- DL manuals

- Campbell

- Weather Station

- ET107

- Instruction Manual

Campbell ET107 Instruction Manual

Summary of ET107

Page 1

Et107 weather station revision: 5/09 c o p y r i g h t © 1 9 9 3 - 2 0 0 9 c a m p b e l l s c i e n t i f i c , i n c ..

Page 2: Warranty and Assistance

Warranty and assistance the et107 weather station is warranted by campbell scientific, inc. To be free from defects in materials and workmanship under normal use and service for twelve (12) months from date of shipment unless specified otherwise. Batteries have no warranty. Campbell scientific, inc....

Page 3: Et107 Weather Station

Et107 weather station table of contents pdf viewers note: these page numbers refer to the printed version of this document. Use the adobe acrobat® bookmarks tab for links to specific sections. 1. Preparation and siting .............................................1-1 1.1 siting and exposure............

Page 4

Et107 weather station table of contents 2.4.9 cs616-lc water content reflectometer sensor (optional) .... 2-19 2.4.9.1 changing the jumper ....................................................... 2-19 2.4.9.2 site installation ................................................................ 2-21 2.4....

Page 5

Et107 weather station table of contents appendices a. Et107 maintenance log ......................................... A-1 b. Ps24 24 ahr power supply and 10 x 12 inch enclosure ............................................................ B-1 b.1 ps24 components..........................................

Page 6

Et107 weather station table of contents 2.4-12. Pyranometer leveling................................................................... 2-18 2.4-13. Remove red or green pyranometer cap...................................... 2-18 2.4-14. Screws that secure the electronics cover ..........................

Page 7

Et107 weather station table of contents b.2-2. Both strut clamps and brackets on et107 pole .............................B-5 b.2-3. Top clamp hook side up ...............................................................B-6 b.2-4. Enclosure mounted on et107 pole...........................................

Page 8

Et107 weather station table of contents vi this is a blank page..

Page 9: 1.1 Siting and Exposure

Section 1. Preparation and siting 1.1 siting and exposure if any part of the weather station comes in contact with power lines, you could be killed. Contact local utilities for the location of buried utility lines before digging or driving ground rods. Caution selecting an appropriate site for the w...

Page 10

Section 1. Preparation and siting 1.1.3 solar radiation pyranometers should be located to avoid shadows on the sensor at any time. Mounting it on the southern most (northern hemisphere) portion of the weather station will minimize the chance of shading from other weather station structures. Reflecti...

Page 11: 1.2 Installation Tasks

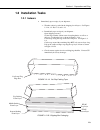

Section 1. Preparation and siting 1.2 installation tasks 1.2.1 indoors • immediately upon receipt of your shipment… ⇒ weather station is packed in the shipping box in layers. See figures 1.2-1a, 1.2-1b, 1.2-2, and 1.2-3. ⇒ immediately upon receipt of your shipment… open shipping carton(s). Set the l...

Page 12

Section 1. Preparation and siting top layer instruction manual cardboard m anual win d v ane crossarm with rain, solar, and temp/%rh sensors enclosure wind set instruction manual figure 1.2-2. Et107 with the met one 034b-etm wind sensor, top layer cardboard containing wind vane 301-t bottom layer ba...

Page 13: 1.3 Tools Required

Section 1. Preparation and siting • several days prior to the planned installation date… ⇒ collect tools and site information (section 1) ⇒ install datalogger support software (section 3) 1.2.2 outdoors • locate suitable site (section 1) • prepare concrete base (section 2) • et107 installation: ⇒ pl...

Page 14: Orientation

Section 1. Preparation and siting needle-nose pliers wire strippers pocket knife calculator volt / ohm meter electrical tape step ladder (6') station manuals station log and pen open end wrenches: 3/8", 7/16", 1/2", 9/16" socket wrench and 7/16" deep well socket adjustable wrench pliers conduit and ...

Page 15

Section 1. Preparation and siting general map showing magnetic declination for the contiguous united states is shown in figure 1.5-1. Declination angles east of true north are considered negative, and are subtracted from 0 degrees to get true north as shown figure 1.5-2. Declination angles west of t...

Page 16

Section 1. Preparation and siting nssdc transformation between cgm and geo coordinates and modeling of the geomagnetic field parameters results of geo-cgm calculations: geocentric cgm l- value igrf magnetic field oval & azimuth mltmn lat. Long. Lat. Long. Re h,nt d,deg z,nt angles n/s:+e/w in ut sta...

Page 17

Section 1. Preparation and siting magnetic declination is bold in this example to show its location in the table. A positive declination is east, while a negative declination is west. The declination in this example is 13.80 degrees. As shown in figure 1.5-1, the declination for logan, ut is east, s...

Page 18

Section 1. Preparation and siting 1-10 3 the state climatologist, (1985) publication of the american association of state climatologists: height and exposure standards for sensors on automated weather stations, v. 9, no. 4 october, 1985. 4 epa, (1989). Quality assurance handbook for air pollution me...

Page 19

Section 2. Hardware installation danger: do not install near power lines. If any part of the tower comes in contact with power lines you could be killed. Contact local utilities for the location of buried utility lines before digging or driving grounding rods. Caution: do not fit the 3 meter et towe...

Page 20: 2.1 Base Foundation

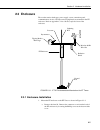

Section 2. Hardware installation 2.1 base foundation 2.1.1 supplied components (3) ½ inch l-bolts (9) ½ inch nuts (1) anchor template refer to section 1 for components supplied by installer and bring components. 2.1.2 installation 1. The et tower attaches to a user supplied concrete foundation const...

Page 21

Section 2. Hardware installation side view top view anchor bolt form form wire cement pad small cavity 24" 24" 24" template 2" north form wire figure 2.1-2. Et tower base installation conduit anchor bolt figure 2.1-3. Cut-away view shows anchor bolt and conduit placement in cement pad 2-3.

Page 22: 2.2 Tower/pole

Section 2. Hardware installation 2.1.3 ac power installation a) the ac power option includes a 120 vac to 16 vac step down transformer. The transformer should be mounted inside a user-supplied junction box according to local electrical codes. Dangerous electrical accidents may be avoided by locating...

Page 23

Section 2. Hardware installation pole sections is acceptable. Lay the assembled pole on the ground next to the concrete foundation. 3. Cut and save a 9 inch piece of 12 awg ground wire from the 12 foot length provided. This will be used later to attach the enclosure ground to the lightning rod assem...

Page 24

Section 2. Hardware installation 4 awg wire ground rod figure 2.2-2. Close up of ground rod and 4 awg cable 2.2.3 tower grounding 2.2.3.1 supplied components (1) 5 foot 4 awg ground cable (1) copper ground lug, bolt (1) ground rod, clamp 2.2.3.2 grounding procedure ground the tower as shown in figur...

Page 25: 2.3 Enclosure

Section 2. Hardware installation 2.3 enclosure the weather station datalogger, power supply, sensor connection panel, communications devices, and data retrieval peripherals are mounted in the et enclosure. Refer to appendix c.1 for a labeled, exploded view of the enclosure. Logan, utah made in usa l...

Page 26

Section 2. Hardware installation b. Loosen the mounting bracket bolts on the back of the enclosure wide enough to slide over the pole. Slide the enclosure over the pole. Position the enclosure so it faces east for northern latitudes or west for southern latitudes. The top of the enclosure should be ...

Page 27

Section 2. Hardware installation screws (4) figure 2.4-1. Et107 sensor arm mounting 1) remove the front lid and the protective connector cover from the back of the et enclosure by loosening the one phillips screw at the bottom of the cover. 2) place the sensor arm on top of the enclosure, lining up ...

Page 28

Section 2. Hardware installation 2.4.3 rh and temperature radiation shield 1. Remove the two phillips screws taped underneath the crossarm. 2. Remove the yellow shipping cap from off the end of the temperature/relative humidity sensor. See figures 2.4-2 and 2.4-3. Remove yellow cap figure 2.4-2. Tem...

Page 29

Section 2. Hardware installation temp/rh with cap removed figure 2.4-3. Temperature/relative humidity sensor without yellow protective cap 3. Insert the temperature/relative humidity into the gill radiation shield until it stops or a “click” is heard. 4. Attach the gill radiation shield to the under...

Page 30

Section 2. Hardware installation figure 2.4-4. Wind and rh/temperature sensor installation ution entiometer ent 5ma face south figure 2.4-5. 034b mounting to pipe shoulder screw south alignment sticker temp/% rh gill radiation shield phillips mounting screws wind vane counter weight mounting pipe al...

Page 31

Section 2. Hardware installation the wind vane can be easily damaged if dropped or bent. Leave the wind vane in the protective cardboard sleeve until it’s ready to be installed. Warning 2. Remove the alignment screw at the base of the 034b-et (figure 2.4-5). Insert the 034b into the 034b mounting sh...

Page 32

Section 2. Hardware installation loosen screws figure 2.4-6. Screws that secure the electronics cover 4. Remove the electronics cover to expose the pcb (see figure 2.4-7). Lift here figure 2.4-7. Removal of the electronics cover 2-14.

Page 33

Section 2. Hardware installation 5. Move the jumper at the top of connector pc board so that it is placed over the center and right pins (see figure 2.4-8). New jumper position figure 2.4-8. Jumper set for windsonic1 6. Replace electronics cover. 7. Tighten screws. 8. Reattach 10588 ribbon cable to ...

Page 34

Section 2. Hardware installation figure 2.4-9. Gill windsonic mounting shaft 3. Slide the connector and cable up through the center of the mounting shaft. Plug the cable into the gill windsonic sensor. The connector has a key and needs to be pushed in then rotated clockwise to lock it in place. See ...

Page 35

Section 2. Hardware installation 4. Center the gill windsonic over the three threaded screw holes on the mounting shaft and screw it in place using the three phillips screws taken off the shaft in step 1. 5. Slide the shaft and sensor back through the u-bolt. Align the sensor with north by pointing ...

Page 36

Section 2. Hardware installation 2.4.7 pyranometer level the pyranometer as indicated in figure 2.4-12. Adjust the three leveling screws until the bubble level indicates plumb. Remove the red or green shipping cap from the pyranometer. See figure 2.4-13. Leveling screws figure 2.4-12. Pyranometer le...

Page 37

Section 2. Hardware installation 2.4.8 107-lc or 108-lc soil temperature sensor (optional) soil temperature sensors do not have an armored outer jacket. The jacket is waterproof but not cut proof. The recommended method is to bury conduit from the weather station to the soil temperature site and rou...

Page 38

Section 2. Hardware installation loosen screws figure 2.4-14. Screws that secure the electronics cover 4. Remove the electronics cover to expose the pcb (see figure 2.4-15). Lift here figure 2.4-15. Removal of the electronics cover 2-20

Page 39

Section 2. Hardware installation 5. Move the jumper so that it is placed over the center and right pins (see figure 2.4-16). New jumper position figure 2.4-16. Jumper set for cs616 6. Replace electronics cover. 7. Tighten screws. 8. Reattach 10588 ribbon cable to the cs i/o port. 9. Replace enclosur...

Page 40

Section 2. Hardware installation 2.4.10 sensor connections sensor schematics are provided in section 4.3.1. 1. Each sensor cable plug attaches to a unique bulkhead connector as shown in figure 2.4-17. The sensor cables are individually marked to match up with the sensor labeling on the back of the e...

Page 41

Section 2. Hardware installation it’s very important that each plug is completely seated on to the connector and the locking ring turned ¼ revolution clockwise. Failure to seat the plug completely could cause corrosion and water damage to both the enclosure and the sensor cable. Note notice how the ...

Page 42

Section 2. Hardware installation 2.4.11 sensor verification and clock set 1. Send the weather station program to the station using your campbell scientific software such as visualweather, pc400, or loggernet. Verify all sensors are functioning correctly. Verify the weather station clock and set as n...

Page 43

Section 2. Hardware installation serial cable. The cr1000 datalogger used in the et107 station can speak with more than one device at a time allowing troubleshooting to be done in the field with a laptop while remote communication devices are accessing the station. It’s best to use device configurat...

Page 44

Section 2. Hardware installation 2.5.2 phone modem phone modems enable communications between the et enclosure and a hayes compatible modem at your pc over a dedicated phone line. Phone line surge protection is built into the et enclosure. By default, the com220 phone modem is configured for sdc7. R...

Page 45

Section 2. Hardware installation 2. Connect the modem 9-pin port to the et enclosure cs i/o port with the p/n 10588 ribbon cable supplied with the et enclosure (see figure 2.5-1 and 2.5-2). 3. Connect the modem rj-ll jack to the et enclosure rj-11 jack with the rj-ll patch cord (see figure 2.5-2). 4...

Page 46

Section 2. Hardware installation rad short haul modem sc932c 12” 4-wire patch cable (see figure 2.5-4 for wiring) 10588 ribbon cable (see figure 2.5-4 for wiring) figure 2.5-3. Short-haul modem mounting and connection 2.5.3.1 internal installation if the short haul modem was ordered with the et107, ...

Page 47

Section 2. Hardware installation install the short-haul modems as shown in figure 2.5-3 and 2.5-4. 1. Mount the rad / sc932c mounting bracket into the et enclosure with the three pre-threaded screws provided. 2. Connect the rad modem and sc932c. Strap them into the mounting bracket under the velcro ...

Page 48

Section 2. Hardware installation note the splice and wire nut must be completely immersed into the silicon gel inside the splice tube to be waterproof. 2) mount the surge protector box to a flat surface within 5 feet of the pc's serial port. Ground the center terminal to an earth (or building) groun...

Page 49

Section 2. Hardware installation 2.5.4.1 power considerations ac power is recommended when using rf450 radios with the station. A 10 watt solar panel can be used but days without sunlight and winter months with little sunlight should be considered. The et107 station comes with a 7 amp- hour battery ...

Page 50

Section 2. Hardware installation 2.5.4.3 internal installation if the rf450 radio was ordered with the et107, you can skip this section and go directly to the external installation section. Note the following components are provided in the rf450 radio kit for installation inside the et enclosure: (1...

Page 51

Section 2. Hardware installation 3. Connect the long 9-pin female end of the 10588 ribbon cable to the cs i/o port on the rf450 radio. Screw the connector to the radio using the provided two screws. See figures 2.5-6. 10588 ribbon cable figure 2.5-6. Attach ribbon cable to rf450 cs i/o port 2.5.4.4 ...

Page 52

Section 2. Hardware installation figure 2.5-7. Loosely wire tie antenna cable figure 2.5-8. Loosely drape antenna cable over back of enclosure 2-34.

Page 53

Section 2. Hardware installation 3. Use the 2.125 stainless steel u-bolt to attach the adjustable angle mounting bracket to the pole. Depending on the size of the antenna position the bracket directly below, or above, the enclosure top mounting bracket. The top of an omni directional antenna should ...

Page 54

Section 2. Hardware installation figure 2.5-10. Antenna bracket mounted to pole 4. Mount the saddle bracket to the adjustable angle mount bracket by inserting the ends of the bracket through the quarter circle notches. Put a flat washer, lock washer, and a silicon bronze nut, in that order, on the e...

Page 55

Section 2. Hardware installation rotate enclosure to expose antenna. Ensure that the solar radiation sensor is not shaded. Note 5. Use the following procedure to install the yagi antenna. Mounting hardware that comes in the box with the yagi antenna will not be used. Note i. Slide the back of the ya...

Page 56

Section 2. Hardware installation the bnc connector end of the cable. Take the cover off when you’re done. Iv. Use one of the black wire ties to strap the antenna cable to the bundle of sensor cables. V. Tighten up the wire ties holding the antenna cable to the wire tie mount at the top of the enclos...

Page 57

Section 2. Hardware installation 2.5.4.5 base radio installation the base radio kit comes with the following items. (1) 10873 rs-232 serial data cable with 6 feet of cable (1) 15966 wall adapter: 100 to 240 vac, 50-60 hz input to 12 vdc 80 0ma output with 6 feet of cable. (1) 18327 rf450 900 mhz, 1 ...

Page 58

Section 2. Hardware installation figure 2.5-15. Base rf450 installation figure 2.5-16. A base radio installed in an office 2-40

Page 59

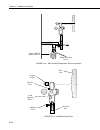

Section 2. Hardware installation 2.6 lightning rod installation install lightning rod as shown in figure 2.6-1 and 2.6-2. 1. Carefully mount the lightning rod clamp to the top of the pole (see figure 2.6-1). Position the clamp so it won’t interfere with the connector cover. Figure 2.6-1. Lightning r...

Page 60

Section 2. Hardware installation figure 2.6-2. Grounding to lightning rod clamp 3. Strip 2.54 cm (1”) from both ends of the 9” (23 cm) piece of 10 awg green ground wire. Insert one end into the enclosure ground lug located at the top back of the enclosure. Put the other end in the same clamp opening...

Page 61

Section 2. Hardware installation 2.7 solar panel installation figure 2.7-1. Solar panel mounting and cabling a) mount the solar panel to the tower using the mounting brackets as shown in figure 2.7-1. Mount the solar panel to the tower so it faces south (northern hemisphere). Position it as high off...

Page 62

Section 2. Hardware installation site latitude tilt angle ( α) 0 to 10 degrees 10 degrees 11 to 20 latitude + 5 degrees 21 to 45 latitude + 10 degrees 46 to 65 latitude + 15 degrees >65 80 degrees α figure 2.7-2. Side view of solar panel shows tilt angle b) after determining the tilt angle, loosen t...

Page 63: 2.8 Battery Installation

Section 2. Hardware installation 2.8 battery installation power switch figure 2.8-1. Ps100 battery installation the ps100 power switch should be in the “off” position. To install the battery, remove the cover from the ps100 by sliding the latch up at one end of the cover and sliding the cover down a...

Page 64: Enclosure

Section 2. Hardware installation 2.9 restraining cables and sealing/desiccating enclosure 2.9.1 restraining cables 1. Loosely wire tie power, communication, and grounding cable to the wire tie harness at the top of the back of the station. Do not clip back the wire tie at this time. See figure 2.9-1...

Page 65

Section 2. Hardware installation figure 2.9-2. Connector cover in place 6. Tighten down the wire ties holding cabling to the wire tie harness and clip off any excess. See figure 2.9-2. 2.9.2 sealing and desiccating the enclosure the et enclosure is supplied with two desiccant packs. The desiccant ma...

Page 66

Section 2. Hardware installation 2) be sure to close the enclosure hasp securely. A padlock may be used on the latch for extra security. Desiccant figure 2.9-3. Desiccant installation 2-48.

Page 67: Section 3. Et Software

Section 3. Et software the et107 comes with a default program, and typically does not require additional programming (see appendix d). Note a variety of different software packages are available to work with the et107 station. This section introduces software packages that can be used with the et107...

Page 68

Section 3. Et software 3-2 this is a blank page..

Page 69: Section 4. Maintenance,

Section 4. Maintenance, troubleshooting, and schematics 4.1 maintenance proper maintenance of the et107’s components is essential to obtain accurate data. Equipment must be in good operating condition, which requires a program of regular inspection and maintenance. Routine and simple maintenance can...

Page 70

Section 4. Maintenance, troubleshooting, and schematics desiccant packs may be ordered in quantity of 20 individually sealed packs at a time (item# 6714) or by the individual pack (item# 4905). Campbell scientific does have a $50.00 minimum charge. Any orders under $50.00 require a $15.00 handling f...

Page 71

Section 4. Maintenance, troubleshooting, and schematics 6 months • replace 034b-et’s anemometer bearings and reed switch if operating under harsh conditions, such as constant high winds, blowing dust, and/or salt spray contamination. 1 year • replace 034b-et wind speed (anemometer) bearings (item #3...

Page 72

Section 4. Maintenance, troubleshooting, and schematics 2 years • replace 034b-et’s vane potentiometer if needed (call for part number and price). To send the sensor to campbell scientific for potentiometer replacement call for return material authorization number or contact campbell scientific for ...

Page 73

Section 4. Maintenance, troubleshooting, and schematics 4.1.5 cr1000m module the cr1000m module contains a lithium battery that operates the clock and sram when the module is not powered. The cr1000m does not draw power from the lithium battery while it is powered by a 12 vdc supply. In an et107 sto...

Page 74: 4.2 Troubleshooting

Section 4. Maintenance, troubleshooting, and schematics 4.2 troubleshooting 4.2.1 no response using the cr1000kd keypad check keypad response after each of the following steps. A. Make sure the battery has been installed and the ps100 power switch is set to “on” (section 2.8). B. Use a voltmeter to ...

Page 75

Section 4. Maintenance, troubleshooting, and schematics e. Check the cable(s) between the serial port and the modem. If cables have not been purchased through campbell scientific, check for the following configuration using an ohm meter: 25-pin serial port: computer end modem end 2 2 3 3 7 7 20 20 9...

Page 76: Rf450

Section 4. Maintenance, troubleshooting, and schematics 4.2.5 nan or ±inf stored in a data table a. Something is wrong with the datalogger and/or sensor(s) if short cut or visualweather was used to create the station program. Make sure the sensor is plugged into the correct bulkhead connector. If cr...

Page 77

Section 4. Maintenance, troubleshooting, and schematics table 4.2-1. Multi-point network led status master slave repeater condition carrier detect (cd) transmit (tx) clear to send (cts) carrier detect (cd) transmit (tx) clear to send (cts) carrier detect (cd) transmit (tx) clear to send (cts) powere...

Page 78

Section 4. Maintenance, troubleshooting, and schematics radios not networked together, not communicating: 1. Check the baud rate of all rf450s; they should be the same. 2. Check network ids of all rf450s; they should be the same. 3. Check frequency key number of all rf450s; they should be the same u...

Page 79

Section 4. Maintenance, troubleshooting, and schematics table 4.2-2. Gill windsonic diagnostic codes diagnostic status comment 0 okay all okay 1 axis 1 failed insufficient samples, possible path obstruction 2 axis 2 failed insufficient samples, possible path obstruction 4 both axis failed insufficie...

Page 80

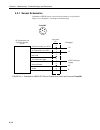

Section 4. Maintenance, troubleshooting, and schematics 4.3.1 sensor schematics schematics of et107 sensors and associated connectors are provided in figures 4.3-1 through 4.3-7 for help in troubleshooting. Temp/rh 1 2 3 4 5 6 air temperature and relative humidity sensor connector pin datalogger rel...

Page 81

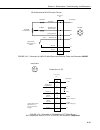

Section 4. Maintenance, troubleshooting, and schematics 3 connector pin magnetically activated reed switch wind speed and wind direction sensor ground pulse wind speed analog ground wind direction signal return excitation 10k ohm 10k ohm potentiometer 1k ohm datalogger shield 1 2 4 p1 ag 2h ex2 g g ...

Page 82

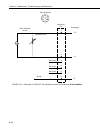

Section 4. Maintenance, troubleshooting, and schematics solar radiation sensor 450-650 ohms connector pin datalogger 1 3 2 not used not used not used 3 h 3 l g shield 4 5 6 1 2 3 4 5 6 solar radiation figure 4.3-4. Schematic of cs305-et solar radiation sensor and connector solar radiation 4-14.

Page 83

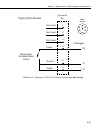

Section 4. Maintenance, troubleshooting, and schematics 1 not used connector pin magnetically activated reed switch tipping rain bucket not used not used ground pulse datalogger shield 2 4 3 p2 g g 5 6 1 2 3 4 5 6 rain (precip) figure 4.3-5. Schematic of te525-et rain sensor and connector rain (prec...

Page 84

Section 4. Maintenance, troubleshooting, and schematics 1 connector pin temperature or soil volumetric water content cs616 control cs616 +12v supply temperature excitation cs616 signal return temperature signal return datalogger ground 2 3 4 +12v ex3 4l 4h g c7 5 6 1 2 3 4 5 6 temp cs616 figure 4.3-...

Page 85

Section 4. Maintenance, troubleshooting, and schematics 4.3.2 power schematics 1 ac ac ps100 charger/regulator note: ps100 charger/regulator is not sensitive to polarity. 2 charge charge (solar panel+) (solar panel-) red black 1 2 power 16-19 vac or 16-24 vdc solar panel power figure 4.3-8. Schemati...

Page 86

Section 4. Maintenance, troubleshooting, and schematics 4-18.

Page 87

Appendix a. Et107 maintenance log station installation date: __________________ clean/inspect rain gage sensor (recommended - weekly) clean/inspect rain gage sensor (recommended - weekly) date ok/comments date ok/comments a-1.

Page 88

Appendix a. Et107 maintenance log a-2 clean/inspect solar radiation sensor (recommended - monthly) date ok/comments clean/inspect temp/% rh sensor & gill radiation shield (recommended - quarterly) date ok/comments replace wind speed bearings and reed switch (recommended - yearly) date ok/comments re...

Page 89: And 10 X 12 Inch Enclosure

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure the ps24 power supply is typically used when the et107 transmits data via rf450 spread spectrum radios. However, the ps24 can be used for any situation where a larger capacity battery is desirable. B.1 ps24 components the ps24 consists ...

Page 90

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure figure b.1-2. 24 ahr battery and battery cable b-2.

Page 91

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure humidity indicator humidity indicator ms20003-2 examine item do not eat united desiccants-gates 101christine, belen, now mexico 87002 desi pak specification mil-d-3464 type i &ii reactivation time in-bag 16 hours at 250 f desiccant acti...

Page 92: B.2 Installation

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure b.2 installation the ps24 is purposely shipped without the battery mounted in its bracket. Do not install the battery until instructed to do so. Caution 1. Place the top enclosure bracket on the pole at approximately 40 inches above the...

Page 93

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure 3. Place the bottom strut clamp and bracket approximately 12 inches below the top clamp. This clamp is installed with the hook side down. The bracket might have to be moved a little to accept the enclosure bracketing, so don’t tighten t...

Page 94

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure 4. Hook the enclosure on the top bracket as shown in figure b.2-3. Figure b.2-3. Top clamp hook side up b-6.

Page 95

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure 5. The bottom enclosure bracket should slide between the top lip of the bottom strut mount bracket and the notch directly below. Move the bottom bracket if necessary, then bolt the bottom bracket down (see figure b.2-4). Do not over tig...

Page 96

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure 6. The bottom enclosure bracket has a small metal locking mechanism. Push up on the small phillips screw underneath the mechanism and slide it to the left. Once in place, put a small wire tie in the hole to the right of the locking mech...

Page 97

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure 7. Install the solar panel above the 10 x 12 enclosure, and face the solar panel south. See figure b.2-6 for fully mounted solar. Figure b.2-6. Mounted solar panel 8. Throw a blanket or box over the solar panel to prevent any voltage ou...

Page 98

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure 10. Wire the solar panel to the ch100 terminal blocks as follows. Solar panel to ch100 red: chg black: chg polarity makes no difference. Connect one wire per chg terminal block. Note 11. Remove the blanket or box from the solar panel on...

Page 99

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure 13. Follow the installation of battery procedure provided in figure b.2-7. Plug the battery into the connector on the ch100 marked “int”. Figure b.2-7. Procedure for installing and connecting battery 14. An extra loop of ground wire was...

Page 100

Appendix b. Ps24 24 ahr power supply and 10 x 12 inch enclosure the enclosure needs to be sealed up tight so don’t be stingy with the putty. Caution 17. Put both bags of desiccant inside of the enclosure. 18. Stick the humidity indicator card on a wall inside of the enclosure. Pink on the humidity i...

Page 101: Appendix C. Exploded Views

Appendix c. Exploded views c.1 enclosure c-1.

Page 102: C.2 Crossarm

Appendix c. Exploded views c.2 crossarm c-2.

Page 103

Appendix d. Default programs d.1 program for et107 with gill windsonic stationname(et107_gill) 'datalogger status information public battvolt public logrtmpc public encl_rh public watchdog public overruns public lowvolts public libattv 'gill sonic rs232 variables public windspd_ms public windspd_mph...

Page 104

Appendix d. Default programs maximum(1, logrtmpc, fp2, 0, false) minimum(1, logrtmpc, fp2, 0, false) maximum(1, windspd_ms,ieee4,disable_flag, false) windvector (1,windspd_ms,winddir,ieee4,disable_flag,0,0,1) totalize(1, rain_mm, fp2, 0) average(1, airtempc, fp2, 0) maximum(1, airtempc, fp2, 0, fals...

Page 105

Appendix d. Default programs voltse(encl_rh, 1, mv2500, 10, false, 0, _60hz, 0.1, 0) if encl_rh > 100 then encl_rh = 100 serialinrecord (com1,in_bytes_str,&h02,0,&h0d0a,nmbr_bytes_rtrnd,01) winddir = mid (in_bytes_str,3,3) windspd_ms = mid (in_bytes_str,7,6) diag = mid (in_bytes_str,16,2) checksum_f...

Page 106

Appendix d. Default programs heatindxc = (5/9) * (heatindxc - 32) calltable vw_hourly calltable stats nextscan endprog d.2 program for et107 with 034b stationname(et107_034b) 'datalogger status information public battvolt public logrtmpc public encl_rh public watchdog public overruns public lowvolts...

Page 107

Appendix d. Default programs windvector (1,windspd_ms,winddir,fp2,false,0,0,1) fieldnames ("windspd_ms_avg,winddir_avg") totalize(1, rain_mm, fp2, 0) average(1, airtempc, fp2, 0) maximum(1, airtempc, fp2, 0, false) minimum(1, airtempc, fp2, 0, false) average(1, relhum, fp2, 0) maximum(1, relhum, fp2...

Page 108

Appendix d. Default programs voltse(relhum, 1, mv2500, 1, false, 0, _60hz, 0.1, 0) if (relhum >= 100) and (relhum airtempf = airtempc * 1.8 + 32 voltdiff(slrrad_w, 1, mv7_5, 3, true, 0, _60hz, 200, 0) if (slrrad_w dewpoint (dewpntc,airtempc,relhum) if dewpntc > airtempc or dewpntc = nan then dewpntc...

Page 110

Campbell scientific companies campbell scientific, inc. (csi) 815 west 1800 north logan, utah 84321 united states www.Campbellsci.Com • info@campbellsci.Com campbell scientific africa pty. Ltd. (csaf) po box 2450 somerset west 7129 south africa www.Csafrica.Co.Za • cleroux@csafrica.Co.Za campbell sc...