- DL manuals

- CADDY

- Furnace

- PF01302

- Installation And Operating Instructions Manual

CADDY PF01302 Installation And Operating Instructions Manual

45835A

Printed in Canada

18-05-2016

Installation and operating instructions

for the MINI-CADDY WOOD FURNACE

(PF01302)

Certified according to CSA B415.1-10, CSA B366.1, UL391,

CSA C22.2 NO.236, UL 1995

FURNACE MODELS INCLUDED IN THIS MANUAL

WOOD

ONLY

COMBINATION

WOOD/ELECTRIC

(11.25 kW)

Read these instructions carefully before installing

and operating your furnace.

CONGRATULATIONS!

You have purchased one of the finest wood or combination furnaces

available on the market. We are confident that your furnace will provide

years of comfort and safe operation.

Please keep this document!

Verified and tested for Canada and

the United States by an accredited

laboratory.

This manual is available for free download on the

manufacturer’s web site. It is a copyrighted document. Re-sale

is strictly prohibited. The manufacturer may update this manual

from time to time and cannot be responsible for problems,

injuries, or damages arising out of the use of information

contained in any manual obtained from unauthorized sources.

Eco-energy at the hearth

of your home

PSG

250, de Copenhague,

St-Augustin-de-Desmaures (Quebec)

CANADA G3A 2H3

Summary of PF01302

Page 1

45835a printed in canada 18-05-2016 installation and operating instructions for the mini-caddy wood furnace (pf01302) certified according to csa b415.1-10, csa b366.1, ul391, csa c22.2 no.236, ul 1995 furnace models included in this manual wood only combination wood/electric (11.25 kw) read these in...

Page 2

2 table of content 1. Introduction ......................................................................................................................................................................... 4 2. Appliance performance (1) ...................................................................

Page 3

3 11.8. Wood heating ............................................................................................................................................................... 36 11.8.1. Lighting ......................................................................................................

Page 4

4 important note the installation of this central heating system must be performed by a qualified technician. Psg reserves itself the right to void its warranty or deny technical advice if the furnace has not been sold or installed by a professional. Register you warranty online to receive full warr...

Page 5

5 2. Appliance performance (1) fuel type dry cordwood recommended heating area [*] 500 to 1,500 ft² (46 to 139 m²) firebox volume 2.3 ft³ (0.065 m³) maximum burn time [*] 13 h maximum input capacity (dry cordwood) (2) 198,000 btu overall heat output rate (min. To max.) (3) 11,319 btu/h to 37,053 btu...

Page 6

6 3. General features maximum log length 20 in (508 mm) / north-south* diameter of the flue collar 6 in (152 mm) recommended connector pipe diameter 6 in (152 mm) (wood only or combined wood-electric) recommended chimney diameter 6 in (152 mm) (wood only or combined wood-electric) required type of c...

Page 7

7 5. General technical data model (direct drive) debi t temp var. Btu/ h static pressure filter vent mot. Vit. (cfm) ( o f) (bois) min. Max. 1 h 2 o mini- caddy dct-916-800-5 ¼ hp 4 1400 125 198,000 0.2 0.5 15’’ x 20’’ x 1’’ 6. Furnace dimensions 6.1. Wood only.

Page 8

8 6.2. Combined wood-electric.

Page 9

9 7. Chimney and draft this furnace must be connected to a chimney certified for use with wood burning heating appliances. A 6 chimney and flue pipe are mandatory for the mini-caddy. The unit is not to be connected to a chimney serving another appliance. If the flue pipe draft exceeds -0.06 in.W.C.,...

Page 10

10 air ducts serving a garage should not be connected to other parts of a house and the ducting serving a house should not be connected to a garage. Warning the ash drawer and exchangers access panel get very hot. Do not manipulate with bare hands. 8.2. Odour from the paint it is normal that smoke a...

Page 11

11 8.6.1. Glass specifications the glass is made of 3/16" (5mm) thick ceramic glass. Do not operate your wood furnace with a broken glass, as this could seriously damage your furnace. You can purchase a replacement glass from your psg dealer. 8.7. Ash drawer your furnace is equipped with an ash draw...

Page 12

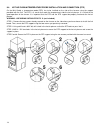

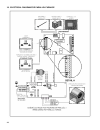

12 installation and operation instructions for mini-caddy wood only furnace or combined wood / electric or parallel add-on pf01302 fournaise mini-caddy – bois seulement fournaise mini-caddy – combinÉe bois / Électrique.

Page 13

13 9. Installation instructions installation must be made in accordance with the csa b.365 « installation code for solid-fuel-burning appliances and equipment » standard in canada and nfpa 90b « standard for the installation of warm air heating and air conditioning system » in the united states. Mor...

Page 14

14 remove the four screws on the furnace, located on the side of the desired installation. Keep the screws. Align the holes of the link board housing with the holes on the side of the furnace. Use the screws removed in the previous step to secure the housing to the furnace. Once installed, the link ...

Page 15

15 take the telecommunication wire and pull it through the middle grommet on the blower box once the telecommunication wire is out run it along the back of the furnace and pass it through the grommet at the bottom of the link board housing. Complete the connection by plugging the 8 strands telecommu...

Page 16

16 your furnace should also be connected to a 115v power source. To do so, open the cover of the power board housing. Connect the power cord to the terminals n (neutral) f (ground) l (line). Refer to wiring diagram for connecting components. When done, secure the wires with a bx connector (not inclu...

Page 17

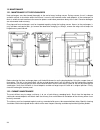

17 9.3. Touchscreen installation and connection the touch screen is used to operate the system. It must be installed on the support provided at the back of the furnace, on the same side as the link board housing. Connect link board with the touch screen using the telecommunication wire provided with...

Page 18

18 9.4. Hot air plenum temperature probe installation and connection (rtd) on the mini-caddy, a temperature probe (rtd) has to be installed on the side of the furnace using the support provided with the unit. The rtd is a sensor that reads the temperature inside the hot air plenum. It is critical to...

Page 19

19 once the rtd is installed on the support, proceed to its connection to the link board. Pass the rtd wires along the furnace and bring them close to the link board. For board connections, refer to the wiring diagram. 9.5. Servomotor installation and connection your mini-caddy furnace is equipped w...

Page 20

20 then, you must connect the servomotor and the link board. Take the wires out of the servomotor and pass them along the furnace. Bring them close to the link board. For connection, refer to wiring diagram. Warning: use wiring suitable for 75 °c (not included). 9.6. Unit location for a safe and qui...

Page 21

21 9.7.1. Minimum clearances to combustible materials minimum clearances a 24" (610 mm) h 8" (203 mm) b 18" (457 mm) i 24" (610 mm) c 3" (76 mm) d 0" (0 mm) required measurements e 60" (1 524 mm) f 18" (457 mm) g 7" (178 mm) 9.7.2. Minimum clearances to combustibles materials for air return duct the...

Page 22

22 9.7.4. Floor protection if the floor is made of non combustible material, no floor protector is required. If the floor is made of combustible material, a non combustible material floor protector is required (see table below). Floor protection* canada usa a 18" (457 mm) from door opening 16" (406 ...

Page 23

23 9.8. Flue and barometric draft control connection the flue outlet on the mini-caddy furnace is 6" in diameter and the wood only or wood/electric models may be installed with a 6" chimney approved for use with wood burning heating appliances (2100°f). If the draft exceeds -0.06 in.W.C., a barometr...

Page 24

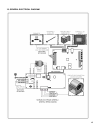

24 9.9. Electrical connections the following instructions do not replace those of the local code. Installation and verification of this appliance must be done by a qualified service man. All wiring from the service panel to the heating unit must comply with the electrical code in force and all local...

Page 25

25 note: it is recommended to install an outside air inlet with a diameter of at least 4" in the room where the heating appliance is installed (see drawing below). It is preferable to choose a wall which is not exposed to dominant winds, depending on the conditions surrounding your house. N.B. The o...

Page 26

26 canada; the installation in parallel i.E. The mini-caddy furnace combined with another, using the same system of hot air ducts is not allowed in canada. United states; the installation in parallel i.E. The mini-caddy furnace combined with another, using the same hot air duct system is allowed the...

Page 27

27 to ensure a safe installation, the two furnaces must not, at any time, run simultaneously. To do so, the thermostat controlling the existing furnace must be connected to your mini-caddy link board. This way, when a heating signal is sent to the existing furnace, the mini-caddy receives the same s...

Page 28

28 9.14. Electrical element installation (optional) 9.14.1. Introduction only one 11.25kw electrical elements is available for the mini-caddy. This option includes all components necessary for the installation. Instructions for installing the electrical element are provided with the electrical eleme...

Page 29

29 10. Thermostat installation 10.1. Wood furnace only the furnace must be connected to a thermostat. You can use the one provided with the unit or use one that is already installed in your home. The thermostat must be installed on an inside wall and located where it is not likely to be affected by ...

Page 30

30 10.2. Installation of an air conditioning unit the mini-caddy furnace has been tested with an optional air conditioning unit. If this option is chosen, we recommend an installation as per the graphic provided below. A/c coil damper damper this installation will provide the most efficient and safe...

Page 31

31 the furnace uses a touch screen, the latest technology in control devices. Blowers and power supplies are controlled from this screen. It is important to note that your furnace is equipped with three main electronic components: the link board, the power board and the touch screen. The power board...

Page 32

32 11.3.1. Icons description icons description icons description wood heating green : heating mode yellow : auxiliary heating mode electrical element green : unit on yellow : on hold heat pump green : unit on yellow : on hold displayed when an auxiliary heat source has been selected. Settings distri...

Page 33

33 11.4.1. Transition to an auxiliary heat source when there is a demand for heat, the furnace checks the temperature in the plenum. If the temperature is beyond the kip, the fan will turn on. If the temperature is below the kip, the furnace will wait the "rise time" delay and check the temperature ...

Page 34

34 11.4.4. External temperature probe it is possible to connect an external temperature probe on the mini-caddy. This temperature probe is used primarily to reduce electricity consumption and reduce the bill by prioritizing the transition to an auxiliary heating source when it is too cold outside or...

Page 35

35 11.6. System balancing it is important to call upon a professional installer for the installation of the furnace and the ducting system configuration. Certain check-ups must be performed and certain rules must be respected in order not to damage the blower. When all components are installed on th...

Page 36

36 11.8. Wood heating 11.8.1. Lighting 1. Open the door note: if there is already a bed of coals in the firebox, go to pre-heating. 2. Place one or two dry kindlings at the front of the furnace. 3. Place newspaper strips on top of the kindlings. 4. Cover the newspaper with more kindlings and small p...

Page 37

37 11.8.5. Wood as heating fuel caution do not burn wastes or flammable liquids such as gasoline, naphtha, motor oil, or other unsuitable matters. We recommend that you burn dry hard wood only. There are two important factors to be considered when choosing a type of wood: the moisture content and th...

Page 38

38 12. Maintenance 12.1. Maintenance of the exchangers heat exchangers must be cleaned thoroughly at the end of every heating season. During summer, the air is damper and with minimal air circulation within the furnace, it can mix with creosote and/or sooth deposits in the exchangers to form an acid...

Page 39

39 12.3. Flue pipe inspection the flue pipe must be inspected regularly during the heating season. The pipe must be dissembled and cleaned. The pipe must be examined carefully to detect any defect or damage. The pipe can be reassembled if no defect is detected and defective pipe must be replaced imm...

Page 40

40 13.1. Door glass inspect the glass regularly to detect any glass failure. If you find any defect, stop using the wood furnace immediately. Never operate a wood furnace with a broken glass. If you have to change your door glass, you must use ceramic glass 3/16" (5mm) thick. Use genuine parts sold ...

Page 41

41 14.1.1. Distribution blower to check the status of the distribution blower, go to the main menu under “troubleshoot link" then go to page 5. When the fan is on, the selected speed is black. 14.1.2. Air control damper to check the status of the air damper, go to the main menu under "troubleshoot l...

Page 42

42 note: if you need to contact your dealer or after-sale service, make sure to have the model of your furnace and the serial number on hand. (they can be found on the certification label on the side of the furnace). 14.2.1. Unit overheat the temperature probe (rtd) is disconnected or defective: if ...

Page 43

43 distribution blower . Replace it if necessary. The fuse of the distribution fan is blown: change the 12a fuse on the power board. The pressure in the plenum is too high: make sure your air distribution system is well balanced and that the filter is not dirty or clogged. Ensure that returns / side...

Page 44

44 telecommunication wire is defective or not connected properly. The temperature of the screen is below zero. When the screen is exposed to temperatures too cold, the liquid crystals may not function properly which causes a loss of communication. This situation may occur in cases where the unit has...

Page 45

45 15. General electrical diagram.

Page 46

46 16. Electrical diagram for parallel furnace.

Page 47

47 17. Electrical diagram for electric unit.

Page 48

48 18. Link board options connections 18.1. Electrical consumption your mini-caddy furnace is able to supply electrical 24v current to control various options. The options that can be supported are described in the table below. The maximum available 24v current is 1.66 amps (transformer 24v @ 40va)....

Page 49

49 18.4. Air conditionning damper 18.5. Humidifier 18.6. Heat pump.

Page 50

50 19. Exploded view and part list.

Page 51

51.

Page 52

52.

Page 53

53.

Page 54

54.

Page 55

55 important: this is dated information. When requesting service or replacement parts for your stove, please provide the model number and the serial number. We reserve the right to change parts due to technology upgrade or availability. Contact an authorized dealer to obtain any of these parts. Neve...

Page 56

56 # item description qty 39 30124 screw #8 - 32 x 5/16'' truss quadrex zinc 8 40 se51799 furnace ash drawer 1 41 21443 c-cast baffle 13 3/8'' x 16 1/16'' 1 42 pl51762 middle rear secondary air tube 3 43 pl51763 front secondary air tube 1 44 pl51761 primary air deflector 1 45 21442 rear panel insula...

Page 57

57 # item description qty 81 44136 fuse 12a / 250v / 1/4" dia. X 1 1/4'' long 1 82 44137 fuse 1a / 250v / 1/4" dia. X 1 1/4'' long 1 83 60368 transformer 120v/24 v class 2 - 40 va 1 84 pl48243 power board housing 1 85 pl48242 power board access panel 1 86 pl51455 side access panel to blower 2 87 305...

Page 58

58 why purchase through an authorized psg dealer? To make sure your psg furnace provides comfort and energy savings in your home for many years, your choice of installer is extremely important. An authorized psg dealer will ensure that the system is optimized and installed according to standards. Gi...

Page 59

59 psg limited lifetime warranty (regular) the warranty of the manufacturer extends only to the original consumer purchaser and is not transferable. This warranty covers brand new products only, which have not been altered, modified nor repaired since shipment from factory. Proof of purchase (dated ...

Page 60

60 psg limited lifetime warranty (privilege) the warranty of the manufacturer extends only to the original consumer purchaser and is not transferable. This warranty covers brand new products only, which have not been altered, modified nor repaired since shipment from factory and purchased through an...