- DL manuals

- CAME

- Garage Door Opener

- BX10

- Installation Manual

CAME BX10 Installation Manual

Summary of BX10

Page 1

Bx series installation manual bx10 automation systems for sliding gates english en.

Page 2

4.1 operator 4 description 2.1 intended use 1 legend of symbols this symbol tells you to read the section with particular care. This symbol tells you that the sections concern safety issues. This symbol tells you what to say to the end-users. 2 conditions of use the bx10 operator is designed to powe...

Page 3

4.4 dimensions 4.3 description of parts (mm) 5 installation installation must be carried out by expert qualified personnel and in full compliance with current regulations. 5.1 preliminary checks before installing, do the following: • make sure that the gate is stable, and that the castors are in goo...

Page 4

Make sure you have all the tools and materials you will need for the installation at hand to work in total safety and compliance with the current standards and regulations. The following figure illustrates the minimum equipment needed by the installer. N.B.: if the cable length differs from that spe...

Page 5

- dig a pit to the side of the gate (see measurements from diagram). Prepare the corrugated tubes you will need when making connections coming from the shunt pit. N.B. The number of tubes depends on the type of system and the accessories you will hook up. The following applications are only examples...

Page 6

H - to position the plate in relation to the rack please see the measurements on the diagram. Fill the form box with cement and wait for at least 24 hours for it to solidify. - remove the form box, fi ll the pit around the cement block with soil. - unbolt the nuts and washers from the bolts. The secu...

Page 7

- remove the cover from the gearmotor by loosening the side bolts, perforate the cable shafts using a screwdriver or a pair of scissors and position the gearmotor atop the plate. Careful! The electric cables must pass through the cable shafts. - lift the gearmotor from the securing plate by about 5 ...

Page 8

- open and close the gate manually and register the pinion-to-rack distance using the threaded steel-levelling feet (for vertical adjusting) and the slotted holes (horizontal adjusting). This prevents the weight of the gate from bearing on the operator. Once adjustments are fi nished, secure the asse...

Page 9

5.7 manually releasing the gearmotor - insert the trilobed key into the lock, push it in and turn it clockwise .... 5.6 mounting the endstop fins place the endstop fi ns onto the rack and secure them using a 3 mm allen wrench. Their positioning limits the gate run. Note: the gate schould not slam aga...

Page 10

F u s e ta b l e z b x 1 0 to protect: fuse: control board (line) 3.15a-f accessories 1.6a-f command devices 1a-f t e c h n i c a l i n f o r m at i o n power supply 230v - 50/60 hz maximum power allowed 300 w absorption at rest 110 ma maximum power for 24v accessories 37 w 6 control board 6.1 gener...

Page 11

6.3 electrical connections 230v (a.C.) motor with encoder closing microswitch gearmotor, endstop and encoder modifications to the electrical connections for right-hand installations invert the gearmotor (u-v) and (fa-fc) endstop phases. Opening microswitch description of the standard electrical conn...

Page 12

Open-gate status light (contact range: 24v – 3w max) - signal that gate is open; turns off when gate is closed. Movement fl ashing light (contact range: 230v – 25w max) - flashes during the gate’s opening and closing phases. Command and control devices warning devices %%87 cycle lamp: (contact rating...

Page 13

Safety devices rx tx confi gure either (n.C.) contacts cx or cy, input for safety devices such as photocells, that comply with en 12978 standards. See cx or cy input functions in: - c1 «re-open during closing phase» , when the gate leaf is closing, opening the contact triggers the inversion of the di...

Page 14

6.4 electrical connection to operate the photocells’ safety test 4 3 2 1 ,4 ,4 ,4 ,4 #4 63 ./ .# # &53)"),%m! 48 48 48 # .# (doc) (dir) at each open/close command, the card check the photocells’ effi ciency. Any problems with the photocells will cause the (prog) led to fl ash on the electronic card, w...

Page 15

7.1 description of display commands the enter key is for: - entering the menu - confirming and memorising set values the esc key is for: - exiting the menu - cancelling modifications the keys are for: - shifting from one menu item to another - increase or decrease values the symbols on the display a...

Page 16

7.3 menu structure language > > > enter > enter > > enter > > enter > > > enter > > enter > > enter > enter > enter enter enter enter enter do you conf.? > enter enter enter ver. 1.0 > 16480 > > > > > > > > > > reading ooooooo ••• writing ooooooo ••• n.001 in use > n.002 empty > enter n.001 in use >...

Page 17

> enter > enter > > enter > > > > > > > enter > > enter > > enter > enter > > > > > > enter > > enter > > enter > enter > > > > enter > > enter > > > > > > > > > > > > > > > > > enter > > pa g. 1 7 17 - ma n u al c od e: 11 9 b u 5 7 11 9 b u 5 7 ve r. 0 .2 0. 2 0 2 /2 0 0 8 © c a m e c an celli aut...

Page 18

7.3 main menu language english functions timing adj. Radio usrs adjustments info press enter for 1 second 7.4 language menu select language: selects among the languages displayed. English language language language language language functions functions timing adj. Iming adj radio usrs adio usrs adju...

Page 19

X 2 pre-flashing : after an opening or closing command, the fl ashing light, connected to w-e1, starts fl ashing before the gate begins its run (to set the time, see “pre-fl ashing timing” from the adjust timings menu x 2 off preflash preflash maintained action: the gate works by keeping the button pre...

Page 20

X 2 x 8 cy input: n.C. Safety contact input, lets you pair up the following functions: c1 (re-opening during closing), c2 (re-closing during ope- ning), c3 (partial stop), c4 (obstacle stall), or, deactivated c7 input: n.C. Safety contact input (re-opening when closing). This input is for en 12978-c...

Page 21

X 2 x 12 safety test : allows the card to check the efficiency of any safety devices (i.E. Photocells) after every opening or closing com- mand. Lamp output: to configure the lamp connected to e1-ex: - cycle: outdoor lamp, which can be positioned at leisure, for better illumination in the parking/dr...

Page 22

X 2 x 2 x 2 x 2 10 s a.C.T. A.C.T. 7.6 time setting menu automatic closing: to set the waiting time when gate is in the open position. Once this time is elapsed, the gate closes automatically. The waiting time can be set to between 0” and 120”. 90 s cycle time working time: the motor’s working time ...

Page 23

X 2 users radio menu related func. New user: to create a new user and assigned function (see detailed function on page 27). The user will be assigned a number (max. 250 users) with a function. X 2 related func. Related func. Modify user modify user: to modify a user’s assigned function (see detailed...

Page 24

Load memory: to load the data saved on the memory roll onto card do you confirm? Cancel all: to cancel all registered users. Confirm cancellation of all users with enter. Gate-run calibration: to calibrate the opening and closing gate-run. 7.8 calibration menu reading ooooooo x 4 ••• do you confirm?...

Page 25

Deceleration speed: to adjust the deceleration speed when opening and closing. X 2 slow.Down spd. •••• -ooooo+ slow.Down spd. ••• ••• x 2 gate-run sensitivity: to calibrate the amperometric sensitivity that controls the force generated by the motor during movement; if the force exceeds the calibrate...

Page 26

Brake force: to calibrate the braking force on the gate during run-inversions and at endstops. X 2 -oooo+ brake force • • x 6 brake force • disabled net address web address: to define the master card or slave in paired connections (see detailed function on page 29). X 2 net address net address x 7 7...

Page 27

Frequency/mhz card transmitter fm 26.995 af130 tfm fm 30.900 af150 tfm am 26.995 af26 top am 30.900 af30 top am 433.92 af43s tam / top atomo / twin am 433.92 af43tw twin am 40.685 af40 touch new user Þ ß related func. 2-7 function Þ ß 1 ) from the radio users menu, select “ new user”. Press enter to...

Page 28

7.12 modifying user (modifying the function) 7.13 gate-run calibration modify user Þ ß modify user n.001 in use Þ ß 1 ) from the users radio menu, select “modify user”. Press enter to con- firm. 2 ) select the user number or name for which you wish to modify the assigned function and press enter to ...

Page 29

7.14 net address net address disabled Þ ß 1 ) on the master card. From the calibration menu, select “net address” and press enter. 2 ) select “master” and press enter to confirm the calibration. Rse card the “net address” function is set when connecting two paired operators. Connect the two cards us...

Page 30

8 safety instructions this product must only be employed for its originally intended use. Any other use is wrong and potentially dangerous. The manufacturer cannot be held liable for any damages resulting from wrongful, erroneous or negligent uses. Avoid working close to the hinges or other moving m...

Page 31

9 maintenance 9.1 periodic maintenance periodic maintenance to be carried out by the end-user is as follows: wipe clean the glass surface of the photocells; check that the safety devices work properly; remove any obstructions. We suggest checking the state of lubrication and tightness of the anchori...

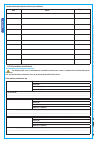

Page 32

9.3 extra-ordinary maintenance the following table serves to note down any extraordinary maintenance, repairs or improvements performed by specia- lised firms. N.B.: any extraordinary maintenance must be performed by specialised technicians. Extra-ordinary maintenance log date notes signature period...

Page 33

10 phasing out and disposal came cancelli automatici s.P.A. Via martiri della libertà, 15 31030 dosson di casier - treviso - italy tel (+39) 0422 4940 - fax (+39) 0422 4941 internet: www.Came.It - e-mail: info@came.It declares under its own responsibility that the equipments for automatic garage doo...

Page 34

Came france s.A. Came france s.A. 7, rue des haras z.I. Des hautes patures 92737 nanterre cedex - nanterre cedex - france (+33) 1 46 13 05 05 (+33) 1 46 13 05 00 came gmbh seefeld came gmbh seefeld akazienstrasse, 9 16356 seefeld seefeld bei berlin - deutschland (+49) 33 3988390 (+49) 33 39883985 ca...