- DL manuals

- Calomax

- Boiler

- KUDOS 6 DUAL FLOW

- Installation, Operation And Servicing Instructions

Calomax KUDOS 6 DUAL FLOW Installation, Operation And Servicing Instructions

MODEL: KUDOS 6

DUAL

FLOW

KUDOS 9

DUAL

FLOW

INSTALLATION, OPERATION AND SERVICING INSTRUCTIONS

Calomax Limited

Lupton Avenue, Leeds LS9 7DD

Tel. 0113 249 6681 Fax. 0113 235 0358

e-mail: service@calomax.co.uk www.calomax.co.uk

Please read these

instructions carefully

before operating your

boiler for the first time

Issue 8 09/07/13 DCR 872

Summary of KUDOS 6 DUAL FLOW

Page 1

Model: kudos 6 dual flow kudos 9 dual flow installation, operation and servicing instructions calomax limited lupton avenue, leeds ls9 7dd tel. 0113 249 6681 fax. 0113 235 0358 e-mail: service@calomax.Co.Uk www.Calomax.Co.Uk please read these instructions carefully before operating your boiler for t...

Page 2

Page 2 contents introduction 3 check list 3 approvals 3 construction 4 installation 4 location 4 cold water inlet 4 dimensions and weights 5 vent / overflow 5 electrical connections 6 user instructions 6 scale 7 general operation 8 general notes 8 cleaning 8 accessories 9/10/11 service instructions ...

Page 3: Introduction

Page 3 introduction thank you for purchasing a calomax kudos range boiler. All our products are designed to give years of simple, reliable operation. To ensure this, it is important that the installation and subsequent servicing is carried out by a suitably qualified engineer in accordance with thes...

Page 4: Location

Page 4 location cold water inlet installation all metalic components of the machine, in direct contact with drinking water are manufactured from high quality 304 grade stainless steel, or non ferrous materials, providing maximum resistance to corrosion. Construction to comply with recommendations fr...

Page 5: Dimensions And Weights

Page 5 model a b c dry weight working weight kudos 6 kudos 9 mm 745 380 275 21 kg 48 kg all dimensions are approximate dimensions and weights c b a before connecting, the supply pipe must be thoroughly flushed out to ensure that foreign matter does not block or enter the solenoid valve the boiler mu...

Page 6: Electrical Connections

Page 6 electrical connections kudos6 dual-flow boilers require fixed wiring to the rear terminal block. A means of disconnection must be provided in which at least 3mm seperation between the live and neutral poles of the supply exists. Kudos9 dual-flow boilers require fixed wiring to a 3 phase 4 wir...

Page 7: This

Page 7 the element(s) may be also be energized at the same time. If water is drawn from the machine but boiling water is still available, the wait/ready light will be illuminated solid yellow. If full draw off capacity is removed the boiler may cool, indicated by the wait/ready light flashing yellow...

Page 8: Cleaning

Page 8 cleaning general notes general operation • hold a cup below the tap or place large vessels on the drip tray. Care must be taken to avoid injury through splashing or over-filling. • to begin filling, pull the handle forward or push it backward – hot water begins to flow. If the tap is opened f...

Page 9: Accessories

Page 9 accessories worktop-mounting stainless steel drip tray ref. Ssdtk (freestanding) wall-mounting bracket (for boiler) ref. Kwmbk stainless steel drip tray for wall-mounting bracket (above) ref. Kwmbdtk (free standing) kwmbdtwdk (with drain outlet) ssdtwdk (with drain outlet) boiler securing cla...

Page 10: Ingredient Caddy

Page 10 ingredient caddy ref. Ic3 (3 bay) - as shown shelf unit (for storing cups / saucers etc.) ref. Shu back panels (to conceal water & electrical connections) ref. K9bac for kudos6 dual flow & kudos9 dual flow) ic4 (4 bay).

Page 11: Water Filter Kit

Page 11 for more information visit our website at www.Calomax.Co.Uk or call 0113 249 6681 water filter kit (to reduce taste & odour problems) ref. Cwfk filter cartridge (replacement filter for kit shown above) ref. Cwfc1.

Page 12: And Hygiene Are Concerned.

Page 12 when the green service indicator light on the front of the boiler is showing solid colour, the header tank sensor has been starved of water for in excess of 30 seconds and the bottom thermistor & bottom element(s) have been disabled. To reinstate normal operation the water supply needs to be...

Page 13: General Function

Page 13 scale deposits should be removed from all internal surfaces, particularly the heating element, thermistors and level sensors by gently tapping or scraping. If the deposits are soft, use a nylon pad and flush out. Abrasive cleaning materials containing scouring powders and detergents must not...

Page 14

Page 14 necessary to replace the lid gasket to ensure a reliable steam-tight seal. Note: the elements have a permanent ‘live’ feed, and the ‘neutrals’ are switched. Printed circuit board replacement (pcb) in the event of a pcb failing and a replacement being required, full instructions will be suppl...

Page 15

Page 15 e xp lo de d pa rts vie w ku do s6 d ua l f low (t o b e r ea d in co nju nc tio n w ith th e s pa re p art s li st) 1 2 5 * fit te d a s s ta nd ard . It em s 3 , 4 or 5 a va ila ble a s a lte rn ativ es h ou se s it em 2 3 in clu de s th erm isto r p oc ke t, a ll w as he rs & n uts 6 7 9 ...

Page 16

Page 16 e xp lo de d pa rts vie w ku do s9 d ua l f low (t o b e r ea d in co nju nc tio n w ith th e s pa re p art s li st) 1 2 5 * fit te d a s s ta nd ard . It em s 3 , 4 or 5 a va ila ble a s a lte rn ativ es h ou se s it em 2 3 in clu de s th erm isto r p oc ke t, a ll w as he rs & n uts 6 7 9 ...

Page 17

Page 17 spare parts are usually available ex-stock. Please quote model & serial number. Tbt tn2ck tn3ck cbts cbtcw ktt knk ksv nbe3hk cbtss k6pcbt kudtc draw off tap body tap body heat shield slow-fill nozzle fast-fill nozzle tap top assembly extended fast-fill nozzle tap cup washer tap spring tap s...

Page 18: Nbprg

Page 18 nb: not to scale. Spare parts are usually available ex-stock. Please quote model & serial number. 17 18 19 20 24 23 22 21 nbprg kdflpcba kdfpmfk body lid grommet water level control pipe water inlet hose plastic fascia for dual flow boilers light pcb for dual flow boilers ktsk tank sensor ki...

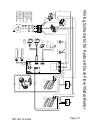

Page 19

Page 19 nb: not to scale. W irin g s ch em atic fo r k ud os -6 d ua l f lo w w ate r b oile r red yell o w blac k blue p in k br o w n o r a n g e no c onn ec tion black re d yello w whit e black black r e d n l blue l n black yellow / green yello w / green red red cold wat er inlet sol enoid valve...

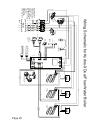

Page 20

Page 20 w iring schem atic for kudos- 9 d ual flow w ater boiler red yello w blac k blu e pin k b r o w n or an g e no c onn ec tion black re d ye ll o w white black black re d n l blue n black yellow / green ye ll o w / g r e e n red red col d wat er inlet solenoid va lve top element triac pcb high...

Page 21: Basic Trouble Shooting

Page 21 basic trouble shooting symptoms possible cause remedy no boiling water available broken tap top normal level sensor holding signal thermal cut-out tripped (no light) element failed replace tap top (or component) de-scale reset and check for faults replace element thermal cut-out trips regula...

Page 22: Service History And Notes

Page 22 nb: not to scale. Service history and notes.

Page 23

Page 23 calomax have manufactured water boilers in the uk for over 50 years. We are proud of our products and the back-up service we provide properly maintained and serviced, a calomax boiler should last many years and we have no hesitation in providing a full 12 months (mainland u.K.) parts and lab...

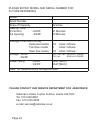

Page 24

Page 24 model serial number draw off capacity 22 litres heat-up time (first fill to - k6/df full capacity) - k9/df 31 minutes 23 minutes average flow rate from tap extended nozzle fast flow nozzle slow flow nozzle 8.5 litres / minute 6 litres / minute 3.5 litres / minute voltage - k6/df - k9/df 220 ...