- DL manuals

- Can-Am

- Offroad Vehicle

- 2010 ACS

- Technical Manual

Can-Am 2010 ACS Technical Manual

® AND THE BRP LOGO ARE TRADEMARKS OF BOMBARDIER RECREATIONAL PRODUCTS INC. OR ITS AFFILIATES.

©2009 BOMBARDIER RECREATIONAL PRODUCTS INC. ALL RIGHTS RESERVED. PRINTED IN CANADA.

219 100 388

CA

DPS/ACS TECHNICAL MANUAL / ENGLISH

MANUEL TECHNIQUE DPS/ACS / ANGLAIS

FAIT AU / MADE IN CANADA

U/M:P.C.

Technical Manual

2 1 9 1 0 0 3 8 8

DPS

TM

/ACS

DPS

TM

/ACS

2010

Summary of 2010 ACS

Page 1

® and the brp logo are trademarks of bombardier recreational products inc. Or its affiliates. ©2009 bombardier recreational products inc. All rights reserved. Printed in canada. 219 100 388 ca dps/acs technical manual / english manuel technique dps/acs / anglais fait au / made in canada u/m:p.C. Te...

Page 2: 2010

2010 dps/acs technical manual.

Page 3

Legal deposit: national library of quebec national library of canada 2009 all rights reserved. No parts of this manual may be reproduced in any form without the prior written permission of bombardier recreational products inc. (brp) © bombardier recreational products inc. (brp) 2009 printed in canad...

Page 4

Table of contents safety notice . . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. Ii introduction .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . . .. . ...

Page 5: Safety Notice

Safety notice safety notice this manual has been prepared as a guide to cor- rectly service and repair the dps™ and acs sys- tems on 2010 can-am™ atvs. This edition was primarily published to be used by mechanical technicians who are already familiar with all service procedures relating to brp prod-...

Page 6: Introduction

Introduction introduction this technical manual covers the following brp made 2010 can-am atvs with a dps or acs system. Outlander™ engine model color model number xt yellow, red, camo 2uaa, 2uab, 2uac, 2uad, 2uae xt-p black 5jab max xt yellow, red, camo 2xaa, 2xab, 2xac, 2xad, 2xae max xt-p black 5...

Page 7

Iv vmr2010-002.

Page 8

Service tools index fluke 115 multimeter (p/n 529 035 868) page: 9, 11, 32, 35, 37–38, 43–44 oetiker pliers (p/n 295 000 070) page: 44 spring remover (p/n 529 036 007) page: 46 1.

Page 9

2.

Page 10

Section 01 technical manual subsection 01 (dynamic power steering (dps)) dynamic power steering (dps) service tools description part number page fluke 115 multimeter ............................................................ 529 035 868 ....................................... 9, 11 service tools –...

Page 11

Section 01 technical manual subsection 01 (dynamic power steering (dps)) 38 nm (28 lbfft) if torqued by screw head xps synthetic grease (400 g) new new xps synthetic grease (400 g) new 24.5 nm (18 lbfft) new new 72 nm (53 lbfft) new new 24.5 nm (18 lbfft) if torqued by elastic nuts 24.5 nm ...

Page 12: General

Section 01 technical manual subsection 01 (dynamic power steering (dps)) general during assembly/installation, use the torque val- ues and service products as in the exploded view. Warning torque wrench tightening specifications must be strictly adhered to. Locking devices (e.G.: locking tabs, elast...

Page 13

Section 01 technical manual subsection 01 (dynamic power steering (dps)) the active dps mode will be displayed in the lower portion of multifunction gauge. Vmo2010-004-004_a 1. Dps mode indication how to change dps assist mode to change dps assist mode, press and hold the override/dps button for app...

Page 14: Adjustment

Section 01 technical manual subsection 01 (dynamic power steering (dps)) steering torque sensor rmr2008-019-017 the steering column is connected to the shaft on the dps unit. A small area of the dps shaft is magnetized. Inside the dps unit, a torque sensor surrounds the magnetized area of the dps sh...

Page 15: Troubleshooting

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmo2010-004-006_a 1. Override/dps button the active dps mode will be displayed in the lower portion of multifunction gauge. Vmo2010-004-004_a 1. Dps mode indication 2. To change dps assist mode, press and hold the override/dps ...

Page 16: Procedures

Section 01 technical manual subsection 01 (dynamic power steering (dps)) 3. Faulty dps ground circuit. - carry out a dps unit ground circuit test. Ensure dps ground connector pins (dps3-a and dps3-b) and frame ground post are clean, corro- sion free, tight, and make good contact. Repair or replace w...

Page 17

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmr2010-003-005_a 1. 40 amp dps fuse (pf2-f3) 3. Replace fuse as required. Dps unit input voltage test (power side) 1. Disconnect the dps pwr (power) connector. Vmr2010-003-013_d 1. Dps pwr connector (motor power) 2. Test for 1...

Page 18

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmr2010-003-013_c 1. Dps ground connector (gdn) 2. Test for continuity between dps3-a and dps3-b to battery ground. Multimeter probe positions reading dps gdn connector pin a dps gdn connector pin b battery ground continuity (c...

Page 19

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmr2010-003-006_a 1. Negative (-) battery terminal 2. Rear fuse box battery terminal 3. Measure the battery voltage. Note: if battery voltage is low, recharge battery. 4. Ensure the vehicle transmission is set to park. 5. Start...

Page 20

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmr2010-003-007 if the electrical system cannot sustain at least 12 vdc, check the following: – battery – battery connections – dps unit power and ground connections – charging system – frame and engine ground studs. If the pre...

Page 21

Section 01 technical manual subsection 01 (dynamic power steering (dps)) – steering column shim adjustment at half bush- ings as described in the dps unit installa- tion procedure detailed in this section. – torque offset reset procedure detailed in this section. – replace dps unit. Dps unit removal...

Page 22

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmr2010-003-013_a 1. Dps connectors (3x) 12. Cut the locking tie securing the bellows at the bottom of steering column near the dps unit, and pull the bellows upwards sufficiently to access the steering column pinch bolt. Vmr20...

Page 23

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmr2010-003-019_a 1. Shim 2. Steering column frame support 3. Half bushings 17. Pull up on the steering column to disengage it from the dps unit and move it to the side. Vmr2010-003-020_a step 1: pull up on steering column step...

Page 24

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmr2010-003-024_a typical - left side illustrated step 1: remove dps retaining screws (2 each side) step 2: discard conical washers under screw head 20. Pull up on dps unit to align the 2 small hexag- onal forming screws with t...

Page 25

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmr2010-003-023_a 1. Pitman arm 2. Tie rod ends inserted in pitman arm 3. Hardened steel washer on tie rod end 4. Engage new m8 hexagonal flanged screws through the dps frame support and into the dps unit. Note: ensure each ret...

Page 26

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmr2010-003-032 pull bellows down over steering column bolt and edge of dps unit housing extension. Secure bel- lows using the appropriate locking tie. Note: ensure the locking tie is on the tube part of the steering column, no...

Page 27

Section 01 technical manual subsection 01 (dynamic power steering (dps)) vmr2010-003-035_a 1. These nuts installed hand tight at this time 11. Torque dps unit mounting screws to 24.5 n•m (18 lbf•ft). Vmr2010-003-028_b typical - rh side illustrated 1. Torque dps mounting screws (x4) 12. Using an 8 mm...

Page 28

Section 01 technical manual subsection 01 (dynamic power steering (dps)) if total shim thickness exceeds 4 mm (.157 in), carry out the following: – re-measure the distance between steering column and support. Ensure the forward end of the tool is in the center of the steering col- umn, and the rearw...

Page 29

Section 01 technical manual subsection 01 (dynamic power steering (dps)) 20. Install and connect ecm. Torque ecm mount- ing screws to 7 n•m (62 lbf•in). 21. Install dash board and reconnect the following: – multifunction gauge – ignition switch – 12 vdc accessories outlet. 22. If installing a replac...

Page 30

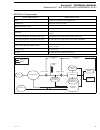

Section 01 technical manual subsection 02 (air controlled suspension (acs)) air controlled suspension (acs) service tools description part number page fluke 115 multimeter ............................................................ 529 035 868 ............. 32, 35, 37–38, 43–44 oetiker pliers.........

Page 31

Section 01 technical manual subsection 02 (air controlled suspension (acs)) 53 nm (39 lbfft) new 53 nm (39 lbfft) 53 nm (39 lbfft) loctite 592 (pipe sealant) acs module new acs compressor acs solenoid release valve acs hose vmr2010-004-033_a 24 vmr2010-004.

Page 32: General

Section 01 technical manual subsection 02 (air controlled suspension (acs)) general during assembly/installation, use torque values and service products as in the exploded views. Warning torque wrench tightening specifications must be strictly adhered to. Locking devices (e.G.: locking tabs, cotter ...

Page 33

Section 01 technical manual subsection 02 (air controlled suspension (acs)) the requested setting is controlled by the acs electronic module. The module is equipped with a pressure transducer to keep air pressure con- stant in the system. Depending on the rider ad- justment, the module will increase...

Page 34

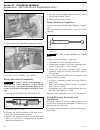

Section 01 technical manual subsection 02 (air controlled suspension (acs)) vmr2010-004-001_a 1. Pneumatic valve cap 4. Push and hold pneumatic valve pin using a small screwdriver. Vmr2010-004-002 5. Wait until the system is completely empty of air. Note: make sure to wait enough time in order to le...

Page 35

Section 01 technical manual subsection 02 (air controlled suspension (acs)) outlander 800r ltd vmr2010-004-105_a outlander 800r ltd model 1. Acs compressor relay (r5) 28 vmr2010-004.

Page 36

Section 01 technical manual subsection 02 (air controlled suspension (acs)) acs main components acs components main function filter to filter air intake of the compressor compressor to pressurize the system solenoid release valve to release air in the system electronic module to control the compress...

Page 37: Troubleshooting

Section 01 technical manual subsection 02 (air controlled suspension (acs)) troubleshooting diagnostic tips error code (air fault) displayed in gauge the error code air fault can appear on the mul- tifunction gauge for different reasons that are not necessarily related to a failure of the acs system...

Page 38: Procedures

Section 01 technical manual subsection 02 (air controlled suspension (acs)) troubleshooting with b.U.D.S. Acs system leak test 1. Connect vehicle to b.U.D.S. Refer to commu- nication tools and b.U.D.S. Software subsection of the appropriate shop manual. 2. Select activation page. 3. Select acs folde...

Page 39

Section 01 technical manual subsection 02 (air controlled suspension (acs)) vmr2010-004-201_b step 1: activation page step 2: acs folder step 3: solenoid valve operation test button 5. Verify that air exits from side port to confirm proper solenoid operation. Vmr2010-004-202_a 1. Side port acs solen...

Page 40

Section 01 technical manual subsection 02 (air controlled suspension (acs)) 2. Disconnect solenoid valve connector. Vmr2010-004-003_a 1. Solenoid valve connector 3. Unscrew solenoid valve from manifold while holding support. Vmr2010-004-004_a 1. Solenoid valve acs solenoid valve installation the ins...

Page 41

Section 01 technical manual subsection 02 (air controlled suspension (acs)) vmr2010-004-006_a 1. Retaining screws 6. Unscrew air fittings, pneumatic valve and check valve. Vmr2010-004-007_a 1. Manifold air inlet fitting (from compressor) 2. Auxiliary line check valve 3. Pneumatic valve 4. Shocks fit...

Page 42

Section 01 technical manual subsection 02 (air controlled suspension (acs)) acs module acs module signal circuit continuity test 1. Remove seats and rh side panel. 2. Disconnect multifunction gauge from vehicle. Refer to lights, gauge and accessories subsection of the appropriate shop manual. 3. Dis...

Page 43

Section 01 technical manual subsection 02 (air controlled suspension (acs)) acs module removal 1. Release air pressure, refer to releasing air pressure in system for servicing in this subsection. 2. Disconnect module hose from manifold air fit- ting as follows: 2.1 push fitting ring toward manifold....

Page 44

Section 01 technical manual subsection 02 (air controlled suspension (acs)) acs compressor relay (r5) acs relay continuity test 1. Remove relay (r5), refer to fuse and relay at the beginning of this section. 2. Set the fluke 115 multimeter (p/n 529 035 868) to . 3. Measure resistance as per the foll...

Page 45

Section 01 technical manual subsection 02 (air controlled suspension (acs)) 2. Select activation page. 3. Select acs folder. 4. Press compressor button to proceed. Vmr2010-004-201_c step 1: activation page step 2: acs folder step 3: compressor operation test button 5. Verify if compressor works prop...

Page 46

Section 01 technical manual subsection 02 (air controlled suspension (acs)) vmr2010-004-101_a 1. Actual setting (pressure transducer reading) 8. Measure voltage between compressor connec- tor terminals as per the following table. Test probes voltage pin c (be/vi) pin a (bk) battery voltage (± 12 vdc...

Page 47

Section 01 technical manual subsection 02 (air controlled suspension (acs)) 10. To disconnect hoses, proceed as follows: 10.1 push fitting ring toward manifold. 10.2 hold ring in place. 10.3 pull air hose. 11. Remove compressor side retaining bolts and nuts. Vmr2010-004-017_a 1. Rh side retaining bo...

Page 48

Section 01 technical manual subsection 02 (air controlled suspension (acs)) vmr2010-004-022_a 1. Front support mounting nuts 2. Compressor connector 3. Front support notice do not remove rear support from compressor. 17. Remove the following fittings from compres- sor. – compressor air inlet fitting...

Page 49

Section 01 technical manual subsection 02 (air controlled suspension (acs)) acs air filter acs air filter removal 1. Remove seat. 2. Remove central panel. Vmo2006-007-026_a 1. Central panel 2. Tabs to pull 3. Lift dashboard upwards. Vmr2008-068-002_a typical 1. Central panel 2. Dashboard 4. Release ...

Page 50

Section 01 technical manual subsection 02 (air controlled suspension (acs)) 3. Rinse the prefilter with warm water until all cleaning solution disappears. 4. Let the prefilter dry completely. Filter (disc) cleaning 1. Blow low pressure compressed air on filter to clean it. Notice do not wash the fil...

Page 51

Section 01 technical manual subsection 02 (air controlled suspension (acs)) vmr2010-004-108 pressure transducer ground test 1. Remove seats and rh side panel. 2. Disconnect pressure transducer connector. Vmr2010-004-104_a 1. Pressure transducer connector 3. Set the fluke 115 multimeter (p/n 529 035 ...

Page 52

Section 01 technical manual subsection 02 (air controlled suspension (acs)) vmr2010-004-031_a 1. Auxiliary line adapter 2. Fitting ring 3. Drill retaining rivets. Vmr2010-004-032_a 1. Retaining rivets 4. Install new adapter. 5. Secure adapter support using rivets. 6. Connect auxiliary line hose into...

Page 53

Section 01 technical manual subsection 02 (air controlled suspension (acs)) vmr2010-004-028_a 1. Shock absorber lower bolt 5. Remove the shock absorber upper bolt and nut. Vmr2010-004-029_a 1. Shock absorber upper bolt 6. Remove shock absorber from vehicle. Shock absorber disassembly notice be caref...

Page 54

Section 01 technical manual subsection 02 (air controlled suspension (acs)) vmr2010-004-701_a 1. Sleeve 2. O-ring vmr2010-004-702_a 1. Sleeve 2. O-ring vmr2010-004-703_a typical 1. Circlip 2. Small sleeve 3. Lower cap 4. Upper cap 5. Large sleeve install shock absorber cap opening at 180° from sprin...

Page 55

Section 01 technical manual subsection 02 (air controlled suspension (acs)) vmr2010-004-027_a 1. Shock absorber fitting 2. Air hose fitting ensure that there is no air leaks from shock ab- sorber fitting and air hose. Refer to acs system leak test (with b.U.D.S.) . Notice never screw shock absorber ...

Page 56

Notes.

Page 57

Notes.

Page 58: 2010

® and the brp logo are trademarks of bombardier recreational products inc. Or its affiliates. ©2009 bombardier recreational products inc. All rights reserved. Printed in canada. 219 100 388 ca dps/acs technical manual / english manuel technique dps/acs / anglais fait au / made in canada u/m:p.C. Te...