data label (see sample) oil dipstick exhaust enclosure composite base oil filter battery compartment fuel regulator fuel inlet (back) air filter circuit breaker control panel data label (see sample) oil dipstick exhaust enclos...

Page 11: 1.6 Specifications

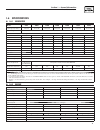

7 section 1 — general information air-cooled generators 1.6 specifications 1.6.1 generator model 8kw 10kw 12kw 14kw 16kw 17kw 20kw rated maximum power capacity (watts*) 7,000 ng 8,000 lp 9,000 ng 10,000 lp 12,000 ng 12,000 lp 13,000 ng 14,000 lp 16,000 ng 16,000 lp 16,000 ng 17,000 lp 18,000 ng 20,0...

Page 12: 1.7 System Set Led

1.7 system set led the “system set” led (single cylinder) or "ready to run" on the display (v-twin) is ready when all of the following conditions are true: 1. The auto/off/manual switch is set to the auto position. 2. The utility voltage being supplied to the unit is being sensed by the pcb. If the ...

Page 13: 1.10

9 note: a minimum of one approved manual shut-off valve must be installed in the gaseous fuel supply line. The valve must be easily accessible. Local codes determine the proper location. 1.10 reconfiguring the fuel system 1.10.1 8 kw, 410cc engine to reconfigure the fuel system from ng to lp, follow...

Page 14: 1.11 Location

10 figure 1.6 - 10kw, gt-530 (inlet hose slid back) fuel selection lever - "out" position for liquid propane (vapor) fuel figure 1.7 - 12, 14, 16, 17, & 20kw, gt-990/gt-999 (airbox cover removed) fuel selection lever - "in" position for natural gas fuel figure 1.8 - 12, 14, 16, 17, & 20kw, gt-990/gt...

Page 15: 1.12 Battery Requirements

11 install the generator as close as possible to the fuel • supply, to reduce the length of piping. Install the generator as close as possible to the • transfer switch. Remember that laws or codes may regulate the distance and location. The genset must be installed on a level surface. • the base fra...

Page 16: 1.14 The Battery

12 note: dielectric grease should be used on battery posts to aid in the prevention of corrosion. Note: damage will result if battery connections are made in reverse. Note: in areas where temperatures regularly fall below 10° f (-12° c) it is recommended that a pad type battery heater be installed t...

Page 17: 2.2

13 section 2 — post installation start-up and adjustments air-cooled generators 2.1 before initial start-up note: these units have been run and tested at the fac- tory prior to being shipped and do not require any type of break-in. Before starting, complete the following: 1. Set the generator’s main...

Page 18: 2.4 Generator

14 12. Set the generator’s main circuit breaker to its off (or open) position. Let the engine run at no- load for a few minutes to stabilize internal engine generator temperatures. 13. Set the generator's auto/off/manual switch to off. The engine should shut down. Note: it is important not to procee...

Page 19: 2.7

15 2.6 engine governor adjustment if both ac frequency and voltage are correspondingly high or low, adjust the engine governor as follows: 2.6.1 8 kw units the engine must be off to perform steps 1 and 2. 1. Loosen the governor clamp bolt (figure 2.1). 2. Hold the governor lever at its wide open thr...

Page 20

16 3.1 control panel interface 3.1.1 using the auto/off/manual switch (figures 3.1 & 3.2) 1. “auto” position – selecting this switch activates fully automatic system operation. It also allows the unit to automatically start and exercise the engine every seven days with the setting of the exercise ti...

Page 21: 3.2

17 section 3 — operation air-cooled generators note: the exerciser will only work in the auto mode and will not work unless this procedure is per- formed. The exerciser will need to be reset every time the 12 volt battery is disconnected and then reconnected, and when the fuse is removed and/ or rep...

Page 22: 3.3

18 3.3 sequence of automatic operation 3.3.1 utility failure initial conditions: generator in auto, ready to run, load being supplied by utility source. When utility fails (below 65% of nominal), a 10 second (optionally programmable on the 17 and 20kw only) line inter- rupt delay time is started. If...

Page 23

19 2. Auto will start and run if utility fails for 10 consecu- • tive seconds. Will start a five (5) second engine warm-up • timer. Will not transfer if utility subsequently returns. • will transfer to generator if utility is still not pres- • ent. Will transfer back to utility once utility returns ...

Page 24: 3.5

20 danger do not attempt to activate the transfer switch manually until all power voltage supplies to the switch have been positively turned off. Failure to turn off all power voltage supplies may result in extremely hazardous and possibly fatal elec- trical shock. 5. Use the manual transfer handle ...

Page 25

21 high engine temperature (shutdown alarm – auto reset) a 10 second delay on start-up and one (1) second delay before shutdown. Auto reset when the condition clears and restart the engine if a valid start signal is still present. This switch’s contacts (figure 3.6) close if the tem- perature should...

Page 26: 4.1 Fuse

22 3.6.3 maintenance alerts (10 - 20kw only) third priority maintenance message when a maintenance period expires, a warning mes- sage will be displayed. (16 through 20kw models include an external yellow led which will illuminate.) the alert can be reset by pressing the enter key, which will cause ...

Page 27: 4.4

4.3 changing the engine oil 4.3.1 oil change intervals see the "service schedule" section. 4.3.2 engine oil recommendations all oil should meet minimum american petroleum institute (api) service class sj, sl or better. Use no special additives. Select the oil's viscosity grade according to the expec...

Page 28: 4.5 Spark

24 figure 4.5 — 12, 14, 16, 17 & 20kw engine air cleaner cover filter screw 4.4.2 10kw generators see "the generator" section for the location of the air cleaner. Use the following procedure (figure 4.6): 1. Lift the roof and remove the door. 2. Turn the worm gear clamp screw counterclock- wise to l...

Page 29: 4.6 Battery

25 figure 4.8 – setting the spark plug gap 4.6 battery maintenance the battery should be inspected per the "service schedule" section. The following procedure should be followed for inspection: 1. Inspect the battery posts and cables for tightness and corrosion. Tighten and clean as necessary. 2. Ch...

Page 30: 4.8 Cooling

26 make sure the piston is at top dead center (tdc) • of its compression stroke (both valves closed). To get the piston at tdc, remove the intake screen at the front of the engine to gain access to the flywheel nut. Use a large socket and socket wrench to rotate the nut and hence the engine in a clo...

Page 31: 4.10 Corrosion Protection

27 4.10 corrosion protection periodically wash and wax the enclosure using auto- motive type products. Frequent washing is recom- mended in salt water/coastal areas. Spray engine linkages with a light oil such as wd-40. 4.11 out of service procedure 4.11.1 removal from service if the generator canno...

Page 32: 4.12 Service Schedule

28 section 4 — maintenance air-cooled generators 4.12 service schedule attention: it is recommended that all service work be performed by the nearest dealer. System/component procedure frequency x = action r = replace as necessary * = notify dealer if repair is needed. Inspect change clean w = weekl...

Page 33

29 section 5 — troubleshooting air-cooled generators 5.1 troubleshooting guide problem cause correction the engine will not crank. 1. Fuse blown. 1. Correct short circuit condition, replace 7.5a fuse in generator control panel. 2. Loose, corroded or defective 2. Tighten, clean or replace battery cab...

Page 34: 6.1 Menu

30 6.1 menu system navigation to get to the menu, use the "esc" key from any page. It may need to be pressed many times before getting to the menu page. The currently selected menu is displayed as a flashing word. Navigate to the menu required by using the +/- keys. When the menu required is flashin...

Page 35: Menu System

31 section 6 — appendix air-cooled generators 31 main menu r un log alarm log hist or y st a tus command s tat e versions displa y genera t o r freq uency engine hours engine rpm b a tter y v o lta g e deb u g inputs outputs displa y s st ar tup dela y edit contrast langu a ge freq u ency time/d a t...

Page 36

32 32 section 7 — notes air-cooled generators.

Page 37

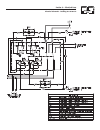

33 section 8 — installation diagrams air-cooled generators circuit breakers - drawing no. 0g8573-a.

Page 38

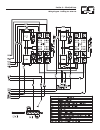

34 section 8 — installation diagrams air-cooled generators generator - drawing no. 0g8280-d.

Page 39

35 section 8 — installation diagrams air-cooled generators generator - drawing no. 0g8280-d.

Page 40

36 california emission control warranty statement your warranty rights and obligations the california air resources board (carb) and generac power systems, inc. (generac) are pleased to explain the emission control system warranty on your new engine. * in california, new utility, and lawn and garden...

Page 41

37 emission control system warranty emission control system warranty (ecs warranty) for 1995 and later model year engines: (a) applicability: this warranty shall apply to 1995 and later model year engines. The ecs warranty period shall begin on the date the new engine or equipment is purchased by/de...

Page 42

Part no. 0g8334 revision d (09/16/08) printed in u.S.A. Catalog no. Omaspca-s-01.

Page 43: Technical

Technical manual this manual should remain with the unit. Rtss load shed automatic transfer switch.

Page 44

The manufacturer cannot anticipate every possible circumstance that might involve a hazard. The warn- ings in this manual, and on tags and decals affixed to the unit are, therefore, not all-inclusive. If using a procedure, work method or operating technique the manufacturer does not specifically rec...

Page 45

Table of contents 1 safety rules .........................................Inside front cover section 1 — general information ...................................2 1.1 introduction............................................................. 2 1.2 equipment description ...................................

Page 46: 1.1 Introduction

2 section 1 — general information rtss type transfer switch 1.1 introduction this manual has been prepared especially for the purpose of familiarizing personnel with the design, application, installation, operation and servicing of the applicable equipment. Read the manual carefully and comply with ...

Page 47

3 1.2.2 utility service disconnect circuit breaker the utility service disconnect circuit breaker for the 200 amp models are: generac, type 225af, 2-pole • 120/240vac, 200a • 50/60 hertz • wire range: 300 mcm - 6 str (line), 250 mcm • - 6 str (load) the conductor tightening torque is 375 in-lbs. • (...

Page 48: 2.2 Unpacking

4 section 2 — installation rtss type transfer switch 1.5 safe use of transfer switch before installing, operating or servicing this equip- ment, read the safety rules (inside front cover) carefully. Comply strictly with all safety rules to prevent accidents and/or damage to the equipment. The manufa...

Page 49: 2.5 Neutral

5 before connecting wiring cables to terminals, remove any surface oxides from the cable ends with a wire brush. All power cables must enter the enclosure through the knockouts provided. This is necessary to maintain the nema/ul type 3 rating. If mounted indoors, conduits can enter the enclosure abo...

Page 50: 3.2 Manual Operation

6 3.2 manual operation danger do not manually transfer under load. Disconnect transfer switch from all power sourc- es by approved means, such as the main circuit breaker(s). 3.2.1 ats manual operation a manual handle is shipped with the transfer switch. Manual operation must be checked before the t...

Page 51: 3.3 Voltage

7 3.2.3 close to utility source side before proceeding, verify the position of the switch by observing the position of manual operation handle in figure 3.1. If the handle is up, the contacts are closed in the utility (normal) position, no further action is required. If the handle is down, proceed w...

Page 52: 3.4 Generator

8 the voltage measurements should be as follows: n1 - n2 240 vac nominal n1 - neutral 120 vac nominal n2 - neutral 120 vac nominal 5. Let the generator stabilize and warm up at no- load for at least five minutes. 6. Set the generator's main circuit breaker (cb1) to its on or closed position. Danger ...

Page 53

9 3.4.2 load shed functional test 1. Set the generator’s main circuit breaker to its off or open position. 2. Set the utility service disconnect circuit breaker to the off position. 3. Manually actuate the transfer switch main con- tacts to the generator position. Refer to “manual operation” section...

Page 54

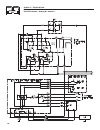

10 section 4 — installation diagrams rtss type transfer switch load shed interconnection - drawing no. 0g8774-b.

Page 55

11 section 4 — installation diagrams rtss type transfer switch 200 amp load shed enclosure - drawing no. 0g8775-b.

Page 56

12 section 5 — electrical data rtss type transfer switch electrical schematic - drawing no. 0g7816-a.

Page 57

13 section 5 — electrical data rtss type transfer switch electrical schematic - drawing no. 0g7816-a.

Page 58

14 section 5 — electrical data rtss type transfer switch wiring diagram - drawing no. 0g7817-b.

Page 59

15 section 5 — electrical data rtss type transfer switch wiring diagram - drawing no. 0g7817-b.

Page 60

16 section 6 — exploded views & parts lists rtss type transfer switch load shed transfer switch - drawing no. 0g8054 $ -c parts list on page 19..

Page 61

17 section 6 — exploded views & parts lists rtss type transfer switch load shed transfer switch - drawing no. 0g8054 $ -c parts list on page 19..

Page 62

18 section 6 — exploded views & parts lists rtss type transfer switch load shed transfer switch - drawing no. 0g8054 $ -c parts list on page 19..

Page 63

19 item part no. Qty. Description 1 0d9618 2 transfer sw. Hsb 200a 2p 250v 2 074908 10 screw hhtt m5-0.8 x 10 bp 3 0g4478 1 circuit breaker, 200a 2-pole 4 053640 2 screw rhm #8-32 x 3-1/4 5 0f8843 2 busbar, 200a lug adapter 6 0f8451 2 lug 300 mcm-6str 7 0g4413 4 spacer 200 amp transfer 8 024334 4 bo...

Page 64

20 section 7 — notes.

Page 65

21 section 7 — notes.

Page 66

Part no. 0g8637 revision d (08/27/08) catalog no. Kgalt-1si printed in u.S.A..

Page 67: Installation Guide

This manual should remain with the unit. Installation guide for 100 amp automatic transfer switch/load center models: 8, 10, 12, 14 and 16 circuit. Installed with 8, 10, 12, 14, 16, 17 and 20kw generators. This automatic transfer switch with built-in load center includes an express install kit. • sa...

Page 69

1 introduction thank you for purchasing this 100 amp automatic transfer switch/load center with express install kit. The express install kit includes: • 30 foot, five foot, and two foot pre-wired conduits for making all required wiring runs. • an outdoor junction box for making connections between o...

Page 70: 100 Amp Automatic Transfer

2 100 amp automatic transfer switch/load center with express install kit kit includes: the outdoor connection box with five foot pre-wired liquid tight conduit mounted outside the home or business nearest the planned generator location. This is for connection to gen- erator controls and main line ci...

Page 71

3 1. Plan the location of the generator. Note: do not place the generator directly under a window. Select an area outside of the home or business nearest the incoming gas service. Determine where the genera- tor will be placed outside of the building. Arrange for fuel piping with shut-off valve to b...

Page 72

4 8. From inside the building, feed the end of the 30-foot conduit (included and pre-wired from transfer switch) through the wall to the outside. 9. Remove the threaded lock nut from the conduit coupling. 10. Lift cover. Remove internal cover plate screw and internal cover. Remove the knock out in t...

Page 73

Note: balance must be maintained when moving circuit loca- tions from main electrical distribution panel to emergency load center. Circuit breaker positions alternate buss bars vertically. Circuits sharing a neutral wire should either be moved together to adjacent positions in emergency load center ...

Page 74

6 if a generator is being installed at this time, proceed to step 19. If a generator will not be installed at this time, perform steps 14 through 17 to complete the pre-wiring project. 14. Open the outdoor connection box and unplug the 4-pin and 2-pin connector. Remove the black, white, red, and gre...

Page 75

7 remove the small black cap (covering 1-1/16” diameter hole) from back of enclosure. Remove threaded lock nut from conduit coupling (with 90° elbow) and wires. Feed wires into 1-1/16” diameter hole. Place threaded lock nut over wires and onto conduit coupling. Tighten securely with screwdriver and ...

Page 76

8 residential transfer switch installation guide installation drawing 0h0258-a.

Page 77

9 residential transfer switch installation guide installation drawing 0h0258-a.

Page 78

Residential transfer switch installation guide installation drawing 0g8573-a 10 10

Page 79

11 residential transfer switch installation guide electrical schematic - drawing 0g7959-a.

Page 80

12 residential transfer switch installation guide wiring diagram - drawing 0g7958-a.

Page 81

13 residential transfer switch installation guide wiring diagram - drawing 0g7958-a.

Page 82

14 residential transfer switch installation guide load center exploded view - drawing 0g8786-c.

Page 83

15 item part no. Qty. Description 1 0g80700st14 1 gts load center enclosure gray 2 0g81010st14 1 cover 8 pos gts load ctr gray 0g81020st14 1 cover 10 pos.Gts load ctr gray 0g81030st14 1 cover 12 pos.Gts load ctr gray 0g81040st14 1 cover 14 pos.Gts load ctr gray 0g81060st14 1 cover 16 pos.Gts load ct...

Page 84

16 residential transfer switch installation guide notes.

Page 85

17 residential transfer switch installation guide notes.

Page 86

Part no. 0g8571 revision d (07/31/08) catalog no. Kgatx100-1si printed in u.S.A..

Page 87

Installation instructions genready load center ez transfer™ operator m o d e l # 0 0 5 4 4 7 - 0 revision d (04/17/08) printed in u.S.A p/n 0g6419 danger hazardous voltage that will cause death, serious injury or substan- tial property damage. Turn off power supplying this equipment before working i...

Page 88

2 step 3: remove the red retaining clip by unscrewing the fastener in the center of clip and discard. Step 4: a. Add additional 125 amp, 2-pole switch on right. Place in off posi- tion. Before lowering switch on stabs install interlock bar under the exist- ing switch handle and the new switch handle...

Page 89

3 step 6: install the four (4) screws (10-32 x 5/16 hhtt) to mount operating mechanism to the back of the panel board. Step 7: install the 15 amp 2-pole circuit breaker in the position shown. Step 8: install generator control wiring (must be installed in conduit). Install 5a fuse (if required) to th...

Page 90

4 step 9: apply one of the ats danger decals to the load center as shown. Step 10: place the front cover on the panel board. Install the six (6) screws to hold the front cover on. Step 11: apply decal 0g4742a on the left side, and decal 0g4732b on right side of the ez transfer™ operator box as shown...

Page 91

5 reference: items supplied in the ez transfer™ operator kit..

Page 92

6.

Page 93

7.

Page 94

® the national electrical code is a registered trademark of the national fire protection association. Part number 0g6419 revision d (04/17/08) printed in u.S.A.

Page 95: Air-Cooled Generator

Air-cooled generator battery charger installation guidelines.

Page 96: 1.1 Introduction

Table of contents ................................Inside front cover section 1 — general information ............................... Ifc 1.1 introduction.......................................................... Ifc 1.2 battery charger compatibility ................................. 1 1.2.1 determin...

Page 97: 1.2

1 these installation guidelines are designed to famil- iarize personnel with the installation process for the battery charger required for the air-cooled generator only. It does not replace or supersede any information contained in any of the written documents shipped with the unit. This booklet sho...

Page 98: 2.1

2 2.1 load shed transfer switch (rtss) installation 2.1.1 wiring and connections at the transfer switch connect the 15b, 0, and 23 low voltage control wires to the load shed controller connector j5 per the wir- ing diagram. Wires should be sized according to the following table. Charger dc output (t...

Page 99: 3.1

3 4. If the voltage is within range installation of the battery charger is complete. If the voltage is not within range verify all wiring and sizing and retest. 5. Re-connect the battery cables. Positive cable first followed by the negative cable. 3.1 standard transfer switch (rtsn) or (rtse) servic...

Page 100

4 section 3 — standard or service entrance transfer switch installation battery charger installation guidelines figure 3.3 — rtsn fuse block installation when completed figure 3.4 — rtse fuse block installation t1 connection figure 3.5 — rtse neutral connection figure 3.6 — rtse fuse block installat...

Page 101

5 figure 3.7 — mounting location of charger in generator charger mounting figure 3.8 — removal of adhesive covering on hook and loop for mounting 3.1.3 wiring and connections at the generator 1. Identify the dc output wires on the battery char- ger and crimp spade lugs onto both the positive and neg...

Page 102: 4.1 Genready

6 note: see the appropriate rtsn or rtse installation/ wiring diagram in the "interconnection diagrams" section for connections. 3.1.4 operational testing 1. If already connected, disconnect the battery in the generator. Remove the negative cable first fol- lowed by the positive cable. Take care not...

Page 103

7 4.1.2 charger mounting 1. Remove the cover over the controller in the gen- erator 2. The battery charger can be located anywhere within the controls area on the generator. It is convenient to mount the charger on the verti- cal surface on right-hand side of the controller (figure 4.3). Figure 4.3 ...

Page 104

8 3. Using wire nuts attach the 120vac input wires from the battery charger to the generator backed- up 120vac circuit from the transfer switch (figure 4.6). Figure 4.6 — connection of charger ac input wires in generator control panel 4. Dress all wires neatly (figure 4.7). Note: see the genready in...

Page 105

9 section 5 — interconnection diagrams battery charger installation guidelines rtss diagram - drawing no. 0g8774-b.

Page 106

10 section 5 — interconnection diagrams battery charger installation guidelines rtsn diagram: option 1 - drawing no. 0g8832-a.

Page 107

11 section 5 — interconnection diagrams battery charger installation guidelines rtsn diagram: option 2 - drawing no. 0g8832-a.

Page 108

12 section 5 — interconnection diagrams battery charger installation guidelines rtse diagram: option 1 - drawing no. 0g8829-a.

Page 109

13 section 5 — interconnection diagrams battery charger installation guidelines rtse diagram: option 2 - drawing no. 0g8829-a.

Page 110

14 section 5 — interconnection diagrams battery charger installation guidelines genready diagram - drawing no. 0g4744-d.

Page 111

15 section 5 — interconnection diagrams battery charger installation guidelines genready diagram - drawing no. 0g4744-d.

Page 112

16 section 5 — interconnection diagrams battery charger installation guidelines genready diagram - drawing no. 0g4744-d.

Page 113

17 section 6 — notes battery charger installation guidelines.

Page 114

Part no. 0g7956 revision b (11/14/08) printed in u.S.A..

Page 116

Cac / bdp 7310 w. Morris street indianapolis, in 46231 specifications are subject to change without notice. Catalog no. Aspds-y-1sg printed in usa 01.09.