- DL manuals

- Can-Am

- Offroad Vehicle

- DS 450 X mx

- Operator's Manual

Can-Am DS 450 X mx Operator's Manual

Summary of DS 450 X mx

Page 1

2 1 9 0 0 0 6 2 7.

Page 2: Warning

Warning your vehicle can be hazardous to operate. A collision or rollover can occur quickly, even during routine maneuvers such as turning and driving on hills or over obstacles, if you fail to take proper precautions. For your safety, understand and follow all the warnings contained in this operato...

Page 3: Foreword

Foreword congratulations on your purchase of a new can-am™ atv. It is backed by the brp warranty and a network of autho- rized can-am dealers ready to provide the parts, service or accessories you may require. Your dealer is committed to your sat- isfaction. He has taken training to per- form the in...

Page 4: Warning

Foreword products without imposing upon itself any obligation to install them on prod- ucts previously manufactured. Due to late changes, some differences be- tween the manufactured product and the descriptions and/or specifications in this guide may occur. Brp reserves the right at any time to disc...

Page 5: Table Of Contents

Table of contents foreword . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 know before you go . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 6

Table of contents controls/instrument/equipments (cont’d) 7) indicator lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61 8) rear brake pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...

Page 7

Table of contents maintenance procedures (cont’d) clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98 throttle cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ....

Page 8

Table of contents customer information privacy information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144 change of address/ownership. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145 6 __________...

Page 9: Safety

Safety information ________ safety information ________ 7.

Page 10: General Precautions

General precautions avoid carbon monoxide poisoning all engine exhaust contains carbon monoxide, a deadly gas. Breathing car- bon monoxide can cause headaches, dizziness, drowsiness, nausea, confu- sion and eventually death. Carbon monoxide is a colorless, odor- less, tasteless gas that may be prese...

Page 11: Special Safety Messages

Special safety messages this vehicle is not a toy and can be hazardous to operate. – this vehicle handles differently from other vehicles including motorcycles and cars. – a collision or rollover can occur quickly, even during routine maneuvers such as turning and driving on hills or over obstacles,...

Page 12

Special safety messages – always follow proper procedures for climbing hills as described further in this operator's guide. Check the terrain carefully before you start up any hill. Never climb hills with excessively slippery or loose surfaces. Shift your weight forward. Never open the throttle sudd...

Page 13

Special safety messages for more information about atv safety, contact an authorized can-am dealer to find out about available training courses nearest you. Usa and canada only: call the specialty vehicle institute of america (svia) at 1 800 887-2887 or in canada, the canada safety council (csc) at ...

Page 14: Operation Warnings

Operation warnings the following warning and their format have been requested by the united states consumer product safety commission and are required to be in the operator's guide for all atvs. Note: the following illustrations are general representations only. Your model may differ. Warning v00a0a...

Page 15: Warning

Operation warnings warning v00a01q potential hazard failure to follow the age recommendations for this vehicle. What can happen a lack of respect for this age recommendation can lead to severe injury or death of the child. Even though a child may be within the age group for which this vehicle is rec...

Page 16: Warning

Operation warnings warning v00a02q potential hazard carrying a passenger on this vehicle. What can happen greatly reduces your ability to balance and control this vehicle. Could cause an accident, resulting in harm to you and/or your passenger. How to avoid the hazard never carry a passenger. Even w...

Page 17: Warning

Operation warnings warning v00a03q potential hazard operating this vehicle on paved surfaces. What can happen the tires are designed for off-road use only, not for use on pavement. Paved surfaces may seriously affect handling and control of this vehicle, and may cause the vehicle to go out of contro...

Page 18: Warning

Operation warnings warning v00a04q potential hazard operating this vehicle on public streets, roads or highways. What can happen you can collide with another vehicle. How to avoid the hazard never operate this vehicle on any public street, road or highway, even a dirt or gravel one. In many states o...

Page 19: Warning

Operation warnings warning v00a06q potential hazard riding this vehicle without wearing an approved helmet, eye protection and protective clothing. What can happen the following items concern all atv's operator: – riding without an approved helmet increases the chances of a severe head injury or dea...

Page 20: Warning

Operation warnings warning v00a07q potential hazard riding this vehicle after consuming alcohol or drugs. What can happen could seriously affect your judgment. Could cause you to react more slowly. Could affect your balance and perception. Could result in an accident or death. How to avoid the hazar...

Page 21: Warning

Operation warnings warning v00a08q potential hazard operating this vehicle at excessive speeds. What can happen increases your chances of losing control of the vehicle, which can result in an accident. How to avoid the hazard always travel at a speed which is proper for the terrain, visibility and o...

Page 22: Warning

Operation warnings warning v00a09q potential hazard attempting wheelies, jumps and other stunts. What can happen increases the chance of an accident, including an overturn. How to avoid the hazard never attempt stunts, such as wheelies or jumps. Do not try to show off. Warning potential hazard failu...

Page 23: Warning

Operation warnings warning potential hazard riding on frozen waterways. What can happen breaking through the ice can lead to severe injury or death. How to avoid the hazard never ride this vehicle on a frozen surface before you are sure the ice is thick enough and sound enough to support the vehicle...

Page 24: Warning

Operation warnings warning v00a0cq potential hazard failure to use extra care when operating this vehicle on unfamiliar terrain. What can happen you can come upon hidden rocks, bumps, or holes, without enough time to react. Could result in the vehicle overturning or loss of control. How to avoid the...

Page 25: Warning

Operation warnings warning v00a0dq potential hazard failure to use extra care when operating on excessively rough, slippery or loose terrain. What can happen could cause loss of traction or vehicle control, which could result in an acci- dent, including an overturn. How to avoid the hazard do not op...

Page 26: Warning

Operation warnings warning v00a0eq potential hazard turning improperly. What can happen vehicle could go out of control, causing a collision or overturn. How to avoid the hazard always follow proper procedures for turning as described further in this op- erator's guide. Practice turning at low speed...

Page 27: Warning

Operation warnings warning v00aqq potential hazard operating on excessively steep hills. What can happen the vehicle can overturn more easily on extremely steep hills than on level surfaces or small hills. How to avoid the hazard never operate this vehicle on hills too steep for the vehicle or for y...

Page 28: Warning

Operation warnings warning v00a0fq potential hazard climbing hills improperly. What can happen could cause loss of control or cause vehicle to overturn. How to avoid the hazard always follow proper procedures for climbing hills as described further in this operator's guide. Always check the terrain ...

Page 29: Warning

Operation warnings warning v00a0gq potential hazard going down a hill improperly. What can happen could cause loss of control or cause vehicle to overturn. How to avoid the hazard always follow proper procedures for going down hills as described further in this operator's guide. Note: a special tech...

Page 30: Warning

Operation warnings warning v00a0hq potential hazard improperly crossing hills or turning on hills. What can happen could cause loss of control or cause vehicle to overturn. How to avoid the hazard never attempt to turn the vehicle around on any hill until you have mastered the turning technique as d...

Page 31: Warning

Operation warnings warning v00a0iq potential hazard stalling, rolling backwards or improperly dismounting while climbing a hill. What can happen could result in vehicle overturning. How to avoid the hazard use proper gear and maintain steady speed when climbing a hill. If you lose all forward speed:...

Page 32: Warning

Operation warnings warning v00a0jq potential hazard improperly operating over obstacles. What can happen could cause loss of control or a collision. Could cause the vehicle to overturn. How to avoid the hazard before operating in a new area, check for obstacles. Never attempt to ride over large obst...

Page 33: Warning

Operation warnings warning v00a0kq potential hazard skidding or sliding improperly. What can happen you may lose control of this vehicle. You may also regain traction unexpectedly, which may cause the vehicle to overturn. How to avoid the hazard learn to safely control skidding or sliding by practic...

Page 34: Warning

Operation warnings warning v00a0lq potential hazard operating this vehicle through deep or fast flowing water. What can happen tires may float, causing loss of traction and loss of control, which could lead to an accident. How to avoid the hazard never operate this vehicle in fast flowing water or i...

Page 35: Warning

Operation warnings warning v00a0oq potential hazard operating this vehicle with improper tires, or with improper or uneven tire pressure. What can happen use of improper tires on this vehicle, or operation of this vehicle with improper or uneven tire pressure, may cause loss of control, tire blow ou...

Page 36: Warning

Operation warnings warning v00a0nq potential hazard operating this vehicle with improper modifications. What can happen improper installation of accessories or modification of this vehicle may cause changes in handling which in some situations could lead to an acci- dent. How to avoid the hazard nev...

Page 37: Warning

Operation warnings warning v02a02q potential hazard overloading this vehicle or carrying or towing cargo improperly. What can happen could cause changes in vehicle handling which could lead to an accident. How to avoid the hazard never exceed the stated load capacity for this vehicle including opera...

Page 38: Warning

Operation warnings warning v03m01q potential hazard transporting flammable or dangerous material can lead to explosions. What can happen this can cause serious injury or death. How to avoid the hazard never transport flammable or dangerous material. 36 _______ safety information ________.

Page 39: Riding The Vehicle

Riding the vehicle to fully appreciate the pleasures and excitement of riding this vehicle, there are some basic rules and tips that you must follow. Some may be new to you while others may be common sense or obvious. Please take the time to study this operator's guide and all on-product safety labe...

Page 40: Pre-Ride Inspection

Riding the vehicle never assume that the vehicle will go everywhere safely. Sudden changes in ter- rain caused by holes, depressions, banks, softer or harder “ground” or other irreg- ularities may cause the vehicle to topple or become unstable. To avoid this, slow down and always observe the terrain...

Page 41: Clothing

Riding the vehicle – ensure the path of travel is free of persons and obstacles. – check operation of ignition switch, engine start button, engine stop switch, headlights, taillight and indicator lights. – start engine, remove parking brake and drive forward slowly a few feet then ap- ply all brakes...

Page 42: Carrying Passenger

Riding the vehicle boots long, sturdy pants gloves long sleeves rigid chin guard eye protection chest protector v00a0rn approved helmet carrying passenger this vehicle is designed specifically to carry an operator only. This vehicle is not designed nor intended to carry passenger(s). Carrying passen...

Page 43: Environment

Riding the vehicle users on the trail. Always stay to the complete right of the trail and do not zig zag to one side of the trail then the other. Be prepared to stop or pull off to the side if another trail user appears in front of you. Join a local atv club. It will provide you with a map and advic...

Page 44: Off-Highway Operation

Riding the vehicle off-highway operation the very nature of off-highway operation is dangerous. Any terrain, which has not been specially prepared to carry vehicles, presents an inherent danger where angularity, terrain substance and exact steepness are unpredictable. The terrain itself presents a c...

Page 45: Warning

Riding the vehicle downhill driving this vehicle can climb steeper slopes that it can descend safely. Therefore, it is es- sential to assure that a safe route exists to descend a slope before you climb it. Decelerating while negotiating a slippery downhill slope could “toboggan” the ve- hicle. Maint...

Page 46: Riding Techniques

Riding the vehicle while doing so in low risk driving situations you will test for grip level and keep yourself alerted to how the vehicle reacts to your control inputs. Always keep brake pedal, footrests, floor boards, brake and throttle levers free of snow and ice. Frequently wipe snow off seat, h...

Page 47

Riding the vehicle v00a0ul even though there is an adequate suspension systems on this vehicle there are “washboard” or rough terrain conditions that will make you feel uncomfortable and even cause back injury. “posting” or riding in a crouched position will often be required. Slow down and allow yo...

Page 48

Riding the vehicle v00a0vl water will affect the braking ability of your vehicle. Make sure you dry the brakes by applying them several times after the vehicle leaves the water. Mud or marsh lands may be encountered near water. Be prepared for sudden “holes” or changes in depth. Similarly so, be wat...

Page 49

Riding the vehicle when riding in sand dunes it is advisable to equip the vehicle with an antenna type safety flag. This will help make your location more visible to others over the next sand dune. Proceed carefully should you see another safety flag ahead. Since the antenna type safety flag can sna...

Page 50

Riding the vehicle uphill keep your body weight forward towards the top of the hill. Keep your feet on the footpegs and shift into low gear then accelerate and when necessary, change gear quickly as you climb. Do not over-speed since this may cause the front of the vehi- cle to lift from the ground ...

Page 51: Warning

Riding the vehicle v00a0yl side hilling this is one of the most risky types of riding since it may drastically change the bal- ance of the vehicle. It should be avoided wherever possible. If it is necessary to do so however, it is important that you always keep your body weight on the upside of the ...

Page 52: Hang Tag

Important on-product labels hang tag this vehicle comes with a hang tag and labels containing important safety informa- tion. Any person who rides this vehicle should read and understand this information be- fore riding. Vmo2009-005-003_en 704901107 vmo2006-005-009_en vehicle safety labels the follo...

Page 53

Important on-product labels vmo2008-011-021_a vmo2008-011-022_a vmo2008-011-098_b vmo2008-011-023_a vmo2008-011-061_b underneath access cover vmo2008-011-025_a ________ safety information ________ 51.

Page 54

Important on-product labels never use under the influence of drugs or alcohol. Vmo2009-003-004_en label 1 v01m02z label 2 v02m05y label 3 vmo2010-004-002_en label 4 v01m07z label 5 always maintain proper tire pressure as shown. Never set tire pressure below minimum. It could cause the tire to dislog...

Page 55: Compliance Labels

Important on-product labels vmo2010-010-100_a label 7 vmo2008-011-090 label 8 compliance labels vmo2010-004-001_en located on left side member of frame this vehicle is an all terrain vehicle and is not intended for use on public roads. Power puissance poids en etat de marche wet weight kw kg ce vehi...

Page 56: Technical Information

Important on-product labels technical information label vmo2008-011-024_b typical 1. Drive chain label drive chain drive chain must be well adjusted and lubric ated. Free pl ay is xx mm (x/x") with driver on vehicle. See owners manual for complete instructions. Xx mm (x/x") vmo2008-011-088_en while ...

Page 57: Vehicle

Vehicle information _______________ 55.

Page 58: Warning

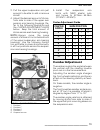

Controls/instrument/equipments 10 8 1 7 6 3 5 9 11 2 4 vmo2009-005-002_c typical while reading this operator’s guide, reminder that: warning indicates a potential hazard that, if not avoided, could result in serious injury or death. 56 ______________.

Page 59: 1) Throttle Lever

Controls/instrument/equipments 1) throttle lever the throttle lever is located on the rh side of the handlebar. When pushed, it increases the engine speed that allows the engagement of the transmission on the selected gear when clutch is engaged. When released, the engine speed should return automat...

Page 60: 3) Clutch Lever

Controls/instrument/equipments 3) clutch lever the clutch lever is located on the lh side of the handlebar. When compressed, the clutch is dis- engaged. When released, the clutch is engaged. Vmo2008-011-004_a 1. Clutch lever 2. To disengage 3. To engage warning always release the throttle when shift...

Page 61: 5) Multifunction Switch

Controls/instrument/equipments note: parking brake can be adjusted in four (4) different positions. Vmo2008-011-006_a parking brake positions notice parking brake position can vary depending on brake pads wear. Ensure when the parking brake is applied that the vehicle stays securely in place. To rel...

Page 62: 6) Ignition Switch

Controls/instrument/equipments vmo2008-011-027_a ignition switch positions 1. Off 2. On “with light” 3. On “without light” engine stop switch this switch is used to stop the engine and as an emergency control. To stop engine, fully release throttle lever then use the engine stop switch. Note: while ...

Page 63: 7) Indicator Lamps

Controls/instrument/equipments note: when selecting either on with headlights or on without headlights, the taillight will be on. On both on po- sitions, the lights will be on with the engine running or not. Always turn the ignition key to off position after en- gine has been stopped. 7) indicator l...

Page 64: 10) Tool Kit

Controls/instrument/equipments 10) tool kit the tool kit is located in the service compartment underneath seat. Vmo2008-011-029_a 1. Tool kit the tool kit contains tools for basic maintenance. 11) seat latch located underneath rear end of seat. It allows the removal of seat to give access to air fil...

Page 65: Warning

Controls/instrument/equipments warning make sure seat is securely latched before riding. _______________ 63.

Page 66: Fuel

Fuel recommended fuel use premium unleaded gasoline, avail- able from most service stations or oxy- genated fuel containing a maximum total of 10% of ethanol or methanol or both. The gasoline used must have the following recommended minimum octane rating. Minimum octane rating inside north america (...

Page 67: Warning

Fuel 5. Pour fuel slowly so that air can es- cape from the tank and prevent fuel flow back. Be careful not to spill fuel. 6. Stop filling when the fuel reaches the bottom of filler neck. Do not overfill. 7. Fully tighten fuel tank cap clock- wise. 8. Position vent tube in steering col- umn. Vmo2008-...

Page 68: Operating Instructions

Operating instructions operation during break-in period engine a break-in period of 10 operating hours is required before running the vehicle at sustained full throttle. During this period, maximum throttle should not exceed 1/2 to 3/4 opening. However, brief full acceleration and speed variations c...

Page 69: Warning

Operating instructions vmo2008-011-038_b release button immediately when en- gine has started. Vmo2008-011-038_c warning do not apply throttle while start- ing. Shifting the transmission gearshift control to shift the transmission, pull in the clutch lever, then operate transmis- sion lever as follo...

Page 70: Warning

Operating instructions vmo2008-011-001_b apply the parking brake. Vmo2008-011-006_a depress and hold clutch lever. Vmo2008-011-004_b shift to 1 st gear. Warning always use the clutch lever when shifting gears. Vmo2008-011-019_d set engine stop switch to off posi- tion. Vmo2008-011-009_c turn ignitio...

Page 71: Post-Operation Care

Operating instructions vmo2008-011-027_c post-operation care when vehicle is used in salt-water en- vironment, rinsing the vehicle with fresh water is necessary to preserve vehicle and its components. Metal- lic parts lubrication is highly recom- mended. Use xps lube (p/n 293 600 016) or an equivale...

Page 72: Tune Your Ride

Tune your ride warning suspension, steering angle and track width adjustment could af- fect vehicle handling and are inter- related. Always take time to famil- iarize yourself with the vehicle's behavior after any suspension, steering angle or track width ad- justment have been made. Steering alignm...

Page 73: Rear Track Width

Tune your ride vmr2008-029-033_b wheel side shown 1. Tie-rod 2. Tie-rod lock nut (one per tie-rod end) 6. Recheck the measurement after torquing tie-rod lock nuts. Rear track width adjustment the rear track width, measured out- side the wheels, can be adjusted from 117 cm to 127 cm (46 in to 50 in) ...

Page 74: Warning

Tune your ride warning always install all 4 spacers on each axle side. The spacers not in- stalled on inner side of wheel hub must be installed on outer side. 8. Install flat washer and nut then torque nut to 260 n•m ± 15 n•m (192 lbf•ft ± 11 lbf•ft). If neces- sary, tighten nut further until one of...

Page 75: Camber Adjustment

Tune your ride 3. Pull the upper suspension arm just enough to be able to add or remove shims. 4. Adjust the desired amount of shims, from side to side of the upper sus- pension arm bearing housings, re- fer to the following illustration and the caster adjustment guide below. Keep the total amount o...

Page 76

Tune your ride vmo2009-010-001_a 1. Suspension arm 2. Ball joint assembly 3. Lock nut 4. Retaining nut 5. Mounting sleeve note: the caster, camber and steer- ing alignment (toe) are interrelated. Start from the factory settings and customize each adjustment one at a time. Correct the other adjustmen...

Page 77: Suspension Adjustments

Tune your ride suspension adjustments guideline your vehicle handling and comfort de- pend upon suspension adjustments. Choice of suspension adjustments vary with driver's weight, personal preference, riding speed and field con- dition. Starting from the factory settings, cus- tomize each adjustment...

Page 78: Rear Suspension

Tune your ride vmo2008-021-004_a 1. Low speed compression adjuster (flat screwdriver) turning it clockwise (h) increases shock damping action (stiffer). Turning it counterclockwise (s) de- creases shock damping action (softer). High speed compression damping use a 17 mm wrench to adjust it. Vmo2008-...

Page 79: Front Suspension Factory

Tune your ride vmo2008-011-079_a typical a. Spring length low speed compression damping the adjuster is located at rear beneath the rh fender. Use a flat screwdriver to adjust it. Vmo2009-010-002_b 1. Low speed compression adjuster (flat screwdriver) turning it clockwise (h) increases shock damping ...

Page 80: Rear Suspension Factory

Tune your ride to adjust compression and rebound, proceed as follows: 1. Turn adjuster clockwise until it stops. 2. Turn adjuster counter clockwise by the specified amount, see table be- low. Front suspension factory settings spring preload 325 mm (12.8 in) compression damping (low speed) 12 clicks ...

Page 81: Vehicle Transportation

Vehicle transportation when transporting a vehicle, secure vehicle to trailer or pickup box with suitable tie-downs. Using ordinary ropes is not recommended. Warning never tip this vehicle on end for transporting. We recommend that you carry the vehicle in its nor- mal operating position (on all 4 w...

Page 82: This Page Is

Vehicle transportation this page is intentionally blank 80 ______________.

Page 83: Maintenance

Maintenance information _______________ 81.

Page 84: Maintenance Schedule

Maintenance schedule maintenance is very important for keeping your vehicle in safe operating condi- tion. Proper maintenance is the owner's responsibility. Perform periodic checks and follow the maintenance schedule. The maintenance schedule does not exempt the pre-ride inspection. Warning failure ...

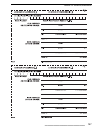

Page 85

Maintenance schedule periodic maintenance chart initial inspection 10 h or 400 km 25 h or 1250 km 50 h or 2500 km 100 h or 1 year or 5000 km 200 h or 2 years or 10000 km a: adjust c: clean i: inspect l: lubricate r: replace to be performed by part/task legend fuel system throttle body i i, l dealer ...

Page 86

Maintenance schedule periodic maintenance chart initial inspection 10 h or 400 km 25 h or 1250 km 50 h or 2500 km 100 h or 1 year or 5000 km 200 h or 2 years or 10000 km a: adjust c: clean i: inspect l: lubricate r: replace to be performed by part/task legend wheels/tires wheel nuts/studs i i custom...

Page 87

Maintenance schedule periodic maintenance chart initial inspection 10 h or 400 km 25 h or 1250 km 50 h or 2500 km 100 h or 1 year or 5000 km 200 h or 2 years or 10000 km a: adjust c: clean i: inspect l: lubricate r: replace to be performed by part/task legend brakes brake fluid i i r (10) customer b...

Page 88: 10-Hour Inspection

Maintenance schedule 5-hour engine oil and filter replacement the can-am ds 450 series is the most advanced sport atv and it has been designed using the latest technology all the way down to its synthetic multi-layer oil filter and break-in oil. To maintain your ds 450 x mx at the highest level of p...

Page 89: Maintenance Procedures

Maintenance procedures this section includes instructions for basic maintenance procedures. If you have the necessary mechanical skills and the required tools, you can per- form these procedures. If not, see your authorized can-am dealer. Other important items in the mainte- nance schedule that are ...

Page 90

Maintenance procedures recommended oil note: the same oil lubricates both engine and transmission. Use only xps synthetic blend oil (summer grade) (p/n 293 600 121). This is a special synthetic oil formu- lated for wet clutch type gearbox. Notice the xps synthetic blend oil is specially formulated a...

Page 91: Warning

Maintenance procedures vmo2008-011-105_a 1. Oil tank drain plug 2. Engine drain plug clean drain plugs area. Place a drain pan under the oil tank drain plug area. Remove drain plug and drain all oil from oil tank. Place a drain pan under the engine drain plug area. Remove drain plug and drain all oi...

Page 92: Engine Coolant

Maintenance procedures notice take care not to damage o-ring while inserting outlet fitting into oil tank. Apply oil on o-ring to ease installation. Vmo2008-011-100_a oil outlet assembly 1. Hexagonal bolt 2. Washer 3. Insert 4. Outlet fitting 5. O-ring 6. Strainer oil filter replacement unscrew oil ...

Page 93

Maintenance procedures note: while checking the coolant level, visually inspect engine area for leaks. The engine coolant tank cap is located underneath access cover near fuel tank cap. Vmo2008-011-061_a underneath access cover 1. Coolant tank cap location vmo2008-011-034 coolant tank cap to remove ...

Page 94: Warning

Maintenance procedures vmo2008-011-033_b remove filler cap. With vehicle on a level surface, liquid is at a proper level when seen through reservoir cap hole. Vmo2008-011-087_a coolant reservoir 1. Coolant here fluid level can also be validated using reservoir level marks (small ribs). Vmo2008-011-1...

Page 95: Warning

Maintenance procedures engine coolant replacement warning in order to avoid potential burns, do not remove the coolant tank cap or loosen the engine drain plug if the engine is hot. Remove access cover, refer to en- gine coolant level in this section. Turn the coolant tank cap counterclock- wise and...

Page 96: Air Filter

Maintenance procedures run engine at idle with the coolant tank cap off. Slowly add additional coolant if necessary. Do not overfill. With vehicle on a level surface, liquid is at a proper level when seen through reservoir cap hole. Vmo2008-011-087_a coolant reservoir 1. Coolant here liquid can also...

Page 97: Air Filter Housing

Maintenance procedures vmo2008-011-016_b 1. Clamps 2. Air filter housing cover loosen clamp and remove filter. Vmo2008-011-043_a 1. Clamp air filter cleaning 1. Spray the foam filter element inside and out with air filter cleaner (p/n 219 700 341). 219700341 air filter cleaner (p/n 219 700 341) 2. L...

Page 98: Muffler Spark Arrester

Maintenance procedures vmo2008-011-020_a 1. Air filter housing 2. Drain tube 3. Clamp note: if vehicle is used in dusty areas, inspect more frequently than specified in maintenance schedule . If liquid or deposits are found, squeeze and remove the clamp. Pull drain tube out then empty it. Notice do ...

Page 99: Radiator

Maintenance procedures vmo2008-011-069_a clean 1. Clean this portion for installation, reverse the removal procedure. Radiator radiator cleaning inspect radiating fins. They must be clean, free of mud, dirt, leaves and any other deposit that would prevent the radiator to cool properly. Vmo2008-011-0...

Page 100: Clutch

Maintenance procedures vmo2008-011-019_b 1. Socket screw install tansmission lever at your conve- nience then torque socket screw. Clutch clutch adjustment guidelines the clutch lever nominal free play is 10 mm to 15 mm (.39 in to .59 in). Vmo2010-012-005_a clutch lever — nominal free play a. 10 mm ...

Page 101

Maintenance procedures loosen clutch cable adjuster to provide maximum free play. Vmo2010-012-004_a typical 1. Cable adjuster remove clutch cover access plugs. Vmo2010-012-001_a lh side of engine 1. Access plugs 2. Clutch cover verify through clutch cover upper win- dow if clutch cable and clutch re...

Page 102

Maintenance procedures vmo2008-011-085_a 1. Screwdriver 2. Clutch adjustment wrench by using the screwdriver, gently turn clutch adjuster screw clockwise to lo- cate the point of contact with release bearing, then turn screw out (counter- clockwise) 3/8 to 1/2 turn from contact point. Hold adjustmen...

Page 103: Throttle Cable

Maintenance procedures throttle cable throttle cable lubrication the throttle cable must be lubricated with cable lubricant (p/n 293 600 041) or an equivalent. Warning always use a silicone-based lu- bricant. Using another lubricant (like water-based lubricant) could cause the throttle lever/cable t...

Page 104: Warning

Maintenance procedures v00i03y typical insert the needle of the spray can in the cable luber hole. Warning always wear eye protection and gloves when you lubricate a cable. Note: place a rag around the cable lu- ber to prevent the lubricant to splash. Put the lubricant until it passes through the ca...

Page 105: Spark Plugs

Maintenance procedures vmo2008-011-073_a 1. Lock nut 2. Adjuster note: measure throttle free play at the tip of throttle lever. Tighten lock nut and reinstall protector. Vmo2008-011-001_c 1. Throttle lever a. 2 mm to 4 mm (5/64 ft to 5/32 ft) spark plugs spark plugs removal unplug spark plug cables....

Page 106: Battery

Maintenance procedures apply heat-sink paste p12 (p/n 420 897 186) on spark plugs threads to pre- vent a possible seizure and to increase heat transfer from spark plugs to cylin- der head. Screw spark plugs into cylinder head by hand and tighten using a torque wrench and a proper socket. Torque spar...

Page 107

Maintenance procedures a15e0ky 1 2 typical 1. Fuse 2. Check if melted fuse location the fuse holders are located under- neath the seat and on the lh side of the engine. Fuses under seat vmo2008-011-029_b fuses location 1. Fuse holder vmo2008-011-081_a fuses description 1. Main (20 a) 2. Spare (20 a)...

Page 108: Lights

Maintenance procedures lights beam aiming adjustment to adjust beam, proceed as follows. 1. Loosen the bolts shown on the fol- lowing illustrations but do not re- move them. Mmr2009-005-001_a vmo2008-018-040_a 2. Adjust headlight housing angle by hand. 3. Adjust both headlights evenly. 4. Tighten sc...

Page 109: Indicator Lamps

Maintenance procedures vmo2008-018-036_a typical 1. Retaining clip lift and hold the retaining clip then re- move the bulb. Vmo2008-018-037 typical replace defective bulb. Properly reinstall removed parts in the reverse order of their removal. Taillight bulb replacement turn the ignition switch to o...

Page 110: Drive Chain

Maintenance procedures v02a0fy 1 1 1. Tabs for installation, reverse the removal procedure. Drive chain warning always turn ignition switch to the off position before you check, ad- just or lubricate the drive chain. Drive chain inspection this vehicle is equipped with o-ring sealed permanently grea...

Page 111: Drive Chain Slider

Maintenance procedures vmo2008-011-109_a 1. Drive chain 2. Screw driver pin (tool kit) 3. Sprocket hub 4. Eccentric axle housing 3. With the screw driver pin properly in place, push or pull the vehicle for- ward to increase or backwards to decrease chain free play. Refer to the following table for p...

Page 112: Warning

Maintenance procedures for your convenience, a pressure gauge is supplied in tool box. Tire pressure front rear maximum 69 kpa (10 psi) 62 kpa (9 psi) up to 100 kg (220 lb) minimum 55 kpa (8 psi) 48 kpa (7 psi) although the tires are specifically de- signed for off-road use, a flat may still occur. ...

Page 113: Front Wheel Bearings

Maintenance procedures gently tighten nuts in a criss-cross sequence then apply a final torque of 52 n•m (38 lbf•ft). Notice always use the recom- mended wheel nuts and washers (if applicable). Using a different nut and washer could cause damages to the rim. Front wheel bearings front wheel bearings...

Page 114: Brakes

Maintenance procedures vmr2008-031-027_a bell crank lever 1. Grease fittings vmo2009-005-008_a pivot arm 1. Grease fitting brakes brake fluid level note: a low level may indicate leaks or worn brake pads. See an authorized can-am dealer. Front brake fluid reservoir turn steering in the straight-ahea...

Page 115: Warning

Maintenance procedures vmo2008-011-013_a located near the right rear fender 1. Rear brake fluid reservoir it should be above min. Mark. Vmo2008-011-018_a rh side of vehicle 1. Maximum level (max.) 2. Minimum level (min.) clean and remove the filler cap then add fluid as required. Do not overfill. Wa...

Page 116: Warning

Maintenance procedures – brake pads for wear, damage or looseness – front brake disc protector for dam- age, replace if necessary. Service limits brake pads thickness 1 mm (.04 in)) discs thickness 3.5 mm (.138 in) maximum discs warpage 0.2 mm (.008 in) see your authorized can-am dealer if a problem...

Page 117: Technical

Technical information ______________ 115.

Page 118: Vehicle Identification

Vehicle identification the main components of your vehicle (engine and frame) are identified by different serial numbers. It may some- times become necessary to locate these numbers for warranty purposes or to trace your vehicle in the event of loss. These numbers are required by the authorized can-...

Page 119: Usa And Canada Only

Noise emission control system regulation usa and canada only tampering with noise control system is prohibited! U.S. Federal law and canadian provincial laws may prohibit the following acts or the causing there of: 1. The removal or rendering inoperative by any person other than for purposes of main...

Page 120: Specifications

Specifications model ds 450 x mx engine type brp rotax, 4-stroke. Double overhead camshaft engine, chain drive number of cylinder 1 number of valves 4 displacement 449.3 cm³ (27.4 in³) bore 97 mm (3.82 in) stroke 60.8 mm (2.4 in) compression ratio 11.8:1 type dry sump lubrication (lubrication of eng...

Page 121

Specifications model ds 450 x mx electrical make denso magneto generator type 250 w @ 6000 rpm ignition type idi (inductive digital ignition) ignition timing not adjustable engine limiter 10 200 rpm make ngk (apply heat-sink paste p12 (p/n 420 897 186) on spark plug threads) type dcpr9e spark plug g...

Page 122

Specifications model ds 450 x mx suspension type independent suspension - double a-arm shock absorbers hpg (fully adjustable) front travel 271.8 mm (10.7 in) type rigid swing arm shock absorbers hpg (fully adjustable) rear travel 282 mm (11.1 in) tires front 68.9 kpa (10 psi) maximum 55.2 kpa (8 psi...

Page 123

Specifications model ds 450 x mx loading capacity total vehicle load allowed 100 kg (220 lb)includes operator, all other loads and added accessories gvwr (gross vehicle weight rating) 283 kg (625 lb) dimensions overall length 1.839 m (72.4 in) overall width 1.168 m (46 in) overall height 1.064 m (41...

Page 124: Warning

Specifications model ds 450 x mx capacities fuel tank 11.5 l (3 u.S. Gal.) including an approximate reserve of 2.5 l (.7 u.S. Gal.) engine oil 1.8 l (1.9 qt (u.S. Liq.)) coolant 1.8 l (1.9 qt (u.S. Liq.)) while reading this operator’s guide, reminder that: warning indicates a potential hazard that, ...

Page 125: Troubleshooting

Troubleshooting ______________ 123.

Page 126: Troubleshooting Guidelines

Troubleshooting guidelines engine does not turn 1. Ignition switch is in the off position. – place switch to the on position. 2. Engine stop switch is in the off position. – place switch to the on position. 3. Transmission is not set on neutral. – set transmission either in neutral or depress the cl...

Page 127

Troubleshooting guidelines engine turns over but fails to start (cont’d) 4. Spark plug/ignition (no spark). – check ignition fuse condition. – remove spark plugs then reconnect to spark plug caps. – check that ignition switch and engine stop switch are at the on position. – start engine with spark p...

Page 128

Troubleshooting guidelines engine backfire (cont’d) 2. Exhaust system leakage. – contact an authorized can-am dealer. 3. Engine is running too hot. – refer to engine lacks acceleration or power. Engine misfire 1. Fouled/damaged/worn spark plugs. – clean/verify spark plugs and heat range. Replace as ...

Page 129

Troubleshooting guidelines check engine indicator lamp stays on 1. Engine is overheating. – refer to engine overheats. 2. Low or high battery voltage. – check battery voltage and charging system. – contact an authorized can-am dealer. Check engine indicator lamp flashes 1. Engine is under a protecti...

Page 130: This Page Is

Troubleshooting guidelines this page is intentionally blank 128 ______________.

Page 131: Warranty

Warranty ______________ 129.

Page 132: Can-Am

Brp limited warranty usa and canada: 2010 can-am tm atv 1) scope of the limited warranty bombardier recreational products inc. (“brp”)* warrants its 2010 can-am atv sold by authorized brp dealers (as hereinafter defined) in the fifty united states and canada from defects in material or workmanship f...

Page 133: Coverage

– damage resulting from removal of parts, improper repairs, service, mainte- nance, modifications or use of parts not manufactured or approved by brp or resulting from repairs done by a person that is not an authorized servicing brp dealer; – damage caused by abuse, abnormal use, neglect or operatio...

Page 134: 7) What Brp Will Do

– the 2010 can-am atv must be purchased in the country in which the purchaser resides; – routine maintenance outlined in the operator’s guide must be timely per- formed in order to maintain warranty coverage. Brp reserves the right to make warranty coverage contingent upon proof of proper maintenanc...

Page 135: 8) Supplier Warranties

8) supplier warranties a gps receiver may be supplied by brp as standard equipment on certain 2010 can-am atv's. The gps receiver is covered by the limited warranty issued by the gps receiver’s manufacturer and is not covered by this limited warranty. Please contact the following distributors: in th...

Page 136: 9) Transfer

9) transfer if the ownership of a product is transferred during the warranty coverage period, this warranty shall also be transferred and be valid for the remaining coverage period provided that brp is notified of such transfer of ownership in the following way: 1. The former owner contacts brp (at ...

Page 137: Can-Am

Brp international limited warranty: 2010 can-am tm atv 1) scope of the limited warranty bombardier recreational products inc. (“brp”)* warrants its 2010 can-am atv sold by authorized can-am distributors/dealers (as hereinafter defined) outside of the fifty united states, canada and states members of...

Page 138

– damage caused by failure to provide proper maintenance and/or storage, as de- scribed in the operator's guide; – damage resulting from removal of parts, improper repairs, service, mainte- nance, modifications or use of parts not manufactured or approved by brp or resulting from repairs done by a p...

Page 139: 7) What Brp Will Do

Brp will not honour this limited warranty to any private use owner or commercial use owner if the preceding conditions have not been met. Such limitations are necessary in order to allow brp to preserve both the safety of its products, and also that of its consumers and the general public. 6) what t...

Page 140

2. If further assistance is required, the distributor's service department should be contacted in order to resolve the matter. 3. If the matter still remains unresolved then contact brp by writing to us at the address listed below. For countries within europe, middle east, africa, russia & cis, plea...

Page 141: Atv

Brp limited warranty for the european economic area: 2010 can-am tm atv 1) scope of the limited warranty bombardier recreational product inc. (“brp”)* warrants its new and unused model-year 2010 can-am atvs sold by authorized brp distributors/dealers (“distributors/dealers”) in the states members of...

Page 142

– damage caused by failure to provide proper maintenance and/or storage, as de- scribed in the operator's guide; – damage resulting from removal of parts, improper repairs, service, mainte- nance, modifications or use of parts not manufactured or approved by brp or resulting from repairs done by a p...

Page 143: 7) What Brp Will Do

– the 2010 can-am atv must be purchased in the eea; – routine maintenance outlined in the operator’s guide must be timely per- formed in order to maintain warranty coverage. Brp reserves the right to make warranty coverage contingent upon proof of proper maintenance. Brp will not honour this limited...

Page 144: 9) Consumer Assistance

9) consumer assistance in the event of a controversy or a dispute in connection with this limited warranty, brp suggests that you try to resolve the issue at the dealership level. We rec- ommend discussing the issue with the authorized distributor/dealer's service manager or owner. If further assist...

Page 145: Customer

Customer information ______________ 143.

Page 146: Privacy Information

Privacy information brp wishes to inform you that your coordinates will be used for safety and war- ranty related purposes. Furthermore, brp and its affiliates may use its customer list to distribute marketing and promotional information about brp and related products. To exercise your right to cons...

Page 147

Change of address/ownership if your address has changed or if you are the new owner of the atv, be sure to no- tify brp by either: – mailing one of the following cards below. – north america only: calling at 715 848-4957 (usa) or 819 566-3366 (canada). – notifying an authorized can-am dealer. In cas...

Page 148: This Page Is

Change of address/ownership this page is intentionally blank 146 ______________.

Page 149

Change of address/ownership ______________ 147.

Page 150

Change of address/ownership 148 ______________.

Page 151: Warning

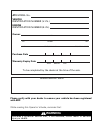

Atv model no. Vehicle identification number (v.I.N.) engine identification number (e.I.N.) owner: purchase date year month day warranty expiry date year month day to be completed by the dealer at the time of the sale. Dealer imprint area name no. Street apt city state/province zip/postal code v00a2i...

Page 152

2 1 9 0 0 0 6 2 7.