- DL manuals

- Camus Hydronics

- Boiler

- DMC 753

- Installation, operation and service manual

Camus Hydronics DMC 753 Installation, operation and service manual

6226 Netherhart Road, Mississauga, Ontario, L5T 1B7

99-0056

Rev. 01

INSTALLATION OPERATION

AND SERVICE MANUAL

GAS FIRED WALL HUNG & FLOOR MOUNT RESIDENTIAL

COMMERCIAL STAINLESS STEEL BOILERS

DynaMax SERIES

HYDRONIC HEATING

Models; DMH081, 101, 151, 201, 251,

211, 261, 291, 391, 501, 601, 751

HOT WATER SUPPLY

Models

;

DMW082 ,102, 152, 202, 252,

212, 262, 292, 392, 502, 602, 752

COMBINATION HEATING/HOT WATER SUPPLY

Models

;

DMC083, 103, 153, 203, 253,

213, 263, 293, 393, 503, 603, 753

W

W

A

A

R

R

N

N

I

I

N

N

G

G

:

:

If the information in these instructions is not followed

exactly, a fire or explosion may result causing property

damage, personal injury or death

Do not store or use gasoline or other flammable

vapours and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS

o

Do not try to light any appliance,

o

Do not touch any electrical switch; do not

use any phone in your building,

o

Immediately call your gas supplier from a

neighbour’s phone. Follow the gas

supplier’s instructions,

o

If you cannot reach your gas supplier, call

the fire department.

Qualified installer, service agency or the

gas supplier must perform installation and

service.

To the Installer: After installation, these instructions

must be given to the end user or left on or near the

appliance.

To the End User: This booklet contains important

information about this appliance. Retain for future

reference.

CAMUS HYDRONICS LTD.

Summary of DMC 753

Page 1

6226 netherhart road, mississauga, ontario, l5t 1b7 99-0056 rev. 01 installation operation and service manual gas fired wall hung & floor mount residential commercial stainless steel boilers dynamax series hydronic heating models; dmh081, 101, 151, 201, 251, 211, 261, 291, 391, 501, 601, 751 hot wat...

Page 2

Table of contents part 1 general information.................................................................................................... 1 1.1 introduction ......................................................................................................................... 1 1.2 special ...

Page 3

5.1 electrical conections................................................................................................... 18 5.2 high limit ............................................................................................................................... 18 5.3 dynamax controller ......

Page 4

11.4.1 condensate volume ............................................................................................................. 46 11.5 igniter and flame sensor electrodes .................................................................. 46 11.6 check igniter ground wiring .....................

Page 5

1 part 1 general information 1.1 introduction the dynamax boiler is a fan assisted boiler based on a push through design which offers several venting options. Heat output is controlled by a one to one air/gas ratio control gas valve which provides seamless modulation. The boiler provides central hea...

Page 6

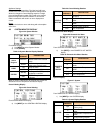

2 table 1: dynamax ignition cycle (in labvision) note: 1. If a flame signal is detected at the end of the pre-purge period a lockout will occur. 2. If at the end of the safety period (6 sec) no flame is detected the control will go to post-purge to remove the unburned gas. After this, a re-ignition ...

Page 7

3 1.7 warranty • factory warranty (shipped with unit) does not apply to units improperly installed or improperly operated. • factory warranty shall apply only when the appliance is installed in accordance with local plumbing and building codes, ordinances and regulations, the printed instructions pr...

Page 8

4 1.10 location of unit install this appliance in a clean, dry location with adequate service clearance. • do not locate this appliance in an area where it will be subject to freezing unless precautions are taken. Radiant losses from the dynamax are minimal and should not be relied on to keep the ap...

Page 9

5 table 3: dynamax wall hung service clearances service clearance, inches (cm) input [btu/hr] front top right side left side rear 80,000 24” (61cm) 0” (0 cm) 0” (0 cm) 0” (0 cm) 0” (0 cm) 100,000 24” (61cm) 0” (0 cm) 0” (0 cm) 0” (0 cm) 0” (0 cm) 150,000 24” (61cm) 0” (0 cm) 0” (0 cm) 0” (0 cm) 0” (...

Page 10

6 table 5: dynamax floor mount service clearances service clearance, inches (cm) input [btu/hr] front top right side left side rear 200,000 12” (31cm) 24” (61cm) 0” (0cm) 12” (31cm) 14” (36 cm) 250,000 12” (31cm) 24” (61cm) 0” (0cm) 12” (31cm) 14” (36 cm) 299,000 12” (31cm) 24” (61cm) 0” (0cm) 12” (...

Page 11

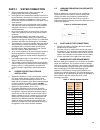

7 figure 5: dynamax wall hung service clearances figure 6: dynamax floor mount service clearances.

Page 12

8 part 2 air inlet and venting it is extremely important to follow these venting instructions carefully. Failure to do so can cause severe personal injury, death or substantial property damage. 2.1 general venting guide • single pipe vent with common air from room. Figure 7: vertical venting configu...

Page 13

9 2.2.1 approved venting materials category iv 1) pvc and cpvc (chlorinated polyvinyl chloride) schedule 40 or 80 approved to ulc s636. 2) manufactured prefabricated ul/ulc listed vent of al29- 4c or 316l stainless steel. Use of 316l is limited to use in applications where there is no possibility of...

Page 14

10 2.5 vent termination and air inlet clearances 2.5.1 sidewall venting • the first 3 feet (1m) of vent from the appliance flue outlet must be readily accessible for inspection. Figure 8: vertical configuration * always check local codes for minimum distance above ground or snow levels figure 9: hor...

Page 15

11 7) locate terminations so they are not likely to be damaged by foreign objects, or exposed to build-up of debris. 8) perform regularly scheduled inspections to ensure that the air inlet terminal is unobstructed. Termination and fittings 1) insert the bird screens into the air inlet and exhaust ve...

Page 16

12 part 3 gas connection verify that the appliance is supplied with the type of gas specified on the rating plate. Consult factory for installations at high altitude. 3.1 gas connection • safe operation of unit requires properly sized gas supply piping. See gas line sizing data. • gas pipe size may ...

Page 17

13 important upon completion of initial installation or following any repair work on the gas system, leak test all gas connections with a soap solution while the main burner is firing. Immediately repair any leak found in the gas train or related components. Do not operate an appliance with a leak i...

Page 18

14 part 4 water connection • check all applicable local heating, plumbing and building safety codes before proceeding. • if the appliance is installed above radiation level it must be provided with a low water cut-off device at the time of appliance installation (available from camus). Some local co...

Page 19

15 4.5 heat exchanger this appliance uses precision formed stainless steel tubing to maximize the heat transfer process and achieve 97% steady-state efficiency. This heat exchanger is designed to withstand 160 psig working pressure. A factory installed circulating pump ensures proper water flow duri...

Page 20

16.

Page 21

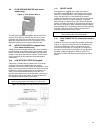

17 4.8 flow proving device (wall mount models only) figure 17: flow proving device the flow proving device is designed to detect when flow is present. This is done by detecting the amount of current (amperes) that exists in the neutral wire from the pump. When the current becomes too low a flow swit...

Page 22

18 part 5 electrical & controls it is extremely important that this unit be properly grounded! 5.1 electrical conections minimum 120vac 60hz single phase (15a circuit) is required for the dynamax models dm-080 through dm-750. The appliance, when installed, must be electrically grounded in accordance...

Page 23

19 5.4.1 hard lockout ‘a’ codes table 15: lockout codes ‘a’ code error int nr. Description 01 ignit_error 1 three unsuccessful ignition attempts in a row 02 too_many_flame _failures 24 three times flame lost during one demand 03 t_max_lock_err or 18 overheat stat is open 04 gv_relay_error 5 problems...

Page 24

20 part 6 control panel 6.1 dynamax controller the appliance is provided with a operator interface panel at the front. On a dynamax wall hung boiler the dynamax controller can be accessed by removing the upper stainless steel jacket and the lower black sheetmetal jacket which are each held on by two...

Page 25

21 mode 3: central heating with constant temperature loop no outdoor sensor is needed. The supply temperature is kept constantly at the setpoint temperature. The burner is controlled in a similar way as mode 0. When the room thermostat contact closes the ch_setpoint will be decreased with t_night_re...

Page 26

22 part 7 components 7.1 direct spark igniter the direct spark igniter is inserted directly through the combustion chamber front door and held in place by two torx screws. Care must be taken when removing and/or installing the igniter. Always remove the igniter prior to removing the fan assembly for...

Page 27

23 part 8 labvision software note labvision software is available on request from the factory and is not shipped with the boiler/ water heater. To operate labvision software a laptop and lpt1/usb connection cable are needed. 8.1 starting up lab vision locate the file named labvision.Exe, the appeara...

Page 28

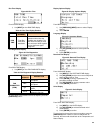

24 parameters shown in blue text can be adjusted. To change a blue coloured parameter, place the cursor on top a parameter and double-click. This will bring up a window to enter the desired values of operation. Figure 29: settings screen • the appliance name is listed under appliance type • fan spee...

Page 29

25 table 18: ch input screen parameters parameter parameter description ch demand displays the state of the room thermostat. When ‘on’ is shown the thermostat is closed, when ‘off’ is shown the thermostat is open. Ch_request displays the response of the boiler. ‘on’ is displayed when the boiler is r...

Page 30

26 8.4 labvision domestic hot water use the pull down menu and select dhw mode 4 to adjust parameters. Before the parameters can be adjusted the blue status bar must track left-to-right and back again. Refer to section 8.1 to resolve connection issues. Real-time temperatures are tracked by labvision...

Page 31

27 table 22: dhw mode = 4 parameters parameter parameter description dhw_setpoint to provide a target setpoint for dhw. (default: 120 o f) dhw hystereses up to provide modulation rate above dhw setpoint. (default: 9 o f) dhw hystereses down to provide modulation rate below dhw setpoint. (default: 4 ...

Page 32

28 8.5 labvision cascade when connected in a cascade setup the master boiler can control up to 7 slave boilers (ie. A total of 8 boilers) from the control panel of the master boiler. All diagnostic, control operation can be performed on the master boiler, which can then relay the relevant informatio...

Page 33

29 figure 45: adjust viewing area to record the data that is shown on screen, go to the toolbar and click on logging > start logging. A window will pop up on screen asking for a file name for the log file to be captured. Do not change the file type, as labvision must record the log file as .Csv. As ...

Page 34

30 8.7 error history labvision has the ability to record past blocking (e) and lockout (a) errors. To access this feature use the pull down menu and select history. Figure 47: error history the blocking and lockout errors are separated into their own respective rows and are identified by their respe...

Page 35

31 up down • press to change boiler parameter values (setpoint temperature, date & time) • press to enter main menu. This provides access to system monitor, settings, programs and errors • press to reset a lockout error. This shown on the display as a## * * where # denotes a digit from 0 – 9. • pres...

Page 36

32 9.1 introduction to the dynamax control panel for times when a notebook computer is not available, a service technician will still be able to perform all the functions described in labvision, except for the logging aspect. The menu structure for the dynamax control panel was designed to be intuit...

Page 37

33 appliance settings changes boiler characteristics. The user level will have access to the first screen inside appliance settings which allows for changes in central heating setpoint. A 4-digit personal identification number (pin) needs to be entered before moving further into the controller. If a...

Page 38

34 run time display figure 58: run time from system display; 1) use [next] to view run time display table 32: run time display readout display readout description run time total run time since installation monitors the amount of operational time since the dynamax was installed. The timer starts coun...

Page 39

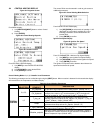

35 9.4 central heating display figure 64: programs screen from menu display; 1) use [previous]/[next] button to select ‘central heating’ 2) press [enter] figure 65: central heating setpoint figure 66: installer access from central heating display; 1) use [next] to enter installer access display 2) u...

Page 40

36 9.5 domestic hot water display figure 69: program selection from menu display; 1) use [previous]/[next] to select ‘domestic hot water’ 2) press [enter] figure 70: domestic hot water setpoint 3) use [up]/[down] to select dhw setpoint. 4) press [enter] figure 71: installer access from domestic hot ...

Page 41

37 9.6 cascade control from menu display. Figure 74: menu display 1) use [previous]/[next] to select ‘appliance settings’ 2) press [enter] figure 75: selecting cascade control 3) use [previous]/[next] to select ‘cascade control’ 4) press [enter] figure 76: enter pin# 5) use [up]/[down] to enter the ...

Page 42

38 figure 82: enter pin# 5) use [up]/[down] to enter the correct pin#. 6) press [enter]. Figure 83: boiler control the following parameters can be scrolled through using the [next] button. Table 36: system test parameters display readout description 0 system test off l low power operation i ignition...

Page 43

39 part 10 troubleshooting table 37: troubleshooting table component failure mode analysis incoming power • two wires interchanged, e21 • no effect on safety • live and neutral wires are interchanged. Transformer tripped • the 24volts and 120 volts wired are interchanged • transformer immediately bu...

Page 44

40 symptom failure mode analysis flame failure (pressing the manual reset on the dynamax control panel will be required to restart the ignition sequqnce) • the boiler has failed to ignite the burner after 3 unsuccessful attempts • verify that all air has been purged from gas line • inspect spark ele...

Page 45

41 symptom failure mode analysis • supply gas issue • refer to part 3 gas connection in this manual. • natural gas pressure should read between 3” w.C. And 14” w.C. • l.P. Gas pressure should be at 11” w.C. • air/gas mixture issue • refer to gas valve adjustment procedure in section 10.2 of this man...

Page 46

42 symptom failure mode analysis • stack temperature has exceeded the limit set on the boiler. • measure the resistance of the flue sensor at room temperature, it should be approximately 10k Ω . Temperature overshoot • the supply/outlet temperature has exceeded the setpoint temperature specified. • ...

Page 47

43 10.1 setting the correct combustion 1) switch the main power off to the boiler by placing the toggle switch in the ‘off’ position 2) switch the main power on to the boiler and adjust setpoint so that boiler begins ignition sequence. 3) observe the boiler as it goes through its startup cycle and o...

Page 48

44 dm 200 – 399 figure 88: dm 200 – 399 gas valve to adjust the high-fire setting use the dynamax control panel press the [menu] button > select appliance settings and press [enter] > select boiler control and press [enter] > enter the correct installer passcode. Select ‘h’ for high power. The dynam...

Page 49

45 part 11 maintenance caution it is important that all gas appliances be serviced by a qualified technician trained by camus hydronics. It is in your own interest and that of safety to ensure that all local codes, and all the “notes” and “warnings” in this manual are complied with. To service or ad...

Page 50

46 note all gaskets on disassembled components must be replaced with new gaskets/sealant on re-assembly, if required. Gasket kits are available from the factory caution when the vent system is disconnected for any reason it must be reassembled and resealed according to vent manufacturer’s instructio...

Page 51

47 • remove the direct spark igniter and the flame sensor. • remove the three (3) t-25 screws holding the front burner flange in place to gain access to the burner. • the burner can now be pulled horizontally out of the heat exchanger cavity. • use care to prevent damage to the knitted metal fiber o...

Page 52

48 part 12 installations warning before starting the boiler, smell near the floor and around the boiler for any gas odours or any unusual odour. Remove the stainless steel jacket and smell the interior of the boiler. If there is any sign of a gas leak, do not proceed with startup. Repair all the lea...

Page 53

49 b) placing the boiler in operation pre-start check list 1) review the location of the boiler, clearances from combustible surfaces and available service clearances. 2) review part 2 venting. Ensure that all vent components are fabricated from the correct category of materials with adequate cleara...

Page 54

50 12.10 temperature rise at full firing rate 1) the pump must run continuously when the burner is firing. 2) with the pump running and the burner in the water heater or hot water supply boiler in the off cycle, the return/inlet temperature and supply/outlet temperature readings on the dynamax contr...

Page 55

51 12.11 setting the correct combustion refer to section 10.1 setting the correct combustion. 12.12 cascade setup the dynamax can be placed into a multiple boiler system in a cascade setup. In such a cascade configuration all boilers should be connected with an additional connection between the mast...

Page 56

52 12.14 ignition cycle the ignition cycle is shown in the table below. The values are the default factory settings. Table 41: dynamax ignition cycle state standby pre purge safety on safety off 6 ignit_0 ignit_1 burn post purge_0 post purge_1 time 0s 5s after fan speed is within 600rpm 2 sec 6 sec ...

Page 57

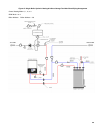

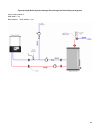

53 part 13 piping diagrams figure 94: single boiler hydronic heating zoned piping arrangement this piping arrangement is designed for: central heating mode: 0, 1, 2, or 3 dhw mode: 0 boiler address: 100

Page 58

54 figure 95: single combination boiler zoned piping arrangement central heating mode: 0, 1, 2, or 3 dhw mode: 3, or 4 boiler address: boiler address = 100

Page 59

55 figure 96: single boiler hydronic heating & indirect storage tank zoned piping arrangement central heating mode: 0, 1, 2, or 3 dhw mode: 1, or 2 boiler address: boiler address = 100

Page 60

56 figure 97: single boiler hydronic heating & indirect storage tank non-zoned piping arrangement central heating mode: 0, 1, 2, or 3 dhw mode: 1or 2 boiler address: boiler address = 100

Page 61

57 figure 98: single boiler hydronic heating & direct storage tank zoned piping arrangement central heating mode: 0 dhw mode: 1 or 2 boiler address: boiler address = 100

Page 62

58 figure 99: multiple boiler hydronic heating zoned piping arrangement central heating mode: 0, 1, 2, 3 dhw mode: 0 boiler address: master boiler address = 101 slave boiler address = 102.

Page 63

59 part 14 exploded view & parts list dynamax wall hung.

Page 64

60 dynamax floor mount.

Page 65

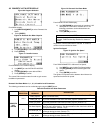

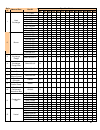

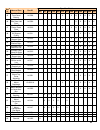

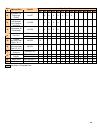

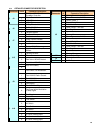

61 dynamax models ref # name of part part id all 80 100 150 200 210 250 260 299 399 500 600 750 4 + 1 wall x x 5 + 2 wall x 8 + 4 wall x x 8 + 4 floor x x 10 + 6 floor x 15 + 8 floor x 18 + 10 floor x 24 +11 floor x 1 heat exchanger 24 + 12 floor x 80,000 btu x 100,000 btu x 150,000 btu x 200,000 bt...

Page 66

62 dynamax models ref # name of part part id all 80 100 150 200 210 250 260 299 399 500 600 750 vk8115 v1036 x x x x x x x vr8615vb1044/b x x 13 gas valve v8730v1015 x x x astro 30 x x astro 50 x x x s25 x x s35 x x x x x x x x pl30 x x x pl36 x x x pump (non e- series) pl45 x e7 x e8 x x x x x x x ...

Page 67

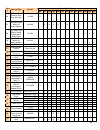

63 dynamax models ref # name of part part id all 80 100 150 200 210 250 260 299 399 500 600 750 27 dynamax wall mount support frame assembly 14-5409 x x x 28 dynamax wall mount bracket front 14-5410 x x x x x 29 dynamax wall mount rear bracket 14-5411 x x x x x 30 dynamax wall mount bezel stiffener ...

Page 68

64 dynamax models ref # name of part part id all 80 100 150 200 210 250 260 299 399 500 600 750 45 dynamax floor front panel bottom 14-5508 x x x x x x x 46 dynamax floor side panel left front 14-5509 x x x x x 47 dynamax floor control panel plate 14-5510 x x x x x x x 48 dynamax floor hx support fr...

Page 69

65 dynamax models ref # name of part part id all 80 100 150 200 210 250 260 299 399 500 600 750 66 electrical strip plate protector 14-5420 x 67 dynamax wall mount air intake adapter 44-0008 x x x x x 68 dynamax floor mount plastic flange with 3" street elbow 44-0009 x x x 69 dynamax floor mount air...

Page 70

66 dynamax models ref # name of part part id all 80 100 150 200 210 250 260 299 399 500 600 750 88 dynamax fan discharge orifice 14-0377 x x x x x x x 89 expandable air inlet adapter w/o pressure test point 14-0378 x x x x x 90 expandable air inlet adapter 14-0379 x x x x x 2" diameter x x x x x x x...

Page 71

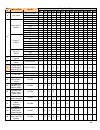

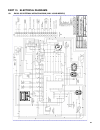

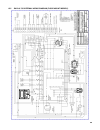

67 part 15 electrical diagrams 15.1 dm 80- 250 internal wiring diagram (wall hung models).

Page 72

68 15.2 dm 210- 750 internal wiring diagram (floor mount models).

Page 73

69 15.3 field wiring 15.3.1 system sensor the temperature of the primary return can be controlled by installing a system sensor. The dynamax controller automatically detects the use of this sensor and controls the burner modulation rate accordingly to maintain the system supply temperature to the se...

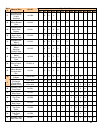

Page 74

70 15.4 detailed connector description connector pin # connector description provides 120vac to the dynamax controller 1 earth/ ground 2 120vac neutral j2 3 120vac live 3-way diverter valve 1 dhw 120vac live 2 ch 120vac live j6 3 120vac neutral on-board pump 1 not used 2 pump 120vac neutral 3 not us...

Page 75

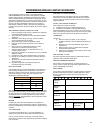

71 condensing boiler limited warranty camus hydronics limited (“camus”) extends the following limited warranty to the owner of this appliance, provided that the product has been installed and operated in accordance with the installation manual provided with the equipment. Camus will furnish a replac...

Page 76

Camus hydronics is a manufacturer of replacement parts for most copper finned the camus certified! Seal assures you that reliability, efficiency & serviceability are built water heaters and heating boilers as well as a into every single unit! For more information supplier of specialty hvac products....