Came united kingdom ltd unit 3 orchard park industrial estate, town street, sandiacre, nottingham ng10 5bp tel: 0115 921 0430 fax: 0115 921 0431 internet - www.Cameuk.Com e-mail - enquiries@cameuk.Com technical helpline 0115 921 0430 ver kit installation instructions kit u 4281 includes: 1 x 001 v 6...

1 introduction these instructions will show you how to install a ver automatic traction system for overhead and sectional doors. 1 - ver unit 2 - incorporated control panel accessories 3 - radio receiver 4 - internal pushbutton under no circumstances should this equipment be operated unless fitted t...

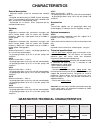

2 r o t o m r a e g t h g i e w y l p p u s r e w o p n o i t p r o s b a r o t o m r e w o p x a m e l c y c y t u d e c r o f n o i t c a r t d e e p s e g a r e v a 0 0 6 v g k 7 , 5 . C . A v 0 3 2 x a m a 6 w 0 3 1 % 0 5 n 0 0 5 n i m / m 6 0 0 7 v g k 9 , 5 x a m a 1 1 w 0 6 2 n 0 5 8 characte...

3 * for heights exceding 540 mm., it is necessary to use additional brackets or struts cable exit 400 212 140 18 540 max* * c b a a - sectional door b - spring-balanced overhead door c - overhead door with counterweight balancing examples of applications use onl y 250v fuses n l examples of applicat...

4 m6x14 m6 = = v122 upper edge of door 30 ÷ 60 cm = = spring-bar unit assembly prearrangement of transmission guide - fasten the bracket to the transmission guide’s front terminal with the nuts and bolts provided; transmission guide fastening - fasten the transmission guide in the following manner: ...

5 = = = = v201 10 ÷ 20 mm fig. 1 b) for spring garage-type doors, fasten the bracket on the fixed frame with adequate screws or rivets. C) for garage-type doors with counterweights or canopy doors, verify the maximum door sliding point (fig.1) and consequently fasten the bracket on high with adequat...

6 Ø7 m6x14 m6x14 m6 - raise and set the guide horizontally to establish the distance from the ceiling; then fasten the angle sections or fastening brackets provided (cutting off any excess part) to the guide’s back terminal. N.B. The transmission guide has three ø7 holes for further fastening should...

7 sliding lever fastening - centrally fix the sliding lever to the door’s upper crosspiece with the rivets provided; - mount the unlocking handle by screwing it to the preassembled unlocking unit’s revolving plug and fasten it in the recommended position with the lock nut; - move the sliding runner ...

8 ø6,3x45 came ø3,9x13 v121 gear motor installation - remove the automation container cover by unscrewing the ø3.9x13 screw; - fasten the container to the sliding guide’s back terminal in the desired position with the ø6.3x45 screws provided; gear motor unlocking - turn the handle as illustrated; th...

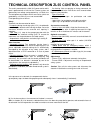

9 b) if in the clos re technical description zl55 control panel the card is powered with a 230v (ac) power outlet and its input is protected with a 1.6a line fuse. Control systems are powered by low voltage and protected by a 315ma fuse. The total power consumption of 24v accessories (which are prot...

10 0v 230v 0 17 26 t.C.A. Sens. Fus. Motore 8a fus. Acc. 3,15a fus. Centr. 630ma ch1 apre ap / ch af green red white - white red red br o w n green/yello w white blue red 34v 26v17v 0v m n fa fc f 8 4 6 10 11 12 13 14 15 16 17 18 19 3 5 20 21 7 9 2 1 t.C.A. Sens. Fus. Motore 8a ch1 ch2 apre chiude a...

11 electrical connections m n fa fc f 10 11 e e3 1 2 3 7 c1 24 (dc) motor connection limit switch open (n.C.) connection limit switch closes (n.C.) powering accessories (maxc 40w) - 24v (a.C.) with power supply at 230v (a.C.) - 23v (d.C.) with power supply at 24v (a.C.) 24v output in motion (e.G. Fl...

12 adjustments trimmer t.C.A. = automatic closing time adjustment trimmer sens. = amperometric sensitivity adjustment t.C.A. Zl55 sens. Fus. Motore 8a 2 1 2 1 3456789 1 0 on fus. Acc. 3,15a fus. Centr. 630ma ch1 apre ap / ch af t.C.A. Sens. T.C.A. 120" 1" sens. Max. Min. Minimum power maximum power.

13 t.C.A. Zl55 sens. Fus. Motore 8a 2 1 2 1 3456789 1 0 on fus. Acc. 3,15a fus. Centr. 630ma ch1 apre ap / ch af 2 1 3 456789 1 0 on on off t.C.A. Zl55 sens. Fus. Motore 8a 2 1 2 1 3456789 1 0 on fus. Acc. 3,15a fus. Centr. 630ma ch1 apre ap / ch af 1 2 on off selection of functions 10-way dip-switc...

14 .A. Sens. 2 1 3 456789 1 0 on ap / ch 6 on t.C.A. Sens. 2 1 3 456789 1 0 on ap / ch 6 off t.C.A. Sens. Ap / ch 2 1 3456789 1 0 on opening end-stop microswitch white cam adjusting the limit switches important: read instructions carefully before proceeding with adjustments. During opening there is ...

15 t.C.A. Sens. Ap / ch 2 1 3456789 1 0 on red cam closing end-stop microswitch sens. 2 1 3456789 1 0 on ap / ch 10 on closing end-stop adjustment - set dip 10 to on. - keep the "ap/ch" key pressed until the door reaches the closing ledge position. - turn the red cam until the closing end-stop micro...

16 20 cm t.C.A. Sens. Ap / ch 2 1 3 456789 1 0 on t.C.A. Sens. 2 1 3456789 1 0 on ap / ch 10 off red cam closing end-stop microswitch slowing when closing end-stop adjustment - set dip 10 to off. - keep the “ap/ch” key pressed until the door is approximately 20 cm from the closing ledge; - turn the ...

17 sliding block mechanical end-stop sliding block mechanical end-stop safety screw-locks with the door either open or closed, set safety screw-locks placed in the transmission guide on the sliding runner and screw them on..

Motherboard "af" board t.C.A. Zl55 sens. 2 1 2 1 3456789 1 0 on ch1 apre ap / ch af 18 radio control installation procedure a. Insert an af card **. B. Encode transmitter/s. C. Store code in the motherboard. The af board should always be inserted when the power is off because the motherboard only re...

19 transmitter encoding use on existing system (with top at 433.92 mhz) 1. Press the key to encode until, after 7 seconds of flashing, the red signalling led remians on. (fig a) 2. Within 10 seconds, bring the existing transmitter closer from the rear part and press the pushbutton you want to copy f...

Zl55 zl55e fus. Motore 8a 2 1 fus. Acc. 3,15a fus. Centr. 630ma ch1 apre ap / ch af zl55 zl55e fus. Motore 8a 2 1 a fus. Centr. 630ma ch1 apre ap / ch af "ch1" flashing led lit led "af" board 20 p eriodic maintenance code storage keep the ch1 key pressed on the base card (the signal led will flash),...

Notes.

Notes.

Contact information came united kingdom ltd unit 3 orchard park industrial estate town street, sandiacre, nottingham ng10 5bp tel: 0115 921 0430 fax: 0115 921 0431 internet : www.Cameuk.Com e-mail: enquiries@cameuk.Com this installation was completed by: ................................................