- DL manuals

- CADDY

- Furnace

- PF01102

- Installation And Operating Instructions Manual

CADDY PF01102 Installation And Operating Instructions Manual

45833A

Printed in Canada

07-06-2016

Installation and operating instructions

for the MAX CADDY WOOD FURNACE

(PF01102 model)

Certified according to CSA B415.1-10, CSA B366.1, UL391,

CSA C22.2 NO.236, UL 1995, CAN/CSA B140.4 and UL 727

FURNACE MODELS INCLUDED IN THIS MANUAL

WOOD ONLY

COMBINATION

20 kW / 25 kW AND OIL

Read these instructions carefully before installing

and operating your furnace.

CONGRATULATIONS!

You have purchased one of the finest wood or combination furnaces available

on the market. We are confident that your furnace will provide years of comfort

and safe operation.

Please keep this document!

Verified and tested for Canada and

the United States by an accredited

laboratory.

This manual is available for free download on the manufacturer’s

web site. It is a copyrighted document. Re-sale is strictly

prohibited. The manufacturer may update this manual from time

to time and cannot be responsible for problems, injuries, or

damages arising out of the use of information contained in any

manual obtained from unauthorized sources.

Eco-energy at the hearth

of your home

PSG

250, de Copenhague,

St-Augustin-de-Desmaures (Quebec)

CANADA G3A 2H3

Summary of PF01102

Page 1

45833a printed in canada 07-06-2016 installation and operating instructions for the max caddy wood furnace (pf01102 model) certified according to csa b415.1-10, csa b366.1, ul391, csa c22.2 no.236, ul 1995, can/csa b140.4 and ul 727 furnace models included in this manual wood only combination 20 kw ...

Page 2

2 table of content 1. Introduction ......................................................................................................................................................................... 5 2. Appliance performance (1) ...................................................................

Page 3

3 11.7.2. Cool m ode ..................................................................................................................................................................... 37 11.7.3. Circ m ode ( air circulation ) ..........................................................................

Page 4

4 23.5. Temporary disengagement of the burner ............................................................................................................ 56 23.6. Combustion adjustment and verification ....................................................................................................

Page 5

5 important note: the installation of this central heating system must be performed by a qualified technician. Psg reserves itself the right to void its warranty or deny technical advice if the furnace has not been sold or installed by a professional. Register you warranty online to receive full war...

Page 6

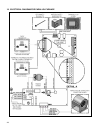

6 2. Appliance performance (1) fuel type dry cordwood recommended heating area [*] 1,500 to 3,500 ft² (139 to 325 m²) firebox volume 4.9 ft³ (0.139 m³) maximum burn time [*] 17 h maximum input capacity (dry cordwood) (2) 421,000 btu overall heat output rate (min. To max.) (3) 19,243 btu/h to 67,069 ...

Page 7

7 3. General features maximum log length 25 in (635 mm) / north-south* diameter of the flue collar 6 in (152 mm) recommended connector pipe diameter 6 in (152 mm) if installed as wood only or combined wood-electric mandatory connector pipe diameter 7 in (178 mm) if installed as combined wood-oil rec...

Page 8

8 4. Specifications color grey thermostatic control yes door type single, glass with cast iron frame glass type ceramic glass air return plenum – dimensions (depth or height) 17 15/16 in air return plenum – dimension (width) 19 15/16 in hot air plenum – dimensions (depth or height) 32 1/8 in hot air...

Page 9

9 5. Max caddy furnace technical data model (direct drive) theoretical debit temp var. Static pressure filter vent mot. Vit. (cfm) (of) min. Max. (1) inch h2o max caddy with blower / max caddy add-on (parallel) g-10 1/2 4 2,100 100 0,2 0,5 16" x 20" x 1" 6. Furnace dimensions wood and wood/electric ...

Page 10

10

Page 11

11 7. Chimney and draft this furnace must be connected to a chimney certified for use with wood burning heating appliances. A 7-inch chimney and connector must be installed for the max caddy if it is used as a wood-oil unit, a wood-electrical-oil unit or if an oil option may be installed in the futu...

Page 12

12 when ignited, creosote produces an extremely hot fire inside the chimney. In the first year of use, inspect the chimney system at regular intervals to determine a cleaning cycle. Depending on the type of wood used and its quality, a semi-annual cleaning may be required. A yearly cleaning is manda...

Page 13: Parallel Add-On (Us Only)

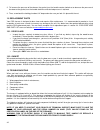

13 installation and operation instructions for max caddy wood only furnace, combined wood / electric or parallel add-on (us only) pf01102 max caddy furnace – wood only max caddy furnace – combined wood/electric.

Page 14

14 9. Installation instructions installation must be made in accordance with the csa b.365 « installation code for solid-fuel-burning appliances and equipment » standard in canada and nfpa 90b « standard for the installation of warm air heating and air conditioning system » in the united states. Mor...

Page 15

15 remove the four screws on the furnace, located on the side of the desired installation. Align the holes of the board housing the holes on the side of the furnace. Use the screws removed in the previous step to secure the housing to the furnace. Once installed, the link board must be connected to ...

Page 16

16 take the telecommunication wire and pull it through the grommet located on the side where the housing board is installed. Once the telecommunication wire is out on the desired side, run it along the back of the furnace and pass it through the grommet at the bottom of the link board housing. Compl...

Page 17

17 your furnace should also be connected to a 115v power source. To do so, open the cover of the power board housing. Connect the power cord to the terminals n (neutral) f (ground) l (line). Refer to wiring diagram for connecting components. When done, secure the wires with a bx connector (not inclu...

Page 18

18 9.3. Touchscreen installation and connection the touch screen is used to operate the system. It must be installed on the support provided at the back of the furnace, on the same side as the link board housing. Connect link board with the touch screen using the telecommunication wire provided with...

Page 19

19 9.4. Hot air plenum temperature probe installation and connection (rtd) on the max caddy, a rtd has to be installed on the side of the furnace using the support provided with the unit. The rtd is a sensor that reads the temperature inside the hot air plenum. It is critical to the good operation o...

Page 20

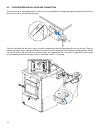

20 9.5. Servomotor installation and connection your max caddy furnace is equipped with a servomotor. To install it, simply screw it in place in the two pre-drilled holes in the front of the furnace using two screws as shown below. Once installed, install the chain linking the servomotor with the air...

Page 21

21 then, you must connect the servomotor and the link board. Take the wires out of the servomotor and enter the wires in the wire cover through the grommet. Pull them out through the grommet next to the link board housing. For connection, refer to wiring diagram. Warning: use wiring suitable for 75 ...

Page 22

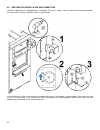

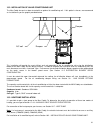

22 9.7.1. Minimum clearances to combustible materials minimum clearances a 24" (610 mm) g 8" (204 mm) b 18" (458 mm) h 1 1/2" (38.1 mm) c 6" (153 mm) i 6" (153 mm) d 1" (26 mm) j 24" (610 mm) e 72" (1 829 mm) f 24" (610 mm) -1- heat shield.

Page 23

23 9.7.2. Minimum clearances to combustibles materials for air return duct the return air duct should be at least equal in size to the return air plenum. The air return duct can be installed at zero clearance to combustibles. 9.7.3. Minimum clearances to combustibles materials for hot air plenum ple...

Page 24

24 9.8. Flue and barometric draft control connection before connecting the stove pipe, make sure you have removed any accessory from the flue pipe such as the scraper, shovel, and the poker. The flue outlet on the max caddy furnace is 6" in diameter and the wood only or wood/electric models may be i...

Page 25

25 9.9. Electrical connections the following instructions do not replace those of the local code. Installation and verification of this appliance must be done by a qualified service man. All wiring from the service panel to the heating unit must comply with the electrical code in force and all local...

Page 26

26 note: it is recommended to install an outside air inlet with a diameter of at least 4" in the room where the heating appliance is installed (see drawing below). It is preferable to choose a wall which is not exposed to dominant winds, depending on the conditions surrounding your house. N.B. The o...

Page 27

27 conditional to; o the maximum input power of the existing gas, oil or electric furnace should be equal or lower than 120 000 btu/h. O the clearances required for wood furnace must be respected. O the clearances between the hot air ducts and combustible materials must meet the highest values betwe...

Page 28

28 to ensure a safe installation, the two furnaces must not, at any time, run simultaneously. To do so, the thermostat controlling the existing furnace must be connected to your max caddy link board. This way, when a heating signal is sent to the existing furnace, the max caddy receives the same sig...

Page 29

29 9.14. Electrical element installation (optional) 9.14.1. Introduction two electrical elements are available for the max caddy: and 20kw et 25kw. These options include all components necessary for the installation. Instructions for installing the electrical elements are provided with the electrica...

Page 30

30 10. Thermostat installation 10.1. Wood furnace only the furnace must be connected to a thermostat. You can use the one provided with the unit or use one that is already installed in your home. The thermostat must be installed on an inside wall and located where it is not likely to be affected by ...

Page 31

31 10.2. Installation of an air conditioning unit the max caddy furnace has been tested with an optional air conditioning unit. If this option is chosen, we recommend an installation as per the graphic provided below. A/c coil damper damper this installation will provide the most efficient and safe ...

Page 32

32 10.4. Installation of a domestic water pre-heating system or a humidifier a water heating loop option is also available to pre-heat domestic water using the energy produced by the max caddy wood furnace. This water loop kit will be inserted between the wood combustion chamber and the heat exchang...

Page 33

33 11.2. System configuration once the installation is complete and before using the unit, the furnace should be configured to activate all applicable functions depending on options chosen. To do this, it is important to know which options are installed on your furnace. 11.3. Touch screen the lcd co...

Page 34

34 11.3.2. Language selection and temperature unit to choose the language and temperature unit, press the "settings" button. In the "main" menu, choose "setup" and then "general". Choose the preferred language and temperature unit. 11.4. Adding auxiliary heating source and selection of options to ad...

Page 35

35 11.4.3. Auxiliary heat source prioritization if you have configured one or many auxiliary heating sources (electrical element, heat pump, oil), you must choose the priority order when there is a heating demand. If, for example, the wood no longer provides sufficient heat, the auxiliary heating se...

Page 36

36 11.5. Distribution blower speed configuration it is possible to adjust the speed of the distribution blower for circulation mode, air conditioning and any other mode of auxiliary heaters. Note: when heating with wood, the fan distribution speeds are programmed in order to provide the best thermal...

Page 37

37 it is important to respect the velocity in the main duct, the secondary ducts, as well as the velocity at the room outlets. The static pressure of your system must be adjusted to at least 0.2 in.W.C. And must not exceed 0.5 in.W.C. Finally, make sure that you never exceed the maximum blower curre...

Page 38

38 11.8. Wood heating 11.8.1. Lighting 1. Open the furnace door note: if there is already a bed of coals in the firebox, go to pre-heating. 2. Place one or two dry kindlings at the front of the furnace. 3. Place newspaper strips on top of the kindlings. 4. Cover the newspaper with more kindlings and...

Page 39

39 11.8.5. Wood as heating fuel attention ne jamais faire brÛler de dÉchets, de la gazoline, du naphta, de l’huile À moteur ou tout autre produit semblable. We recommend that you burn dry hard wood only. There are two important factors to be considered when choosing a type of wood: the moisture cont...

Page 40

40 12. Maintenance 12.1. Maintenance of the exchangers heat exchangers must be cleaned thoroughly at the end of every heating season. During summer, the air in basements is damper and with minimal air circulation within the furnace, it can mix with creosote and/or sooth deposits in the exchangers to...

Page 41

41 12.2. Chimney maintenance the most efficient way to sweep a chimney is to run a hard chimney sweeping brush. Brush from the top down so sooth and creosote deposits will detach from the chimney liner and fall down to the bottom of the chimney where it can be easily removed. The chimney must be ins...

Page 42

42 2. To increase the pressure of the door on the gasket, turn the handle counter clockwise; to decrease the pressure of the door on the gasket, turn the handle clockwise until desired pressure is attained. 3. Then, screw back the locking pin about 1/4" deep and make sure you lock it in place with t...

Page 43

43 14.1. Validating status of a component when using your furnace, you can validate at any time, the status of any of the following components: • distribution blower • air damper • temperature probe (rtd) • hot water system • humidifier • heat pump 14.1.1. Distribution blower to check the status of ...

Page 44

44 14.1.3. Temperature probe (rtd) the temperature probe continuously reads the temperature in the plenum and displays it on the main page in the upper right corner. If the probe fails, the error message "plenum overtemp" will appear. See section 14.2 - main error codes, possible causes and solution...

Page 45

45 the temperature probe (rtd) is disconnected or defective: if the displayed plenum temperature on the touch screen is 0 ̊ f or 1140 ̊ f, the temperature probe is either disconnected or defective. Check the probe connection (see section 9.4 - hot air plenum temperature probe installation and connec...

Page 46

46 14.2.4. Smoke smell • venting system leaks. Inspect all vent connections. All vent connector joints must be sealed and fastened in accordance with the vent manufacturer's instructions to ensure consistent performance and avoid smoke and ash spillage. • worn gaskets. Gaskets may be allowing smoke ...

Page 47

47 15. General electrical diagram.

Page 48

48 16. Electrical diagram for parallel furnace.

Page 49

49 17. Electrical diagram for electric unit.

Page 50: Wood/oil

50 installation and operation instructions for wood/oil combination furnace necessary components for max caddy wood/oil combination furnace to use the configuration of the max caddy wood/oil furnace you have to assemble the blower assembly (pa08566), sold separately. The assembly instructions are in...

Page 51: Caution

51 general information for oil furnace read this manual thoroughly before operating the furnace caution caution explosion or fire hazard. For your safety: do not store or use gasoline or any flammable liquids or vapors in the vicinity of this heating unit. Do not attempt to light the burner when exc...

Page 52

52 18. General notes this instructions manual treats mainly of the oil burning unit of your wood/oil combination furnace. To obtain the maximum efficiency out of your furnace, follow the advice below regarding the installation and operation of your wood/oil combination furnace. • respect the local c...

Page 53

53 22. Appliance installation a blocked vent switch is mandatory for installation with an oil fired appliance that normally operates with its vent system under a negative pressure. This device is intended to detect a blocked vent system, responds to hot flue gases backing up through its heat transfe...

Page 54

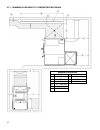

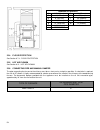

54 miminum clearances a 24" (610 mm) g 8" (203 mm) b 18" (457 mm) h 1.5" (mm) c 6" (152 mm) i 24" (610mm) d 1" (25 mm) j 24" (610mm) e 72" (1829 mm) k 9" (229mm) f 24" (610 mm) -1- heat shield 22.4. Floor protection see section 9.7.4 - floor protection 22.5. Hot air plenum see section 9.12 - hot air...

Page 55

55 22.7. Different installation.

Page 56

56 22.8. Combustion air see section 9.11 - combustion air and fresh air intake adapter installation (optional) 22.9. Electrical wiring see section 9.9 - electrical connections 22.10. Thermostat see section 10 - thermostat installation 23. Operation instruction 23.1. Fan speed control see section 11....

Page 57

57 23.6. Combustion adjustment and verification to enjoy the efficiency of our oil burning units, you must respect the following criterion: oil burning units must be connected to flue pipes having at all times a sufficient draft to ensure an efficient and safe operation of unit. Before turning on th...

Page 58

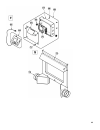

58 23.6.2. Electrodes setting the electrodes must be adjusted by a qualified technician. A proper positioning of the electrodes is important to get an efficient lighting of the oil. Electrode setting for "f" head 7/16" 5/32" 1/16" nozzle electrode warning: 1. Refer to the rating plate for the pump p...

Page 59

59 23.7. Appliance start-up the start-up must be performed by a qualified technician. Make sure the installation is completed and the oil tank has been filled up. The oil line must also have been purged. Caution: close the blower compartment access panel before starting the burner. 23.8. Prolonged c...

Page 60

60 25.2. Service before calling for service, first check the following - fuel supply - electric fuses or breakers - thermostat setting - pc board settings - the state of the green diagnostic led on the burner control. Burner no.: _________________ model: _______________ date of installation: _______...

Page 61

61 26. Electrical diagram beckett oil unit.

Page 62

62 27. Electrical diagram riello oil unit.

Page 63

63 28. Link board options connections 28.1. Electrical consumption your max caddy furnace is able to supply electrical 24v current to control various options. The options that can be supported are described in the table below. The maximum available 24v current is 1.66 amps (transformer 24v @ 40va). ...

Page 64

64 28.4. 24v additionnal equipment 28.5. Air conditionning damper 28.6. Humidifier.

Page 65

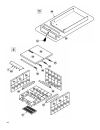

65 28.7. Heat pump 29. Exploded view and part list.

Page 66

66.

Page 67

67.

Page 68

68.

Page 69

69.

Page 70

70

Page 71

71.

Page 72

72.

Page 73

73 important: this is dated information. When requesting service or replacement parts for your stove, please provide the model number and the serial number. We reserve the right to change parts due to technology upgrade or availability. Contact an authorized dealer to obtain any of these parts. Neve...

Page 74

74 # item description qty 43 30124 screw #8 - 32 x 5/16'' truss quadrex zinc 4 44 se56274 ash drawer 1 45 21220 c-cast baffle 19 3/4" x 11 3/8" x 1 1/4" 2 46 pl56764 rear secondary air tube 1 47 pl56763 middle rear secondary air tube 1 48 pl56761 middle front secondary air tube 1 49 pl56760 front se...

Page 75

75 # item description qty 89 21079 oil unit cover gasket 1 90 se53269 oil unit cover assembly with vision tube 1 91 30210 washer 29/32" od x 3/8" id zinc 12 92 30425 nut brass 5/16 - 18 hex 12 93 21085 burner / oil unit gasket 1 94 30423 3/8'' - 16 hex zinc nut 3 95 pl56465 right oil unit panel 1 96...

Page 76

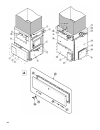

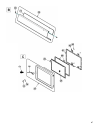

76 # item description qty 131 se56450 filter drawer 1 132 30108 mechanical screw m4 x 4mm pan phillips zinc 2 133 28062 black drawer handle 3 25/32" 1 134 pa08566 blower assembly 1 135 pa08500 top air return plenum kit 1 136 se45833 max caddy instruction manual kit 1 137 ac05961 psg grey 424c spray ...

Page 77

77 why purchase through an authorized psg dealer? To make sure your psg furnace provides comfort and energy savings in your home for many years, your choice of installer is extremely important. An authorized psg dealer will ensure that the system is optimized and installed according to standards. Gi...

Page 78

78 psg limited lifetime warranty (regular) the warranty of the manufacturer extends only to the original consumer purchaser and is not transferable. This warranty covers brand new products only, which have not been altered, modified nor repaired since shipment from factory. Proof of purchase (dated ...

Page 79

79 psg limited lifetime warranty (privilege) the warranty of the manufacturer extends only to the original consumer purchaser and is not transferable. This warranty covers brand new products only, which have not been altered, modified nor repaired since shipment from factory and purchased through an...