- DL manuals

- CANAWELD

- Welding System

- MIG/MMA 201

- User Manual

CANAWELD MIG/MMA 201 User Manual - Table of Contents

2

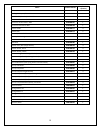

TABLE OF CONTENTS

EQUIPMENT PACKAGE

3

SECTION 1- SAFETY CAUTIONS & SYMBOLS

4-7

SECTION 2- INSTALLATION & SPECIFICATIONS

8-9

SECTION 3- OPERATION OF EQUIPMENT

10-13

SECTION 4- MAINTENANCE & BASIC TROUBLESHOOTING

14-15

SECTION 5- ELECTRICAL SPECIFICATIONS

16-17

SECTION 6- PARTS LIST

18-19

SECTION 7- WARRANTY & SERVICE

20-21

NOTES

22

Summary of MIG/MMA 201

Page 1

User manual model: mig/mma 201.

Page 2

1 thank you from canaweld thank you for choosing a canaweld machine, with 30+ years of welding equipment manufacturing experience overseas, you can feel confident that you have made the right choice. Canaweld inc. Was started in canada to manufacture the highest quality welding and cutting equipment...

Page 3: Table of Contents

2 table of contents equipment package 3 section 1- safety cautions & symbols 4-7 section 2- installation & specifications 8-9 section 3- operation of equipment 10-13 section 4- maintenance & basic troubleshooting 14-15 section 5- electrical specifications 16-17 section 6- parts list 18-19 section 7-...

Page 4

3 mig / mma 201- welder package 1 2 3 4 5 6 name product number quantity 1. Machine plc7580146 1 2. Work/ground clamp set alp1980126 1 3. Electrode holder set alp2280095 1 4. Mig torch tgd0180150 1 5. Gas flow regulator tlj1080187 1 6. Gas hose tlj1080188 1 7. Machine bag tgj2780145 1.

Page 5

4 section 1- safety cautions & symbols caution: read user manual indicates any section that the user must read the manual to fully understand the machine’s characteristics to avoid any hazardous situation. Electric shock touching live electrical parts can cause fatal shocks or severe burns. The elec...

Page 6

5 welding fumes welding produces fumes and gases. Breathing these fumes and gases can be hazardous to your health. Keep your head out of the fumes stream while welding. Do not breathe the fumes. If inside, ventilate the area and/or use local forced ventilation at the welding point to remove welding ...

Page 7

6 gases dangerous gases can be produced during welding, breathing these gases in can be hazardous to your health. Shut off shielding gas supply when not in use. Always ventilate confined spaces or use approved air-supplied respirator. Do not weld in locations near degreasing, cleaning, or spraying o...

Page 8

7 esd- electric static discharge an electric static charge can be created during welding and discharged immediately after into any items touched by the welder after welding. Put on grounded wrist strap before handling boards or parts. Use proper static-proof bags and boxes to store, move, or ship pc...

Page 9

8 section 2- installation and overview installation electrical the serial number and rating information is located on the bottom of the machine. Use the rating labels to determine input power requirements and rated output. Check whether the voltage value variations are within the acceptable working ...

Page 10

9 overview product & design our unique electric structure and air channeling design in this series of welding machines are designed to increase the heat dissipation of the power device improving the duty cycle of the machine. The unique heat dissipation design leads to less damage done to the power ...

Page 11

10 section 3- operation of equipment operation after being installed according to the prescribed method, switch the power to on (rear panel) and the power led will light and the fan will turn on. Using the rocker switch on the front panel choose the welding process desired (mig or stick). Pay attent...

Page 12

11 mig operation (flux core wire welding) (a) insert the welding torch into the output socket on the front panel of the machine, and tighten it. (b) insert the cable plug from the work / ground clamp into the (+) output terminal on the front panel of the welding machine, and tighten it clockwise. (c...

Page 13

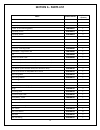

12 mig welding parameter table (for reference only) this table is suitable for mild steel mig/mag welding. For other materials, consult related materials and welding process for reference. Wire size (mm) spray arc intermediate range short arc a v a v a v 0.8 140 - 180 23 – 28 110 – 150 18 – 22 50 – ...

Page 14

13 stick welding parameter table (for reference only) this table is suitable for mild steel stick welding. For other materials, consult related materials and welding process for reference. Electrode diameter (mm) recommended welding current (a) recommended welding voltage(v) 2.0 60 - 100 22.4 - 24.0...

Page 15

14 section 4- maintenance & basic troubleshooting maintenance please disconnect power to machine before performing maintenance. Check periodically whether cable connection is in good condition (esp. Plugs). Tighten any loose connections. If there is oxidization, remove it with sandpaper and then rec...

Page 16

15 basic troubleshooting problem causes remedy there is output current when pulling the torch trigger, gas feeding but there is no wire feeding out. 1. The wire feeder is clogged. 2. The wire feeder has failed. 3. The control pcb or wire feeding power pcb inside the machine has failed. 1. Unclog it....

Page 17

16 section 5- electrical specifications machine specifications: mig/fcaw process input voltage- single phase 230v (+10 / -15%) maximum input amperage 34a output current range 40a - 200a open circuit voltage 52v output voltage range 16v - 24v duty cycle @ 40˚c 200a @ 35% 190a @ 60% 170a @ 100% machin...

Page 18

17 electrical schematic diagram.

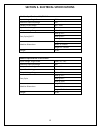

Page 19: Section 6 - Parts List

18 section 6 - parts list name product number mma/mig201 - quantity enclosure -bottom plate cga2880053 1 box for protection pcb cga2880055 1 burn back potentiometer cgb1880056 1 ca-mf 35-70 panel plug (male) cgb0680070 1 cap (red), 15mm cga6280072 1 cap (red), 20mm cga6280073 3 central connector cgb...

Page 20

19 name product number mma/mig201 - quantity nut m9.5mm cga2280158 1 package 200a, mig/mma 201 cgc9180162 1 panel socket (female) ca-ff 35-70 cgb0680064 1 enclosure front panel- mig cga2880164 1 enclosure vertical panel –mig cga2880167 1 enclosure-rear panel- mig cga2880168 1 plastic holder cga63801...

Page 21

20 section 7- warranty & service statement of limited warranty: canaweld inc. Warrants to the end user (purchaser) of all new welding and cutting equipment, and accessories (the “warranted goods”) that such warranted goods will be free of defects in workmanship and material. This warranty is void if...

Page 22

21 damage resulting from normal wear and tear; and repairs or replacement of any parts reasonably considered to be consumables, including but not limited to the following tig torch components: (i) collet and collet body, (ii) gas nozzles, (iii) gas cups, (iv) insulators, (v) back cups, and (vi) gas ...

Page 23: Notes

22 notes.

Page 24

23.