Campbell Hausfeld Welder / Generator GW4500 Operating Instructions And Parts Manual

Welder /

Generator

Table of Contents

Description . . . . . . . . . . . . . . . . . . . . . .1

Unpacking . . . . . . . . . . . . . . . . . . . . . . .1

Safety Guidelines . . . . . . . . . . . . . . . . .1

Specifications. . . . . . . . . . . . . . . . . . . . .1

General Safety Information . . . . . . 2 - 4

Glossary of Terms . . . . . . . . . . . . . . . . .5

Pre-operation . . . . . . . . . . . . . . . . . 6 - 7

Operation . . . . . . . . . . . . . . . . . . . . 7 - 9

Maintenance . . . . . . . . . . . . . . . . . . . . .9

Storage . . . . . . . . . . . . . . . . . . . . . . . . .9

Welding Guidelines. . . . . . . . . . . 10 - 12

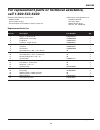

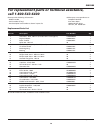

Troubleshooting Chart . . . . . . . . 13 - 14

General . . . . . . . . . . . . . . . . . . . . . .13

Generator . . . . . . . . . . . . . . . . . . . .13

Welder . . . . . . . . . . . . . . . . . . . . . .14

Welds . . . . . . . . . . . . . . . . . . . . . . .14

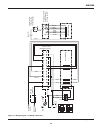

Wiring Diagram. . . . . . . . . . . . . . . . . .15

Welder / Generator Assembly. . . 16 - 17

Alternator Assembly . . . . . . . . . . 18 - 19

Warranty . . . . . . . . . . . . . . . . . . . . . . .20

Description

This welder / generator is powered by

an air-cooled four cycle engine and

designed to run at maximum RPM and

give a continuous wattage as rated.

A low-oil level shutoff is provided to

protect the engine. The alternator is

thermostatically protected. To operate

this unit as a generator or welder,

set the switch on the front panel

accordingly.

Unpacking

After unpacking the welder / generator,

inspect carefully for any damage that

may have occurred during transit. Make

sure to tighten fittings, bolts, etc.,

before putting unit into service. Report

any missing items by calling

1-800-543-6400.

Safety Guidelines

This manual contains information

that is very important to know and

understand. This information is

provided for SAFETY and to PREVENT

EQUIPMENT PROBLEMS. To help

recognize this information, observe the

following symbols.

Danger indicates an

imminently

hazardous situation which, if not

avoided, WILL result in death or serious

injury.

Warning indicates a

potentially

hazardous situation which, if not

avoided, COULD result in death or

serious injury.

Caution indicates a

potentially

hazardous situation which, if not

avoided, MAY result in minor or

moderate injury.

Notice

indicates

important

information, that if not followed, may

cause damage to equipment.

NOTE: Information that requires special

attention.

Specifications

ENGINE

Engine Type . . . . . 270cc, 4 stroke OHV

Net Power . . . . . . . . . . . . . . . . . . . . 6.0

Ignition System . . Transistor Magneto

Start Mode . . . . . . . . . . . . . . . . Manual

Fuel Capacity . . . . . . . . . . . 1.4 gallons

Oil Capacity . . . . . . . 38.4 fluid ounces

GENERATOR

Type . . . . . . 2 pole, brushless rotating

Phase . . . . . . . . . . . . . . . . . . . . . Single

Continuous Power

Rating (KVA) . . . . . . . . . . . . . . . . . . 4.5

Rated Voltage (V) . . . . . . . . . 120 / 240

WELDER

Max Open Circuit Voltage (V). . . . 62.5

Rated Voltage (V) . . . . . . . . . . . . . 25.6

Rated Current (A) . . . . . . . . . . . . . .140

Max No Load Speed (r/min) . . . . .3850

Current Control Range (A) . . . 60 - 140

Rated Duty Cycle (%) . . . . . . . . . . . .35

Electrode Diameter (mm) . . . . 2.4 - 3.2

IN954000AV 8/08

Q

UA

LIT

Y

A

SSURANCE

P

ROGR

AM

Need

Assistance?

Call Us First!

1-800-543-6400

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described.

Protect yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and/or

property damage! Retain instructions for future reference.

For parts, product & service information

visit www.chpower.com or call 1-800-543-6400

REMINDER: Keep your dated proof of purchase for warranty purposes!

Attach it to this manual or file it for safekeeping.

© 2008 Campbell Hausfeld/Scott Fetzer

Operating Instructions and Parts Manual

GW4500

See Warranty on page 20 for important information about commercial use of this product.