- DL manuals

- Calculated Industries

- Calculator

- 4088

- User Manual

Calculated Industries 4088 User Manual

Summary of 4088

Page 2: 2 — M

2 — m achinist c alc ® p ro 2 machinist calc ® pro 2 the machinist calc ® pro 2 advanced machining math + materials calculator (model 4088) provides hundreds of fast, precise machining-specific solutions for turning, drilling, boring and face, end and slot milling. Built-in tables for 20 materials, ...

Page 3: User'S Guide — 3

User's guide — 3 using the machinist calc pro 2 .................................15 u.S./metric modes ...........................................................15 materials, processes and tools .............................15 materials ..................................................................

Page 4: 4 — M

4 — m achinist c alc ® p ro 2 internal thread..............................................................39 external thread ............................................................40 thread classification ..................................................40 changing thread classes ...............

Page 5: User'S Guide — 5

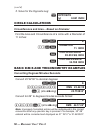

User's guide — 5 basic function keys o on/clear key — turns on power. Pressing once clears the last entry and the display. Pressing twice clears all non-permanent values. Go off — turns all power off. Clears all non- permanent values. +-* ,= arithmetic operation keys 0 -9 and . Keys used for enterin...

Page 6: 6 — M

6 — m achinist c alc ® p ro 2 g5 centimeters (cm) — identifies entry as centimeters, with repeated presses toggling between linear, area and volume units. G9 meters (m) — identifies entry as meters, with repeated presses toggling between linear, area and volume units. G7 feet — identifies entry as f...

Page 7: User'S Guide — 7

User's guide — 7 weight and volume function keys g6 tons — enters or converts a weight or volume value to tons. G4 pounds (lbs) — enters or converts a weight or volume value to pounds. G3 metric tons (met tons) — enters or converts a weight or volume value to metric tons. G2 grams — enters or conver...

Page 8: 8 — M

8 — m achinist c alc ® p ro 2 g/ arctangent (arctan) — calculates the angle for the entered or calculated tangent value. Miscellaneous functions g. Degrees:minutes:seconds (dms◄►deg) — converts between d:m:s and decimal degree formats; repeated presses will toggle between the two formats. % percenta...

Page 9: User'S Guide — 9

User's guide — 9 d diameter — enters a diameter. Calculates circle area and circumference given entered diameter. Gd bolt pattern — enters the number of holes in a bolt pattern. Calculates the hole center-to-center spacing and the x and y coordinates for each hole in a bolt pattern given entered dia...

Page 10: 10 — M

10 — m achinist c alc ® p ro 2 gl length of cut (loc) — enters a cut length to calculate cut time. S surface feet per minute — enters or calculates cutting speed. Unitless entries are assumed to be feet in u.S. Mode, meters in metric mode. Calculates cutting speed given entered diameter and rpm. Pro...

Page 11: User'S Guide — 11

User's guide — 11 gt inches per revolution (ipr) — enters or calculates cutting feed or feed per revolution (ipr). Provides tabular feed per revolution based on process, material, tooling and depth of cut. I inches per minute — enters or calculates feed rate or feed per minute (ipm). When applicable...

Page 12: 12 — M

12 — m achinist c alc ® p ro 2 gt thread classification (thread class) — used to select the thread class for numeric and fractional threads and the tolerance class for metric threads. The default class for numeric and fractional thread sizes is 2b (internal) and the default tolerance class for metri...

Page 13: User'S Guide — 13

User's guide — 13 n angle (θ) — enters or calculates an angle, providing the adjacent angle for both instances. Calculates an angle given two other right-triangle values. Also enters lead angle adjustment for face milling, as well as starting angle of the first hole of a bolt pattern, with 0° being ...

Page 14: 14 — M

14 — m achinist c alc ® p ro 2 255m m+ & 255. 745gm (m-) m- & 745. Rm total value m+ & - 135. M average value m+ & - 45. M total entries m+ & 3. Rr m+ - 135. Using memory storage keys (m1- m9) in addition to the standard cumulative memory (as previously described), your calculator has nine independe...

Page 15: User'S Guide — 15

User's guide — 15 175gr1 memory m-Ø1 175. Goo 0. R1 memory m-Ø1 175. 0gr1 memory m-Ø1 0. Using the machinist calc pro 2 u.S. And metric mode settings the machinist calc pro 2 allows you to set the calculator to use either u.S. Mode or metric mode. The default setting is u.S. Units. You can change to...

Page 16: 16 — M

16 — m achinist c alc ® p ro 2 4. 4140 chromium-molybdenum alloy steel 5. 4340 nickel-chromium-molybdenum alloy steel 6. 52100 chromium alloy steel 7. 304 austenitic stainless steel 8. 316 austenitic stainless steel 9. 410 martensitic stainless steel 10. 430 ferritic stainless steel 11. P20 mold typ...

Page 17: User'S Guide — 17

User's guide — 17 1. Face milling (default) 4. Turning 2. End milling 5. Boring 3. Slot milling 6. Drilling tools the machinist calc pro 2 has three built-in tool types that can be used to determine tabular feed and speed values. You can scroll through the available tool types by repeatedly pressing...

Page 18: 18 — M

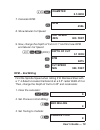

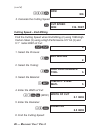

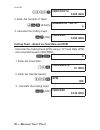

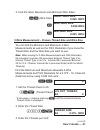

18 — m achinist c alc ® p ro 2 .375d diameter 0.375 inch 2. Enter the cut speed: 300s cut speed /min 300. Feet 3. Calculate the spindle speed (rpm): r rpm 3056. Rpm – face milling find the spindle speed when milling 1060 hi-carbon steel (3) with a 0.5" high performance bit (3) at a depth of cut of 0...

Page 19: User'S Guide — 19

User's guide — 19 .5d diameter 0.5 inch 7. Calculate rpm: r rpm 4584. 8. Show tabular cut speed: r cut speed /min 600. Feet 9. Now, change the depth of cut to 0.1" and find new rpm and tabular cut speed: .1gn (doc) depth of cut 0.1 inch r rpm 6875. R cut speed /min 900. Feet rpm – end milling find t...

Page 20: 20 — M

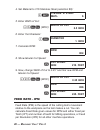

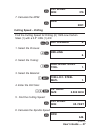

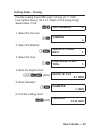

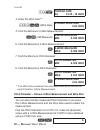

20 — m achinist c alc ® p ro 2 4. Set material to 316 stainless steel (selection #8): 8n 316-aus. S. Steel matl 8. 5. Enter width of cut: .5gp (woc) width of cut 0.5 inch 6. Enter tool diameter: 1d diameter 1. Inch 7. Calculate rpm: r rpm 802. 8. Show tabular cut speed: r cut speed /min 210. Feet 9....

Page 21: User'S Guide — 21

User's guide — 21 feed rate – based on cutting feed and rpm (for turning) calculate the feed rate if you are turning a 1" steel round stock down using a cutting feed of 0.031 inches per revolution and a rotational speed of 900 rpm: oo 0. 1. Enter the feed per revolution: .031gt (ipr) feed/rev. 0.031...

Page 22: 22 — M

22 — m achinist c alc ® p ro 2 i feed/minute 3.200 inch feed rate – based on feed per tooth, rpm and # of teeth calculate the feed rate for a four-fluted end mill using a feed per tooth (chip load) of 0.005" turning at 1,000 rpm: rpm: 1000 feed rate feed per tooth: 0.005″ number of teeth: 4 g* all c...

Page 23: User'S Guide — 23

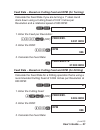

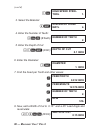

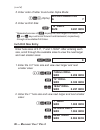

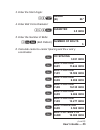

User's guide — 23 (cont'd) feed rate – end milling for end milling (2), find the feed rate (ipm) using 1020 low-carbon steel (1) and a 4-tooth high speed steel tool (1) with a diameter of 0.5", a 0.25" width of cut and a 20" length of cut. Then, change the width of cut to 0.15" to show the adjusted ...

Page 24: 24 — M

24 — m achinist c alc ® p ro 2 7. Enter the diameter: .5d diameter 0.5 inch 8. Calculate the feed rate: i feed/minute 3.667 inch 9. Calculate the cut time: i cut time min 5.454 10. Calculate the rpm: i rpm 917. 11. Change the width of cut (radial chip thinning adjustment): .15gp (woc) width of cut 0...

Page 25: User'S Guide — 25

User's guide — 25 i rct. Adj. Factor 1.091 14. Now, add a 0.125" depth of cut and find the material removal rate, spindle power and spindle torque: .125gn (doc) depth of cut0.125 inch i feed/minute 9.336 inch i material removal /min 0.175 cu inch i spindle power hp 0.123 i spindle torque lbft 0.602 ...

Page 26: 26 — M

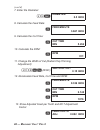

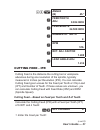

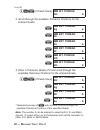

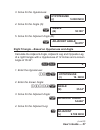

26 — m achinist c alc ® p ro 2 300r rpm 300. 3. Calculate the cutting speed: s cut speed /min 314. Feet cutting speed – end milling find the cutting speed when end milling (2) using 1060-high carbon steel (3) using a high performance 0.5" bit (3) and 0.1" radial width of cut: oo 0. 1. Select the pro...

Page 27: User'S Guide — 27

User's guide — 27 (cont'd) s cut speed /min 370. 7. Calculate the rpm: s rpm 2827. Cutting speed – drilling find the cutting speed for drilling (6) 1020-low carbon steel (1) with a 0.5" hss (1) drill: g* all cleared 0. 1. Select the process: 6p drilling 6. 2. Select the tooling: 1l high speed steel ...

Page 28: 28 — M

28 — m achinist c alc ® p ro 2 7. Change the material to 1060-high carbon steel and recalculate: 3n 1060-hi c. Steel matl 3. S cut speed /min 65. Feet s rpm 497. Feed per tooth/chip load - ipt feed per tooth (ipt), or chip load, is the distance that the workpiece feeds into each tooth on a multi-poi...

Page 29: User'S Guide — 29

User's guide — 29 (cont'd) feed per tooth – based on feed rate, rpm and # of teeth calculate feed per tooth (ipt) with a feed rate (ipm) of 12.8" per minute, 4 teeth and a spindle speed of 775 rpm: oo 0. 1. Enter the feed rate: 12.8i feed/minute 12.8 inch 2. Enter the number of teeth: 4gi (#teeth) n...

Page 30: 30 — M

30 — m achinist c alc ® p ro 2 1l high speed steel tool 1. 3. Select the material: 4n 4140-alloy steel matl 4. 4. Enter the number of teeth: 2gi (#teeth) number of teeth 2. 5. Enter the depth of cut: .1gn (doc) depth of cut 0.1 inch 6. Enter the diameter: 1d diameter 1. Inch 7. Find the feed per too...

Page 31: User'S Guide — 31

User's guide — 31 45 n angle (Ө) 45.° t feed/tooth adj. 0.024 inch t feed/minute 24.508 inch t number of teeth 2. T rpm 516. T rct. Adj. Factor 1.400 t lead angle adj. 1.414 cutting feed – ipr cutting feed is the distance the cutting tool or workpiece advances during one revolution of the spindle, t...

Page 32: 32 — M

32 — m achinist c alc ® p ro 2 .005t feed/tooth 0.005 inch 2. Enter the number of teeth: 4gi (#teeth) number of teeth 4. 3. Calculate the cutting feed: gt (ipr) feed/rev. 0.020 inch cutting feed – based on feed rate and rpm calculate the cutting feed (ipr) using a 15" feed rate (ipm) and a spindle s...

Page 33: User'S Guide — 33

User's guide — 33 cutting feed – turning find the cutting feed (ipr) when turning (4) 1", 1020 low-carbon steel (1) at a 0.1" depth of cut using a high speed steel (1) bit: g* all cleared 0. 1. Select the process: 4p turning 4. 2. Select the material: 1n 1020-lo c. Steel matl 1. 3. Select the tool: ...

Page 34: 34 — M

34 — m achinist c alc ® p ro 2 drill sizes the d key allows the selection of a desired drill size, which can be entered as a: ● numeric value (whole digits 1 through 97) ● letter between a and z ● fractional or decimal inch value (max. Of 3-1/2") ● millimeter value (max. Of 78 mm). The selected dril...

Page 35: User'S Guide — 35

User's guide — 35 (cont'd) letter drill size entry you can enter letter drill sizes by selecting an alphabet character via alpha mode (g8) and then storing it using the d key. The desired letter can be selected by scrolling through alpha mode until the letter is reached or by specifying the numerica...

Page 36: 36 — M

36 — m achinist c alc ® p ro 2 5. Enter order of letter g and enter alpha mode: 7g8 (alpha) alpha character g 7. 6. Enter as drill size: d * "g" drill size 0.261 inch * repeated presses of d display the next larger drill sizes. The + and - keys will scroll forward and backward, respectively, through...

Page 37: User'S Guide — 37

User's guide — 37 3. Enter the 1-19/64" hole size and view next larger and next smaller sizes: 1i19/64d 1-19/64" drill size 1.297 inch d 33.00mm drill size 1.299 inch -- 1-9/32" drill size 1.281 inch millimeter drill size entry enter a 5.7 mm hole size and scroll through the available sizes to view ...

Page 38: 38 — M

38 — m achinist c alc ® p ro 2 oo 0. 1. Enter the drill size: 1/2d 1/2" drill size 0.500 inch 2. Enter 118° angle and calculate the drill point cut depth: 118gd (drill point) drill point cut dpth 0.150 inch d drill cut angle118.000° d 1/2" drill size 0.500 inch 3. Enter 127° angle and calculate the ...

Page 39: User'S Guide — 39

User's guide — 39 the following specifies the entry ranges that the calculator allows for the thread size and tpi/pitch values for numeric, fractional and metric thread sizes: thread size tpi/pitch numeric 0, 1, 2, 3, 4, 5, 6, 8, 10, 12, 14 less than 100 fractional 0.06" to 6" less than 100 metric 1...

Page 40: 40 — M

40 — m achinist c alc ® p ro 2 external thread thread size minimum pitch diameter thread pitch* maximum major diameter cut rod size minimum major diameter roll shank size maximum minor diameter maximum pitch diameter * thread pitch is only displayed for numeric and u.S. Thread sizes. Thread classifi...

Page 41: User'S Guide — 41

User's guide — 41 changing thread classes to display the current thread classification, press gt . Repeated presses of t will toggle between external and internal thread types. You can change the number of a thread class by entering the number of the desired class/ grade and pressing gt . Changing a...

Page 42: 42 — M

42 — m achinist c alc ® p ro 2 4gt (thread class) mm int. Thread 4h 4. 2. Scroll through the available tolerance positions for the entered grade: t mm ext. Thread 4g 4. T mm ext. Thread 4h 4. T mm ext. Thread 4e 4. T mm ext. Thread 4f 4. T mm int. Thread 4g 4. T mm int. Thread 4h 4. 3. Enter a toler...

Page 43: User'S Guide — 43

User's guide — 43 numeric thread size enter an 8-32 screw and scroll through the available internal thread (class 2b) characteristics, then switch to external thread (class 2a) and scroll through the available thread characteristics: note: the default u.S. Thread class is 2b (internal). To view the ...

Page 44: 44 — M

44 — m achinist c alc ® p ro 2 t close fit drill #18 0.170 inch t free fit drill #16 0.177 inch t pitch diameter min 0.144 inch t pitch diameter max 0.147 inch t minor diameter min 0.130 inch t minor diameter max 0.139 inch t major diameter min 0.164 inch 5. Switch to thread class 2a: gtt (thread cl...

Page 45: User'S Guide — 45

User's guide — 45 (cont'd) t pitch diameter min 0.140 inch t major diameter max 0.163 inch t major diameter min 0.157 inch t minor diameter max 0.126 inch fractional thread size find the available internal and external thread characteristics for a 1/4 inch, 28 tpi screw: g* all cleared 0. 1. Verify ...

Page 46: 46 — M

46 — m achinist c alc ® p ro 2 t close fit drill f 0.257 inch t free fit drill h 0.266 inch t pitch diameter min 0.227 inch t pitch diameter max 0.231 inch t minor diameter min 0.211 inch t minor diameter max 0.220 inch t major diameter min 0.250 inch 5. Switch to thread class 2a: gtt (thread class)...

Page 47: User'S Guide — 47

User's guide — 47 (cont'd) t pitch diameter min 0.223 inch t major diameter max 0.249 inch t major diameter min 0.243 inch t minor diameter max 0.207 inch metric thread size find the available internal and external thread characteristics for a 5 mm, 0.75 mm pitch screw with a tolerance class of 4h: ...

Page 48: 48 — M

48 — m achinist c alc ® p ro 2 t roll tap drill #14 0.182 inch t close fit drill 5.300 mm t free fit drill 5.800 mm t pitch diameter min 4.513 mm t pitch diameter max 4.588 mm t minor diameter min 4.188 mm t minor diameter max 4.306 mm t major diameter min 5.000 mm 5. Switch to external 4g tolerance...

Page 49: User'S Guide — 49

User's guide — 49 t pitch diameter min 4.435 mm t major diameter max 4.978 mm t major diameter min 4.888 mm t minor diameter max 4.166 mm custom thread percentage the machinist calc pro 2 uses a default thread grip percentage of 75% when calculating tap drill sizes. With the custom percentage thread...

Page 50: 50 — M

50 — m achinist c alc ® p ro 2 2. Change the thread grip percentage to 50% and calculate the new cut tap and roll tap drill sizes: 50gn (% of thread) thread % - grip 50. T thread size 2b 0.25 - 26 inch t thread pitch 0.038 inch t tap drill size #1 0.228 inch t roll tap drill 6.000 mm * repeated pres...

Page 51: User'S Guide — 51

User's guide — 51 (cont'd) 3. Find the ideal, maximum and minimum wire sizes: gs (wire size) ideal wire size 0.036 inch s max wire size 0.056 inch s min wire size 0.035 inch 3-wire measurement – known thread size and wire size you can find the minimum and maximum 3-wire measurements as well as the p...

Page 52: 52 — M

52 — m achinist c alc ® p ro 2 16t thread size 2a 0.375 - 16 inch 4. Enter the wire size**: .04gs (wire size) stored wire size 0.04 inch 5. Find the minimum 3-wire measurement: gr (3w measure) 3-wire measure min 0.395 inch 6. Find the maximum 3-wire measurement: r 3-wire measure max 0.399 inch 7. Fi...

Page 53: User'S Guide — 53

User's guide — 53 1. If necessary, set the thread class to 2a: 2gt * (thread class) u.S. Ext. Thread 2a 2. * if necessary, continue pressing t until the desired external thread class is displayed. 2. Enter the thread size: .375it thread size 2a 0.375 - inch 3. Enter the threads per inch: 16t thread ...

Page 54: 54 — M

54 — m achinist c alc ® p ro 2 bolt pattern with the machinist calc pro 2, you can determine a bolt pattern by entering the bolt circle diameter, the number of bolt holes and the angle of the first bolt hole (optional). You can also enter an optional center x and y-coordinate of the bolt pattern. In...

Page 55: User'S Guide — 55

User's guide — 55 3. Enter the start angle: 20n angle (Ө) 20.° 4. Enter bolt circle diameter: 3.5d diameter 3.5 inch 5. Enter the number of bolts: 3gd (bolt pattern) number of bolts 3. 6. Calculate center-to-center spacing and the x and y coordinates: d oc spacing 3.031 inch d bolt position x-Ø1 11....

Page 56: 56 — M

56 — m achinist c alc ® p ro 2 d bolt pattern ctr y-ØØ 15.000 inch d starting angle 20.000 ° right triangle functions with the machinist calc pro 2, you can easily solve right triangle problems by simply entering two of four variables: adjacent, opposite, hypotenuse or angle. Right triangle – based ...

Page 57: User'S Guide — 57

User's guide — 57 3. Solve for the hypotenuse: h hypotenuse (r) 5.000 inch 4. Solve for the angle (a): n angle (Ө) 53.130° 5. Solve for the adjacent angle (b): n adjacent angle36.870° right triangle – based on hypotenuse and angle calculate the adjacent angle, adjacent leg and opposite leg of a righ...

Page 58: 58 — M

58 — m achinist c alc ® p ro 2 5. Solve for the opposite leg: o opposite (y) 6.941 inch circle calculations circumference and area – based on diameter find the area and circumference of a circle with a diameter of 11 inches: oo 0. 11id diameter 11. Inch d circular area 95.033 sq inch d circumference...

Page 59: User'S Guide — 59

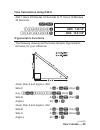

User's guide — 59 time calculations using d:m:s add 7 hours 45 minutes 33 seconds to 11 hours 16 minutes 20 seconds: oo 0. 7.45.33+ dms 7.45.33° 11.16.20= dms 19.01.53° trigonometric functions the following drawing and formulas list basic trigonometric formulas, for your reference: given side a and ...

Page 60: 60 — M

60 — m achinist c alc ® p ro 2 given side b and angle a, find: side a b , a gh (tan) = side c b , a ga (sine) = given side c and angle a, find: side a c * a go (cos) = side b c * a ga (sine) = given side a and side c, find: angle a a , c =gi (arccos) angle b a , c = gm (arcsine) given side b and ang...

Page 61: User'S Guide — 61

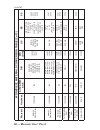

User's guide — 61 (cont'd) a ppen d ix a - wor k piece ma terial c on version table w or k piece m aterials con version t able (1 of 3) material h ardness aisi /ast m / sae d in w r (d in ) jis bs ss low-carbon steel 120-170 hb 1020 c22 1.0402 s 20 c; s 20 ck s 22 c 055 m 15 1450 medium-carbon steel...

Page 62: 62 — M

62 — m achinist c alc ® p ro 2 w or k piece m aterials con version t able (2 of 3) material h ardness aisi /ast m / sae d in w r (d in ) jis bs ss austenitic stainless steel 150-200 hb 304 x5crni18-9 x2crni19-1; gx2crnin18-9 x2crnin18-10 x5crni18-10 (x4crni18-10) 1.4306 1.431 1 1.4301 scs 19, sus 30...

Page 63: User'S Guide — 63

User's guide — 63 w or k piece m aterials con version t able (3 of 3) material h ardness aisi /ast m / sae d in w r (d in ) jis bs ss magnesium and silicon al alloy 95 hb 6061-t6 almgsicu 3.321 1 a6061, a2x4 6061, h20, l1 17, l1 18 silicon, copper , and magnesium cast al 125 hb a390.0-t5 ti-6al-4v a...

Page 64: 64 — M

64 — m achinist c alc ® p ro 2 appendix b – default settings after a clear all (g*), your calculator will return to the following settings: stored values default value material none process face milling tool high speed steel tool number of teeth 1 drill cut angle 118° weight per volume 490 pounds pe...

Page 65: User'S Guide — 65

User's guide — 65 appendix c – preference settings the machinist calc pro 2 has preference settings that allow you to customize or set desired unit formats and calculations. If you replace your batteries or perform a full reset* (turn calculator off, hold down *, and press o), your calculator will r...

Page 66: 66 — M

66 — m achinist c alc ® p ro 2 3) functional result rounding – 0.000 (fix): calculation results using machinist functions are always displayed to three decimal places. – 0.0000 (fix): calculation results using machinist functions are always displayed to four decimal places. – 0. (actual): calculatio...

Page 67: User'S Guide — 67

User's guide — 67 5) volume answer format – standard: if units entered are the same – e.G., inch x inch x inch – the answer will remain in this format (cubic inch), but if units entered are different – e.G., feet x feet x inches – volume answer will be displayed in cubic inch. – cubic feet: volume a...

Page 68: 68 — M

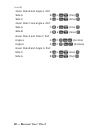

68 — m achinist c alc ® p ro 2 appendix d – basic calculator functions and dimensional math operations entering dimensions note: unlike other calculated industries/construction master calculators, the machinist calc pro 2 does not have a dedicated feet key. Feet is a secondary function located above...

Page 69: User'S Guide — 69

User's guide — 69 14 square inches 14ii 11 square millimeters 11mm 1.5 cubic meters 1.5g999 3 cubic feet 3 g 7 g 7 g 7 conversions linear conversions convert 10 feet 6 inches to other dimensions, including metric: oo 0. 10g76i 10 feet 6 inch gb * 126.000 inch g7 (feet) 10.5 feet gi 126. Inch gm 3200...

Page 70: 70 — M

70 — m achinist c alc ® p ro 2 convert 17.32 feet to feet-inch-fractions: oo 0. 17.32g7 (feet) 17.32 feet = g7 17 feet 3-27/32 inch g7 17.32 feet gi 207.84 inch g7g7 17 feet 3-27/32 inch convert 8-1/8 inches to decimal inches. Then convert to decimal feet: oo 0. 8i1/8 8-1/8 inch gi 8.125 inch g7 (fe...

Page 71: User'S Guide — 71

User's guide — 71 convert 0.05 cubic meters to other dimensions: oo 0. . 05g999 (m) 0.05 cu m gm 50000000. Cu mm g5 (cm) 50000. Cu cm gi 3051.1872 cu inch g7 (feet) 1.7657333 cu feet weight conversions convert 1.5 tons to pounds and kilograms: oo 0. 1.5g6 (tons) 1.5 ton g1 (kg) 1360.7771 kg g4 (lbs)...

Page 72: 72 — M

72 — m achinist c alc ® p ro 2 g6 (tons) ton 0.4669611 g1 (kg) kg 423.62003 g3 (met tons) mton 0.42362 4. Change the weight per volume back to the default value: 490g00 (wt/vol) lbs./ cu. Feet 490. * the number of 0 presses may vary, depending on the last units displayed when wt/vol was last recalle...

Page 73: User'S Guide — 73

User's guide — 73 basic math operations adding and subtracting dimensions add the following measurements: • 6 feet 2-1/2 inches • 11 feet 5-1/4 inches • 18.25 inches then subtract 2-1/8 inches: 6g72i1/2+ 6 feet 2-1/2 inch 11g75i1/4+ 17 feet 7-3/4 inch 18.25i= 19 feet 2 inch -2i1/8= 18 feet 11-7/8 in...

Page 74: 74 — M

74 — m achinist c alc ® p ro 2 appendix e – accuracy/errors, auto shut-off, batteries, reset error codes display error type overflow overflow (too large) math error divide by 0 dimension error dimension error entry error invalid entry error auto shut-off your calculator is designed to shut off after...

Page 75: User'S Guide — 75

User's guide — 75 reset if your calculator should ever "lock up," insert the tip of a paperclip or a small diameter wire into the small reset hole above the d key. Repair and return return guidelines 1. Please read the warranty in this user's guide to determine if your calculated industries product ...

Page 76: 76 — M

76 — m achinist c alc ® p ro 2 warranty calculated industries ("ci") warrants this product against defects in materials and workmanship for a period of one (1) year from the date of original consumer purchase in the u.S. If a defect exists during the warranty period, ci at its option will either rep...

Page 77: User'S Guide — 77

User's guide — 77 repair service – outside the u.S.A. To obtain warranty or non-warranty repair service for goods purchased outside the u.S., contact the dealer through which you initially purchased the product. If you cannot reasonably have the product repaired in your area, you may contact ci to o...

Page 78: 78 — M

78 — m achinist c alc ® p ro 2 fcc class b this equipment has been certified to comply with the limits for a class b calculating device, pursuant to subpart j of part 15 of fcc rules. Legal notes software copyrighted and licensed by calculated industries, inc., 2014. User's guide copyrighted by calc...

Page 79: User'S Guide — 79

User's guide — 79 looking for new ideas calculated industries, a leading manufacturer of special- function calculators and measuring instruments, is always looking for new product ideas in these areas. If you have a new product idea, please visit our "bright idea" page at www.Calculated.Com/brightid...

Page 80

4840 hytech drive carson city, nv 89706 u.S.A. 1-800-854-8075 • fax: 1-775-885-4949 e-mail: info@calculated.Com www.Calculated.Com designed in the united states of america. Printed in china. 11/14 ug4088e-b.