- DL manuals

- Cam

- Mixer

- SX50

- Installation Operating And Maintenance Istructions

Cam SX50 Installation Operating And Maintenance Istructions

Summary of SX50

Page 1

Spiral kneading machine models: sx50-sx60-tsx50-tsx60 tsvx50-tsvx60 installation operating and maintenance istructions.

Page 2: Eng

2 - ed.1/2012 rev.0 eng introduction read this entire manual before unpacking and installing this product. Dear client, thank you for choosing a quality product manufactured by us. Our expert production follows the guiding principle of the strictest quality control of each component so as to guarant...

Page 3: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 3 eng general table of contents section 1: general information - instructions 1.1 - introduction and safety recommendations 1.1.1 - residual risks 1.2 - machine data and use 1.2.1 - application sectors 1.3 - ec declaration of conformity 1.4...

Page 4: Eng

4 - ed.1/2012 rev.0 eng section 1 general information - instructions 1.1 introduction and safety recommendations these operating and maintenance instructions are intended to operators and qualified personnel for the correct use of the machine. In order to facilitate understanding of the content of t...

Page 5: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 5 eng 1.1.1 residual risks in compliance with section 1.7.3 “warning of residual risks” of the machine directive 89/392 and subsequent amendments, if the protections applied, also in compliance with the aforementioned directive, do not obse...

Page 6: Eng

6 - ed.1/2012 rev.0 eng 1.2.1 application sectors all the models are suitable to be used in the field of handmade or professional products, therefore, they can be used in: kitchens of restaurants, communities, canteens, pizza houses, etc. In bakeries or pasta factories. Wherever it is necessary to p...

Page 7: Eng

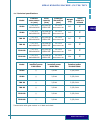

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 7 eng 1.4 technical specifications model external measuremen ts (mm) bowl capacity (mm) packages dimensions (mm) weight (kg) gears motors in oil bath sx 50 l x p x h 530x940x930 53 lt 45 kg Ø500x300 l x p x h 690x1040x1100 207 x sx 60 l x p...

Page 8: Eng

8 - ed.1/2012 rev.0 eng 1.4.1 sound level the machine has been designed to operate within the power limits established by the legislation in force. You should encounter these average sound levels in your work place during the main operating phases: no load noise 55db(a). Full load noise 67db(a). Hal...

Page 9: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 9 eng 1.5 machine description the machine consist mainly of the following groups: 1) base; 2) mixing bowl; 3) cover; 4) release lever; 5) push button control panel (1 or 2 speed); 6) column. 1.6 packaging and standard equipment in order to ...

Page 10: Eng

10 - ed.1/2012 rev.0 eng protective wrapping of semi-rigid expanded polystyrene shaped to the machine internal stability and anti-shock protection the packaging of all the models is secured to a wooden support (pallet) so that they can be perfectly handled with lifting means/transport. The standard ...

Page 11: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 11 eng 1.7.1 safety devices of the electrical equipment – wiring diagram the electrical circuits of the machine, the wiring diagram, the buttons, the switches and the selectors are all designed and manufactured in conformity with the specif...

Page 12: Eng

12 - ed.1/2012 rev.0 eng 1.7.3 operator safety the operators must: reach the age foreseen by the social laws, have good general competence and manual ability for coordination and be precise; have received proper technical and practical preparation (training) from an skilled operator; be aware of the...

Page 13: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 13 eng 3 remove the upper cover of the cardboard packaging. 4 take away the anti-static pvc bag and the expanded polystyrene. 5 unscrew the “l” elements around the machine. 6 open the packaging completely and introduce the ropes and the lif...

Page 14: Eng

14 - ed.1/2012 rev.0 eng 2.2 position in place to position the machine in place proceed as follows: step action 1 place the machine in a suitable area protected against atmospheric agents; considering the size and the space necessary for the containers of raw and finished materials. Check that there...

Page 15: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 15 eng all the components and materials necessary to perform the installation must: be done in full compliance with the laws in force and abide by the dictates of the low voltage directive and the electromagnetic compatibility directive in ...

Page 16: Eng

16 - ed.1/2012 rev.0 eng the three-phase motor 400v 50hz has two flexible wires, each of them consisting of three wires, in three different colours: the three wires of different colours of one of the two straps are short-circuited and segregated at a terminal or at a terminal board; the other three ...

Page 17: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 17 eng section 3 machine use 3.1 controls description the electrical control panel is placed in front of the machine in an ergonomic position, next to the mechanical controls and is configured as follows: a. The green warning light, if on, ...

Page 18: Eng

18 - ed.1/2012 rev.0 eng 3.2 machine start-up before starting an operating cycle, ensure that the materials that will be used are suitable and available in the quantity needed based on the kind of product that will be produced. This is the correct procedure that the operator must follow to start the...

Page 19: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 19 eng 7 introduce the plug in the socket and turn the main switch on the switchboard to “on”. 8 check pre start-up by verifying: i. Mains voltage (green light on of the control panel of the machine); ii. That the protection cover of the ro...

Page 20: Eng

20 - ed.1/2012 rev.0 eng 3.3 cleaning the machine it is recommended to clean the machine daily, both for it to be clean and to preserve it over time and ensure proper operation. It is recommended to use odourless non toxic cleaning products and for food use. Do not use abrasive detergents, anti-calc...

Page 21: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 21 eng do not wash and/or clean: i. By spraying water jets on the machine or its components; ii. By immersing the machine in liquids or detergents. 3.4 regular maintenance if the machine is used as prescribed and indicated in this manual, t...

Page 22: Eng

22 - ed.1/2012 rev.0 eng it is absolutely forbidden for the user to modify the machine for any reason. The manufacturer shall not be liable for any damages to people, animals, objects or the environment that may derive from: tampering with the machine; installation of non original spare parts; modif...

Page 23: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 23 eng section 4 spare parts – electric diagram 4.1 list of spare parts.

Page 24: Eng

24 - ed.1/2012 rev.0 eng.

Page 25: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 25 eng.

Page 26: Eng

26 - ed.1/2012 rev.0 eng.

Page 27: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 27 eng.

Page 28: Eng

28 - ed.1/2012 rev.0 eng.

Page 29: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 29 eng 4.2 connecting diagram.

Page 30: Eng

30 - ed.1/2012 rev.0 eng.

Page 31: Eng

Spiral kneading machine - sx / txs / tsvx ed.1/2012 rev.0 - 31 eng warranty conditions 1) the manufacturer guarantees the operation and the duration of the products it manufactures. These products were built in a professional manner and underwent a functioning test in the manufacturer's workshop acc...

Page 32: Eng

32 - ed.1/2012 rev.0 eng.