Hvlp paint sprayers please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or p...

2 operating instructions and parts manual description this product is a high volume low pressure (hvlp) paint sprayer, a durable, self-contained painting system suited for painting cabinets, furniture, machinery, equipment, walls, trim, and many other surfaces. Hvlp systems operate differently than ...

Hvlp paint sprayers 3 operating instructions and parts manual general safety information (cont.) • hazardous vapors: paints, solvents, insecticides, and other materials may be harmful if inhaled, causing severe nausea, fainting, or poisoning. • always wear a mask or respirator and eye protection whe...

4 operating instructions and parts manual hvlp paint sprayers how your hvlp system works your turbine system has three components: the turbine unit, an air hose and a spray gun. The turbine unit, when connected to the correct electrical power supply and powered on, provides a continuous source of cl...

5 operating instructions and parts manual pre-operation (cont.) 4. Loosen the air cap locking ring one or two turns. This will feather the top and bottom of the fan pattern and slightly reduce the fan pattern size. Coatings coating properties: coatings are a blend of resins and additives to create a...

6 pre-operation (cont.) preparing to spray after some practice, you should be ready to spray your coating of choice on your work piece. (see the operation section for more information on spray patterns, spray gun use, and other usage procedures). Good quality results with your hvlp system are a comb...

7 hvlp paint sprayers operating instructions and parts manual www.Chpower.Com hv2100, hv2105 operation (cont.) 13. Pull the trigger. Notice the pattern has become smaller. (you can continue reducing the material flow and move the spray gun even closer to the surface and the pattern will keep getting...

8 operating instructions and parts manual hvlp paint sprayers operation (cont.) using pressure pots with turbine systems (hv2105) when using a remote cup or pressure pot, it is necessary to introduce compressed air in order to pressurize the remote pot and move the fluid from the pot to the tip/nozz...

9 hvlp paint sprayers operating instructions and parts manual additional instructions for model hv2105 (cont.) return valve, leaving the valve attached to the lower section of the tube. This will provide safe storage while using the spray gun without the cup in a production mode. B. With a wrench, l...

10 operating instructions and parts manual hvlp paint sprayers additional instructions for model hv2105 (3f485) (cont.) note: the following action should be done without the turbine running. 10. When your desired pot pressure has been set, pull the spray gun trigger back. The first time you are usin...

11 hvlp paint sprayers operating instructions and parts manual www.Chpower.Com hv2100, hv2105 maintenance (cont.) necessary to remove the tip/nozzle and needle for cleaning, the following procedure should be used: a. Unscrew the material flow knob. Remove the needle spring, and then withdraw the nee...

12 operating instructions and parts manual hvlp paint sprayers www.Chpower.Com hv2100, hv2105 no paint comes out when trigger is pulled excessive overspray coating on surface of work piece is not flat and level after drying (orange peel effect) when spray gun is connected to turbine and turbine is o...

13 operating instructions and parts manual www.Chpower.Com hv2100, hv2105 turbine repair parts 2-1/2 gallon (10l) cart and fluid feed system part no. Hv210510av filter assembly part no. Ch4098 5’ whip hose part no. Hv0125 25’ air hose part no. Hv0126 for replacement parts, call 1-800-626-4401 please...

14 www.Chpower.Com operating instructions and parts manual hv2100, hv2105 spray gun with quick release cup.

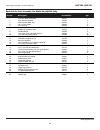

15 www.Chpower.Com operating instructions and parts manual hv2100, hv2105 ref. No. Description part number qty. 1 air cap ring a.5200 1 2 air cap #2 hv104505av 1 air cap #3 a.5297 1 3 air distributor plate (stainless) hv104511av 1 4 air distributor spring (stainless) hv104512av 1 5 not applicable 6 ...

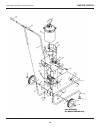

Www.Chpower.Com operating instructions and parts manual hv2100, hv2105 16 cart assembly for model hv2105 only.

17 www.Chpower.Com operating instructions and parts manual hv2100, hv2105 ref. No. Description part number qty. 1 cart base plate paint blue a.4554 1 2 cart axle (zinc plated) a.4555 1 3 wheel spacer (6061 alu.) a.4556 2 4 10” x 1-3/4” wheel a.4558 2 5 1/2” axle cap a.4374 2 6 frame tube (chrome) a....

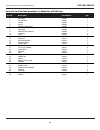

18 operating instructions and parts manual www.Chpower.Com hv2100, hv2105 fluid tank assembly for model hv2105 only.

19 www.Chpower.Com operating instructions and parts manual hv2100, hv2105 ref. No. Description part number qty. 1 fluid tank a.4901 1 2 lid assembly a.4902 1 3 handle a.4903 1 4 gasket a.4904 1 5 material pickup tube a.4905 1 6 material filter housing a.4906 1 7 filter base a.4907 1 8 material filte...

20 operating instructions and parts manual www.Chpower.Com hv2100, hv2105 limited warranty 1. Duration: from the date of purchase by the original purchaser as follows: standard duty paint application systems and all paint application accessories - 1 year, serious duty paint application systems - 3 y...