CAC / BDP BW4 Installation instructions manual

BW4

BW5

Installation Instructions

Oil---Fired Cast Iron

Hot Water Boilers

Sizes 140,000 through 280,000

NOTE: Read the entire instruction manual before starting the

installation.

TABLE OF CONTENTS

PAGE

SAFETY CONSIDERATIONS

1

. . . . . . . . . . . . . . . . . . . . . . . .

INTRODUCTION

3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Explanation of Model Numbers and Rating Plate

3

. . . . . . . . .

General Information

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Locating the Boiler

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INSTALLATION

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Requirements

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

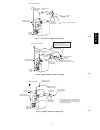

Fresh Air for combustion

4

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

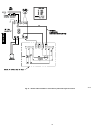

Boilers with Tankless Heater Coil

7

. . . . . . . . . . . . . . . . . . . . .

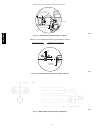

Installation System Piping

8

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chimney and Chimney Connection

10

. . . . . . . . . . . . . . . . . . .

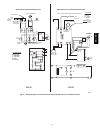

Electrical Wiring

10

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment and Optional Accessories

10

. . . . . . . . . . . . . . . . . .

Filling Boiler

12

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

OPERATING BOILER

13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Start

13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Units and Oil Lines

13

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Supply for Combustion

13

. . . . . . . . . . . . . . . . . . . . . . . . .

Draft Regulators

13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Nozzles

13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Final Burner Adjustments

13

. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Burner Maintenance

15

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking and Adjusting Controls

16

. . . . . . . . . . . . . . . . . . . .

MAINTENANCE

16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relief Valve

16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventional Expansion Tank

16

. . . . . . . . . . . . . . . . . . . . . . .

Diaphragm Expansion Tank

16

. . . . . . . . . . . . . . . . . . . . . . . . .

Water System

16

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tankless Coil (or Cover Plate Gasket)

16

. . . . . . . . . . . . . . . . .

Oil Boiler/Burner Cleaning Instructions

17

. . . . . . . . . . . . . . . .

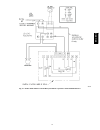

Sequence of Operation

17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Hints

22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

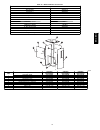

Parts List

22

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASME

ama

®

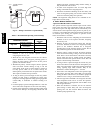

SAFETY CONSIDERATIONS

Installing and servicing heating equipment can be hazardous due

to oil and electrical components. Only trained and qualified

personnel should install, repair, or service heating equipment.

Untrained personnel can perform basic maintenance functions

such as maintaining water level. All other operations must be

performed by trained service personnel. When working on

heating equipment, observe precautions in literature, on tags, and

on labels attached to or shipped with unit and other safety

precautions that may apply. Recognize safety information. This is

the safety--alert symbol . When you see this symbol on unit or in

instructions and manuals, be alert to potential for personal injury.

Understand

the

signal

words

DANGER,

WARNING,

CAUTION, and NOTE. These words are used with the

safety--alert symbol. DANGER identifies the most serious

hazards which will result in severe personal injury or death.

WARNING signifies hazards which could result in personal

injury or death. CAUTION is used to identify unsafe practices

which may result in minor personal injury or product and

property damage. NOTE is used to highlight suggestions which

will result in enhanced installation, reliability, or operation. Read

and obey the following rules to ensure safe installation and

operation:

1. Read the Owner’s Manual carefully for safe operation.

Failure to follow the rules of safe operation and the

instructions can cause a

malfunction of the boiler and result in death, serious

bodily injury, and/or property damage.

2. Check local codes and utility requirements before

installation. The installation must be in accordance with

their directives, or follow NFPA 31–Installation of Oil

Burning Equipment, latest revision.

3. Before servicing, allow boiler to cool. Always shut off any

electricity and oil to boiler when working on it. This

prevents any electrical shocks or burns.

4. Inspect oil line and connections for leaks.

5. Be certain oil burner nozzle is size required. Overfiring

will result in early failure of boiler sections. This causes

dangerous operation.

6. Never vent this boiler into an enclosed space. Always vent

to the outside. Never vent to another room or inside a

building.