- DL manuals

- Calomax

- Boiler

- Clipper 2 10L

- Installation, Operation And Servicing Instructions

Calomax Clipper 2 10L Installation, Operation And Servicing Instructions

Summary of Clipper 2 10L

Page 1

Manuals and documents brought to you by wechillit.Com ltd wci group house 18 pride hill shrewsbury sy1 1dq tel: 01743 289418 fax: 01743 289416 web: www.Wechillit.Com.

Page 2

Model: clipper 2 5l, 7.5l, 10l & 15l installation, operation and servicing instructions calomax limited lupton avenue, leeds ls9 7dd tel. 0113 249 6681 fax. 0113 235 0358 e-mail: service@calomax.Co.Uk www.Calomax.Co.Uk please read these instructions carefully before operating your boiler for the rst...

Page 3

Page 2 page 3 contents introduction 3 check list 3 approvals 3 construction 4 installation 4 location 4 cold water inlet 5 dimensions and weights 5 vent / overflow 6 electrical connections 6 user instructions 6 scale 7 general operation 8 general notes 8 cleaning 8 service instructions 9 general fun...

Page 4

Page 4 page 5 location cold water inlet installation all metalic components of the machine, in direct contact with drinking water are manufactured from high quality 304 grade stainless steel, or non ferrous materials, providing maximum resistance to corrosion. Construction the boiler must be install...

Page 5

Page 6 page 7 electrical connections user instructions during normal operation some external parts will become very hot, particularly the tap body. Care must be taken to avoid injury, a burn or scald. Commissioning turn on the water supply and then switch on the electrical supply. The wait/ready lig...

Page 6

Page 8 page 9 cleaning • hold a cup below the tap or place large vessels on the drip tray. Care must be taken to avoid injury through splashing or over- lling. • to begin lling, pull the handle forward or push it backward – hot water begins to ow. If the tap is opened fully it can be locked open (fo...

Page 7

Page 10 page 11 scale deposits should be removed from all internal surfaces, particularly the heating element and thermistor. If the deposits are soft, use a nylon pad and ush out. Abrasive cleaning materials containing scouring powders and detergents must not be used, such materials can cause taste...

Page 8

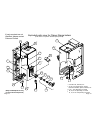

Page 12 page 13 (body and backplate cut away to show internal components) if parts required are not identified, please contact calomax limited includes nuts, washers, etc. Exploded parts view for clipper range boilers (to be read in conjunction with the spare parts list) 25, 26 or 27 depending on mo...

Page 9: Accessories

Page 14 page 15 accessories wall-mounting drip tray (no drain) ref. Wmpdtk1 (to suit 5l) worktop-mounting stainless steel drip tray ref. Ssdtk (freestanding) ssdtwdk (with drain outlet) counter-insertion plastic moulded drip tray ref. Pdtwdk (with drain outlet) wmpdtk2 (to suit 7.5l & 10l) wmpdtk3 (...

Page 10

Page 16 page 17 nb: not to scale. Spare parts (refer to centre pages for location). Cbtcw cbtss uthsg nb15gs nb10gs nb5gs tn2ck tap cup washer tap spring tap slotted stem grey tap body heat shield gasket set for model 5l slow fill nozzle 17 18 19 20 24 23 22 21 cbts nb5ba body for model 5l 25 nb15ba...

Page 11

Page 18 page 19 w irin g s ch em a tic fo r c a lo m ax c lip pe r w ate r b oil er s r e d y e l lo w b la c k b lu e p in k b r o w n o r a n g e w h it e b l a c k r e d y e ll o w w h it e b la c k b l a c k r e d n l blue blue black yellow / green y e ll o w /g r e e n red red c o ld w a t e r ...

Page 12

Page 20 page 21 service history and notes symptoms possible cause remedy no boiling water available broken tap top normal level sensor holding signal thermal cut-out tripped (no light) element failed replace tap top (or component) de-scale reset and check for faults replace element thermal cut-out t...

Page 13

Page 22 page 23 service history and notes calomax have manufactured water boilers in the uk for over 50 years. We are proud of our products and the back-up service we provide properly maintained and serviced, a calomax boiler should last many years and we have no hesitation in providing a full 12 mo...

Page 14

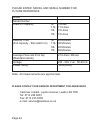

Page 24 model serial number draw off capacity 5l 7.5l 10l 15l 5 litres 7.5 litres 10 litres 15 litres heat-up time 5l (full capacity - rst switch on) 7.5l 10l 15l 20 minutes 30 minutes 40 minutes 60 minutes average flow rate from tap (standard nozzle) 2.5 litres / minute voltage 220 - 240 v ac 50-60...