- DL manuals

- Campbell

- Accessories

- CR23X

- Operator's Manual

Campbell CR23X Operator's Manual

Summary of CR23X

Page 1

Cr23x micrologger revision: 11/06 c o p y r i g h t © 1 9 8 6 - 2 0 0 6 c a m p b e l l s c i e n t i f i c , i n c ..

Page 2: Warranty and Assistance

Warranty and assistance the cr23x micrologger is warranted by campbell scientific, inc. To be free from defects in materials and workmanship under normal use and service for thirty-six (36) months from date of shipment unless specified otherwise. Batteries have no warranty. Campbell scientific, inc....

Page 3

I cr23x measurement and control module table of contents pdf viewers note: these page numbers refer to the printed version of this document. Use the adobe acrobat® bookmarks tab for links to specific sections. Page ov1. Physical description ov1.1 wiring terminals .......................................

Page 4

Cr23x table of contents ii 2. Internal data storage 2.1 final storage areas, output arrays, and memory pointers .................................................. 2-1 2.2 data output format and range limits .................................................................................. 2-3 2.3 di...

Page 5

Cr23x table of contents iii 7.12 lysimeter - 6 wire full bridge ............................................................................................... 7-9 7.13 227 gypsum soil moisture block......................................................................................... 7-11 7.14 n...

Page 6

Cr23x table of contents iv installation 14. Installation and maintenance 14.1 protection from the environment ......................................................................................... 14-1 14.2 power requirements ..........................................................................

Page 7

Cr23x table of contents v h. Call another datalogger via phone or rf h.1 introduction ............................................................................................................................H-1 h.2 programming .........................................................................

Page 8

Cr23x table of contents vi this is a blank page..

Page 9

Vii selected operating details 1. Storing data - data are stored in final storage only by output processing instructions and only when the output flag (flag 0) is set. (sections ov4.1.1 and 3.7.1) 2. Storing date and time - date and time are stored with the data in final storage only if the real tim...

Page 10

Viii cautionary notes 1. Damage will occur to the analog input circuitry if voltages in excess of ± 16 v are applied for a sustained period. Voltages in excess of ± 8 v will cause errors and possible overranging on other analog input channels. 2. Do not download an operating system (os) written for ...

Page 11

Ov-1 cr23x micrologger overview read the selected operating details and cautionary notes at the front of the manual before using the cr23x. The cr23x micrologger combines precision measurement with processing and control capability in a single battery operated system. Campbell scientific, inc. Provi...

Page 12

Cr23x micrologger overview ov-2 1 2 3 a 4 5 6 b 7 8 9 c * 0 # d figure ov1-1. Cr23x micrologger.

Page 13

Cr23x micrologger overview ov-3 h l 1 2 1 h l 3 4 2 h l 5 6 3 h l 7 8 4 h l 9 10 5 h l 11 12 6 diff se h l 13 14 7 h l 15 16 8 h l 17 18 9 h l 19 20 40 h l 21 22 11 h l 23 24 12 diff se ex1 ex2 ex3 ex4 cao1 cao2 p1 p2 p3 p4 g 5v g sw12 g 12v 12v g c1 c2 c3 c4 g c5 c6 c7 c8 g power out control i/o gr...

Page 14

Cr23x micrologger overview ov-4 the 9-pin serial cs i/o port provides connection to data storage peripherals, such as the sm192/716 storage module, and provides serial communication to computer or modem devices for data transfer or remote programming (section 6). This 9 pin port does not have the sa...

Page 15

Cr23x micrologger overview ov-5 return currents from the cao and pulse- counter channels should be tied to the terminals in the cao and pulse-counter terminal strip to prevent them from flowing through the analog measurement section. The ground lug is also marked and provides a rugged ground path fr...

Page 16

Cr23x micrologger overview ov-6 1. System memory - used for overhead tasks such as compiling programs, transferring data, etc. The user cannot access this memory. 2. Active program memory - available for user entered programs. 3. Input storage - input storage holds the results of measurements or cal...

Page 17

Cr23x micrologger overview ov-7 operating system (128 kbytes) active program (32 kbytes code) stored programs (32 kbytes code) (32 kbytes labels) temporary copy of current program saved during download if download is aborted (64 kbytes) alphanumeric labels (32 kbytes) unassigned (192 kbytes) sram/fl...

Page 18

Cr23x micrologger overview ov-8 ov2.2 program tables, execution interval and output intervals the cr23x must be programmed before it will make any measurements. A program consists of a group of instructions entered into a program table. The program table is given an execution interval which determin...

Page 19

Cr23x micrologger overview ov-9 each instruction in the table requires a finite time to execute. If the execution interval is less than the time required to process the table, an execution interval overrun (table overrun) occurs; the cr23x finishes processing the table and waits for the next executi...

Page 20

Cr23x micrologger overview ov-10 input/output instructions specify the conversion of a sensor signal to a data value and store it in input storage. Programmable entries specify: (1) the measurement type (2) the number of channels to measure (3) the input voltage range (4) the input storage location ...

Page 21

Cr23x micrologger overview ov-11 ov3. Communicating with cr23x the user can communicate with the cr23x through either the integral keyboard and two line lcd display, or through a telecommunications link with a terminal or computer. The preferred method for routine operation is through a telecommunic...

Page 22

Cr23x micrologger overview ov-12 ov3.1.2 key definition keys and key sequences have specific functions when using the keypad or a computer/terminal in the remote keyboard state (section 5). Table ov3.1-2 lists these functions. In some cases, the exact action of a key depends on the mode the cr23x is...

Page 23

Cr23x micrologger overview ov-13 to communicate with any device, the cr23x enters its telecommunications mode and responds only to valid telecommunications commands. Within the telecommunications mode, there are 2 "states"; the telecommunications command state and the remote keyboard state. Communic...

Page 24

Cr23x micrologger overview ov-14 storage locations on which to find maxima, (2) time, an option of storing the time of occurrence with the maximum value, and (3) loc, the first input storage location operated on by the maximum instruction. The codes for the time parameter are listed in the "instruct...

Page 25

Cr23x micrologger overview ov-15 display explanation hello on power-up, the cr23x displays "hello" while it checks the memory after a few seconds delay 1664 kbytes the size of the machine's total memory memory when the cr23x is turned on, it tests the flash memory and loads the current program to ra...

Page 26

Cr23x micrologger overview ov-16 a 02:p00 enter the location # and advance to the second program instruction. The cr23x is now programmed to read the panel temperature every 5 seconds and place the reading in input storage location 1. The program can be compiled and the temperature displayed (note t...

Page 27

Cr23x micrologger overview ov-17 the cr23x is now programmed to measure the internal temperature every 5 seconds and send each reading to final storage. Values in final storage can be viewed using the ∗ 7 mode. Display will show: key (id:data) explanation ∗ 7 mode 07 enter ∗ 7 mode. The loc 13 data ...

Page 28

Cr23x micrologger overview ov-18 to make a thermocouple (tc) temperature measurement, the temperature of the reference junction (in this example, the panel temperature) must be measured. The cr23x takes the reference temperature, converts it to the equivalent tc voltage relative to 0 o c, adds the m...

Page 29

Cr23x micrologger overview ov-19 an instruction is deleted by advancing to the instruction number (p in display) and keying #d (table 4.2-1). To change the value entered for a parameter, advance to the parameter and key in the correct value then press a. Note that the new value is not entered until ...

Page 30

Cr23x micrologger overview ov-20 09: p74 minimize instruction 01:1 one repetition 02:10 output the time of the daily minimum in hours and minutes 03:2 data source is input storage location 2. The program to make the measurements and to send the desired data to final storage has been entered. At this...

Page 31

Cr23x micrologger overview ov-21 ov6. Data retrieval options there are several options for data storage and retrieval. These options are covered in detail in sections 2, 4, and 5. Figure ov6.1-1 summarizes the various possible methods. Regardless of the method used, there are three general approache...

Page 32

Cr23x micrologger overview ov-22 dsp4 heads up display cs i/o port md9 multidrop interface md9 multidrop interface csm1 sm192/716 storage modules csm1 sm192/716 storage modules sc532 rs-232 interface rf95 rf modem rf100/rf200 transceiver w/ antenna & cable rf100/rf200 transceiver w/ antenna & cable ...

Page 33

Cr23x micrologger overview ov-23 ov7. Specifications program execution rate program is synchronized with real-time up to 100 hz. Two fast (250 µs integration) single-ended measure- ments can write to final storage at 100 hz. Burst measurements are possible at rates up to 1.5 khz over short intervals...

Page 34

Cr23x micrologger overview ov-24 this is a blank page..

Page 35

1-1 section 1. Functional modes 1.1 datalogger programs - 1 , 2 , 3 , and 4 modes data acquisition and processing functions are controlled by user-entered instructions contained in program tables. Programming can be separated into 2 tables, each having its own user-entered execution interval. A thir...

Page 36

Section 1. Functional modes 1-2 1.1.2 subroutines table 3 is used to enter subroutines which may be called with program control instructions in tables 1 and 2 or other subroutines. The group of instructions which form a subroutine must begin with instruction 85, label subroutine, and end with instru...

Page 37

Section 1. Functional modes 1-3 multiplier and offset can be entered in 4 locations 1 and 2, respectively. A 4 location can be used in only one program parameter. For example, 4 locations 0, 1, and 2 used in the example cannot be reused in another instruction in the same program. If the 4 feature is...

Page 38

Section 1. Functional modes 1-4 1.2 setting and displaying the clock - 5 mode the 5 mode is used to display or set time. When " ∗ 5" is entered, time is displayed. It is updated approximately once a second or longer depending on the rate and degree of data collection and processing taking place. The...

Page 39

Section 1. Functional modes 1-5 updated each time the instruction is executed. When using the 6 mode from a remote terminal, a number (any number) must be sent before the value shown will be updated. Input locations can be used to store parameters for use in computations. To store a value in a locat...

Page 40

Section 1. Functional modes 1-6 of memory can be displayed in the 0 mode. A “--“ after the number displayed means that the memory test was aborted. The number shown indicates how far the test progressed before aborted. Input storage is used to store the results of input/output and processing instruc...

Page 41

Section 1. Functional modes 1-7 operating system (128 kbytes) active program (32 kbytes code) stored programs (32 kbytes code) (32 kbytes labels) temporary copy of current program saved during download if download is aborted (64 kbytes) alphanumeric labels (32 kbytes) unassigned (192 kbytes) sram/fl...

Page 42

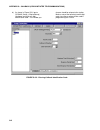

Section 1. Functional modes 1-8 1.5.2 a mode caution: reallocating memory will result in all data being lost. The a mode is used to 1) determine the number of locations allocated to input storage, intermediate storage, final storage area 2, final storage area 1, and program memory; 2) repartition th...

Page 43

Section 1. Functional modes 1-9 a 06: prog. Bytes unused bytes free in program memory. The user cannot change +xxxxx this window. It is a function of window 5 and the program. A 07: prog. Bytes available the user cannot change this window. It is a function of window +xxxxx 5 and total available memo...

Page 44

Section 1. Functional modes 1-10 table 1.6-1. Description of b mode data keyboard display id: entry data description of data ∗ b 01: program memory signature. The value is dependent upon the +xxxxx programming entered and memory allotment. If the program has not been previously compiled, it will be ...

Page 45

Section 1. Functional modes 1-11 table 1.7-1. ∗ c mode entries security disabled keyboard display id: entry data description ∗ c 01: non-zero password blocks entry to 1 , 2 , 3 , xxxx a , and d modes, telecommunication s command. A 02: non-zero password blocks 4 , 5 , and 6 except for display. Xxxx ...

Page 46

Section 1. Functional modes 1-12 pc208w automatically makes use of the d mode to upload and download programs from a computer. Appendix c gives some additional information on commands 1 and 2 that are used for these operations. When " ∗ d" is keyed in, the cr23x will display "13: enter command". A c...

Page 47

Section 1. Functional modes 1-13 table 1.8-4. Retrieving a program from internal flash key entry display d 13: enter command 00 7 a 07: program id 00 you may now enter one of the following options: xx a retrieve program number xx (the most recent xx saved). To have the program compile like 6 (no res...

Page 48

Section 1. Functional modes 1-14 1.8.4 full/half duplex the d mode can also be used to set communications to full or half duplex. The default is full duplex, which works best in most situations. Table 1.8-7. Setting duplex key entry display d 13: enter command 00 9 a 09: comm duplex 0x if x=0 the cr...

Page 49

Section 1. Functional modes 1-15 table 1.8-10. Set initial baud rate / set rs232 power key entry display comments ∗ d 13:enter command 00 1 2 a 12: connect baud rate 00 x c a 12: connect baud rate enter baud 0x-- rate code x (table 1.8-11). Index (--) is optional. Table 1.8-11. Baud rate codes x = 0...

Page 50

Section 1. Functional modes 1-16 this is a blank page..

Page 51

2-1 section 2. Internal data storage 2.1 final storage areas, output arrays, and memory pointers final storage is the memory where final processed data are stored. Final storage data are transferred to your computer or external storage peripheral. The size of final storage is expressed in terms of m...

Page 52

Section 2. Internal data storage 2-2 output processing instructions store data into final storage only when the output flag is set. The string of data stored each time the output flag is set is called an output array. The first data point in the output array is a 3 digit output array id. This id num...

Page 53

Section 2. Internal data storage 2-3 2.2 data output format and range limits data are stored internally in campbell scientific's binary final storage format (appendix c.2). Data may be sent to final storage in either low resolution or high resolution format. 2.2.1 resolution and range limits low res...

Page 54

Section 2. Internal data storage 2-4 the output array equal to or just ahead of the location entered. Whenever a location number is displayed by using the "#" key, the corresponding data point can be displayed by pressing the "c" key. The same element in the next output array with the same id can be...

Page 55

3-1 section 3. Instruction set basics the instructions used to program the cr23x are divided into four types: input/output (i/o), processing, output processing, and program control. I/o instructions are used to make measurements and store the readings in input locations or to initiate analog or digi...

Page 56

Section 3. Instruction set basics 3-2 to be changed. See instructions 87 and 90, section 12, for more details. To index an input location (4 digit integer) or set port command (2 digit integer) parameter, c or "-" is pressed after keying the value but before entering the parameter. Two minus signs (...

Page 57

Section 3. Instruction set basics 3-3 the instructions to output the average temperature every 10 minutes are in table 2 which has an execution interval of 10 seconds. The temperature will be measured 600 times in the 10 minute period, but the average will be the result of only 60 of those measureme...

Page 58

Section 3. Instruction set basics 3-4 as an example, suppose it is desired to obtain a wind speed rose incorporating only wind speeds greater than or equal to 4.5 m/s. The wind speed rose is computed using the histogram instruction 75, and wind speed is stored in input location 14, in m/s. Instructi...

Page 59

Section 3. Instruction set basics 3-5 figure 3.8-2. Logical and construction if then/else comparisons may be nested to form logical and or or branching. Figure 3.8- 2 illustrates an and construction. If conditions a and b are true, the instructions included between if b and the first end instruction...

Page 60

Section 3. Instruction set basics 3-6 table 3.9-1. Cr23x input/output instruction execution t ime (ms) fast 60h z 50h z f ast 60h z f ast 50h z in st. D esc. Inloc b yt es 1- 4 or n a 10 11- 12 13- 14 15 20 21- 22 23- 24 25 30 31- 32 33- 34 35 40 41- 42 43- 45 50 51- 52 53- 55 1 v o lt (s e ) r 15 (...

Page 61

Section 3. Instruction set basics 3-7 table 3.9-2. Processing instruction memory and execution times r = no. Of reps. Input memory prog. Instruction loc. Inter. Loc. Bytes execution time (ms) 30 z=f 1 0 9 + = 0.5 + 0.1 ∗ exponent - = 0.5 + 0.3 * exponent 31 z=x 1 0 6 0.4 32 z=z+1 1 0 4 0.4 33 z=x+y ...

Page 62

Section 3. Instruction set basics 3-8 table 3.9-3. Cr23x output instructions r = no. Of reps. Final inter. Memory flag o flag 0 instruction loc. Values bytes option low high 69 wind vector 2+9r 2r 12 00, 2.7+8.3r 3.9+38.7r 3r 01, 2.7+8.3r 4.5+15.6r 4r 02, 2.4+8.8r 3.8+34.7r 2r 10, 2.1+8.2r 0.0+27.3r...

Page 63

Section 3. Instruction set basics 3-9 3.10 error codes there are four types of errors flagged by the cr23x: compile, run time, editor, and d mode. Compile errors are errors in programming which are detected once the program is entered and compiled for the first time ( 0 , 6 , or b mode entered). If ...

Page 64

Section 3. Instruction set basics 3-10 25 compile else without if 26 compile exit loop without loop 27 compile if case without begin case 30 compile if and/or loop nested too deep 31 run time subroutines nested too deep 32 compile instruction 3 and interrupt subroutine use same port 40 editor instru...

Page 65

4-1 section 4. External storage peripherals external data storage devices are used to provide a data transfer medium that the user can carry from the test site to the lab and to supplement the internal storage capacity of the cr23x, allowing longer periods between visits to the site. The standard da...

Page 66

Section 4. External storage peripherals 4-2 instruction 96 has a single parameter which specifies the peripheral to send output to. Table 4.1-1 lists the output device codes. Table 4.1-1. Output device and baud rate codes code baud rate 0 300 1 1200 2 9600 3 76800 4 2400 5 4800 6 19200 7 38400 param...

Page 67

Section 4. External storage peripherals 4-3 table 4.2-1. 8 mode entries display id: key data description ∗ 8 mode 08: storage area key 1 or 2 for storage area. (this window is skipped if no memory 00 has been allocated to final storage area 2.) a 01: device code key in output device option. See tabl...

Page 68

Section 4. External storage peripherals 4-4 the cr23x to output the date and time values. The output array id, day, and time are always 4 character numbers, even when high resolution output is specified. The seconds resolution is 0.1 seconds. Each full line of data contains 8 data points (79 charact...

Page 69

Section 4. External storage peripherals 4-5 4.4.1 storage module addressing the csm1 does not support individual addresses. Use address "1" when sending data to the csm1. The sm192/716 storage modules can have individual addresses. Different addresses allow 1) up to 8 storage modules to be connected...

Page 70

Section 4. External storage peripherals 4-6 2. Key in the appropriate commands as listed in table 4.2-1. 4.5 9 mode -- sm192/716 storage module commands the csm1 does not support the 9 mode commands. The 9 mode is used to issue commands to the sm192/716 storage module, from the cr23x. These commands...

Page 71

Section 4. External storage peripherals 4-7 07:xxxxxx sm location at end of area selected. Key a to advance to first data. If another location is keyed in sm will jump to 1st start of array following that location. Review data with: a advance and display next data point b back-up one data point # di...

Page 72

Section 4. External storage peripherals 4-8 this is a blank page..

Page 73

5-1 section 5. Telecommunications campbell scientific has developed a software package which automates data retrieval and facilitates the programming of campbell scientific dataloggers and the handling of data files. This package, pc208w, has been designed to meet most needs in datalogger support an...

Page 74

Section 5. Telecommunications 5-2 general rules governing the telecommunications commands are as follows: 1. ∗∗∗∗ from datalogger means "ready for command". 2. All commands are of the form: [no.]letter, where the number may or may not be optional. 3. Valid characters are the numbers 0-9, the capital...

Page 75

Section 5. Telecommunications 5-3 table 5.1-1. Telecommunications commands command description [f.S. Area]a select area/status - if 1 or 2 does not precede the a to select the final storage area, the cr23x will default to the area last used (initially this is area 1). All subsequent commands other t...

Page 76

Section 5. Telecommunications 5-4 [loc. No.]i display/change value at input storage location. Cr23x sends the value stored at the location. A new value and cr may then be sent. Cr23x sends checksum. If no new value is sent (cr only), the location value will remain the same. 3142j toggle flags and se...

Page 77

Section 5. Telecommunications 5-5 ## ## ## ##). Typing 8 numbers, separated by colons, followed by an r, will reset the default settings. Example: 140:110:90:65:50:45:34:30r the setting of the eight contrast temperature bins is initially done at campbell scientific. Below are the contrast settings o...

Page 78

Section 5. Telecommunications 5-6 examples: 14:-3.2450:xxxxu returns v-3.2450 c1357 (sets input location 14 to -3.2450) 9003:1:xxxxu returns v1.0000 cxxxx (sets flag 3 high) 9105:0:xxxxu returns v0.0000 cxxxx (sets port 5 low) 5.2 remote programming of the cr23x remote programming of the cr23x can b...

Page 79

6-1 section 6. 9-pin serial input/output external communication peripherals normally connect to the cr23x through two 9-pin subminiature d-type socket connectors located on the front panel (figure 6.1-1). An optically isolated rs-232 port is provided for direct connection to rs-232 devices such as a...

Page 80

Section 6. 9-pin serial input/output 6-2 table 6.2-1. Pin description abr = abbreviation for the function name. Pin = pin number. O = signal out of the cr10x to a peripheral. I = signal into the cr10x from a peripheral. Pin abr i/o description 1 5 v o 5v: sources 5 vdc, used to power peripherals. 2 ...

Page 81

Section 6. 9-pin serial input/output 6-3 6.2.1 enabling and addressing peripherals while several peripherals may be connected in parallel to the cs i/o port, the cr23x has only one transmit line (pin 9) and one receive line (pin 4, table 6.2-1). The cr23x selects a peripheral in one of two ways: 1) ...

Page 82

Section 6. 9-pin serial input/output 6-4 figure 6.2-3. Servicing of ring interrupts 6.2.4 modem/terminal peripherals the cr23x considers any device with an asynchronous serial communications port which raises the ring line (and holds it high until the me line is raised) to be a modem peripheral. Mod...

Page 83

Section 6. 9-pin serial input/output 6-5 to the address, however. State 2 ends when the 8th bit is received by the sd. Sds implemented with shift registers decode the 4 most significant bits (bits 4, 5, 6, and 7) for an address. Bit 0 is always logic high. Bits 1, 2, and 3 are optional function sele...

Page 84

Section 6. 9-pin serial input/output 6-6 6.2.6.1 sc32a interface to computer most computers require the sc32a optically isolated rs-232 interface to communicate to the cs i/o port. (direct connection to the cr23x is allowed through the “computer rs-232” port.) the sc32a can pass data up to 19.2 k ba...

Page 85

Section 6. 9-pin serial input/output 6-7 table 6.2-4. Dte pin configuration pin = 25-pin connector number abr = abbreviation for the function name o = signal out of terminal to another device i = signal into terminal from another device pin abr i/o function 2 td o transmitted data: data is transmitt...

Page 86

Section 6. 9-pin serial input/output 6-8 figure 6.2-5. Transmitting the ascii character 1 baud rate baud rate is the number of bits transmitted per second. The cr23x can communicate at 300, 1200, 4800, 9600, 19200, 38400, and 76800 baud. In the telecommunications state, the cr23x will set its baud r...

Page 87

Section 6. 9-pin serial input/output 6-9 if garbage appears if garbage characters appear on the display, check that the baud rate is supported by the cr23x. If the baud rate is correct, verify that the computer/terminal is set for 8 data bits, and no parity. Garbage will appear if 7 data bits and no...

Page 88

Section 6. 9-pin serial input/output 6-10 this is a blank page..

Page 89

7-1 section 7. Measurement programming examples this section gives some examples of input programming for common sensors used with the cr23x. These examples detail only the connections, input, program control, and processing instructions necessary to perform measurements and store the data in engine...

Page 90

Section 7. Measurement programming examples 7-2 ;measure relative humidity. ; 04: volts (se) (p1) 1: 1 reps 2: 25 ± 5000 mv slow 60 hz rejection range 3: 6 se channel 4: 2 loc [ rh_pct ] 5: .1 mult 6: 0 offset ;turn cs500 off. ; 05: do (p86) 1: 59 set switched 12 v low input locations 1 temp_c 2 rh_...

Page 91

Section 7. Measurement programming examples 7-3 7.2 differential voltage measurement some sensors either contain or require active signal conditioning circuitry to provide an easily measured analog voltage output. Generally, the output is referenced to the sensor ground. The associated current drain...

Page 92

Section 7. Measurement programming examples 7-4 the temperature of the 107 probe is stored in input location 1 and the thermocouple temperatures in locations 2-6. Program 1: temp (107) (p11) 1: 1 reps 2: 1 se channel 3: 1 excite w/e1+reps 4: 1 loc [ ref_temp ] 5: 1.0 mult 6: 0 offset 2: thermocouple...

Page 93

Section 7. Measurement programming examples 7-5 program 1: pulse (p3) 1: 1 reps 2: 1 pulse channel 1 3: 20 high frequency, output hz 4: 1 loc [ ws_m_s ] 5: .0979 mult 6: .2 offset 7.7 tipping bucket rain gauge with long leads a tipping bucket rain gauge is measured with the pulse count instruction c...

Page 94

Section 7. Measurement programming examples 7-6 i = 50mv/rs = 50mv/115. 54 ohms = 0.433ma next solve for v x : v x = i(r 1 +r s +r f ) = 4.42v if the actual resistances were the nominal values, the cr23x would not overrange with v x = 4.4v. To allow for the tolerances in the actual resistances, it i...

Page 95

Section 7. Measurement programming examples 7-7 the multiplier used in instruction 7 is determined in the same manner as in section 7.8. In this example, the multiplier (r f /r 0 ) is assumed to be 100.93. The 3 wire half bridge compensates for lead wire resistance by assuming that the resistance of...

Page 96

Section 7. Measurement programming examples 7-8 it is desired to control the temperature bath at 50 o c with as little variation as possible. High resolution is desired so the control algorithm will be able to respond to minute changes in temperature. The highest resolution is obtained when the temp...

Page 97

Section 7. Measurement programming examples 7-9 the offset is determined after the pressure transducer is installed in the stilling well. The sensor is installed 65 cm below the water level at the time of installation. The depth of water at this time is determined to be 72.6 cm relative to the desir...

Page 98

Section 7. Measurement programming examples 7-10 cell, the excitation voltage actually applied to the load cell, v 1 would be: v1 = v x rs/rt = v x 350/(350+33) = 0.91 v x where v x is the excitation voltage. This means that the voltage output by the load cell would only be 91% of that expected. If ...

Page 99

Section 7. Measurement programming examples 7-11 cr23x figure 7.12-2. 6 wire full bridge connection for load cell program 1: full bridge w/mv excit (p9) 1: 1 reps 2: 25 5000 mv, 60 hz reject, fast, ex range 3: 21 10 mv, 60 hz reject, slow, br range 4: 1 diff channel 5: 1 excite all reps w/exchan 1 6...

Page 100

Section 7. Measurement programming examples 7-12 2: br transform rf[x/(1-x)] (p59) 1: 6 reps 2: 1 loc [ vs_vx_1 ] 3: .1 multiplier (rf) 3: polynomial (p55) 1: 6 reps 2: 1 x loc [ vs_vx_1 ] 3: 1 f(x) loc [ vs_vx_1 ] 4: .15836 c0 5: 6.1445 c1 6: -8.4189 c2 7: 9.2493 c3 8: -3.1685 c4 9: .33392 c5 7.14 ...

Page 101

Section 7. Measurement programming examples 7-13 7.15 water level - geokon's vibrating wire pressure sensor the vibrating wire sensor utilizes a change in the frequency of a vibrating wire to sense pressure. Figure 7.15-1 illustrates how an increase in pressure on the diaphragm decreases the tension...

Page 102

Section 7. Measurement programming examples 7-14 the following calculations are based on using a geokon model 4500 vibrating wire sensor. An individual multiplier and offset must be calculated for each sensor used in a system. Multiplier the fundamental equation relating frequency to pressure is p =...

Page 103

Section 7. Measurement programming examples 7-15 cr23x & avw1 figure 7.15-2. Well monitoring example.

Page 104

Section 7. Measurement programming examples 7-16 cr23x figure 7.15-3. Hook up to avw1 program avw1 & cr23x used to measure 1 geokon vibrating wire sensor. * table 1 program 01: 60 execution interval (seconds) 01: excite-delay (se) (p4) 1: 1 reps 2: 15 ± 5000 mv fast range 3: 1 se channel 4: 1 excite...

Page 105

Section 7. Measurement programming examples 7-17 04: z=x+f (p34) 1: 1 x loc [ temp ] 2: -24 f 3: 3 z loc [ temp_comp ] 05: z=x*f (p37) 1: 3 x loc [ temp_comp ] 2: -.0698 f 3: 3 z loc [ temp_comp ] 06: z=x+y (p33) 1: 3 x loc [ temp_comp ] 2: 2 y loc [ pressure ] 3: 2 z loc [ pressure ] 07: if (xf) (p...

Page 106

Section 7. Measurement programming examples 7-18 time out, parameter 5 the "time out", parameter 5, specifies the maximum length of time the instruction waits on each repetition to receive the number of cycles specified in parameter 4. The time out units are 0.01 seconds. The minimum time out is the...

Page 107

Section 7. Measurement programming examples 7-19 cr23x connections figure 7.16-1. Cr23x/paroscientific "t" series transducer wiring diagram program example the following example reads the coefficients from a subroutine only when the datalogger program is compiled. The coefficients are stored in inpu...

Page 108

Section 7. Measurement programming examples 7-20 ;find temperature and pressure. ; 04: paroscientific (p64) 1: 1 loc [ temp_us ] 2: 19 loc [ temp_c ] * table 3 subroutines 01: beginning of subroutine (p85) 1: 1 subroutine 1 02: bulk load (p65) 1: 5.8603 f 2: -3970.3 f 3: -7114.3 f 4: 102.78 f 5: 70....

Page 109

Section 7. Measurement programming examples 7-21 4h 4l ag g 12v g cr10x h l gnd 4 to 20 ma sensor 100 Ω ± 0.01% curs100 cr23x 4h 4l g 12v power out g figure 7.17-1 wiring diagram for curs100 terminal input module and 4 to 20 ma sensor..

Page 110

Section 7. Measurement programming examples 7-22 this is a blank page..

Page 111

8-1 section 8. Processing and program control examples the following examples are intended to illustrate the use of processing and program control instructions, flags, dual final storage, and the capability to direct the results of output processing instructions to input storage. The specific exampl...

Page 112

Section 8. Processing and program control examples 8-2 06: sample (p70) 1: 1 reps 2: 2 loc [ 10smpl_mx ] input locations 1 panl_temp 15 temp_i_5 2 10smpl_mx 16 temp_i_4 11 temp_i_#1 17 temp_i_3 12 temp_i_8 18 temp_i_2 13 temp_i_7 19 temp_i_1 14 temp_i_6 20 temp_i in the above example, all samples fo...

Page 113

Section 8. Processing and program control examples 8-3 every 15 minutes, the total rain is sent to input storage. If the total is not equal to 0, output is redirected to final storage area 1, the time is output and the total is sampled. Program * table 1 program 01: 60.0 execution interval (seconds)...

Page 114

Section 8. Processing and program control examples 8-4 12v g c1 c2 1h 1l ex1 2l ex2 2h cr23x am416 figure 8.3-1. Am416 wiring diagram for thermocouple and soil moisture block measurements program * table 1 program 01: 600.0 execution interval (seconds) 01: temp (107) (p11) 1: 1 reps 2: 4 se channel ...

Page 115

Section 8. Processing and program control examples 8-5 input locations 1 ref_temp 12 tc_#11 23 soil_#6 2 tc_#1 13 tc_#12 24 soil_#7 3 tc_#2 14 tc_#13 25 soil_#8 4 tc_#3 15 tc_#14 26 soil_#9 5 tc_#4 16 tc_#15 27 soil_#10 6 tc_#5 17 tc_#16 28 soil_#11 7 tc_#6 18 soil_#1 29 soil_#12 8 tc_#7 19 soil_#2 ...

Page 116

Section 8. Processing and program control examples 8-6 03: if time is (p92) 1: 0 minutes (seconds --) into a 2: 60 interval (same units as above) 3: 10 set output flag high 04: real time (p77) 1: 0110 day,hour/minute 05: totalize (p72) 1: 3 reps 2: 10 loc [ precip_1 ] input locations 10 precip_1 11 ...

Page 117

Section 8. Processing and program control examples 8-7 08: scaling array (a*loc+b) (p53) 1: 5 start loc [ ws_out ] 2: 10 a1 ;scale ws, 0 to 100 mph = 0 to 1000 mv 3: 0 b1 4: 1.8519 a2 ;scale wd, 0 to 540 deg = 0 to 1000 mv 5: 0 b2 6: 25 a3 ;scale temp, 0 to 40 c = 0 to 1000 mv 7: 0 b3 8: 1000 a4 ;sc...

Page 118

Section 8. Processing and program control examples 8-8 07: z=x (p31) 1: 2 x loc [ 0_360_wd ] 2: 10 z loc [ 0_540_wd ] 08: if (xf) (p89) 1: 10 x loc [ 0_540_wd ] 2: 4 3: 180 f 4: 30 then do 09: if flag/port (p91) 1: 11 do if flag 1 is high 2: 30 then do 10: z=x+f (p34) 1: 10 x loc [ 0_540_wd ] 2: 360...

Page 119

Section 8. Processing and program control examples 8-9 07: if flag/port (p91) 1: 21 do if flag 1 is low 2: 30 then do 08: do (p86) 1: 11 set flag 1 high 09: z=f (p30) 1: 10 f 2: 0 exponent of 10 3: 2 z loc [ down_cnt ] 10: end (p95) 11: end (p95) 12: if (xf) (p89) 1: 2 x loc [ down_cnt ] 2: 1 = 3: 0...

Page 120

Section 8. Processing and program control examples 8-10 program * table 1 program 01: 10 execution interval (seconds) ;user must toggle flag 1 to start measurements. ; 01: if flag/port (p91) 1: 21 do if flag 1 is low 2: 0 go to end of program table ;loop 1, output every 10 seconds for 10 minutes. ; ...

Page 121

Section 8. Processing and program control examples 8-11 8.10 covariance correlation programming example the example is a 2 level meteorological tower with 5 sensors at each level. The three components of the wind are measured using prop anemometers. Two thermocouples (tc) are used to measure ambient...

Page 122

Section 8. Processing and program control examples 8-12 table 8.10-3 lists the input channel configuration and input storage allocation for the measured values. After reading the new input samples, the level 2 measurements are relocated using the block move instruction 54, then ta1 is relocated thro...

Page 123

Section 8. Processing and program control examples 8-13 03: am25tmultiplexer (p134) 1: 4 reps 2: 11 10 mv, fast range 3: 1 channel 4: 4 diff channel 5: 21 exchan 1, 60 hz reject 6: 1 clock control 7: 2 reset control 8: 2 type e (chromel-constantan) 9: 16 ref temp (deg. C) loc [ ref_temp ] 10: 7 loc ...

Page 124

Section 8. Processing and program control examples 8-14 11: covariance/correlation (p62) 1: 5 no. Of input locations 2: 5 no. Of means 3: 5 no. Of variances 4: 0 no. Of std. Dev. 5: 4 no. Of covariance 6: 2 no. Of correlations 7: 300 samples per average 8: 1 first sample loc [ w1 ] 9: 20 loc [ mean_...

Page 125

Section 8. Processing and program control examples 8-15 8.11 fast fourier transform examples 8.11.1. Example without bin averaging the cr23x was used to generate data representing two superimposed sine wave signals, one at 1.25 hz (amplitude = 1) and the other at 0.25 hz (amplitude = 2). The 1024 ge...

Page 126

Section 8. Processing and program control examples 8-16 figure 8.11-2. Fft power spectra analysis of 0.25 and 1.25 hz signal table 8.11-1. Fft real and imaginary results 0.25 and 1.25 hz signal bin # hz fft ri fft ii 0 0 0.02303 0 1 0.009766 0.01036 0 2 0.019532 -0.00206 0 3 0.029298 0 0 22 0.214852...

Page 127

Section 8. Processing and program control examples 8-17 table 8.11-2. Fft magnitude and phase results 0.25 and 1.25 hz signal bin # hz fft mi fft pi 0 0 0.02303 0 1 0.009766 0.01036 0 2 0.019532 0.00206 180 3 0.029298 0 -99999 22 0.214852 0.00086 185.58 23 0.224618 0.01154 17.952 24 0.234384 0.20321...

Page 128

Section 8. Processing and program control examples 8-18 02: z=f (p30) 1: 0 f 2: 0 exponent of 10 3: 1025 z loc [ _________ ] 03: z=f (p30) 1: 0 f 2: 0 exponent of 10 3: 1026 z loc [ _________ ] 04: beginning of loop (p87) 1: 0 delay 2: 1024 loop count 05: z=sin(x) (p48) 1: 1025 x loc [ _________ ] 2...

Page 129

Section 8. Processing and program control examples 8-19 figure 8.11-3. Simulated ocean buoy wave data figure 8.11-4. Simulated ocean buoy fft results.

Page 130

Section 8. Processing and program control examples 8-20 table 8.11-4. Fft bin averaging results from simulated ocean buoy wave data bin # frequency fft*0.1 bin # frequency fft*0.1 1 0.00195 0 26 0.0507 0 2 0.0039 0 27 0.05265 0 3 0.00585 0 28 0.0546 0 4 0.0078 0 29 0.05655 0 5 0.00975 0 30 0.0585 0 ...

Page 131

Section 8. Processing and program control examples 8-21 10: if flag/port (p91) 1: 12 do if flag 2 is high 2: 30 then do 11: fft (p60) 1: 11 log (base 2) of samples 2: 1 power spectra/taper 3: 3 log (base 2) of bins 4: 284 first sample loc [ _________ ] 5: .1 mult 12: beginning of loop (p87) 1: 0 del...

Page 132

Section 8. Processing and program control examples 8-22 14: scaling array (a*loc+b) (p53) 1: 8 start loc [ _________ ] 2: 4 a1 3: 0 b1 4: 6 a2 5: 0 b2 6: 9 a3 7: 0 b3 8: 11 a4 9: 0 b4 15: z=f (p30) 1: 0 f 2: 0 exponent of 10 3: 12 z loc [ _________ ] 16: beginning of loop (p87) 1: 0 delay 2: 4 loop ...

Page 133

Section 8. Processing and program control examples 8-23 black red red black asptc (lower) purple red asptc (upper) purple red 2h 2l 3h 3l g g switched 12 v figure 8.12-1. Connections to power two 12 v asptcs with the switched 12 v on the cr23x wiring panel program * table 1 program 01: 20 execution ...

Page 134

Section 8. Processing and program control examples 8-24 this is a blank page..

Page 135

9-1 section 9. Input/output instructions table 9-1. Input voltage ranges and codes resolution range codes* full scale range differential** fast 250 µ s 60 hz 50 hz integ. Reject. Reject. 10 20 30 autorange*** 11 21 31 ± 10 mv 0.33 µv 12 22 32 ±50 mv 1.67 µv 13 23 33 ±200 mv 6.66 µv 14 24 34 ±1000 mv...

Page 136

Section 9. Input/output instructions 9-2 cr23x pi 20k figure 9-1. Conditioning large voltage pulses use separate pulse count instructions when measuring both pulse channels and control ports. All pulse count instructions must be kept in the same program table. If the pulse count instruction is conta...

Page 137

Section 9. Input/output instructions 9-3 • control ports the switch closure is connected between channels c5..C8 and the 5 v terminal. When the switch is open, the control port is pulled to ground through an internal 100 kohm resistor. When the switch is closed, the control port is at 5 v. The count...

Page 138

Section 9. Input/output instructions 9-4 table 9-3. Execution and counter reset intervals and maximum input frequencies user programmed counter counter maximum execution reset reset input interval (s) interval (s) frequency (hz) frequency (khz) 0.01 0.01 100 25.5 0.02 0.02 50 12.75 0.03 0.01 100 25....

Page 139

Section 9. Input/output instructions 9-5 less than 4 seconds, control ports c5..C8 measure frequency much more precisely than do pulse channels. • pulse channels hz = counts / execution interval maximum error (hz) = ± [1/(execution interval - 50 µ s)] • control ports hz = counts / measured time ( ± ...

Page 140

Section 9. Input/output instructions 9-6 *** 5 ac half bridge *** function this instruction is used to apply an excitation voltage to a half bridge (figure 13.5-1), make a single-ended voltage measurement of the bridge output, reverse the excitation voltage, then repeat the measurement. The differen...

Page 141

Section 9. Input/output instructions 9-7 param. Data number type description 01: 2 repetitions 02: 2 range code for both measurements (table 9-1) 03: 2 single-ended channel number for first measurement 04: 2 excitation channel (table 9-2a) 05: 4 excitation voltage (millivolts) 06: 4 input location n...

Page 142

Section 9. Input/output instructions 9-8 param. Data number type description 01: 2 repetitions 02: 2 range code for excitation measurement (v 1 ) (do not use autorange) (table 9-1) 03: 2 range code for bridge measurement (v 2 ) 04: 2 differential channel number for first measurement 05: 2 excitation...

Page 143

Section 9. Input/output instructions 9-9 note: the temperature value used in compensating the rh value (parameter 5) must be obtained (see instruction 11) prior to executing instruction 12 and must be in celsius. The rh results are placed sequentially into the input locations beginning with the firs...

Page 144

Section 9. Input/output instructions 9-10 table 9-5. Voltage and temperature ranges for thermocouples if the reference is 20 °°°° c voltage range type t type e type k type j ± 10 mv -200 to 227 -199 to 169 -56 to 264 -150 to 205 ± 50 mv -200 to 400 -240 to 675 -56 to 1372 -150 to 422 ± 200 mv ----- ...

Page 145

Section 9. Input/output instructions 9-11 *** 15 control port serial i/o *** function send and receive serial data through the cr23x control ports, see appendix b for details on using instruction 15. *** 16 temperature from *** platinum r.T.D. Function this instruction uses the result of a previous ...

Page 146

Section 9. Input/output instructions 9-12 *** 20 set port *** function this instruction sets or configures specified control ports (c1-c8). On power-up, ports default to input configuration (i.E., they are not driven high or low by the cr23x, and can be used to read the status of an external signal ...

Page 147

Section 9. Input/output instructions 9-13 if the excitation channel is indexed, parameter 4 becomes an input location. The excitation voltage must be loaded into the specified input location before instruction 22 is executed. Param. Data number type description 01: 2 excitation channel number (table...

Page 148

Section 9. Input/output instructions 9-14 specified transition to trigger. For example, when triggering on the rising edge, if the input starts out high, it must go low and then high again to trigger. Data sent to input storage when the measurements are sent to input storage, parameter 6 is used to ...

Page 149

Section 9. Input/output instructions 9-15 note: when the raw serial data option is selected, the calibration values are for conversion to millivolts only. Parameters 11 and 12 are ignored. Scan interval instruction 23 has its own scan interval independent of the execution interval of the program tab...

Page 150

Section 9. Input/output instructions 9-16 3 - cs i/o port 76,800 baud to sm192/716 5 - cs i/o port 38.4 k 6 - rs-232 port 38.4 k d measurement 0 - differential measurement 1 - single-ended measurement 05: fp scan interval (ms, minimum 0.6666 x reps, limited to 25 ms) 06: fp number of scans (units of...

Page 151

Section 9. Input/output instructions 9-17 *** 26 timer *** function this instruction will reset a timer or store the elapsed time registered by the timer in seconds in an input storage location. Instruction 26 can be used with program control instructions to measure the elapsed time between specific...

Page 152

Section 9. Input/output instructions 9-18 c v o s sensor with dc offset silicon diodes such as 1n4001 to single - ended input 1µf d1 d2 r 10k figure 9-2. Recommended input conditioning circuit for period averaging. An internal gain stage is used to amplify low- level ac signals prior to a zero-cross...

Page 153

Section 9. Input/output instructions 9-19 04: 4 # cycles to measure 05: 4 time out (0.01 sec, at least the maximum duration of the number of cycles specified + 1 1/2 cycles.) 06: 4 destination input location 07: fp multiplier 08: fp offset input locations altered: 1 per repetition *** 28 vibrating w...

Page 154

Section 9. Input/output instructions 9-20 *** 101 sdm-int8 *** function the 8 channel interval timer (int8) is a measurement module which provides processed timing information to the datalogger. Each of the 8 input channels may be independently configured to detect either rising or falling edges of ...

Page 155

Section 9. Input/output instructions 9-21 indicates bad ram. Function option 3 is not used routinely, but is helpful in "debugging". Only one rep is required for option 3. Parameter 4 specifies the first sw8a channel to be read (1..8). One or more sequential channels are read depending on the reps. ...

Page 156

Section 9. Input/output instructions 9-22 param. Data number type description 01: 2 reps (# of cd16ac modules sequentially addressed) 02: 2 starting address, base 4 (00..33) 03: 4 starting input location input locations read: 16 per repetition *** 105 sdi-12 recorder *** note: version 1.2 of the sdi...

Page 157

Section 9. Input/output instructions 9-23 execution of the instruction, the cr23x will again issue the ‘c’ command. The results of an m, c, m1-m9, or v command sequence is numerical data, stored in input location(s). The response to the i command is text information, which is written directly to fin...

Page 158

Section 9. Input/output instructions 9-24 parameter 3. Port enter the cr23x control port (c5-c8) connected to the sdi-12 sensor data line. The default port is c8. Parameter 4. Input location input location where the returned data is stored. If multiple values are returned from the sdi-12 sensor they...

Page 159

Section 9. Input/output instructions 9-25 this is likely to occur if subroutine 98 execution takes longer than the scan interval programmed for table 1 or 2. It is also possible for instructions in table 1 or 2 to prevent subroutine 98 from being called in time for instruction 106 to receive the add...

Page 160

Section 9. Input/output instructions 9-26 *** 107 sdm-csat3 *** function this instruction controls and receives data from csi’s three-dimensional sonic anemometer (csat3). See the csat3 manual for information on instruction 107. Input locations altered: 5 per repetition *** 108 sdm-udg01 *** functio...

Page 161

Section 9. Input/output instructions 9-27 param. Data number type description 01: 4 bit period, 10 µ s units normally this parameter represents the bit period. If the parameter is indexed (--), the value entered is an input location that contains the bit period to use. Note: the tdr instruction 100 ...

Page 162

Section 9. Input/output instructions 9-28 table 9-10. Extended vibrating wire range codes range peak to peak volts maximum code required @ max. Freq.* frequency 1 2 mv 10 khz 2 5 mv 20 khz 3 20 mv 30 khz 4 500 mv 100 khz param data number type description 01: 2 repetitions (index (- - ) to skip repe...

Page 163

Section 9. Input/output instructions 9-29 param. Data number type description 01: 2 option / cao channel number 02: 4 input location number of analog output magnitude (mv) input location read: 1 *** 134 am25t *** this instruction controls the am25t solid state multiplexer for thermocouples. P134 can...

Page 164

Section 9. Input/output instructions 9-30 this is a blankpage..

Page 165

10-1 section 10. Processing instructions to facilitate cross referencing, parameter descriptions are keyed [ ] to the values given on the prompt sheet. These values are defined as follows: [z] = destination input location for result [x] = input location of x [y] = input location of y [f] = fixed dat...

Page 166

Section 10. Processing instructions 10-2 *** 36 x * y *** function multiply x by y and place the result in an input location (z). Param. Data number type description 01: 4 input location of x [x] 02: 4 input location of y [y] 03: 4 dest. Input location for x*y [z] input locations altered: 1 *** 37 x...

Page 167

Section 10. Processing instructions 10-3 *** 43 abs(x) *** function take the absolute (abs) value of x and place the result in an input location. Param. Data number type description 01: 4 input location of x [x] 02: 4 dest. Input location for abs(x) [z] input locations altered: 1 *** 44 fractional v...

Page 168

Section 10. Processing instructions 10-4 parameter 3 cannot be entered as an indexed location within a loop (instruction 87). To use instruction 49 within a loop, enter parameter 3 as a fixed location and follow 49 with the instruction 31 (move data). In instruction 31, enter the location in which 4...

Page 169

Section 10. Processing instructions 10-5 05: fp offset 2 [b2] 06: fp multiplier 3 [a3] 07: fp offset 3 [b3] 08: fp multiplier 4 [a4] 09: fp offset 4 [b4] input locations altered: 4 *** 54 block move *** function executes a "block move" of data in input locations. Parameters specify the number of val...

Page 170

Section 10. Processing instructions 10-6 *** 57 vapor pressure from *** wet-/dry-bulb temperatures function calculate vapor pressure in kilopascals from wet and dry-bulb temperatures in ° c. This algorithm type is used by the national weather service: vp = vpw - a(1 + b*tw)(ta - tw) p vp = ambient v...

Page 171

Section 10. Processing instructions 10-7 *** 60 fast fourier transform *** theory instruction 60 performs a fast fourier transform (fft) on a set of data contained in contiguous locations in input storage. The fft is used to obtain information on the relative magnitudes and phases of the various fre...

Page 172

Section 10. Processing instructions 10-8 the magnitude and phase components. Bin averaging is not allowed with this option. Second digit: a "0" in the second digit specifies that no taper be applied, whereas a "1" specifies that a taper be applied. If the original data set is not known to be periodi...

Page 173

Section 10. Processing instructions 10-9 real and imaginary components the result of the fft when the real and imaginary option is selected is n/2 input locations containing the real components (r i ) followed by n/2 input locations containing the imaginary components (i i ). There is a real and an ...

Page 174

Section 10. Processing instructions 10-10 bin frequency the band width or the frequency covered by each averaged bin is equal to fa/n where f is the sample frequency in hz (1/scan interval in seconds) and a is the number of bins being averaged. The frequency (f i ) of any given averaged bin i where ...

Page 175

Section 10. Processing instructions 10-11 *** 61 indirect indexed move *** function moves input data from location x to location y, where x and/or y are indirectly addressed (x and y are stored in the locations specified by parameters 1 and 2). If a location parameter is specified as "indexed" (xxxx...

Page 176

Section 10. Processing instructions 10-12 table 10-2. Maximum number of outputs and output order for k input values. (the output order flows from left to right and from top to bottom) inputs: x1 x2 x3 x4 ..... Xk max no. Outputs type outputs (1st) (2nd) (3rd) (4th) (kth) means k m(x1) m(x2) m(x3) m(...

Page 177

Section 10. Processing instructions 10-13 the averaging period processing occurs whenever the number of input samples entered in parameter 7 is satisfied or whenever an output interval occurs (i.E., whenever the output flag is set). Results from these calculations are stored sequentially in input st...

Page 178

Section 10. Processing instructions 10-14 c = k if k requested, or c = number of correlations + 1 if k > the number of correlations requested. 3. Define q as the maximum of either the covariances or correlations desired. 4. Define p as the total number of outputs desired. The amount of intermediate ...

Page 179

Section 10. Processing instructions 10-15 tau = measured pressure (microsecond), u(t) = measured temperature (microsecond). Values for the calibration coefficients (u 0 , y 1 , y 2 , y 3 , c 1 , c 2 , c 3 , d 1 , d 2 , t 1 , t 2 , t 3 , t 4 , t 5 ) are provided by paroscientific. Instruction 64 has ...

Page 180

Section 10. Processing instructions 10-16 *** 66 arctan *** function calculate the angle in degrees whose tangent is x/y. The polarity of x and y must be known to determine the quadrant of the angle, as shown here. If 0 is entered for parameter 2, the arctangent of x is the result (limits of arctan(...

Page 181

11-1 section 11. Output processing instructions *** 69 wind vector *** function instruction 69 processes the primary variables of wind speed and direction from either polar (wind speed and direction) or orthogonal (fixed east and north propellers) sensors. It uses the raw data to generate the mean w...

Page 182

Section 11. Output processing instructions 11-2 there are three output options that specify the values calculated. Option 0: mean horizontal wind speed, s. Unit vector mean wind direction, Θ 1. Standard deviation of wind direction, σ ( Θ 1). Standard deviation is calculated using the yamartino algor...

Page 183

Section 11. Output processing instructions 11-3 *** 71 average *** function this instruction stores the average value over the given output interval for each input location specified. Param. Data number type description 01: 2 repetitions 02: 4 starting input location no. Outputs generated: 1 per rep...

Page 184

Section 11. Output processing instructions 11-4 while the bin select value was within a particular sub-range, the value output to final storage must be divided by the fraction of time that the bin select value was within that particular sub- range (i.E., a standard histogram of the bin select value ...

Page 185

Section 11. Output processing instructions 11-5 code result xxx1 seconds (with resolution of 0.125 sec.) xx1x hour-minute xx2x hour-minute, 2400 instead of 0000 x1xx julian day x2xx julian day, previous day during first minute of new day 1xxx year any combination of year, day, hr-min, and seconds is...

Page 186

Section 11. Output processing instructions 11-6 the burst mode. The rainflow instruction can process either a swath of data following the burst mode, or it can process "on line" similar to other processing instructions. The output is a two dimensional rainflow histogram for each sensor or repetition...

Page 187

Section 11. Output processing instructions 11-7 09: 2 option (ab) a: form 0 = closed, 1 = open form b: output 0 = fraction, 1 = counts 10: 4 input location to start storing histogram. Enter 0 to send output directly to final storage. Execution time: 6.5 - 7.0 ms, with 60 amplitude bins and one mean ...

Page 188

Section 11. Output processing instructions 11-8 this is a blankp age..

Page 189

12-1 section 12. Program control instructions table 12-1. Flag description flag 0 output flag flag 1 to 8 user flags flag 11 to 18 user flags flag 9 intermediate processing disable flag table 12-2. Command codes 0 go to end of program table 3 1-9, 79-99 call subroutine 1-9, 79-99 1 10-19 set flag 0-...

Page 190

Section 12. Program control instructions 12-2 note: do not set the output flag in an interrupt subroutine unless it is the only place the output flag is set and data are output. Note: if control ports 5, 6, 7, or 8 are used for pulse measurements or interrupt subroutines, the cr23x will go into a 10...

Page 191

Section 12. Program control instructions 12-3 locations: one for the number of samples and one for the running total. Each time through the loop the sample counter is incremented and the value in the referenced input location is added to the total. If the input location is indexed, the values from a...

Page 192

Section 12. Program control instructions 12-4 seconds; the rest of the time one minute between samples is sufficient. The execution interval is set to 10 seconds; when a one minute sample rate is desired, a delay of 6 (6 x 10s = 60s) is used in the loop. Table 12-4. Example: loop with delay 1: begin...

Page 193

Section 12. Program control instructions 12-5 location parameters in subsequent instructions. For example, if 4 is specified, the index counter will count up by 4 (0,4,8,12,...) inside the loop. Instruction 90 does not affect the loop counter which still counts by 1. Param. Data number type descript...

Page 194

Section 12. Program control instructions 12-6 param. Data number type description 01: 4 input location for subsequent comparisons example: 1: case (p93) 1: 2 case loc [ valuex ] 2: if case location 1: 69.4 f 2: 3 call subroutine 3 ;else 3: if case location 1: 72 f 2: 10 set output flag high (flag 0)...

Page 195

Section 12. Program control instructions 12-7 the final storage area. Instruction 98 to send characters also uses this queue. When an entry reaches the top of the queue, the cr23x sends all data accumulated since the last transfer to the device up to the location of the dsp at the time the device be...

Page 196

Section 12. Program control instructions 12-8 can be output to cr23x final storage. Doing so will help evaluate the success of p97. P97 should not be placed in a conditional statement or subroutine, but rather controlled by controlling the interrupt disable flag. P97 must be executed twice for each ...

Page 197

Section 12. Program control instructions 12-9 additional programming requirements radio, telephone, and generic modem applications require the use of one or more instruction p68 immediately following p97. P68 hints: digits, such as telephone numbers and rf addresses, are entered directly, one charac...

Page 198

Section 12. Program control instructions 12-10 table 12-8. Instruction p68 parameters specific to generic modem applications parameter description tn transmit n bytes (n = ascii digit, bytes = ascii decimal equivalent) en transmit n bytes, wait for echo (n = ascii digit, bytes = ascii decimal equiva...

Page 199

Section 12. Program control instructions 12-11 note: the memory allocation ( a ) must be the same between the program in ram and the program that is loaded from flash. If the memory allocations are not the same, the cr23x will reallocate memory and the data in final storage will be lost. Do not use ...

Page 200

Section 12. Program control instructions 12-12 special movement codes possible to use 8, 129 backspace 10 clears bottom line 13 blank display 16 turn off display 128 beginning of top line 192 beginning of bottom line 128-151 skip # spaces (please note that not all “characters” are displayed on the s...

Page 201

13-1 section 13. Cr23x measurements note: highlighted portions of this section have not been updated for the cr23x. 13.1 fast and slow measurement sequence the cr23x makes voltage measurements by integrating the input signal for a fixed time and then holding the integrated value for the analog to di...

Page 202

Section 13. Cr23x measurements 13-2 figure 13.1-1. Fast 50 and 60 hz noise rejection 450 us 250 us fast 260 us reset integrator 16.67 ms 60 hz reject 20.00 ms 50 hz reject figure 13.1-2. Timing of single-ended measurement 13.1.1 offset voltage measurement a single-ended measurement on the ± 10 mv an...

Page 203

Section 13. Cr23x measurements 13-3 250 us fast 260 us 500 us 250 us fast 260 us 16.67 ms 60 hz reject 16.67 ms 60 hz reject 20.00 ms 50 hz reject 20.00 ms 50 hz reject figure 13.2-2. Differential voltage measurement sequence another instance where a ground potential difference creates a problem is ...

Page 204

Section 13. Cr23x measurements 13-4 13.3 the effect of sensor lead length on the signal settling time whenever an analog input is switched into the cr23x measurement circuitry prior to making a measurement, a finite amount of time is required for the signal to stabilize at its correct value. The rat...

Page 205

Section 13. Cr23x measurements 13-5 for the rising case, v s = v so -v e , whereas for the decaying transient, v s = v so +v e . Substituting these relationships for v s in equations 13.3-1 and 13.3-2, respectively, yields expressions in v e , the input settling error: v e = v so e-t/r o c t , rise ...

Page 206

Section 13. Cr23x measurements 13-6 determining source resistance the source resistance used to estimate the settling time constant is the resistance the cr23x input "sees" looking out at the sensor. For our purposes the source resistance can be defined as the resistance from the cr23x input through...

Page 207

Section 13. Cr23x measurements 13-7 dielectric absorption the dielectric absorption of insulation surrounding individual conductors can seriously affect the settling waveform by increasing the time required to settle as compared to a simple exponential. Dielectric absorption is difficult to quantify...

Page 208

Section 13. Cr23x measurements 13-8 r o , the source resistance, is not constant because r b varies from 0 to 10 kohms over the 0 to 360 degree wind direction range. The source resistance is given by: r o = r d +(r b (r s -r b +r f )/(r s +r f )) = r d +(r b (20k-r b )/20k) [13.3-12] note that at 36...

Page 209

Section 13. Cr23x measurements 13-9 note: excitation transients are eliminated if excitation leads are contained in a shield independent from the signal leads. The size of the peak transient is linearly related to the excitation voltage and increases as the bridge resistor, r f , increases. Table 13...

Page 210

Section 13. Cr23x measurements 13-10 table 13.3-6. Maximum lead length vs. Error for campbell scientific resistive sensors sensor maximum model # error range v e (µv) length(ft.) 107 0.05 ° c 0 ° c to 40 ° c 5 1000 1 034a 3° @ 360 ° 2083 380 2 227 - - - 2000 3 237 10 kohm 20k to 300k 1000 2000 3 1 b...

Page 211

Section 13. Cr23x measurements 13-11 5. Use the cr23x to measure the input settling error associated with a given configuration. For example, assume long leads are required but the lead capacitance, cw, is unknown. Configure rf on a length of cable similar to the measurement. Leave the sensor end op...

Page 212

Section 13. Cr23x measurements 13-12 figure 13.3-7. Half bridge configuration for ysi #44032 thermistor connected to cr23x showing: a) large source resistance, b) large source resistance at point p, and c) configuration optimized for input settling.

Page 213

Section 13. Cr23x measurements 13-13 cr23x figure 13.3-8. Measuring input settling error with the cr23x cr23x figure 13.3-9. Incorrect lead wire extension on model 107 temperature sensor cr23x figure 13.3-8. Measuring input settling error with the cr23x.

Page 214

Section 13. Cr23x measurements 13-14 cr23x figure 13.3-9. Incorrect lead wire extension on model 107 temperature sensor 13.4 thermocouple measurements a thermocouple consists of two wires, each of a different metal or alloy, which are joined together at each end. If the two junctions are at differen...

Page 215

Section 13. Cr23x measurements 13-15 100k6a1 interchangeability error (deg c) 0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5 -40 -30 -20 -10 0 10 20 25 30 40 50 60 70 80 temperature error (deg c) figure 13.4-1. Betatherm 100k6a1 interchangeability error when the cr23x is subjected to large temperatu...

Page 216

Section 13. Cr23x measurements 13-16 -1 -0.5 0 0.5 1 1.5 2 2.5 3 3.5 4 -10 -5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 time, minutes tc temperature error, deg. C -40 -30 -20 -10 0 10 20 30 40 50 60 temperature, deg. C tc temperature error, channel 4 tc temperature error, channel 1 tc tempera...

Page 217

Section 13. Cr23x measurements 13-17 thermocouple limits of error the standard reference which lists thermocouple output voltage as a function of temperature (reference junction at 0°c) is the national institute of standards and technology monograph 175 (1974). The american national standards instit...

Page 218

Section 13. Cr23x measurements 13-18 table 13.4-2. Limits of error on datalogger thermocouple output linearization (relative to its-90 standard in nist monograph 175) limits of tc type range °c error °c t -200 to 87 ± 0.022 87 to 316 ± 0.042 316 to 400 ± 0.060 e -240 to -130 ± 0.40 -130 to 479 ± 0.0...

Page 219

Section 13. Cr23x measurements 13-19 maximum and additive. A temperature of 45°c is measured with a type t (copper-constantan) thermocouple, using the ±5 mv range. The nominal accuracy on this range is 2.5 µv (0.05% of 5 mv), which at 45°c changes the temperature by 0.06°c. The rtd is 25°c but is in...

Page 220

Section 13. Cr23x measurements 13-20 cr23x figure 13.4-3. Diagram of junction box an external reference junction box must be constructed so that the entire terminal area is very close to the same temperature. This is necessary so that a valid reference temperature can be measured, and to avoid a the...

Page 221

Section 13. Cr23x measurements 13-21 figure 13.5-1. Circuits used with instructions 4-9.

Page 222

Section 13. Cr23x measurements 13-22 figure 13.5-2. Excitation and measurement sequence for 4 wire full bridge table 13.5-1. Comparison of bridge measurement instructions instr. Circuit description 4 dc half bridge user entered settling time allows compensation for capacitance in long lead lengths. ...

Page 223

Section 13. Cr23x measurements 13-23 calculating the actual resistance of a sensor which is one of the legs of a resistive bridge usually requires the use of one or two processing instructions in addition to the bridge measurement instruction. Instruction 59 takes a value, x, in a specified input lo...

Page 224

Section 13. Cr23x measurements 13-24 13.6 resistance measurements requiring ac excitation some resistive sensors require ac excitation. These include the 207 relative humidity probe, soil moisture blocks, water conductivity sensors, and wetness sensing grids. The use of dc excitation with these sens...

Page 225

Section 13. Cr23x measurements 13-25 influence of ground loop on measurements when measuring soil moisture blocks or water conductivity, the potential exists for a ground loop which can adversely affect the measurement. This ground loop arises because the soil and water provide an alternate path for...

Page 226

Section 13. Cr23x measurements 13-26 and would complete in background every (17 segments) * (4 sec/segment) = 68 seconds. If a user selects all possible input range codes, with the exception of either 60 hz or 50 hz rejection, but not both, along with period averaging, the background calibration wou...

Page 227

14-1 section 14. Installation and maintenance 14.1 protection from the environment the normal environmental variables of concern are temperature and moisture. The standard cr23x is designed to operate reliably from -25 to +50°c (-40°c to +80°c, optional) in noncondensing humidity. When humidity tole...

Page 228

Section 14. Installation and maintenance 14-2 table 14.8-1. Typical current drain for common cr23x peripherals typical current drain (ma) peripheral quiescent active am25t .5 1 am416 .1 17 com100 .5 1.8 com200 phone modem 0.0012 140 csm1 .5 18 md9 1.2 80 rad modem and sc932 interface 2.2 10-15 rf100...

Page 229

14-3 1 2 3 a 4 5 6 b 7 8 9 c * 0 # d figure 14.3-1. Cr23x battery pack and panel.

Page 230

Section 14. Installation and maintenance 14-4 14.3 cr23x power supplies the cr23x is available with either alkaline or lead acid battery options. It may also be purchased without a battery option. 10 d-type alkaline batteries figure 14.3-1. Alkaline battery orientation while the cr23x has a wide ope...

Page 231

Section 14. Installation and maintenance 14-5 acid battery specifications are given in table 14.3-3. The leads from the charging source connect to a wiring terminal plug on the side of the base. Polarity of the leads to the connector does not matter. A transzorb provides transient protection to the ...

Page 232

Section 14. Installation and maintenance 14-6 the solar panel selection. For example, local effects such as mountain shadows, fog from valley inversion, snow, ice, leaves, birds, etc. Shading the panel should be considered. Guidelines are available from the solarex corporation for solar panel select...

Page 233

Section 14. Installation and maintenance 14-7 cr23x panel +12v g figure 14.6-2. Connecting to vehicle power supply 14.7 cr23x grounding grounding of the cr23x and its peripheral devices and sensors is critical in all applications. Proper grounding will ensure the maximum esd (electrostatic discharge...

Page 234

Section 14. Installation and maintenance 14-8 h l 1 2 1 h l 3 4 2 h l 5 6 3 h l 7 8 4 h l 9 10 5 h l 11 12 6 diff se h l 13 14 7 h l 15 16 8 h l 17 18 9 h l 19 20 40 h l 21 22 11 h l 23 24 12 diff se ex1 ex2 ex3 ex4 cao1 cao2 p1 p2 p3 p4 g 5v g sw12 g 12v 12v g c1 c2 c3 c4 g c5 c6 c7 c8 g power out ...

Page 235

Section 14. Installation and maintenance 14-9 for these situations, consult the literature on lightning protection or contact a qualified lightning protection consultant. An excellent source of information on lightning protection can be located via the web at http://www.Polyphaser.Com. In vehicle ap...

Page 236

Section 14. Installation and maintenance 14-10 supply terminal, and 1 continuous 5 volt (5v) supply terminal. Voltage on the 12v and sw12 terminals will change with the cr23x supply voltage. The 5v terminal is regulated and will always remain near 5 volts ( ± 4%)so long as the cr23x supply voltage r...

Page 237

Section 14. Installation and maintenance 14-11 figure 14.9-1. Relay driver circuit with relay figure 14.9-2. Power switching without relay 14.10 maintenance the cr23x power supplies require a minimum of routine maintenance. When not in use, the rechargeable supply should be stored in a cool, dry env...

Page 238

Section 14. Installation and maintenance 14-12 14.10.2 replacing the internal battery caution: misuse of the lithium battery or installing it improperly can cause severe injury. Fire, explosion, and severe burn hazard! Do not recharge, disassemble, heat above 100°c (212°f), solder directly to the ce...

Page 239

Section 14. Installation and maintenance 14-13 sanyo figure 14.11-6. Removal of band clamp and battery..

Page 240

Section 14. Installation and maintenance 14-14 this is a blank page..

Page 241

A-1 appendix a. Glossary ascii: abbreviation for american standard code for information interchange (pronounced "askee"). A specific binary code of 128 characters represented by 7 bit binary numbers. Asynchronous: the transmission of data between a transmitting and a receiving device occurs as a ser...

Page 242

Appendix a. Glossary a-2 input storage: that portion of memory allocated for the storage of results of input and processing instructions. The values in input storage can be displayed and altered in the 6 mode. Input/output instructions: used to initiate measurements and store the results in input st...

Page 243

Appendix a. Glossary a-3 print peripheral: see print device. Processing instructions: these instructions allow the user to further process input data values and return the result to input storage where it can be accessed for output processing. Arithmetic and transcendental functions are included in ...

Page 244

Appendix a. Glossary a-4 this is a blank page..

Page 245

B-1 appendix b. Cr23x control port serial i/o instruction 15 b.1 specifications function send/receive full duplex serial data through the cr23x control ports and computer rs-232 9-pin serial port. Received serial data can be buffered. This prevents data from being lost from sensors that output data ...

Page 246

Appendix b. Control port serial i/o instruction 15 b-2 cr23x figure b-1. Circuit to limit input to 0 to 5 volts b.3 instruction 15 and parameter descriptions par. Data no. Type description 01: 2 repetitions 02: 2 configuration code (xy) 03: 4 cts / delay before send 0 = wait for clear to send >0 = d...

Page 247

Appendix b. Control port serial i/o instruction 15 b-3 configuration code the configuration code is a two digit parameter in the form of xy, which specifies the input and output format. For detailed information about the configurations, see configuration codes description. X description 0 rs-232 asc...

Page 248

Appendix b. Control port serial i/o instruction 15 b-4 parameter 3 - cts / delay before send (applies to control port configuration only) if parameter 3 is zero (0), the cr23x waits for the clear to send to come high before sending output. If clear to send does not come high within the time specifie...

Page 249

Appendix b. Control port serial i/o instruction 15 b-5 characters received following the termination character are discarded. Parameter 8 - maximum number of characters to receive parameter 8 defines the total number of characters to expect per input, including numeric, non-numeric, polarity, decima...

Page 250

Appendix b. Control port serial i/o instruction 15 b-6 table b-1. Input/output configurations configuration parameters port function ports number 3 6 8 dtr/rts cts txd rxd used 1 dtr,rx x 0 nz a nc nc b 2 2 dtr,tx nz nz 0 a nc b nc 2 3 dtr,cts,tx 0 nz 0 a a+1 b b+1 3 4 dtr,tx, rx nz nz nz a nc b b+1...

Page 251

Appendix b. Control port serial i/o instruction 15 b-7 (a = 1 and 2 or 3 and 4). The starting control port used for the serial output and serial input pairs is specified as the second digit (b = 5 and 6 or 7 and 8). Control ports 2 and 3 (rts/cts) and 6 and 7 (tx/rx) pairs can also be used but this ...

Page 252

Appendix b. Control port serial i/o instruction 15 b-8 dtr dsr/dcd dsr/dcd dtr rts cts cts rts txd rxd rxd txd gnd gnd b.5.2 data buffering since p15 is executed in a program table at fixed intervals (i.E. 60 seconds), it is possible to miss data transmitted from a sensor if the sensor outputs data ...

Page 253

Appendix b. Control port serial i/o instruction 15 b-9 vtg direction and speed - 37 characters including crlf $gpvtg,010,t,356,m,5.39,n,10.0,k*4fcrlf field data description 1. $gpvtg message identification 2. 010 track made good in degrees true 3. T true 4. 356 track made good in degrees magnetic 5....

Page 254

Appendix b. Control port serial i/o instruction 15 b-10 b.7 program examples the following examples represent portions of a larger, more complete application program, and should not be used verbatim. B.7.1 example 1: atmospheric instruments research air-db-1a barometer various barometer functions (m...

Page 255

Appendix b. Control port serial i/o instruction 15 b-11 table b-2. Cr23x/barometer connection details control port 5 control port 5 cr23x cr23x caution: to avoid damage to the barometer cmos chips, connect ground first and power last. All sensor leads not used in a particular hook-up configuration s...

Page 256

Appendix b. Control port serial i/o instruction 15 b-12 08: 9 max characters to receive 09: 100 delay for input is 1.0 second 10: ? First input location, user's choice 11: 1 multiplier 12: 0.0000 offset the following paragraphs contain more detailed information on some of the parameters. Parameter 2...

Page 257

Appendix b. Control port serial i/o instruction 15 b-13 example: 100 samples are averaged by the barometer connected to the cr23x via hook-up #1. Et = 0.1 * 100 + 0.9 et = 10.9 seconds time out = 10.9/0.01 time out = 1090 in general, the above equations overestimate the execution time. When executio...

Page 258

Appendix b. Control port serial i/o instruction 15 b-14 06: p77 real time 01: 110 day,hour-minute 07: p70 sample output out of range reading 01: 1 rep 02: 1 loc air, mb 08: p86 do set intermediate processing 01: 19 set high flag 9 disable flag 09: p86 do set flag 1 low 01: 21 set low flag 1 10: p95 ...

Page 259

Appendix b. Control port serial i/o instruction 15 b-15 cr23x#1 program - send data * 1 table 1 programs 01: 5 sec. Execution interval 01: p87 beginning of loop start loop to generate values 01: 0 delay 02: 10 loop count 02: p32 z=z+1 01: 11 z loc [:counter ] 03: p31 z=x 01: 11 x loc counter 02: 1--...

Page 260