- DL manuals

- CAMBRIDGE

- Heater

- M-SERIES

- Technical Manual

CAMBRIDGE M-SERIES Technical Manual

M-SERIES

DRAW THRU

DIRECT GAS-FIRED

MAKE-UP AIR HEATERS

TECHNICAL MANUAL

M-TM1-0915

M110-M115 (3HP) REV. G

M115 (5HP) REV. H

M118-M136 REV. C

M140 REV. A

m

WARNING:

Improper installation, adjustment, alteration, service or maintenance can cause property dam-

age, injury or death. Read the installation, operating, and maintenance instructions thoroughly

before installing or servicing this equipment.

FOR YOUR SAFETY

The use and storage of gasoline or other flammable vapors and liquids in open containers in

the vicinity of this appliance is hazardous.

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. Don’t touch electrical switches.

3. Extinguish any open flame.

4. Immediately call your gas supplier.

Made in the USA

®

90.1

ASHRAE

ASHRAE

COMPLIANT

COMPLIANT

®

Summary of M-SERIES

Page 1

M-series draw thru direct gas-fired make-up air heaters technical manual m-tm1-0915 m110-m115 (3hp) rev. G m115 (5hp) rev. H m118-m136 rev. C m140 rev. A m warning: improper installation, adjustment, alteration, service or maintenance can cause property dam- age, injury or death. Read the installati...

Page 2

Limited warranty cambridge engineering, inc. (“manufacturer”) warrants its products (“the products”) to be free from defects in material and workmanship. Manufacturer’s m-series products shall be warranted for a period of twenty-four (24) months from the date of shipment, except that burner assembli...

Page 3: M-Series

Cambridge engineering, inc. 760 long road crossing dr. Chesterfield, mo. 63005 phone: (636) 532-2233, fax: (636) 530-6133 www.Cambridge-eng.Com m-series technical manual copyright 2015 cambridge engineering, inc. All rights reserved contents hazard summary ............................................

Page 4

Cambridge engineering, inc. 2 m-series technical manual hazard summary the following safety precautions apply to the installa- tion, operation, and maintenance of the equipment described by this technical manual. M warning: any unauthorized modification of this equipment shall void the warranty. M w...

Page 5

M-series technical manual 3 cambridge engineering, inc. Typical system overview control systems: maxitrol series 14 the maxitrol series 14 electronic discharge temperature control system maintains a constant discharge tempera- ture. The standard control permits manual adjustment of discharge tempera...

Page 6: Accessory Identification

Cambridge engineering, inc. 4 m-series technical manual typical system overview accessory identification horizontal mount roof top configuration horizontal mount outdoor pad mount configuration horizontal mount thru wall configuration (not applicable to m140) fsid ml floor ic drh ie flashing & trim ...

Page 7: Heater / Accessory Weights

M-series technical manual 5 cambridge engineering, inc. Heater / accessory weights horizontal mount (weights shown in pounds) vertical mount (weights shown in pounds) *due to shipping constraints the m140 consists of a of blower module (3625 lbs.) and burner module (1720 lbs.) **consult factory mode...

Page 8: Heater Configuration

Cambridge engineering, inc. 6 m-series technical manual heater configuration cambridge m-series draw-thru heaters provide fresh air ventilation to a facility, provide tempered air to replace the air that is mechanically exhausted, or address cold drafts from natural infiltration. Heater operation is...

Page 9: Installation Instructions

M-series technical manual 7 cambridge engineering, inc. Installation instructions uncrating instructions 1. Verify the number of items on the bill of lading versus the number of items received. 2. Check for shipping damage. If damage is found, immediately file a claim with carrier before proceeding ...

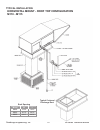

Page 10: M110 - M136

Cambridge engineering, inc. 8 m-series technical manual installation instructions horizontal mount - mounting curb m110 - m136 (shown for roof top configuration - downblast application) model a b c m110 32.38" 27.12" 48" m112 32.38" 27.12" 48" m115 32.38" 40.31" 60" m118 32.38" 44.10" 60" m120 32.38...

Page 11

M-series technical manual 9 cambridge engineering, inc. Installation instructions horizontal mount - roof top configuration m warning: due to the size and weight of this equipment, it is recommended that the heater support structure be reviewed and approved by a qualified structural engi- neer and t...

Page 12: M110 - M115

Cambridge engineering, inc. 10 m-series technical manual typical installation horizontal mount - roof top configuration m110 - m115 typical curb and discharge duct model w l m110 19.25" 19.25" m112 20.75" 20.75" m115 23.5" 23.75" roof opening typical curb and discharge duct.

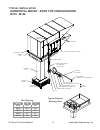

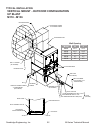

Page 13: M118 - M136

M-series technical manual 11 cambridge engineering, inc. Typical installation horizontal mount - roof top configuration m118 - m136 typical curb and discharge duct model w l m118 26.5" 26.5" m120 30.5" 30.5" m125 36" 36" m130 42" 42" m136 48" 48" roof opening gas control enclosure duct discharge lif...

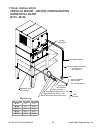

Page 14: M140

Cambridge engineering, inc. 12 m-series technical manual inlet gas pipe high pressure shut-off valve high pressure supply tap high pressure regulator (hpr) sediment trap (by others) vent pipe (by others) vent w/ screen (locate min 10 ft from intake) incoming power rcs discharge plenum hanger bracket...

Page 15

M-series technical manual 13 cambridge engineering, inc. Installation instructions horizontal mount - outdoor pad mount configuration m warning: due to the size and weight of this equipment, it is recommended the heater support structure be reviewed and approved by a qualified structural engi- neer ...

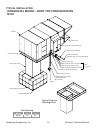

Page 16: M118 - M136

Cambridge engineering, inc. 14 m-series technical manual typical installation horizontal mount - outdoor pad mount configuration m118 - m136 typical curb typical duct interface model w l m118 25.5" 25.5" m120 29.5" 29.5" m125 35" 35" m130 41" 41" m136 47" 47" wall opening.

Page 17: M140

M-series technical manual 15 cambridge engineering, inc. Typical curb typical installation horizontal mount - outdoor pad mount configuration m140 model w l m140 54" 54" wall opening typical duct interface.

Page 18

Cambridge engineering, inc. 16 m-series technical manual installation instructions horizontal mount - thru wall configuration m warning: due to the size and weight of this equipment, it is recommended that the heater support structure be reviewed and approved by a qualified structural engi- neer bef...

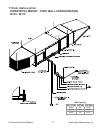

Page 19: M110 - M115

M-series technical manual 17 cambridge engineering, inc. Typical installation horizontal mount - thru wall configuration m110 - m115 model w h m110 32" 35.25" m112 32" 35.25" m115 46" 35.25" wall opening.

Page 20: M118 - M136

Cambridge engineering, inc. 18 m-series technical manual typical installation horizontal mount - thru wall configuration m118 - m136 model w h m118 50" 55" m120 56" 55" m125 68" 71.75" m130 89.75" 71.75" m136 89.75 96.75" wall opening.

Page 21

M-series technical manual 19 cambridge engineering, inc. Important before proceeding with the installation, verify the fea- sibility of the location selected with respect to acces- sibility to the equipment for service and maintenance functions. Important to prevent contaminated air from being drawn...

Page 22

Cambridge engineering, inc. 20 m-series technical manual 10. Apply a bead of latex based polyurethane caulk that best matches the color of the exterior wall surface of the facility and/or the color of the heater acces- sories at the joint between the top discharge duct and outside wall surface. Make...

Page 23: Horizontal Blast

M-series technical manual 21 cambridge engineering, inc. Typical installation vertical mount - outdoor configuration horizontal blast m118 - m136 model w h m118 25.5" 25.5" m120 29.5" 29.5" m125 35" 35" m130 41" 41" m136 47" 47" wall opening vent w/ screen (locate min. Inlet gas pipe high pressure s...

Page 24: Up Blast

Cambridge engineering, inc. 22 m-series technical manual model w h m118 25.5" 25.5" m120 29.5" 29.5" m125 35" 35" m130 41" 41" m136 47" 47" wall opening typical installation vertical mount - outdoor configuration up blast m118 - m136 external wall discharge duct unit roof duct opening collar tek scr...

Page 25

M-series technical manual 23 cambridge engineering, inc. Important before proceeding with installation, verify the feasibil- ity of the location selected with respect to accessibility to the equipment for service and maintenance func- tions. Important to prevent contaminated air from being drawn int...

Page 26

Cambridge engineering, inc. 24 m-series technical manual 10. Apply a bead of latex based polyurethane caulk that best matches the color of the exterior wall surface of the facility and/or the color of the heater accessories at the joint between the top inlet collar and outside wall surface. Make cer...

Page 27: Horizontal Blast

M-series technical manual 25 cambridge engineering, inc. Model w h m118 69" 57.5" m120 75" 57.5" m125 81" 81.5" m130 101.5" 81.5" m136 107" 81.5" wall opening typical installation vertical mount - indoor configuration horizontal blast m118 - m136 vent w/ screen (locate min. Vent pipe (by others) inl...

Page 28: Gas Piping

Cambridge engineering, inc. 26 m-series technical manual important refer to the heater rating plate for determining the minimum gas supply pressure for obtaining the maximum gas capacity for which this heater is specified. 1. Check with the local utility or gas supplier for the facility gas supply p...

Page 29: Electrical

M-series technical manual 27 cambridge engineering, inc. Important before attempting electrical installation, review the following instructions and wiring and connection dia- grams to make sure you have a thorough understand- ing of what is required. M warning: high voltage electrical input to this ...

Page 30

Cambridge engineering, inc. 28 m-series technical manual start-up instructions 1. Visual inspection of equipment (page 28) 2. Electrical supply voltage verification (page 28) 3. Gas supply pressure verification (page 29) 4. Blower rotation check (page 29) 5. Burner profile damper pressure drop check...

Page 31

M-series technical manual 29 cambridge engineering, inc. Of the disconnect switch. For model m118 - m140 heaters, check the electrical supply voltage at the disconnect switch. M caution: do not proceed with start-up unless the supply voltage agrees with the nameplate voltage. If the supply voltage d...

Page 32

Cambridge engineering, inc. 30 m-series technical manual c1. To change the profile plate pressure drop on model m110 - m115 heaters with a manual profile adjust mechanism, locate the adjust- ing mechanism in the electrical control enclo- sure, loosen the lock-down bolt, and rotate the adjuster to in...

Page 33

M-series technical manual 31 cambridge engineering, inc. Setting. If the ambient temperature exceeds its highest setting, remove the set point jumper and rotate 90˚ for the bypass mode. D. Remove the 1/8" npt plug from the manual shut-off valve located just prior to the burner and connect a manomete...

Page 34

Cambridge engineering, inc. 32 m-series technical manual switch in the closed position, and wait 30 seconds to read the manometer. If the reading is greater than 0 inch wc, refer to the maintenance instruction section for information on gas valve cleaning for cleaning the second gas valve and retest...

Page 35

M-series technical manual 33 cambridge engineering, inc. . Ii. Replace the cap (a). Tighten the lock screw (c) on the mr212 valve prior to reinstalling the cap and housing cover. Iii. Turn the blower and burner service switches to the “ off ” position. Iv. Reconnect wire #8 to the amplifier. V. Remo...

Page 36

Cambridge engineering, inc. 34 m-series technical manual c.3. If the make-up air heater is not equipped with a remote control station, activate that part of the control system which will initiate the blower and burner operation. D. After a short delay for damper operation, the blower should operate,...

Page 37: Operating Sequence

M-series technical manual 35 cambridge engineering, inc. Operating instructions operating sequence power on 1. Control transformer energized. 2. Operator must select “summer ventilation” or “heating” mode. Summer ventilation mode 1. Mode switch in “summer ventilation” position. 2. Optional tss contr...

Page 38: Electronic Thermostat

Cambridge engineering, inc. 36 m-series technical manual operating instructions electronic thermostat the cambridge engineering operating electronic thermostat (oet) controls the heater’s on/off operation in a space heating mode. It includes the following features: • digital led display of current t...

Page 39

M-series technical manual 37 cambridge engineering, inc. Setting temperatures the electronic thermostat requires two temperature set- tings. When the temperature drops below the heat on setting, the heater will turn on. When the heater raises the space temperature above the heat off setting, the hea...

Page 40: Tss Controller

Cambridge engineering, inc. 38 m-series technical manual operating instructions tss controller the cambridge engineering tss controller provides several features to tailor the operation of the cambridge heating system to particular applications. • seven day programmable clock. • separate temperature...

Page 41

M-series technical manual 39 cambridge engineering, inc. Setting current day of week, time, month/day, and year for proper operation of the scheduler, the tss controller clock must be set to the correct day of week, time, month/day and year. In the event of power loss of more than 96 hours, these se...

Page 42

Cambridge engineering, inc. 40 m-series technical manual 1. Press the setback schedule/exit button to enter the scheduling program at the first on cycle. 2. Press the up button once to enter the daylight saving time setting ("d-sa" is displayed). 3. Press and hold the year button while pressing the ...

Page 43

M-series technical manual 41 cambridge engineering, inc. 2. Press and bold the heat off button while pressing the up or the down button until the desired tempera- ture for the heater to turn off is displayed. Setback mode (off time schedule) the setback mode requires setting only the on tem- peratur...

Page 44

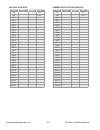

Cambridge engineering, inc. 42 m-series technical manual heating schedule cycle time am/pm day on m-f off m-f on 1 off 1 on 2 off 2 on 3 off 3 on 4 off 4 on 5 off 5 on 6 off 6 on 7 off 7 on 8 off 8 on 9 off 9 on 10 off 10 on 11 off 11 on 12 off 12 on 13 off 13 on 14 off 14 summer ventilation schedul...

Page 45

M-series technical manual 43 cambridge engineering, inc. 1. Switch the keyswitch on the front of the enclosure to the desired operating mode. Allow ten seconds before proceeding. 2. Press the setback schedule/exit button to enter the scheduling program at the first on cycle. 3. Press and bold the ti...

Page 46

Cambridge engineering, inc. 44 m-series technical manual 10. Press the up button once to step to the next off cycle. 11. Press and hold. The time button while pressing the up or the down button to scroll to the desired off time. 12. Press and hold the day of week button while pressing the up or the ...

Page 47

M-series technical manual 45 cambridge engineering, inc. 1. Press the setback schedule/exit button to enter the scheduling program at the first on cycle. 2. Press the up button repeatedly to step to the first holi- day start date (hsd1). 3. Press and hold. The month/day button while press- ing the u...

Page 48

Cambridge engineering, inc. 46 m-series technical manual temperature calibration to compensate for lead wire resistance, it may be neces- sary to make an adjustment to the displayed temperature to correct it to the temperature measured at the thermis- tor sensor. The calibration feature allows the d...

Page 49

M-series technical manual 47 cambridge engineering, inc. Maintenance instructions m warning: turn the disconnect switch off when performing service or maintenance functions. Blower bearing lubrication heaters with 3 hp or smaller motors have permanently lubricated, double shielded, and double sealed...

Page 50

Cambridge engineering, inc. 48 m-series technical manual reference heater roof and wall openings wall opening 1 roof opening 2 discharge inlet model w h w h w l m110 18.25" 18.25" 32" 35.25" 19.25" 19.25" m112 19.75" 19.75" 32" 35.25" 20.75" 20.75" m115 22.75" 22.75" 46" 35.25" 23.5" 23.75" m118 25....

Page 51: Gas Train Drawings

M-series technical manual 49 cambridge engineering, inc. Reference gas train drawings horizontal mount csa certified vertical mount > 400 mbh low pressure csa certified horizontal mount > 400 mbh high pressure csa certified.

Page 52

Cambridge engineering, inc. 50 m-series technical manual blower cleaning the blower wheel should be examined for accumulation of dust on the blades. These surfaces must be kept clean. Dirt accumulation will result in significant air flow reduction and/or possible imbalance of the blower wheel. Prolo...

Page 53

M-series technical manual 51 cambridge engineering, inc. Asco gas valves: series 8214 disassemble the valve (see page 62) and clean all parts as follows: important if parts are worn or damaged, install a complete asco rebuild kit. 1. Remove the solenoid enclosure. 2. Remove the bonnet screws, valve ...

Page 54

Cambridge engineering, inc. 52 m-series technical manual solenoid base subassembly bonnet gasket valve bonnet valve body core/diaphragm subassembly bonnet screw body gasket indicates parts supplied in asco rebuild kit. Caution do not damage valve seat locate bleed hole in core/diaphragm sub--- assem...

Page 55

M-series technical manual 53 cambridge engineering, inc. Filters filters may be installed in the v-bank filter section or in the intake of the rainhoods. These may be of the dispos- able or permanent type. Filters are removed and replaced from the v-bank filter section by opening the filter access d...

Page 56

Cambridge engineering, inc. 54 m-series technical manual * continuous filters are manufactured in lengths of 24 panels. Cut filter panels like chain links. For example, 6 (2x3) means cut 2 rows x 3 panels long for total of 6 panels of this type. Cut only between filter panels. Filters for horizontal...

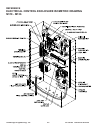

Page 57: M110 - M115

M-series technical manual 55 cambridge engineering, inc. Reference electrical control enclosure isometric drawing m110 - m115.

Page 58: M118 - M136

Cambridge engineering, inc. 56 m-series technical manual reference electrical control enclosure isometric drawing m118 - m136.

Page 59: M140

M-series technical manual 57 cambridge engineering, inc. Electrical control enclosure isometric drawing m140

Page 60: Electrical Wiring Diagrams

Cambridge engineering, inc. 58 m-series technical manual reference electrical wiring diagrams symbol description afl air flow switch - low afh air flow switch - high amp amplifier solid state ax1 auxiliary contact ax auxiliary contact cr1 control relay d & d1 damper motor & end switch disc service d...

Page 61

M-series technical manual 59 cambridge engineering, inc. Symbol description afl air flow switch - low afh air flow switch - high amp amplifier solid state ax auxiliary contact ax1 auxiliary contact ax2 auxiliary contact cr1 control relay disc service disconnect non - fused dts discharge temperature ...

Page 62

Cambridge engineering, inc. 60 m-series technical manual series 44 m140 symbol description afl air flow switch - low afh air flow switch - high amp amplifier solid state ax1 auxiliary contact ax auxiliary contact cr1 control relay d & d1 damper motor & end switch disc service disconnect non - fused ...

Page 63

M-series technical manual 61 cambridge engineering, inc. Series 44 tamperproof controls operating thermostat symbol description afl air flow switch - low afh air flow switch - high amp amplifier solid state ax1 auxiliary contact ax auxiliary contact cr1 control relay d & d1 damper motor & end switch...

Page 64

Cambridge engineering, inc. 62 m-series technical manual series 44 temperature setback system temperature averaging system tamperproof controls symbol description afl air flow switch - low afh air flow switch - high amp amplifier solid state ax1 auxiliary contact ax auxiliary contact cr1 control rel...

Page 65

M-series technical manual 63 cambridge engineering, inc. Symbol description afl air flow switch - low afh air flow switch - high amp amplifier solid state ax1 auxiliary contact ax auxiliary contact br relay - blower cr1 control relay d & d1 damper motor & end switch disc service disconnect non - fus...

Page 66

Cambridge engineering, inc. 64 m-series technical manual connection diagram provided on maxitrol series 44 systems and series 14 systems with optional rha control for maxitrol series 44 systems and series 14 systems with rha control use 2 wire shielded twisted-pair 18 awg minimum run separate from a...

Page 67

M-series technical manual 65 cambridge engineering, inc. Gas control systems maxitrol series 14 the maxitrol series 14 controls electronically modulate the burner input to maintain a selected dis- charge temperature. The discharge temperature is set on the amplifier (ad1014) between 55°f and 90°f wi...

Page 68

Cambridge engineering, inc. 66 m-series technical manual maxitrol series 44 / tamperproof the maxitrol series 44 / tamperproof controls function identically to the maxitrol series 44 con- trols (see gas control system) except the space temperature selector (t244a) is replaced with two devices. The a...

Page 69

M-series technical manual 67 cambridge engineering, inc. Damper motor the damper motor operates on 24 volts ac and transmits power to the motor starter when the damp- er blades are fully open by the closure of the damper end switch. The damper end switch is an adjustable internal auxiliary switch wh...

Page 70

Cambridge engineering, inc. 68 m-series technical manual high temperature limit the high temperature limit opens when the discharge air temperature exceeds 150˚f. This limit must be manually reset. Inclined manometer an inclined manometer with a range of -0.1 to 1.0 inch wc is provided on each heate...

Page 71

M-series technical manual 69 cambridge engineering, inc. Modulating valve also serves as the pressure regulator. The maximum gas supply pressure rating is normally determined by the exposed pressure rating of the regulat- ing device. The rv61 and rv81 are rated at 1 psig; and the mr212 is rated at 5...

Page 72

Cambridge engineering, inc. 70 m-series technical manual damper motor replacement & adjustment 1. Before re-installing the damper motor into the heater assembly, remove the black plastic weather cover from the damper motor by removing the screw that secures the cover to the damper assembly using eit...

Page 73

M-series technical manual 71 cambridge engineering, inc. 9. Remove the wire from the “g” terminal of the termi- nal block. (this is to avoid a “call-for-fan” signal from the remote control station during the next two steps). 10. Let the damper assembly hang down (suspended by the damper motor suppor...

Page 74

Cambridge engineering, inc. 72 m-series technical manual gas train drawings (fm & iri) vertical mount > 2500 mbh factory mutual (fm) compliant csa certified horizontal mount > 400 mbh industrial risk insurers (iri) compliant csa certified.

Page 75

M-series technical manual 73 cambridge engineering, inc. Troubleshooting guide problem possible cause corrective action i. No blower operation 1. Make-up air heater in reset a) outside temperature below ltc setpoin- tin vent mode b) gas valve not energized during call for heat cycle c) pressure drop...

Page 76

Cambridge engineering, inc. 74 m-series technical manual troubleshooting guide problem possible cause corrective action ii. Blower runs; no heat; flame safety relay doesn’t lock out 1. Mode selector switch a) switch in vent position a) place switch in heat position. 2. Burner service switch a) switc...

Page 77

M-series technical manual 75 cambridge engineering, inc. Troubleshooting guide problem possible cause corrective action iii. Blower runs; no heat; flame safety relay locks out (continued) 7. Regulator a) clogged vent orifice b) no supply pressure c) improper manifold pressure d) defective regulator ...

Page 78

Cambridge engineering, inc. 76 m-series technical manual troubleshooting guide problem possible cause corrective action vi. High limit tripped 1. High limit a) high limit will not reset a) replace high limit. 2. Burner overfiring a) manifold pressure too high a) adjust manifold pressure regulator to...

Page 79

M-series technical manual 77 cambridge engineering, inc. Troubleshooting guide problem possible cause corrective action viii. Modulating valve does not modulate; continuous high fire (continued) 4. Space thermostat (series 14 only) a) thermostat out of calibration b) thermostat located improperly c)...

Page 80

Cambridge engineering, inc. 78 m-series technical manual troubleshooting guide problem possible cause corrective action ix. Modulating valve does not modulate; continuous low fire (continued) 5. Space temperature selector (t244a or ts244a/td244a) a) short in sensor circuit a) replace the sensor if t...

Page 81

M-series technical manual 79 cambridge engineering, inc. Ansi/ashrae/iesna standard 90.1 overview energy efficient, genuine cambridge ® direct gas-fired heating equipment can comply with the requirements of ansi/ashrae/iesna standard 90.1. Compliance is shown on the cambridge heater nameplate. Purpo...

Page 82

Cambridge engineering, inc. 80 m-series technical manual m o d e l n o . S e r i a l n o . Date activity technician maintenance log.

Page 83

Cambridge engineering, inc. Reserves the right to change specifications, modify the design and/or substitute equivalent materials without notice as the result of code requirements, product enhancements, ongoing research/development and vendor changes beyond our control..

Page 84

760 long road crossing dr., chesterfield, mo 63006 phone: (800) 899-1989, fax: (636) 530-6133 www.Cambridge-eng.Com.