- DL manuals

- CAME

- Gate Opener

- BX-74

- Installation Manual

CAME BX-74 Installation Manual

Summary of BX-74

Page 1

Bx series installation manual bx-74 / bx-78 automation systems for sliding gates english en.

Page 2

4.1 operator this product is engineered and manufactured by came cancelli automatici s.P.A. In compliance with current safety standards. Guaranteed 24 months if not tampered with. The operator is made of a cast aluminium part inside of which operates the irreversible, electromechanical gearmotor and...

Page 3

4.4 dimensions 4.3 description of parts (mm) 5 installation installation must be carried out by expert qualified personnel and in full compliance with current regulations. 5.1 preliminary checks before installing, do the following: • make sure that the gate is stable, and that the castors are in goo...

Page 4

Make sure you have all the tools and materials you will need for the installation at hand to work in total safety and compliance with the current standards and regulations. The following figure illustrates the minimum equipment needed by the installer. N.B.: if the cable length differs from that spe...

Page 5

- dig a pit to the side of the gate (see measurements from diagram). Prepare the corrugated tubes you will need when making connections coming from the shunt pit. N.B. The number of tubes depends on the type of system and the accessories you will hook up. The following applications are only examples...

Page 6

H - to position the plate in relation to the rack please see the measurements on the diagram. Fill the form box with cement and wait for at least 24 hours for it to solidify. - remove the form box, fi ll the pit around the cement block with soil. - unbolt the nuts and washers from the bolts. The secu...

Page 7

- remove the cover from the gearmotor by loosening the side bolts, perforate the cable shafts using a screwdriver or a pair of scissors and position the gearmotor atop the plate. Careful! The electric cables must pass through the cable shafts. - lift the gearmotor from the securing plate by about 5 ...

Page 8

- open and close the gate manually and register the pinion-to-rack distance using the threaded steel-levelling feet (for vertical adjusting) and the slotted holes (horizontal adjusting). This prevents the weight of the gate from bearing on the operator. Once adjustments are fi nished, secure the asse...

Page 9

5.7 manually releasing the gearmotor - insert the trilobed key into the lock, push it in and turn it clockwise .... 5.6 mounting the endstop fins place the endstop fi ns onto the rack and secure them using a 3 mm allen wrench. Their positioning limits the gate run. Note: the gate schould not slam aga...

Page 10

6.1 general description 6 control board f u s e ta b l e to protect: fuse: control board (line) 5a-f accessories 1a-f command devices 630ma-f t e c h n i c a l i n f o r m at i o n power supply 230v - 50/60 hz maximum power allowed 200 w (bx74) 300 w (bx78) absorption at rest 2,6a (bx74) 2,4a (bx78)...

Page 11

6.3 electrical connections terminals for powering the following accessories: - 24v a.C. Maximum allowed power: 35w power supply for accessories + - com nc nc com gearmotor, endstop and encoder modifications to the electrical connections for right-hand installations orange orange red white black red ...

Page 12

Cycle lamp: (contact rating: 230v – 60w max.). It lights up the driving area and stays on from the moment the gate begins to open until it is fully closed (including the auto- matic closing time). If automatic closing is not activated, the lamp stays on only during movement. Set dip 1 and 6 switch t...

Page 13

«partial stop» (n.C.) contact - input for en 12978 standard-compliant safety devices such as photocells. Gate stops if moving and automatically shuts (if this functions has been selected). Safety devices rx tx dir photocells (n.C.) contact for «re-open during closing phase» - input for en 12978 stan...

Page 14

Dip-switch 10 1 on - automatic closing - the automatic closing timer activates at the end of the opening gate run. The pre-set time is adjustable, and is in any case conditioned by the activation of any safety devices, and does not activate after a total safety “stop” or during a blackout. 2 on - "o...

Page 15

6.6 programming decelerations so as to fully meet the compliance requirements established by european standards en 12445 and en 12453 on matters concerning maximum impact forces, bx-74/78 is set up for deceleration at 50 cm from the opening and closing endpoints. When installing all you need to do i...

Page 16

7 activating the radio command • • • • •• • • 1 2 3 4 o n 5 6 7 8 9 1 0 1 2 3 4 o n 6.8 motor torque limiter to vary the motor torque, move the shown faston (the one with the black wire) to one of the 4 posi- tions: 1 min – 4 max. • • • • •• • • • • • • •• • • ,4 ,4 white red black antenna connect t...

Page 17

• • • • •• • • • • • • •• • • 1 2 3 4 o n 5 6 7 8 9 1 0 1 2 3 4 o n transmitters insert the radio frequency card into the electronic card after disconnecting the power (and disconnecting any batteries). N.B.: the electronic card picks up the radiofrequency card on when it is running on power radiofr...

Page 18

• • • • •• • • • • • • •• • • af 1 2 3 4 o n 5 6 7 8 9 1 0 1 2 3 4 o n • • • • •• • • • • • • •• • • af 1 2 3 4 o n 5 6 7 8 9 1 0 1 2 3 4 o n led on - repeat the procedure for the “ch2” button associating this to another button on the transmitter. Ch2 t2 t1 led flashing ch1 af • • • • •• • • • • • •...

Page 19

A 1) coordinate the direction of travel of geared motors “a” and “b”, by modifying the rotation of motor “b” (see p. 11 geared motor- endstop connection) 2) carry out the electrical connections on the geared-motor “a” command card as per paragraph 6.3 electrical connections. A b 8 connecting two joi...

Page 20

9 safety instructions this product must only be employed for its originally intended use. Any other use is wrong and potentially dangerous. The manufacturer cannot be held liable for any damages resulting from wrongful, erroneous or negligent uses. Avoid working close to the hinges or other moving m...

Page 21

10 maintenance 10.1 periodic maintenance periodic maintenance to be carried out by the end-user is as follows: wipe clean the glass surface of the photocells; check that the safety devices work properly; remove any obstructions. We suggest checking the state of lubrication and tightness of the ancho...

Page 22

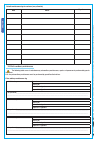

10.3 extra-ordinary maintenance the following table serves to note down any extraordinary maintenance, repairs or improvements performed by specia- lised firms. N.B.: any extraordinary maintenance must be performed by specialised technicians. Extra-ordinary maintenance log date notes signature perio...

Page 23

11 phasing out and disposal came cancelli automatici s.P.A. Via martiri della libertà, 15 31030 dosson di casier - treviso - italy tel (+39) 0422 4940 - fax (+39) 0422 4941 internet: www.Came.It - e-mail: info@came.It declares under its own responsibility that the equipments for automatic garage doo...

Page 24

Came france s.A. Came france s.A. 7, rue des haras z.I. Des hautes patures 92737 nanterre cedex - nanterre cedex - france (+33) 1 46 13 05 05 (+33) 1 46 13 05 00 came gmbh seefeld came gmbh seefeld akazienstrasse, 9 16356 seefeld seefeld bei berlin - deutschland (+49) 33 3988390 (+49) 33 39883985 ca...