- DL manuals

- Camco

- Copier

- HEAVY DUTY SERIES INDEX DRIVES 1150E

- Service Manual

Camco HEAVY DUTY SERIES INDEX DRIVES 1150E Service Manual

®

SERVICE MANUAL

HEAVY DUTY SERIES INDEX DRIVES

MODELS

950E, 1150E, 1550E, 2050E

This is a controlled document. It is our responsibility to deliver this information to the end user of the CAMCO

indexer. Failure to deliver this, could result in your liability for injury to the user or damage to the machine.

For copies of this manual call your Customer Service Representative 800/645-5207.

WARNING

The Driving Force in Automation

Summary of HEAVY DUTY SERIES INDEX DRIVES 1150E

Page 1

® service manual heavy duty series index drives models 950e, 1150e, 1550e, 2050e this is a controlled document. It is our responsibility to deliver this information to the end user of the camco indexer. Failure to deliver this, could result in your liability for injury to the user or damage to the m...

Page 2

Table of contents introduction: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 warnings and cautions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 spare parts kit: . . . . . . . . . . . . . . . . ...

Page 3

Introduction this service manual pertains to the disassembly and assembly of camco’s heavy duty "e" series index drive models 950e, 1150e, 1550e & 2050e. This manual is to be used in conjunction with the general service manual, which describes the lubrication and general maintenance of camco index d...

Page 4

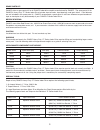

3 spare parts kit: camco offers a spare parts kit for all camco index drive models manufactured by camco. The spare parts kit for camco’s heavy duty "e" series index drive includes input oil seals, input bearings, and input shims. Cam followers are not included in the spare parts kit. Camco recommen...

Page 5

4 warning camco’s heavy duty "e" series index drives cannot be "hand cranked" when completely assembled, i.E. With follower wheel installed. During some portions of repair, the motor drive package is used to rotate the input shaft and follower wheel. Some means for running the motor at extremely low...

Page 6

Disassembly and inspection: disassembly: 1. Remove only those structural members and fixtures required to gain access to the index drive and to allow for complet- ing the necessary procedures. 2. Drain oil and flush with flushing solvent. Retain any chips or broken pieces you may find. These may aid...

Page 7

Oil seal replacement: camco recommends replacing the input oil seals (item #13) anytime the input is disas- sembled regardless of whether they are dam- aged or not. After being in service for some time, the sealing lip can become brittle and easily cracked. Most damage to oil seals occurs at assembl...

Page 8

8.1. Installation tools should have an out- side diameter .010 inch smaller than the bore size. The bore should be .005 larger than the shaft size, and the face of the tool should be relieved so that pressure is applied only near the outside diameter of the seal. 8.2. During installation press the s...

Page 9

4. Remove bore plug (item #33), the cam follower screw (item #15) and the heavy washer (item #9). Camco used red perma-lok‚ to secure these screws if you encounter difficulty when removing the screw, apply heat to the screw and remove while still warm. Caution localized heat can distort the part. Do...

Page 10

2. Install heavy-duty washer and socket head cap screw, assembled as shown in sketch titled "cam follower replacement e-series index drives" in this service manual. Use red perma-lok ® ‚ and torque the socket head cap screw to specification. The tightening torque depends on the size of the cam follo...

Page 11

1. Remove two or three cam followers. See section titled "cam follower removal" in this service manual for detailed instruc- tions on cam follower removal. 2. While referring to the sketch titled "e-series input shaft and cam removal", proceed as follows. 3. Bend lockwasher (item #20) tabs over and ...

Page 12

5.1.5. Put a hex nut on the threaded rod and run it down until the nut is snug against the plate and until the thread- ed rod is supporting the weight of the cam. Note: the hole in the follower wheel and the tapped hole in the cam do not line up exactly. The threaded rod might be at a slight angle u...

Page 13

Cartridges were removed. See sketch titled "e-series input shaft and cam removal" in this service manual. 10.1. Using diametrically opposed tapped holes, install two (2) threaded rods into the tapped holes. These rods should extend beyond the end of the input shaft sufficiently to allow for a hydrau...

Page 14

Cam removal: 1. Once the input shaft has been removed, use one of two methods to lower the cam into the bottom of the housing. 1.1. Use a lift ring on the end of the treaded rod and a boom crane to lift the cam slightly, i. E. To relieve strain on the hex nut. Then while using the lift ring to suppo...

Page 15

14 4.1. Reverse one of the methods described for lowering the cam into the housing when lifting the cam. See section titled "cam and/or input shaft replacement" in this service manual. Input shaft installation: 1. Prepare the input shaft for installation by installing the locknuts and lockwasher on ...

Page 16

7.2. Heat a new bearing cone in a commer- cial bearing oven that has been designed for this purpose. Heat evenly to about 250˚f. 7.3. Alternatively, heat the bearing with a heat gun. Warning use protective gloves while handling bearings after they have been heated in an oven. 7.4. Using a twisting m...

Page 17

2. With a depth micrometer, measure from the face of the dwell track on one side of the cam to the dowel pin. 3. Repeat this measurement from the opposite face of the dwell track to the dowel pin. 4. Use the locknuts to adjust the position of the cam relative to the dowel pin until the cam is center...

Page 18

17 12. Once proper contact has been assured, use the following procedure to tighten the locknuts and secure the lockwasher tabs. 12.1. Back off both locknuts and the lock- washer on one side of the cam. 12.2. Apply green perma-lok‚ to the threads on the input shaft. 12.3. Use a spanner wrench that h...

Page 19

18 refer to the model number of your index drive for the amount of dwell provided. Also refer to "interpretation of index drive model number" in the general service manual. Warning camco’s heavy duty "e" series index drives cannot be "hand cranked" when completely assembled, i.E. With follower wheel...

Page 20

19 3. Thread lifting eyes into the threaded holes in the bearing (two places 180 degrees apart or three places 120 degrees apart) and using a boom crane or hoist set the bearing onto the housing. 4. Coat the dowel pin holes with anti-seize lubricant and drive the dowel pins through the bearing and i...

Page 21

The bearing to ensure that new grease is being distributed throughout the bearing and not just purging past the seals. Inject the recommended amount divided by the number of stops during each index for one full revolution of the table. Warning camco’s heavy duty "e" series index drives cannot be "ha...

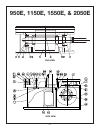

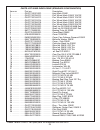

Page 22: 950E, 1150E, 1550E, & 2050E

21 950e, 1150e, 1550e, & 2050e end view side view.

Page 23

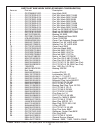

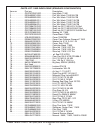

22 parts list 950e index drive (standard configuration) item no part no. Description 1. . . . . . . . . . . . G2g70588001002 . . . . . . . . . .Hsg-mach 950e 2. . . . . . . . . . . . G2d70133034010 . . . . . . . . . .Flwr whl mach 950e 10h80 2. . . . . . . . . . . . G2d70133064016 . . . . . . . . . ...

Page 24

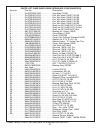

23 parts list 1150e index drive (standard configuration) item no part no. Description 1. . . . . . . . . . . . G3g70729001002. . . . . . . . . . Hsg-mach 1150e 2. . . . . . . . . . . . E3d66990014008 . . . . . . . . . . Flwr whl mach 1150e 8h128 2. . . . . . . . . . . . E3d66990024009 . . . . . . . ...

Page 25

24 parts list 1550e index drive (standard configuration) item no part no. Description 1. . . . . . . . . . . . G4g70768001002. . . . . . . . . . Hsg-mach 1550e 2. . . . . . . . . . . . G4g70349014010. . . . . . . . . . Flwr whl mach 1550e 10h128 2. . . . . . . . . . . . G4g70349024010. . . . . . . ....

Page 26

Parts list 2050e index drive (standard configuration) item no part no. Description 1 . . . . . . . . . . . .G5g71152001002 . . . . . . . . . .Hsg-mach 2050e 2 . . . . . . . . . . . .G5g71187034010 . . . . . . . . . .Flwr wheel mach 2050e 10h192 2 . . . . . . . . . . . .G5g71187044012 . . . . . . . ....

Page 27

Usa 5/00 0079.