- DL manuals

- Caltest

- Power Supply

- CINERGIA

- Installation And Operation Manual

Caltest CINERGIA Installation And Operation Manual

Summary of CINERGIA

Page 1

Dc programmable power supply (dcps) installation and operation manual tel: +49(0)7842-99722-00 fax: +49(0)7842-99722-29 www.Caltest.De kohlmattstrasse 7 d-77876 kappelrodeck info@caltest.De caltest instruments gmbh.

Page 2

Page 2 / 55 index 1. Introduction ..................................................................................................................... 5 1.1. Symbols used ................................................................................................................. 5 1.2. Safety ...

Page 3

4.2.3. Precharge ............................................................................................................ 23 4.2.4. Ready ................................................................................................................... 23 4.2.5. Run ...............................

Page 4

Page 4 / 55 8. Warranty and maintenance ........................................................................................ 54 8.1. Replacing the output fuses.......................................................................................... 54 8.2. Fans ....................................

Page 5

5 / 55 1. Introduction dear customer, on behalf of cinergia team, thank you for the confidence placed in our company and for the purchase of this product. Please, read carefully this manual before using the equipment to get familiarized with it to obtain the maximum performance from it. This documen...

Page 6

6 / 55 • en-iec 62040-1. Uninterruptible power supply (ups). Part 1-1: general and safety requirements for ups’s used in accessible areas by end users. • en-iec 60950-1. It equipments. Safety. Part 1: general requirements. • en-iec 62040-2. Uninterruptible power supply (ups). Part 2: prescriptions f...

Page 7

7 / 55 2. Presentation 2.1. Introduction the dcps is a dc programmable power supply, a power electronics equipment with the following main functionalities: - it converts the ac input, of the main grid, in a controlled dc output by using an igbt- based switching topology and dsp-based state-of-the-ar...

Page 8

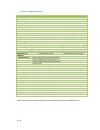

8 / 55 2.2. Power supply features magnitude value power 6.75kw-160kw input ac voltage rated ra 3x400v+neutral+earth voltage range +15% / -20 % ac current 2arms -290arms frequency 50/60hz power factor controllable -1/1 (capacitive/inductive) efficiency at full load >92% overload 125% for 10 min / 150...

Page 9

9 / 55 2.3. Operation and connection modes the output of the power supply is formed by three channels referenced to a common negative channel. The power supply can be used in two different connection modes: - independent channel: each channel (u,v,w) is controlled independently. The setpoint and als...

Page 10

10 / 55 2.5. Configuration and control of the power supply the power supply can be interfaced by three means: - local touchscreen: a 3.2” colour local touchscreen panel can be used to configure, monitor and operate the power supply. See section local touchscreen control panel for further information...

Page 11

11 / 55 the active rectifier has bidirectional power flow capability and the injected reactive power (grid side) can be defined by the customer. - dc/dc output converter: a three-branch igbt converter allows three buck-boost dc- dc conversions from the dc bus to each of the output channels. Each cha...

Page 12

12 / 55 state-of-the art digital control is used in all cinergia products. In the dcps case, the control system algorithms are computed in a dual core dsp-based hardware, designed by cinergia, allowing a multitask execution of the regulation systems for the active rectifier and the dc/dc output. Thi...

Page 13

13 / 55 3. Installation 3.1. Important safety instructions as a device with class l protection against electric shocks, it is essential to install a protective earth wire (connect earth ). Connect the protection earth wire to the terminal (x5) before connecting the grid to the dcps input. All the el...

Page 14

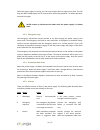

14 / 55 front view (with the door open): q2 q3 q1a detailed view of the signal connectors: x12 x13 x11 x14 x15 x16 x17.

Page 15

15 / 55 general view (with the front door closed): protection elements (q*): (q1a) input thermal-magnetic circuit breaker or disconnector according to power of the equipment. (q2) output disconnector. (q3) output fuses. Connection elements (x*): (x1) phase input terminal r. (x2) phase input terminal...

Page 16

16 / 55 (x12) terminals for external emergency power off (epo) button. (x13) db9 connector for can communications (input). (x14) db9 connector for can communications (output). (x15) rj45 connector for modbus interface. (x16) de15 connector for digital inputs and outputs. (x17) de15 connector for ana...

Page 17

17 / 55 it is also important to consider the most suitable means to place the power supply in its final location (floor, hoist, lift, stairs, …etc). 3.3.4. Location it is necessary to leave a minimum of 25 cm in the contour of the equipment for its ventilation. If possible, as shown in following fig...

Page 18

18 / 55 recommendable minimum distance, 1 m. R ec o m m end abl e m ini m u m d is ta n ce , 1 m . Recommendable minimum distance, 1 m. R ec o m m end abl e m ini m u m d is ta n ce , 1 m . The equipment may be installed in any place as long as the safety and ventilation requirements are fulfilled. ...

Page 19

19 / 55 3.4. Connection 3.4.1. Earth protection as a device with class l protection against electric shocks, it is essential to install a protective earth wire (connect earth ). Connect the protection earth wire to the terminal (x5) before connecting the grid to the dcps input. On the other hand, co...

Page 20

20 / 55 x12 3.4.5. Communications there are several connectors dedicated to communications, which are listed below: - connector for rs485 communications (x11): db9 connector to be used when modbus rs485 option is chosen. - connectors for can communications (x13, x14): db9 connectors to be used when ...

Page 21

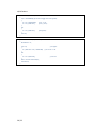

21 / 55 3.4.7. Analog inputs and outputs analog inputs and outputs are gathered in x17. The analog inputs of dcps are isolated and accept a voltage range from -10 to 10v. There are 3 analog inputs and, depending on the connection mode, there are two possible configurations for them: - parallel chann...

Page 22

22 / 55 4. Operation 4.1. Safety before operating the equipment, check that the protective earth is properly connected. Check out the electrical installation in both sides (input and output) of the cabinet. All wires shall be connected and secured before proceeding to the power supply start-up. 4.2....

Page 23

23 / 55 4.2.1. Initialization during the initialization, the power supply control system checks the presence of all internal components, the embedded pc loads the operating system and the isolation detector runs a self-test. No voltage is present at the dc bus and the igbts pwms are completely stopp...

Page 24

24 / 55 stabilizes the dc link voltage. After that, the output side will measure the actual output state (voltage levels) and will start the control algorithms and pwm. This state can evolve to standby state when a not enable signal is received, to ready state when a not run signal is received or to...

Page 25

25 / 55 the user can configure: - amplitude: desired output current value. - sign: a positive sign represents a current sourced from the power supply. A negative sign represents a current sunk by the power supply. - setpoint limitation: this limitation can be lower than the maximum power supply outp...

Page 26

26 / 55 the user can configure: - amplitude: desired output voltage value. - sign: the output voltage between channels u,v,w is always positive with respect to n. No negative voltages can be set. - setpoint limitation: the maximum current may be controlled in this operation mode. The maximum availab...

Page 27

27 / 55 - setpoint limitation: this limitation can be lower than the maximum power supply output current. It can be useful when the power supply is connected to batteries since they may have different current limits for charging and discharging and those limits may be lower than the maximum power su...

Page 28

28 / 55 independent mode: each output channel is connected to an independent load. In this way, the power supply could, for instance, feed three independent loads at the same time and with different capacities, voltages, currents, etc. Please be sure that no electrical connection between the channel...

Page 29

29 / 55 the grid side of the power supply is protected by a thermal-magnetic circuit breaker. Be sure that this breaker is switched off: check that all wires are connected and secured before proceeding to the power supply start-up. If these steps are validated the power supply is ready to be started...

Page 30

30 / 55 other voltage sources at the output. If the power supply is operated as a current source, please do not connect any other current sources at the output. 4.5.2. Stop once the equipment is running (run state) it may be stopped in three ways: 4.5.2.1. Full stop this type of stop is recommended ...

Page 31

31 / 55 when the power supply is running, the user may send the not run signal at any time. This will stop the igbt’s pwm signals but all internal parts will be kept powered. To restart operation, send the run signal. Never connect or disconnect the cables while the power supply is in ready state. 4...

Page 32

32 / 55 there is a sudden overcurrent in the power supply output. Before restarting the power supply. 4 precharge timeout internal error caused by a low voltage in mains. Check the grid voltage. 5 overload in precharge internal alarm caused by a shortcircuit. Contact cinergia for technical support. ...

Page 33

33 / 55 12 no heart beat communication cable broken or control board without response. Contact cinergia in order to isolate the problem. 13 pll error the frequency of the grid is too high or low. Check the grid frequency. 14 mains lost there is no voltage on the grid (short interruption or voltage d...

Page 34

34 / 55 5. Local touchscreen control panel 5.1. Basic functions the lcd touchscreen main purpose is to provide the user with the necessary information about the power converters. Besides, the touchscreen allows the user to interact with the mother board and control multiple variables in regard to th...

Page 35

35 / 55 5.2.2. Operational the main purpose of the operational menu is, in case the lcd control is activated, to allow the user to manage the power converters state machine and to introduce current, voltage and both active and reactive power setpoints. The user gets to read the following information...

Page 36

36 / 55 commands the button commands allows the user to introduce different setpoints: voltage setpoints current setpoints active power setpoints once again, this function is only permitted when the control variable is set to lcd. Information about the different kinds of setpoints that the user can ...

Page 37

37 / 55 in case the user wants to set a negative setpoint, this can be made by pressing the button +/-. The cancel button (green one) can be pressed anytime to return to the operational menu without sending any setpoint..

Page 38

38 / 55 voltage setpoint the user can introduce an independent voltage setpoint per every channel. Current setpoint the user can introduce an independent current setpoint per every channel. Active power setpoint the user can introduce an independent power setpoint per every channel. Set reactive the...

Page 39

39 / 55 in case the control variable is set to lcd, the user may change the current connection mode. Two types are available for the user to choose: independent parallel pressing the back button the user can return to the main configuration window. Mode the following screen appears when the user pre...

Page 40

40 / 55 control the following screen appears when the user presses the control button: in case the control variable is set to lcd, the user may change the current control mode. Three types of control mode are available for the user to choose: lcd modbus analog input pressing the back button the user...

Page 41

41 / 55 6. Remote communications cinergia’s power supplies can be operated and supervised remotely through an ethernet communications bus. An internal embedded pc, with cinergia’s proprietary software, allows the exchange of information between the internal can bus and the external modbus tcp/ip (et...

Page 42

42 / 55 variable modbus address (dec) size access type min max description ar_vrs 154 2 ro iq21 0 _iq(440.0) // voltage phr-phs ar_vst 156 2 ro iq21 0 _iq(440.0) // voltage phs-pht ar_vtr 158 2 ro iq21 0 _iq(440.0) // voltage pht-phr ar_vrn 162 2 ro iq21 0 _iq(440.0) // voltage phr-n ar_vsn 164 2 ro...

Page 43

43 / 55 ar_readqt 242 2 ro iq10 _iq10(-2000000) _iq10(2000000) // reactive power t ar_setq0 256 2 rw iq10 _iq10(-2000000) _iq10(2000000) // reactive power (set-point) dcdc_vab 296 2 ro iq21 0 _iq(440.0) // voltage pha-phb dcdc_vbc 298 2 ro iq21 0 _iq(440.0) // voltage phb-phc dcdc_vca 300 2 ro iq21 ...

Page 44

44 / 55 dcdc_readpc 374 2 ro iq10 _iq10(-2000000) _iq10(2000000) // active power c dcdc_setp0 388 2 rw iq10 _iq10(-2000000) _iq10(2000000) // active power global (set-point) dcdc_setpa 390 2 rw iq10 _iq10(-2000000) _iq10(2000000) // active power a (set-point) dcdc_setpb 392 2 rw iq10 _iq10(-2000000)...

Page 45

45 / 55 dcdc_setchia 454 2 rw iq21 0 0x7fffffff // recommended charging current a dcdc_setchva 456 2 rw iq21 0 0x7fffffff // equalization battery voltage a dcdc_floatingva 458 2 rw iq21 0 0x7fffffff // floating voltage a dcdc_setchpa 460 2 rw iq10 0 0x7fffffff // battery capacity a dcdc_batsoca 462 ...

Page 46

46 / 55 dcdc_alarmbatlc 512 2 rw iq21 0 0x7fffffff // battery low voltage alarm c dcdc_alarmbatmaxchc 514 2 rw iq21 0 0x7fffffff // battery max charging current alarm c dcdc_alarmbatminchc 516 2 rw iq21 0 0x7fffffff // battery max discharging current alarm c dcdc_setchic 518 2 rw iq21 0 0x7fffffff /...

Page 47

47 / 55 dcdc_maxvphc 574 2 rw iq21 0 0x7fffffff // phase c maximum allowable voltage dcdc_minvglobal 578 2 rw iq21 0 0x7fffffff // global dc minimum allowable voltage dcdc_minvpha 580 2 rw iq21 0 0x7fffffff // phase a minimum allowable voltage dcdc_minvphb 582 2 rw iq21 0 0x7fffffff // phase b minim...

Page 48

48 / 55 errors bits 7 6 5 4 3 2 1 0 definition phase overvoltage undervoltage in the dc link overvoltage in the dc link precharge overload precharge time drivers emcy sequence watchdog overvoltage in phase the dc link is discharged the dc link is overcharged overload in precharge state internal erro...

Page 49

49 / 55 6.1. Iq management many of the parameters of this equipment are defined as iq numbers (texas instruments nomenclature). An iq number refers to a 32 bit signed fixed point number where the number of fractional bits is specified. For instance, iq21 means that the number has 21 fractional bits,...

Page 50

50 / 55 iq21 functions: public double iq21tofloat(double var) { if (var > 2147483648) //if the value is bigger than 2^31 (positive) { var = var - 4294967296; // var - 2^32 var = var / (2097152); // var / (2^21) } else { var = var / (2097152); //var/(2^21) } return var; } public uint32 floattoiq21(do...

Page 51

51 / 55 7. Human machine interface cinergia delivers, within the scope of the supply, a human machine interface software that communicates with the equipment using modbus protocol. This application is based on windows 7/windows xp. The software can be installed by executing setup.Exe file in adminis...

Page 52

52 / 55 c- connection parameters for the communications: - ip of the equipment (192.168.55.204), port (502). This equipment has a fixed ip. - pooling time [ms] is the time to refresh all parameters. The minimum value recommended is 500 ms. - connect / disconnect / pause buttons d- information about ...

Page 53

53 / 55 7.3. Alarm tab in this tab, the alarm status of each converter is shown. 7.4. I, v, p configuration tab a- information and setpoints for the electrical parameters associated to the current, voltage and power operating modes. By using the send button the data is downloaded to the equipment. B...

Page 54

54 / 55 8. Warranty and maintenance fans and capacitors must be replaced at the end of their useful lifetime. Inside the equipment there are dangerous voltages and metallic parts at high temperatures even when the equipment is stopped. The direct contact may cause electrocutions and burns. All the o...

Page 55

55 / 55 • replacement of the defective product or component; the decision whether to perform the assistance on-site, to repair or replace the faulty product and/or component shall be taken in any case exclusively by cinergia. 8.5. Claim procedure the warranty rights can be exercised during the valid...