- DL manuals

- Cameron

- Measuring Instruments

- Scanner 2000 microEFM

- Hardware User Manual

Cameron Scanner 2000 microEFM Hardware User Manual

Summary of Scanner 2000 microEFM

Page 1

Nuflo™ scanner ® 2000 microefm hardware user manual manual no. 9a-30165023, rev. 10

Page 2: Important Safety Information

Important safety information symbols and terms used in this manual ! Warning: this symbol identifies information about practices or circumstances that can lead to per- sonal injury or death, property damage, or economic loss. Caution: indicates actions or procedures which if not performed correctly ...

Page 3

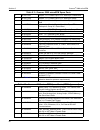

Iii scanner ® 2000 microefm table of contents contents important safety information ...............................................................................................................................Ii section 1—introduction ..................................................................

Page 4

Iv table of contents scanner ® 2000 microefm installation procedure—direct mount to a barton 7000 series turbine meter (atex compliant) ............ 55 performing a manifold leak test .......................................................................................................................

Page 5

V scanner ® 2000 microefm table of contents usb communications adapter (csa div. 1 or div. 2) .....................................................................................A-6 covering the adapter ...................................................................................................

Page 6

Vi table of contents scanner ® 2000 microefm firmware version/register table version ........................................................................................................D-5 manufacture date/sales date ..................................................................................

Page 7: Section 1—Introduction

7 scanner ® 2000 microefm section 1 section 1—introduction the nuflo scanner 2000 microefm packs the gas, steam, and liquid measurement capabilities commonly available only in large instruments into a compact, low-power flow computer. The device is available in a csa-approved explosion-proof and wea...

Page 8

8 section 1 scanner ® 2000 microefm flow rate and fluid property calculations the scanner 2000 calculates flow rates and fluid properties for natural gas, steam and liquid flow. The following descriptions identify the industry standards upon which these calculations are based. Natural gas the scanne...

Page 9

9 scanner ® 2000 microefm section 1 nuflo cone meter (dp input). The scanner 2000 supports steam measurement using industry-recognized algorithms identified in the nuflo cone meter user manual. Fluid properties for steam are calculated in accordance with the iapws industrial-formulation 1997 (if-97)...

Page 10: Standard Features

10 section 1 scanner ® 2000 microefm standard features the standard scanner 2000 microefm features an explosion-proof enclosure with two conduit openings for signal cable, a large lcd, a three-button keypad, integral multi-variable transmitter with integral vent plugs, and a lithium double-d cell ba...

Page 11

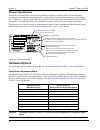

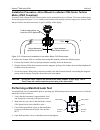

11 scanner ® 2000 microefm section 1 lcd / keypad csa-approved 3/4 in. To 1 in. Adapter csa-approved union (connects directly to the turbine meter) lcd / keypad mount for pole-mount hardware ground screw conduit plug enclosure lid (remove to access keypad) figure 1.2—scanner 2000 microefm for direct...

Page 12: Hardware Options

12 section 1 scanner ® 2000 microefm product identification each device is labeled with a serial tag that identifies the product by model number and serial number and identifies the maximum operating pressure, working pressure, and differential pressure of the integral mvt (figure 1.4). The tag cont...

Page 13

13 scanner ® 2000 microefm section 1 control switch during normal operation, the lcd displays the selected parameters in a continuous scroll. The control switch allows the user to manually control the display of parameters on the lcd and view daily logs instantaneously without removing the instrumen...

Page 14

14 section 1 scanner ® 2000 microefm the nuflo solar power and communications unit (part no. 9a-1000-1086t) continuously powers the scanner 2000 and provides short haul (250m) wifi communication to a user’s pc. A user can download configuration settings or flow data without entering the hazardous lo...

Page 15

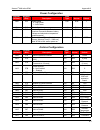

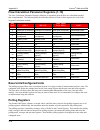

15 scanner ® 2000 microefm section 1 table 1.1—scanner 2000 microefm specifications electrical safety classification (standard scanner 2000 and scanner 2000 with expansion board) approved by csa for us and canada class i, div. 1, groups b, c, d (explosion-proof) class i, div. 2, groups a,b,c,d (non-...

Page 16

16 section 1 scanner ® 2000 microefm table 1.1—scanner 2000 microefm specifications logging daily records: 768 (>2 years) interval records: • adjustable from 5 sec to 12 hours • 2304 (>3 months of 1-hour intervals) with main board • 6392 (>8 months of 1-hour intervals) with main board and expansion ...

Page 17

17 scanner ® 2000 microefm section 1 table 1.1—scanner 2000 microefm specifications flow rate calculations (cont’d) compensated liquids (orifice/nuflo cone/turbine): aga report no. 3: orifice metering of natural gas and other related hydrocarbon fluids; iso 5167: measurement of fluid flow by means o...

Page 18

18 section 1 scanner ® 2000 microefm table 1.1—scanner 2000 microefm specifications mvt accuracy effect on differential pressure for a 100-psi change in static pressure: sp/swp (psia) dp (in h2o) max. Overrange (psia) zero shift span shift 100 30 150 ±0.05% of url ±0.01% of reading 300 200 450 ±0.00...

Page 19

19 scanner ® 2000 microefm section 1 table 1.1—scanner 2000 microefm specifications inputs (expansion board); not applicable to f oundation ™ fieldbus configurations analog input (2) • 3-wire sensor interface • 1-5v or 4-20 ma • sensor power same as external power supply for main board (6 to 30 vdc)...

Page 20

20 section 1 scanner ® 2000 microefm table 1.1—scanner 2000 microefm specifications output (expansion board) not applicable to f oundation ™ fieldbus configurations analog output • 4-20 ma • accuracy: 0.1% of full scale @ 25°c (77°f), 50 ppm/°c (27.8 ppm/°f) temperature drift • represents any measur...

Page 21: Power Options

21 scanner ® 2000 microefm section 1 power options the standard scanner 2000 microefm can be powered two ways: • with the internal lithium battery pack supplied with each scanner 2000 (shown in figure 1.5) • with an external customer-supplied power supply (6 to 30 vdc); the lithium battery provides ...

Page 22: Lcd/keypad Functions

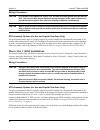

22 section 1 scanner ® 2000 microefm figure 1.6—modworx™ pro software interface the standard scanner 2000 microefm saves up to 2304 interval logs (interval periods are adjustable from 5 sec to 12 hours ), 768 daily logs, and 1152 event/alarm logs in nonvolatile memory. With the optional expansion bo...

Page 23

23 scanner ® 2000 microefm section 1 section 4—configuration and operation via keypad, guides users step by step through the configuration of these parameters using the keypad. Figure 1.7 summarizes the functions that can be accessed with each button. Test access configuration: move between menus an...

Page 24

24 section 1 scanner ® 2000 microefm parameter changes when left arrow button is pressed figure 1.8—lcd display of real-time measurements note if the instrument is equipped with an explosion-proof switch, the user can manually control the pa- rameter displayed without removing the instrument cover. ...

Page 25: Password-Protected Security

25 scanner ® 2000 microefm section 1 log archive—up to 768 daily logs, 2304 adjustable interval logs, and 1152 event/alarm logs— can be viewed using modworx™ pro software. Log index (days since log was created) volume (or other assigned parameter) date stamp (mmddyy) figure 1.10—lcd display of daily...

Page 26

26 section 1 scanner ® 2000 microefm.

Page 27: Overview

27 scanner ® 2000 microefm section 2 section 2—installing the scanner 2000 overview the scanner 2000 microefm is fully assembled at the time of shipment and ready for mounting. However, cameron recommends that operators configure the microefm prior to mounting if the instrument is to be installed in...

Page 28

28 section 2 scanner ® 2000 microefm wiring precautions caution in accordance with en60079-0, clause 16.5, all cable and cable glands must be rated for 80ºc. The scanner 2000 may be fitted as a remote unit when all the cable entries are fit- ted with flameproof glands that have been suitably certifi...

Page 29: Pressure Safety Precautions

29 scanner ® 2000 microefm section 2 class i, div. 2 (csa) installations the scanner 2000 is certified for class i, division 2, groups b, c and d hazardous locations. Wiring precautions caution all field wiring must conform to the national electrical code, nfpa 70, article 501-4(b) for installations...

Page 30: Mounting Options

30 section 2 scanner ® 2000 microefm mounting options the scanner 2000 microefm can be mounted using the following methods: • direct-mount to an orifice or cone type dp meter. The integral multi-variable sensor may be connected to the pressure taps with stabilizers or a heavy wall nipple with adapte...

Page 31

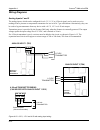

31 scanner ® 2000 microefm section 2 mvt adapter mvt 4.96 (126.0) 5.71 (145.0) 5.32 (135.1) 0.32 (8.1) 5.00 (127) 9.60 (243.8) 1/4-18 npt process connections 2.125 (53.98) 5.32 (135.1) 4.94 (125.5) figure 2.1—scanner 2000 with direct-mount mvt (mvt with bottom ports shown) 3/4” npt to 1” npt m/f ada...

Page 32

32 section 2 scanner ® 2000 microefm 7000 series turbine meter m20 to 3/4”-14 npt reducer 3/4”-14 npt to m20 stand-off tube approx. 9.00 (228.6) figure 2.3—scanner 2000 direct-mounted to a barton 7000 series flowmeter (atex-approved only when direct-mounted to a barton 7000 series flowmeter) pole mo...

Page 33

33 scanner ® 2000 microefm section 2 measuring natural gas via a differential pressure meter note this section contains installation guidelines for orifice and cone meters. If installing the scanner 2000 with an averaging pitot tube meter, refer to manufacturer instructions for installation. Best pr...

Page 34

34 section 2 scanner ® 2000 microefm if the scanner 2000 is mounted to a cone meter, consider the following best practices in addition to the best practices listed above. • position the cone meter so that there are zero to five pipe diameters upstream of the meter and zero to three pipe diameters do...

Page 35

35 scanner ® 2000 microefm section 2 1. Verify that the meter is properly installed in the flow line (per manufacturer’s instructions). 2. Bolt a flange-by-flange 5-valve manifold (as recommended by cameron) to the scanner 2000 mvt sen- sor. A. Locate the h and l markings on the integral mvt sensor ...

Page 36

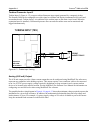

36 section 2 scanner ® 2000 microefm note to prevent fittings from turning and/or to avoid putting tension on stainless steel tubing, use a backup wrench to attach stainless steel tubing to a manifold, shut-off valves, or sensor ports. Flow manifold pressure ports (high/low) l h h l 3/4” conduit con...

Page 37

37 scanner ® 2000 microefm section 2 caution do not use teflon ® tape on the threads of the union, adapter, or pipe plugs. Use of teflon ® tape will void the explosion-proof rating of the instrument. 5. Install the rtd assembly in the thermowell. Route the rtd assembly cable through the conduit open...

Page 38

38 section 2 scanner ® 2000 microefm measuring natural gas via a turbine meter best practices the scanner 2000 microefm calculates gas flow through a turbine meter in accordance with aga-7 and api 21.1 industry standards. For optimum performance, ensure that the turbine and scanner 2000 installation...

Page 39

39 scanner ® 2000 microefm section 2 5. Remove the plug from the conduit opening in the top of the scanner 2000 enclosure, route the turbine sig- nal cable through the opening, and connect it to the main circuit board. A wiring diagram for the turbine input is provided in figure 3.4, page 65 . For h...

Page 40

40 section 2 scanner ® 2000 microefm installation procedure—direct mount to a turbine meter (csa compliant) a scanner 2000 without the mvt bottomworks can be mounted directly to a gas turbine meter for measuring natural gas. A pipe adapter and union are attached to the scanner, allowing a direct con...

Page 41

41 scanner ® 2000 microefm section 2 4. Tighten all sections of the pipe union. 5. Connect the pressure port of the turbine meter to the external pressure transducer. 6. Remove the plug from the conduit opening in the top of the scanner 2000 enclosure, route the cable from the pressure transducer th...

Page 42

42 section 2 scanner ® 2000 microefm measuring steam via a differential pressure meter note this section contains installation guidelines for orifice and cone meters. If installing the scanner 2000 with an averaging pitot tube meter, refer to manufacturer instructions for installation. Best practice...

Page 43

43 scanner ® 2000 microefm section 2 caution before starting the system, remove the caps and add water or antifreeze if necessary to completely fill the pots and cold legs. Air trapped in the lines will produce errors in dif- ferential pressure measurements. Installation procedure—remote mount to or...

Page 44

44 section 2 scanner ® 2000 microefm caution when measuring steam, process connections must be designed to eliminate air pock- ets. This is achieved by making sure all tubing in the cold legs slopes upward. A side- port mvt and block manifold (shown in figure 2.9) is recommended to help prevent air ...

Page 45

45 scanner ® 2000 microefm section 2 d. Connect a hand pump or funnel to the fitting. E. Pour fill liquid into the funnel or pump it into the cold leg, tapping the cold leg occasionally to dis- lodge any bubbles. F. Observe the pipe tee/condensate pot and stop pouring when the fill liquid is visible...

Page 46

46 section 2 scanner ® 2000 microefm measuring liquid via a differential pressure meter note this section contains installation guidelines for orifice and cone meters. If installing the scanner 2000 with an averaging pitot tube meter, refer to manufacturer instructions for installation. Best practic...

Page 47

47 scanner ® 2000 microefm section 2 practices listed above. • position the cone meter so that there are zero to five pipe diameters upstream of the meter and zero to three pipe diameters downstream of the meter. • install the meter so that the static pressure tap is upstream of the differential pre...

Page 48

48 section 2 scanner ® 2000 microefm 3. Align the bolt holes in the scanner 2000 mvt and manifold, and install bolts to mate these components to the football flanges, using o-rings as appropriate. Torque the bolts to the manufacturer’s specification. 4. Route any additional inputs/outputs or com con...

Page 49

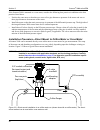

49 scanner ® 2000 microefm section 2 rtd assembly positioning of sensor below the meter and slope of tubing helps prevent gas bubbles from entering the liquid shut-off valves throttle flow to the manifold and mvt figure 2.11—remote-mount liquid run installation (shown here with a cone meter). The re...

Page 50

50 section 2 scanner ® 2000 microefm important if the process fluid does not present an environmental risk and is stable when depressur- ized, it may be used to bleed air from the lines. If the process fluid can contaminate the environment, or is highly volatile when depressurized as with liquified ...

Page 51

51 scanner ® 2000 microefm section 2 measuring compensated liquid via a turbine meter best practices the scanner 2000 microefm calculates compensated liquid flow through a turbine meter in accordance with api-2540 and the measurement principles upon which the aga-7 standard is based. The user suppli...

Page 52

52 section 2 scanner ® 2000 microefm to connect the scanner 2000 to a liquid turbine meter using this method, perform the following steps: 1. Position the scanner 2000 above the flowmeter. 2. Plug the scanner 2000 cable connector into the magnetic pickup of the turbine meter and hand-tighten the knu...

Page 53

53 scanner ® 2000 microefm section 2 to connect the scanner 2000 to a turbine meter using this method, perform the following steps: 1. Position the scanner 2000 and pickup extension assembly above the flowmeter. 2. Plug the scanner 2000 cable connector into the magnetic pickup of the turbine meter a...

Page 54

54 section 2 scanner ® 2000 microefm measuring uncompensated liquid via a turbine meter best practices the scanner 2000 microefm calculates uncompensated liquid flow through a turbine meter in accordance with api mpms, chapter 5, section 3, measurement of liquid hydrocarbons by turbine meters. For o...

Page 55

55 scanner ® 2000 microefm section 2 installation procedure—direct mount to a barton 7000 series turbine meter (atex compliant) a scanner 2000 without the mvt bottomworks can be mounted directly to a barton 7000 series turbine meter for measuring liquid (figure 2.15). A stainless steel turbine meter...

Page 56

56 section 2 scanner ® 2000 microefm 5. Monitor the pressure readout and watch for a steady decrease in pressure. If leakage is indicated, depres- surize the system by opening both bypass/block valves, then check all manifold and piping joints. Tighten connections as necessary. 6. Repeat steps 3 thr...

Page 57

57 scanner ® 2000 microefm section 2 5. Connect to the scanner 2000 with the modworx™ pro software. Click on the calibrate inputs menu button and proceed through the calibration per instructions in the modworx™ pro software user manual. 6. At the appropriate software prompt, enter a known pressure. ...

Page 58: Industry Standard Compliance

58 section 2 scanner ® 2000 microefm 7. Apply the same amount of pressure to the high side of the mvt using the simulator (see the modworx™ pro software user manual, part no. 9a-30165025, for complete instructions). The modworx™ pro software will display a measured value. 8. Repeat steps 6 and 7 as ...

Page 59

59 scanner ® 2000 microefm section 2 table 2.2—industry standards for orifice meters standard applicable section description notes aga report no. 3: orifice metering of natural gas and other related hydrocarbon fluids part 2: specification and installation requirements, section 2.6 (installation req...

Page 60

60 section 2 scanner ® 2000 microefm table 2.3—industry standards for turbine meters standard applicable section description notes aga report no. 7: measurement of natural gas by turbine meters section 7- installation specifications installation of gas turbine meters to include flow direction, meter...

Page 61: Field Wiring Connections

61 scanner ® 2000 microefm section 3 section 3—wiring the scanner 2000 field wiring connections ! Warning: do not connect/disconnect equipment or change batteries unless the area is known to be non-hazardous. The scanner 2000 poses no hazard when opened in a safe area. Caution all field wiring must ...

Page 62: Grounding Procedures

62 section 3 scanner ® 2000 microefm grounding procedures to power the scanner 2000 microefm with an external dc supply, route the ground conductor through a conduit opening in the top of the scanner 2000 enclosure with the power conductors and connect it to the ground screw inside the enclosure (no...

Page 63: Power Supply Wiring

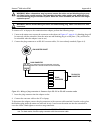

63 scanner ® 2000 microefm section 3 power supply wiring internal power supply the scanner 2000 microefm is shipped with a lithium battery pack. To supply power to the instrument, connect the battery cable to connector j1 on the main circuit assembly (figure 3.2). Low-power microprocessor technology...

Page 64

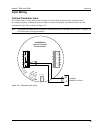

64 section 3 scanner ® 2000 microefm when an external power supply is used as the primary power source, the lithium battery pack serves as a backup power supply. The use of an alternate power source extends battery life and helps ensure that timekeeping and volume accumulation will not be interrupte...

Page 65: Input Wiring

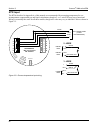

65 scanner ® 2000 microefm section 3 input wiring turbine flowmeter input the turbine input 1 on the main circuit board provides the turbine flowmeter input signal generated by a magnetic pickup, enabling the scanner 2000 to calculate and display instantaneous flow rates and accumulated totals. Wire...

Page 66

66 section 3 scanner ® 2000 microefm rtd input the rtds described in appendix a of this manual are recommended for measuring temperature for use in temperature-compensated gas and liquid calculations, though a 2- or 3-wire rtd may prove functional. Wiring is essentially the same for all three models...

Page 67: Output Wiring

67 scanner ® 2000 microefm section 3 output wiring digital output (pulse or alarm) the standard scanner 2000 supports a solid-state digital output that is configurable as either a pulse output or an alarm output. As a pulse output, the pulse width duration and pulse representation are both configura...

Page 68

68 section 3 scanner ® 2000 microefm rs-485 output—permanent computer connection the rs-485 output is required for communication with the interface software. The wiring diagram in figure 3.7 supports a permanent connection. Tb1 tb2 po w er tf m 1 r td – + po r t 2 po r t 1 – i + + r + r - i - port 2...

Page 69

69 scanner ® 2000 microefm section 3 rs-485 output—laptop computer connection the rs-485 output is required for communication with the interface software. The wiring diagram in figure 3.8 supports a temporary laptop connections using an rs-232 to rs-485 converter. Td(a) td(b) gnd rs-232 9 - pin conn...

Page 70: Configuration Via Keypad

70 section 3 scanner ® 2000 microefm configuration via keypad communication parameters such as slave address and baud rate, the date and time, contract hour and plate size can all be configured via the three-button keypad on the front of the instrument. See section 4— configuration and operation via...

Page 71

71 scanner ® 2000 microefm section 4 section 4—configuration and operation via keypad the following parameters can be configured using the three-button keypad on the front of the instrument, as shown in figure 4.1: • slave address • baud rate • date and time • contract hour • plate size all other in...

Page 72: Entering The Slave Address

72 section 4 scanner ® 2000 microefm entering the slave address the slave address is a setting used in modbus ® communications. It is a number that ranges from 1 to 65535, excluding 252 to 255 and 64764, which are reserved. If the modbus ® request message contains the matching address, the device wi...

Page 73: Entering The Baud Rate

73 scanner ® 2000 microefm section 4 entering the baud rate the baud rate is the number of bits per second that are on the serial port. This setting must match the setting of the master device polling the scanner 2000 or the serial port. This only applies to the modbus ® communi- cations; if modbus ...

Page 74: Editing The Date and Time

74 section 4 scanner ® 2000 microefm editing the date and time a user can change the date and time from the keypad. To edit the date and time: enter the access menu. Press up arrow and enter simultaneously. + 00000000 ... 00000000 ... 00000000 ... 00000000 ... Locate the date and time setting. Press...

Page 75: Editing The Contract Hour

75 scanner ® 2000 microefm section 4 editing the contract hour a user can set the contract hour from the keypad. The contract hour determines the exact time the daily flow is logged, and is represented by a four-digit number displayed in military time. To edit the contract hour: enter the access men...

Page 76: Editing The Plate Size

76 section 4 scanner ® 2000 microefm editing the plate size when the differential pressure producer in a scanner 2000 installation is an orifice meter and security controls allow, a user can change the size of the orifice plate from the keypad. The plate size is displayed in inches. If “strict api c...

Page 77

77 scanner ® 2000 microefm section 5 section 5—scanner 2000 maintenance the scanner 2000 is engineered to provide years of dependable service with minimal maintenance. Batteries require periodic replacement, and battery life depends on whether battery power is the primary or secondary power source, ...

Page 78

78 section 5 scanner ® 2000 microefm 3. Lift the display/keypad assembly from the enclosure, making sure the circuit assembly does not contact the enclosure. 4. Loosen the velcro strap, disconnect the battery from the j1 connector on the circuit assembly, and remove the spent battery pack from the e...

Page 79

79 scanner ® 2000 microefm section 5 important if possible, download the configuration settings and all archive logs before replacing the circuit board. Press the enter/save key on the keypad before disconnecting the bat- tery to save accumulated flow run and turbine volume totals (grand total and c...

Page 80

80 section 5 scanner ® 2000 microefm figure 5.3—disassembly of circuit board/keypad assembly 13. Connect the circuit board to the keypad with the two #4-40 × 5/16” screws removed in step 9. 14. Reconnect the sensor ribbon cable to the j5 connector at the top of the circuit board, by inserting the ri...

Page 81: Keypad Replacement

81 scanner ® 2000 microefm section 5 18. Recalibrate the scanner 2000 and replace the enclosure cover. Important do not overlook the need to recalibrate the scanner 2000. Boards that are shipped inde- pendently of a scanner 2000 are not calibrated to compensate for atmospheric pressure; therefore, a...

Page 82: Mvt Replacement

82 section 5 scanner ® 2000 microefm mvt replacement important press the enter/save key on the keypad before disconnecting the battery to save ac- cumulated flow run and turbine volume totals (grand total and current day total), and energy and mass totals to memory. To replace the mvt of the scanner...

Page 83: Section 6—Spare Parts

83 scanner ® 2000 microefm section 6 section 6—spare parts ! Warning: explosion hazard – substitution of components may impair suitability for class i, division 1 and 2. Use of spare parts other than those identified by cameron internation- al corporation voids hazardous area certification. Cameron ...

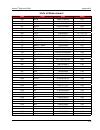

Page 84

84 section 6 scanner ® 2000 microefm table 6.1—scanner 2000 microefm spare parts 1 9a-99177001 adapter, 1 in. Female pipe to ¾ in. Male pipe, plated steel 1 9a-99177004 adapter, 1 in. Female pipe to ¾ in. Male pipe, brass 1 9a-99177005 adapter, 1 in. Female pipe to ¾ in. Male pipe, 316 stainless ste...

Page 85

85 scanner ® 2000 microefm section 6 table 6.2—scanner 2000 microefm spare parts (atex-approved) 1 9a-30025004 tube, standoff, stainless steel, 1.18 in. Hex x 12.00 in. Long with 3/4 in. Npt male & female ends 1 9a-30025005 tube, standoff, stainless steel, 1.18 in. Hex x 18.00 in. Long with 3/4 in. ...

Page 86

86 section 6 scanner ® 2000 microefm table 6.4—multi-variable transmitters select one based on specific application. The mvts listed below have bottom ports. Side port models are available on request. 1 9a-99168081 9a-99168092 9a-99168107 3000 psia, 400 in h2o 1 9a-99168082 9a-99168093 9a-99168108 3...

Page 87

A-1 scanner ® 2000 microefm appendix a appendix a—scanner 2000 hardware options explosion-proof control switch an alternative to the automatic scroll display of parameters on the lcd, an external explosion-proof control switch (figure a.1) allows the user to manually select which parameter is displa...

Page 88

A-2 appendix a scanner ® 2000 microefm switch j1 tb1 battery 13 14 j2 scanner 2000 main circuit board pn: 9a-30160010 tf m 1 r td i + r + r - i - – + 2 3 4 5 6 1 p o w e r p o r t 2 p o r t 1 – + – + – + 7 8 9 10 11 12 tb2 tb3 dig out 1 figure a.3—wiring of explosion-proof control switch to select a...

Page 89: Rtd Assemblies

A-3 scanner ® 2000 microefm appendix a dates will appear on the lcd. The log display will remain in view for 30 seconds before the lcd resumes its automatic scroll of display parameters. Rtd assemblies weatherproof rtd assembly (csa, class i, div. 2) cameron’s weatherproof rtd is csa-certified for u...

Page 90

A-4 appendix a scanner ® 2000 microefm communications adapter (csa div. 1 or div. 2, atex zone 1) the explosion-proof communications adapter ( figure a.7, page a-4 ) provides an rs-485 connection for connecting a laptop or pc to the instrument without removing the instrument cover. When the adapter ...

Page 91

A-5 scanner ® 2000 microefm appendix a ! Warning: when a hazardous area is present, ensure the union nut and blanking plug a prop- erly fitted in the conduit opening. The hazardous location rating applies only when the union nut and blanking plug are secured in place. When the union is broken, the d...

Page 92

A-6 appendix a scanner ® 2000 microefm communications adapter installation (for adapters purchased separately from a scanner 2000) ! Warning: if the communications adapter is ordered separately from the scanner 2000 micro- efm, the conduit openings in the scanner 2000 enclosure will be sealed with b...

Page 93

A-7 scanner ® 2000 microefm appendix a figure a.10—nuflo usb adapter figure a.11—nuflo usb adapter components using the adapter the cd supplied with the nuflo usb adapter contains the drivers required to enable usb communications for a scanner 2000 when the nuflo usb adapter is installed. For step-b...

Page 94: Tb2

A-8 appendix a scanner ® 2000 microefm ! Warning: when a hazardous area is present, ensure the union nut and blanking plug are properly fitted in the conduit opening. The explosion-proof rating applies only when the union nut and blanking plug are secured in place. When the union is broken, the devi...

Page 95

A-9 scanner ® 2000 microefm appendix a if the expansion board is ordered with a scanner 2000, it is installed at the factory. If the board is purchased separately, the user will need to install it on the scanner 2000 main board using the following instructions. Installation (for boards purchased sep...

Page 96

A-10 appendix a scanner ® 2000 microefm wiring diagrams analog inputs 1 and 2 the analog inputs, which can be configured for a 0-5 v, 1-5 v or 4-20 ma signal, can be used to receive readings from a pressure or temperature transmitter for use in aga-7 gas calculations. Alternatively, they can be used...

Page 97: Pulse Input (Tb8)

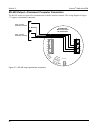

A-11 scanner ® 2000 microefm appendix a pulse input the pulse input provides an optically isolated input for high-amplitude pulse (frequency) signals, which includes signals from a turbine meter equipped with a preamplifier (figure a.16, top diagram) or signals from a positive displacement meter (fi...

Page 98: Turbine Input (Tb9)

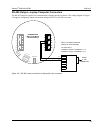

A-12 appendix a scanner ® 2000 microefm turbine flowmeter input 2 turbine input 2 (figure a.17) accepts a turbine flowmeter input signal generated by a magnetic pickup. The scanner 2000 can be configured to use this signal to calculate and display instantaneous flow rates and accumulated totals. Tur...

Page 99

A-13 scanner ® 2000 microefm appendix a 15 16 tb 9 tb 8 tb 7 tb6 tb 4 tb 5 resistor may be included in readout device. * tb2 po w er – + 7 8 9 10 11 12 ground screw inside enclosure analog device power supply 8-30 vdc gnd analog output (tb4) (with power supplied via main board (tb2) scanner 2000 mai...

Page 100: Measurement Canada Seal Kit

A-14 appendix a scanner ® 2000 microefm measurement canada seal kit measurement canada has approved the use of the scanner 2000 for custody transfer applications when it is installed in accordance with the configuration and sealing provisions cited in measurement canada approval no. Ag-0557c. Measur...

Page 101

A-15 scanner ® 2000 microefm appendix a switch j1 tb1 battery 13 14 j2 scanner 2000 main circuit board pn: 9a-30160010 tf m 1 r td i + r + r - i - – + 2 3 4 5 6 1 p o w e r p o r t 2 p o r t 1 – + – + – + 7 8 9 10 11 12 tb2 tb3 dig out 1 figure a.19—j2 receptacle for installing the seal kit jumper 5...

Page 102: Terminal Housing

A-16 appendix a scanner ® 2000 microefm seal wire with lead seal s-shaped bracket with allen head screw factory-applied tag figure a.20—measurement canada seal kit components seal wire properly installed with lead seal crimped figure a.21—scanner 2000 with seal kit installed terminal housing cameron...

Page 103

A-17 scanner ® 2000 microefm appendix a simplify field wiring. Then, once in the field, the user connects all field wiring directly to the terminal strip without opening the scanner 2000 enclosure. The terminal housing is available with either brass or stainless steel plugs. Figure a.22—model th4 te...

Page 104

A-18 appendix a scanner ® 2000 microefm.

Page 105: Lithium Battery Disposal

B-1 scanner ® 2000 microefm appendix b appendix b—lithium battery information lithium battery disposal once a lithium battery is removed from a device and/or is destined for disposal, it is classified as solid waste under epa guidelines. Depleted lithium batteries are also considered to be hazardous...

Page 106

B-2 appendix b scanner ® 2000 microefm.

Page 107: ™ Fieldbus

C-1 scanner ® 2000 microefm appendix c appendix c—scanner 2000 for f oundation ™ fieldbus overview the nuflo™ scanner ® 2000 microefm for f oundation ™ fieldbus communicates via both rtu modbus ® and h1 fieldbus protocol. The device computes volumes of gas, liquid and steam using a differential pres...

Page 108: Specifications

C-2 appendix c scanner ® 2000 microefm lithium battery pack (double d cell), secured by a velcro strap main circuit board battery connector figure c.1— scanner 2000 microefm, internal view hardware options several hardware options are available for customizing the scanner 2000 to a user’s specific n...

Page 109: Installing The Scanner 2000

C-3 scanner ® 2000 microefm appendix c table c.1—scanner 2000 microefm specifications (fieldbus devices only) f oundation ™ fieldbus fieldbus power/communications port on fieldbus interface board fieldbus module contains 1 resource block, 1 transducer block, and 4 analog input blocks device is capab...

Page 110: Field Wiring Connections

C-4 appendix c scanner ® 2000 microefm host safe area hazardous area term term power supply linking device figure c.2—basic installation mounting options for instructions on mounting the scanner 2000, see mounting options, page 30 . Field wiring connections ! Warning: to prevent ignition of hazardou...

Page 111

C-5 scanner ® 2000 microefm appendix c • the fieldbus interface board includes terminals for f oundation ™ fieldbus power/communications. A white potted fieldbus module ( figure c.3, page c-5 ) is attached to the fieldbus interface board, but it has no customer inputs/outputs. It is used solely for ...

Page 112

C-6 appendix c scanner ® 2000 microefm to wire the scanner 2000 for operation, complete the following field connections: 1. Unscrew and remove the cover from the scanner 2000 enclosure. 2. Using a small standard blade screwdriver, remove the two #4-40 × 7/8” screws located to the right and left side...

Page 113

C-7 scanner ® 2000 microefm appendix c internal ground screw external ground screw figure c.4—ground screw locations lithium battery pack the scanner 2000 microefm is shipped with a lithium battery pack. In f oundation ™ fieldbus applications, this battery pack provides backup power. Primary power i...

Page 114

C-8 appendix c scanner ® 2000 microefm caution always connect the lithium battery to the main board before connecting fieldbus power to the fieldbus interface board. See also internal power supply, page 63 . Figure c.5—f oundation ™ fieldbus power supply wiring without junction box terminal housing ...

Page 115: Device Configuration

C-9 scanner ® 2000 microefm appendix c to scanner 2000 main board, tb1, terminals 1-4 junction box (optional) from rtd (4-wire recommended) figure c.7— f oundation ™ fieldbus process temperature input wiring with junction box device configuration basic parameters such as communications port slave ad...

Page 116

C-10 appendix c scanner ® 2000 microefm device description the device description (dd) is a text file that precisely describes scanner 2000 device capabilities for use by the host system. It defines the parameters that are available for building control loops, establishes the arrangement of paramete...

Page 117

C-11 scanner ® 2000 microefm appendix c the resource state parameter shows the status of the hardware. If the hardware is working as designed, the status is displayed as “online.” if the resource block is placed in oos mode, the status will be “standby.” if a hardware failure occurs, the resource st...

Page 118

C-12 appendix c scanner ® 2000 microefm consult your host manual or configuration tool manual for information on accessing this information. Device id each scanner 2000 has a 32-character hardware identifier that is unique to each unit. This address is set by cameron, stored in the firmware for the ...

Page 119

C-13 scanner ® 2000 microefm appendix c setup of the configuration tool and download of the network configuration to the scanner 2000 will vary with product manufacturers. See the host manual or the configuration tool manual for detailed instructions. Caution if installing multiple devices, verify t...

Page 120

C-14 appendix c scanner ® 2000 microefm 5. Set the xd-scale parameter. This setting defines the input values from the transducer block (input range of sensor) that correspond to 0% and 100% values in ai function block calculations. When the desired output is the measured variable (l_type is set to d...

Page 121: Fieldbus Operations

C-15 scanner ® 2000 microefm appendix c fieldbus operations the foundation™ fieldbus protocol manual for scanner 2000 provides a list of the parameters supported by the scanner 2000 fieldbus module. Neither resource blocks nor transducer blocks can be linked to other function blocks to build a contr...

Page 122: Maintenance

C-16 appendix c scanner ® 2000 microefm (block_err) parameter for possible causes. Remember to check the mode of the resource block. If it is in oos mode, all other blocks will automatically be placed in oos mode as well. The block error parameter provides an overview of hardware and software erors....

Page 123

C-17 scanner ® 2000 microefm appendix c board replacement the scanner 2000 electronic circuitry includes three boards (figure c.8). The main board (on bottom of the board stack when the assembly is removed from the enclosure) is attached to a smaller fieldbus interface board, which is in turn attach...

Page 124

C-18 appendix c scanner ® 2000 microefm 4. Record the locations of all cable connections to the main board. 5. Disconnect the fieldbus input cable from terminal block tb4 on the fieldbus interface board (figure c.9). 6. Unplug the battery cable from connector j1 on the main board (figure c.9). 7. Us...

Page 125

C-19 scanner ® 2000 microefm appendix c figure c.11—removal of the fieldbus interface board 10. Disconnect the sensor ribbon cable from the j5 connector on the main board as follows: a. Lift the latch from the black clip securing the ribbon cable (figure c.12). B. When the latch is fully open, the r...

Page 126

C-20 appendix c scanner ® 2000 microefm 11. Remove the main board/keypad assembly from the enclosure. 12. Remove the two #4-40 × 5/16” screws fastening the main board to the keypad (figure c.13). 13. Remove the keypad ribbon cable from the j7 connector on the lcd side of the main board by pressing i...

Page 127

C-21 scanner ® 2000 microefm appendix c 16. Connect the main board to the keypad with the two #4-40 × 5/16” screws removed in step 12. 17. Reconnect the sensor ribbon cable to the j5 connector at the top of the main board, by inserting the ribbon cable into the black clip and securing the latch on t...

Page 128

C-22 appendix c scanner ® 2000 microefm 7. Reattach the board assembly to the standoffs inside the enclosure with the two #4-40 × 7/8” screws re- moved in step 2 of the main board replacement procedure. 8. Replace the enclosure cover. Fieldbus module important if possible, save the network configura...

Page 129: Appendix D—Modbus

D-1 scanner ® 2000 microefm appendix d appendix d—modbus ® communications protocol firmware version: 4.10 register table version: 15 introduction the communications protocol for the scanner 2000 is in accordance with modicon, inc. Rtu mode modbus® as described in modiconmodbusprotocolreferenceguide,...

Page 130: Data Types

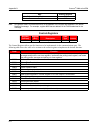

D-2 appendix d scanner ® 2000 microefm • port busdelay • port bustimeout • real date • real time data types various data types are implemented in the scanner 2000. The following table lists the formats and the numbers of bytes and registers associated with each type. Data type byte count register co...

Page 131: Security

D-3 scanner ® 2000 microefm appendix d security to communicate with a scanner 2000 without the use of modworx pro software (i.E. Via a third-party polling device), security permissions for the applicable scanner 2000 communications port must be set to the default (unrestricted) state. If a different...

Page 132

D-4 appendix d scanner ® 2000 microefm map starting register user-defined holding registers 9100 device status 9900 note: all registers cited in this document refer to the address of the register that appears in the actual modbus® message. For example, register 8000 has an address of 0x1f40 hexadeci...

Page 133: Product Code

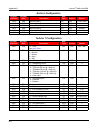

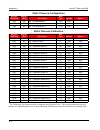

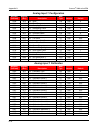

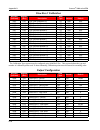

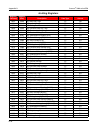

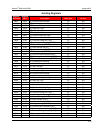

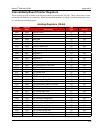

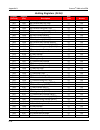

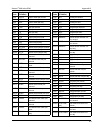

D-5 scanner ® 2000 microefm appendix d system configuration register (decimal) register (hex) description data type access 1000 3e8 product code and feature privileges u16 ro 1001 3e9 register table version u16 ro 1002 3ea firmware version u16 ro 1003 3eb manufacture date u16 ro 1004 3ec sales date ...

Page 134

D-6 appendix d scanner ® 2000 microefm communications configuration register (decimal) register (hex) description data type access default 1100 44c port 1 - port usage 0 - slave 1 - master u16 r/w 0 1101 44d port 1 slave address [1 to 65535, excluding 252 to 255 and 64764] u16 r/w 1 1102 44e port 1 ...

Page 135

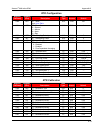

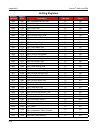

D-7 scanner ® 2000 microefm appendix d power configuration register (decimal) register (hex) description data type access default 1300 514 power mode 0 - high power 1 - low power u16 r/w 1 1301 515 clock override u16 r/w 0 1302 516 internal system sample period [number of seconds between battery vol...

Page 136

D-8 appendix d scanner ® 2000 microefm archive configuration register (decimal) register (hex) description data type access default 1418 58a archive field 11 u16 r/w t1 run time 1419 58b archive field 12 u16 r/w unused 1420 58c archive field 13 u16 r/w unused 1421 58d archive field 14 u16 r/w unused...

Page 137

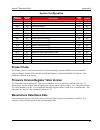

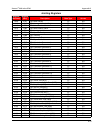

D-9 scanner ® 2000 microefm appendix d turbine 1 calibration register (decimal) register (hex) description data type access default 2030 7ee t1 - calibration type 1 u16 r/w 1 2031 7ef t1 - linear factor fp r/w 900.00 2033 7f1 t1 - calibration absolute offset fp r/w 0.00 2035 7f3 t1 - factor 1 fp r/w...

Page 138

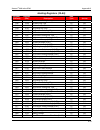

D-10 appendix d scanner ® 2000 microefm turbine 2 configuration register (decimal) register (hex) description data type access default 2100 834 t2 - units see units table u16 r/w 102 – bbl 2101 835 t2 - time base u16 r/w 3 – day 2102 836 t2 - sampling period (sec) u16 r/w 5 2103 837 t2 - dampening f...

Page 139

D-11 scanner ® 2000 microefm appendix d turbine 2 calibration register (decimal) register (hex) description data type access default 2153 869 t2 - factor 10 fp r/w 1.00 2155 86b t2 - factor 11 fp r/w 1.00 2157 86d t2 - factor 12 fp r/w 1.00 2159 86f t2 - frequency 1 fp r/w 1.00 2161 871 t2 - frequen...

Page 140

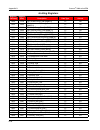

D-12 appendix d scanner ® 2000 microefm static pressure configuration register (decimal) register (hex) description data type access default 2222 8ae sp - unit description 1 lcd r/w 2223 8af sp - unit description 2 lcd r/w 2224 8b0 sp - unit description 3 lcd r/w static pressure calibration register...

Page 141

D-13 scanner ® 2000 microefm appendix d rtd configuration register (decimal) register (hex) description data type access default 2300 8fc pt - units see units table u16 r/w 501 2301 8fd pt - time base 0 = second 1 = minute 2 = hour 3 = day u16 r/w 0 2302 8fe pt - sampling period (sec) u16 r/w 5 2303...

Page 142

D-14 appendix d scanner ® 2000 microefm rtd calibration register (decimal) register (hex) description data type access default 2353 931 pt - calibration actual 10 fp r/w 0.00 2355 933 pt - calibration actual 11 fp r/w 0.00 2357 935 pt - calibration actual 12 fp r/w 0.00 2359 937 pt - calibration mea...

Page 143

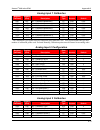

D-15 scanner ® 2000 microefm appendix d differential pressure configuration register (decimal) register (hex) description data type access default 2418 972 dp - units scale factor fp r/w 1.00 2420 974 dp - units offset factor fp r/w 0.00 2422 976 dp - unit description 1 lcd r/w — 2423 977 dp - unit ...

Page 144

D-16 appendix d scanner ® 2000 microefm analog input 1 configuration register (decimal) register (hex) description data type access default 2500 9c4 a1 - units u16 r/w 0 2501 9c5 a1 - time base u16 r/w 0 2502 9c6 a1 - sampling period u16 r/w 1 2503 9c7 a1 - dampening factor u16 r/w 0 2504 9c8 a1 - i...

Page 145

D-17 scanner ® 2000 microefm appendix d analog input 1 calibration register (decimal) register (hex) description data type access default 2567 a07 a1 - calibration measured 5 fp r/w 0.00 2569 a09 a1 - calibration measured 6 fp r/w 0.00 2571 a0b a1 - calibration measured 7 fp r/w 0.00 2573 a0d a1 - c...

Page 146

D-18 appendix d scanner ® 2000 microefm analog input 2 calibration register (decimal) register (hex) description data type access default 2639 a4f a2 - calibration actual 3 fp r/w 0.00 2641 a51 a2 - calibration actual 4 fp r/w 0.00 2643 a53 a2 - calibration actual 5 fp r/w 0.00 2645 a55 a2 - calibra...

Page 147

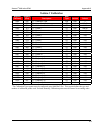

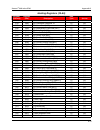

D-19 scanner ® 2000 microefm appendix d flow run 1 configuration register (decimal) register (hex) description data type access default 3004 bbc fr1 flow rate calculation (see definition .) u16 r/w 0 3005 bbd fr1 override enable 0 - disabled 1 - enabled u16 r/w 0 3006 bbe fr1 fluid properties (see d...

Page 148

Flow run 1 configuration register (decimal) register (hex) description data type access default 3033 bd9 fr1 pipe reference temp fp r/w 68.00 deg f 3035 bdb fr1 plate size fp r/w 1.00 in. 3037 bdd fr1 plate reference temp fp r/w 68.00 deg f 3039 bdf fr1 isentropic exponent - k fp r/w 1.30 3041 be1 f...

Page 149

Flow run 1 configuration register (decimal) register (hex) description data type access default 3099 c1b fr1 gc - n-decane (n-c10) fp r/w 0.00 3101 c1d fr1 gc - helium (he) fp r/w 0.00 3103 c1f fr1 gc - argon (ar) fp r/w 0.00 3105 c21 fr1 unit scale fp r/w 1.00 3107 c23 fr1 unit offset fp r/w 0.00 3...

Page 150: Fluid Property Register

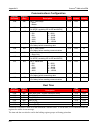

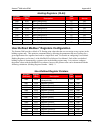

D-22 appendix d scanner ® 2000 microefm flow rate calculation 6 isa nozzle (future) 7 long radius nozzle (future) 8 averaging pitot tube (annubar®) fluid property register 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 hv sg v isen liqdc gpa hvref fluid property calc hv - heating value selection 0 calculated...

Page 151: Tap Type Register

D-23 scanner ® 2000 microefm appendix d fluid property calculation 17 crude oil 18 gasolines 19 jet fuels 20 fuel oils 21 lube oils tap type register 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0 loc tap type loc (pressure tap location) 0 upstream 1 downstream tap type 0 flange 1 corner 2 d and d/2 3 reserv...

Page 152

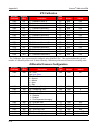

D-24 appendix d scanner ® 2000 microefm flow run 1 calibration register (decimal) register (hex) description data type access default 3233 ca1 fr1 flow coefficient 15 fp r/w 0.00 3235 ca3 fr1 flow coefficient 16 fp r/w 0.00 3237 ca5 fr1 reynolds number 1 fp r/w 1.00 3239 ca7 fr1 reynolds number 2 fp...

Page 153

D-25 scanner ® 2000 microefm appendix d output configuration register (decimal) register (hex) description data type access default 4053 fd5 analog out 2 - high adjust u16 r/w 4095 4054 fd6 analog out 3 - source u16 r/w 0 4055 fd7 analog out 3 - low value fp r/w 0 4057 fd9 analog out 3 - high value ...

Page 154

D-26 appendix d scanner ® 2000 microefm holding registers register (decimal) register (hex) description data type access 8028 1f5c fr1 instantaneous flow rate fp ro 8030 1f5e fr1 daily total fp ro 8032 1f60 fr1 interval total fp ro 8034 1f62 fr1 polling total fp ro 8036 1f64 fr1 previous day total f...

Page 155

D-27 scanner ® 2000 microefm appendix d holding registers register (decimal) register (hex) description data type access 8108 1fac fr1 base density fp ro 8110 1fae fr1 average molecular weight fp ro 8112 1fb0 fr1 molar fraction sum fp ro 8114 1fb2 fr1 mass heating value fp ro 8116 1fb4 fr1 heating v...

Page 156

D-28 appendix d scanner ® 2000 microefm holding registers register (decimal) register (hex) description data type access 8190 1ffe fr1 grand energy total [mmbtu] fp ro 8192 2000 fr1 instantaneous energy rate [mmbtu] fp ro 8194 2002 fr1 daily energy total [mmbtu] fp ro 8196 2004 fr1 interval energy t...

Page 157

D-29 scanner ® 2000 microefm appendix d holding registers register (decimal) register (hex) description data type access 8270 204e t1 previous month total [gal] fp ro 8272 2050 t1 frequency fp ro 8274 2052 t1 active k-factor fp ro 8276 2054 t2 grand total fp ro 8278 2056 t2 instantaneous flow rate f...

Page 158

D-30 appendix d scanner ® 2000 microefm holding registers register (decimal) register (hex) description data type access 8352 20a0 sp daily run time fp ro 8354 20a2 sp interval run time fp ro 8356 20a4 sp polling run time fp ro 8358 20a6 sp previous daily run time fp ro 8360 20a8 sp previous interva...

Page 159

D-31 scanner ® 2000 microefm appendix d holding registers register (decimal) register (hex) description data type access 8434 20f2 pt previous daily average fp ro 8436 20f4 pt previous interval average fp ro 8438 20f6 pt previous polling average fp ro 8440 20f8 pt daily run time fp ro 8442 20fa pt i...

Page 160

D-32 appendix d scanner ® 2000 microefm holding registers register (decimal) register (hex) description data type access 8516 2144 a2 daily average fp ro 8518 2146 a2 interval average fp ro 8520 2148 a2 polling average fp ro 8522 214a a2 previous daily average fp ro 8524 214c a2 previous interval av...

Page 161

D-33 scanner ® 2000 microefm appendix d holding registers register (decimal) register (hex) description data type access 8596 2194 pid stage 2 output fp ro 8598 2196 po1 pulses fp ro 8600 to 8605 reserved 8606 219e ao1 output current fp ro 8608 21a0 ao2 output current fp ro 8610 21a2 ao3 output curr...

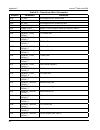

Page 162: Base Units/configured Units

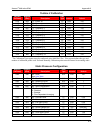

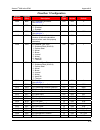

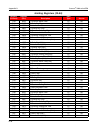

D-34 appendix d scanner ® 2000 microefm flow calculation parameter registers (1-16) the flow calculation parameter registers definition is dependent upon the flow rate calculation method that is implemented. The following table describes the function of each of these registers for each of the suppor...

Page 163

D-35 scanner ® 2000 microefm appendix d interval/daily/event pointer registers these registers provide an index of the last record that was stored in the log data. These values start at 1 and increment with each newly created log. When the maximum number of records is reached, the pointer resets to ...

Page 164

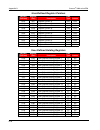

D-36 appendix d scanner ® 2000 microefm holding registers (32-bit) register (decimal) register (hex) description data type access 7036 1b7c fr1 previous polling energy fp ro 7037 1b7d fr1 daily estimated total fp ro 7038 1b7e fr1 monthly total fp ro 7039 1b7f fr1 previous month total fp ro 7040 1b80...

Page 165

D-37 scanner ® 2000 microefm appendix d holding registers (32-bit) register (decimal) register (hex) description data type access 7077 1ba5 fr1 calculation parameter 15 fp ro 7078 1ba6 fr1 calculation parameter 16 fp ro 7079 1ba7 fr1 grand total [mcf] fp ro 7080 1ba8 fr1 instantaneous flow rate [mcf...

Page 166

D-38 appendix d scanner ® 2000 microefm holding registers (32-bit) register (decimal) register (hex) description data type access 7118 1bce t1 previous month total fp ro 7119 1bcf t1 daily run time fp ro 7120 1bd0 t1 interval run time fp ro 7121 1bd1 t1 polling run time fp ro 7122 1bd2 t1 previous d...

Page 167

D-39 scanner ® 2000 microefm appendix d holding registers (32-bit) register (decimal) register (hex) description data type access 7159 1bf7 t2 polling total [gal] fp ro 7160 1bf8 t2 previous day total [gal] fp ro 7161 1bf9 t2 previous interval [gal] fp ro 7162 1bfa t2 previous polling total [gal] fp...

Page 168

D-40 appendix d scanner ® 2000 microefm holding registers (32-bit) register (decimal) register (hex) description data type access 7200 1c20 dp polling run time fp ro 7201 1c21 dp previous daily run time fp ro 7202 1c22 dp previous interval run time fp ro 7203 1c23 dp previous polling run time fp ro ...

Page 169

D-41 scanner ® 2000 microefm appendix d holding registers (32-bit) register (decimal) register (hex) description data type access 7241 1c49 a1 previous polling average fp ro 7242 1c4a a1 daily run time fp ro 7243 1c4b a1 interval run time fp ro 7244 1c4c a1 polling run time fp ro 7245 1c4d a1 previo...

Page 170

D-42 appendix d scanner ® 2000 microefm holding registers (32-bit) register (decimal) register (hex) description data type access 7282 reserved 7283 1c73 live t1 instantaneous flow rate [gal] fp ro 7284 1c74 live t2 instantaneous flow rate [gal] fp ro 7285 1c75 live turbine frequency differential fp...

Page 171: User-Defined Modbus

D-43 scanner ® 2000 microefm appendix d holding registers (32-bit) register (decimal) register (hex) description data type access 7329 1ca1 slave data point 07 fp ro 7330 1ca2 slave data point 08 fp ro 7331 1ca3 slave data point 09 fp ro 7332 1ca4 slave data point 10 fp ro 7333 1ca5 slave data point...

Page 172

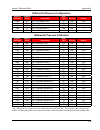

D-44 appendix d scanner ® 2000 microefm user-defined register pointers register (decimal) register (hex) description data type access 9015 2337 register pointer 15 u16 r/w 9016 2338 register pointer 16 u16 r/w 9017 2339 register pointer 17 u16 r/w 9018 233a register pointer 18 u16 r/w 9019 233b regi...

Page 173: Device Status

D-45 scanner ® 2000 microefm appendix d device status the device status includes alarm status and diagnostic information such as input status and calculation status. The scanner 2000 provides 16 user-configurable alarms designated as flow run alarms. The user can assign the alarms to any parameter i...

Page 174

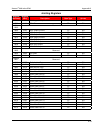

D-46 appendix d scanner ® 2000 microefm bit definitions—alarms and diagnostics bit flow run alarm high flow run alarm low diagnostic 1 diagnostic 2 diagnostic 3 diagnostic 4 2 fra3 high fra3 low pt override pt low mvt user parameter crc fail reserved 1 fra2 high fra2 low a1 override a1 low mvt facto...

Page 175

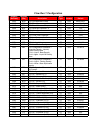

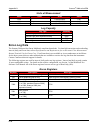

D-47 scanner ® 2000 microefm appendix d units of measurement value units scale offset 404 mmhg 1.865077000000 0.00 405 in hg 0.07342822834646 0.00 406 psi 0.036094567768 0.00 407 kgf/cm2 0.002535630000 0.00 408 mbar 2.48641011188 0.00 501 deg f - base 1.00 0.00 502 deg c 0.555555556 -17.77777778 503...

Page 176: Enron Log Data

D-48 appendix d scanner ® 2000 microefm units of measurement value units scale offset 1502 a 0.0010000000 0.00 1601 cp 1.0000000000 0.00 1602 lbm/ft.Sec 1488.1159420290 0.00 log capacity log type capacity interval logs (without expansion board) 2304 interval logs (with expansion board) 6392 daily lo...

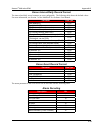

Page 177

D-49 scanner ® 2000 microefm appendix d enron interval/daily record format the interval and daily record contents are user-configurable. The following table shows the default values. For more information, see section 3 of the modworx pro software user manual. Parameter data type date (mmddyy) fp32 t...

Page 178

D-50 appendix d scanner ® 2000 microefm log capacity log type capacity interval logs (without expansion board) 2304 interval logs (with expansion board) 6392 daily logs 768 event logs 1152.

Page 179: Device Properties

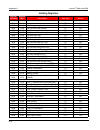

E-1 scanner ® 2000 microefm appendix e appendix e—fieldbus communications protocol device properties the following data may be useful in identifying the scanner 2000 device and device description in a host network: • manufacturer’s id: 0x43414d • device type: 01 • device revision: 01 • device descri...

Page 180

E-2 appendix e scanner ® 2000 microefm table e.1—resource block parameters index parameter definition 413 dd_rev revision of the device description associated with the resource 414 grant_deny option for controlling access of host computer and local panel to operating, tuning and alarm parameters of ...

Page 181

E-3 scanner ® 2000 microefm appendix e table e.1—resource block parameters index parameter definition 435 update_evt alert generated by any change to the static data 436 block_alm alarm used for all configuration, hardware, connection failure or system problems in the block. The cause of the alert i...

Page 182

E-4 appendix e scanner ® 2000 microefm table e.2—transducer block parameters relative parameter definition 2018 tv_unit enumerated unit for tertiary value 2019 qv_value value of quaternary value parameter and its status 2020 qv_unit enumerated unit for quaternary value 2021 simulation_value value of...

Page 183

E-5 scanner ® 2000 microefm appendix e table e.2—transducer block parameters relative parameter definition 2043 generic_usign32_ param_2 real time on sc2000 (yymm) 2044 generic_usign32_ param_3 real time on sc2000 (ddhh) 2045 generic_usign32_ param_4 real time on sc2000 (mmss) 2046 generic_usign32_ ...

Page 184

E-6 appendix e scanner ® 2000 microefm table e.3—analog input block parameters index parameter definition x13 io_opts options for altering input and output block processing. X14 status_opts options which the user may select in the block processing of status. X15 channel identifies by number the logi...

Page 185: Control Registers

E-7 scanner ® 2000 microefm appendix e table e.4—transducer error (xd_error) and block alarm codes value error description 16 unspecified error indicates occurrence of unidentified error 17 general error error cannot be classified as one of the following errors 18 calibration error error occurred du...

Page 186: Unit Conversion

E-8 appendix e scanner ® 2000 microefm unit conversion table e.6 can be used to convert numeric code to units, which may be helpful in working with host systems that do not convert unit codes to text descriptions automatically. Table e.6—unit conversions for xd scale unit code display (fieldbus) uni...

Page 187

E-9 scanner ® 2000 microefm appendix d unit code display (fieldbus) unit 1348 m3/min cubic meter per minute 1349 m3/h cubic meter per hour 1350 m3/d cubic meter per day 1351 l/s liter per second 1352 l/min liter per minute 1353 l/h liter per hour 1354 l/d liter per day 1356 cfs cubic feet per second...

Page 188

E-10 appendix d scanner ® 2000 microefm.

Page 189

E-11 scanner ® 2000 microefm appendix d warranty - limitation of liability: seller warrants only title to the products, software, supplies and materials and that, except as to software, the same are free from defects in workmanship and materials for a period of one (1) year from the date of delivery...

Page 190

R u s s i a +603.5569.0501 ms-kl @ c-a-m.Com.