- DL manuals

- Camon

- Log Splitter

- SP7E

- Operating Instructions Manual

Camon SP7E Operating Instructions Manual

Summary of SP7E

Page 1

Turbo 7 log splitter operating instructions before commissioning the machine, read operating instructions and observe warning and safety instructions..

Page 2: Contents

Turbo 7 log splitter page 2 turbo7/0213 contents pages 3-5 description of machine & illustrations page 6 introduction page 7 explanation of symbols used page 8 technical data pages 9-11 safety page 12 operating the machine page 13 use pages 14-15 routine maintenance pages 16-17 troubleshooting page ...

Page 3: Description of The Machine

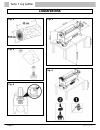

Turbo 7 log splitter turbo7/0213 page 3 description of the machine the camon turbo 7 is a portable horizontal log splitter equipped with its own electric motor. The various parts of the machine are shown in fig. 1 below. 1 - wedge 2 - oil tank 3 - wheels for minor movements 4 - electric motor 5 - el...

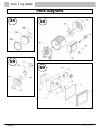

Page 4: Illustrations

Turbo 7 log splitter page 4 turbo7/0213 illustrations fig. 2 fig. 3 fig. 4 fig. 5 fig. 6.

Page 5: Illustrations

Turbo 7 log splitter turbo7/0213 page 5 illustrations fig. 7 fig. 8 fig. 9 fig. 10

Page 6: Introduction

Turbo 7 log splitter page 6 turbo7/0213 introduction before using the log splitter please read this manual carefully. Following all the instructions provided will ensure that you get excellent results and the best performance from your log splitter. The camon turbo 7 log splitter has been designed a...

Page 7: Explanation of Symbols Used

Turbo 7 log splitter turbo7/0213 page 7 explanation of symbols used standard graphic symbols are used on all machines in order to ensure complete safety of all parts of the log splitter. As these symbols are very important, read the information below carefully. It is necessary to read carefully the ...

Page 8: Technical Data

Turbo 7 log splitter page 8 turbo7/0213 technical data length ~ 1070mm width ~ 300mm height ~ 530mm weight ~ 65kg max force ~ 7 tonnes max log capacity ~ 520mm hydraulic oil capacity ~ 6 litres supply 240v 50hz 1-phase absorption 13a power 2hp - 1.5kw noise (average) (ear defenders are not essential...

Page 9: Safety

Turbo 7 log splitter turbo7/0213 page 9 safety important the information given in the chapter is extremely important for safety purposes. It describes possible hazards tied to use of the machine and instructions for correct use of this to avoid injury or damage. Warning: the camon turbo 7 log splitt...

Page 10: Safety

Turbo 7 log splitter page 10 turbo7/0213 safety general safety regulations the machine must always be used by one operator only. Do not use the machine outdoors when it is raining or snowing. Nobody must be allowed to use the log splitter unless they have read the instruction manual and have been in...

Page 11: Safety

Turbo 7 log splitter turbo7/0213 page 11 safety do not force the blade by pushing the log on the upper part (fig. 9, page 5) as this can cause the blade to break or damage the body of the machine. Always set the log on the guides. Never leave the machine unattended while it is running. If you leave ...

Page 12: Operating The Machine

Turbo 7 log splitter page 12 turbo7/0213 operating the machine the log splitter, in compliance with standard en 609-1, is activated with a two hand control. One hand is used to press the motor drive button (fig. 6, no. 1, page 4) while the second activates the lever of the hydraulic control (no. 2, ...

Page 13: Use

Turbo 7 log splitter turbo7/0213 page 13 use connect the log splitter to the power supply. Never pass the power cable over the log pusher, close to the wedge or anywhere where it may be damaged or severed. Position the log on the beam as shown in fig. 6, page 4. The supporting guides (9 in fig. 1, p...

Page 14: Routine Maintenance

Turbo 7 log splitter page 14 turbo7/0213 this chapter describes routine maintenance, i.E. Operations carried out by the operator, on the turbo 7 log splitter to keep it in perfect working order and therefore reliable for continuous, long- term use. All routine maintenance operations must be carried ...

Page 15: Refilling The Hydraulic Oil

Turbo 7 log splitter turbo7/0213 page 15 refilling the hydraulic oil periodically check the oil level, which must be between the two notches on the oil cap dipstick (fig. 7/d, page 5). If the level is low, refill using the recommended types of oil on page 8. Sharpening the wedge after long periods o...

Page 16: How to Free A Jammed Log

Turbo 7 log splitter page 16 turbo7/0213 how to free a jammed log release both controls: the log pusher will be fully retracted. Insert a triangular block of wood under the jammed log and activate the log splitter until the wedge is pushed completely under the piece of wood (fig. 8, page 5). Repeat ...

Page 17: Troubleshooting

Turbo 7 log splitter turbo7/0213 page 17 problem probable cause corrective action log fails to split incorrect positioning of the log. Position the log correctly. Log exceeds permitted di- mensions or the wood is too hard for the capacity of the machine. Try to cut a small part or use other means to...

Page 18

Turbo 7 log splitter page 18 turbo7/0213 the machine must be scrapped in compliance with all safety regulations for the prevention of personal injury and damage to the environment and animals. All parts of the machine must be scrapped and disposed of in accordance with applicable legislation in the ...

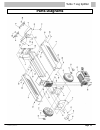

Page 19: Parts Diagrams

Turbo 7 log splitter turbo7/0213 page 19 parts diagrams.

Page 20: Parts Diagrams

Turbo 7 log splitter page 20 turbo7/0213 parts diagrams 1 15.

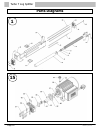

Page 21: Parts Diagrams

Turbo 7 log splitter turbo7/0213 page 21 parts diagrams 26 27.

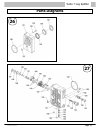

Page 22: Parts Diagrams

Turbo 7 log splitter page 22 turbo7/0213 parts diagrams 34 50 59 69.

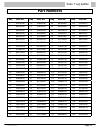

Page 23: Part Numbers

Turbo 7 log splitter turbo7/0213 page 23 part numbers key part no. Key part no. Key part no. Key part no. 1 d02103230 30 e26560518 65 e87300085 132 e25850070 2 b62100230 31 e26515072 66 e87300080 133 e26620248 3 b62100090 32 b50010090 67 d02100073 134 b72150070 4 b66125910 33 d30580020 68 e78000010 ...

Page 24

© tracmaster ltd 2013. Specifications are subject to change without prior notice. Tracmaster ltd, sovereign centre, victoria road, burgess hill rh15 9lr t: +44 (0) 1444 247689 f: +44 (0) 1444 871612 w: www.Tracmaster.Co.Uk e: info@tracmaster.Co.Uk turbo7/opm/02.13.