- DL manuals

- Conair

- Refrigerator

- EARTHSMART ECM Series

- User Manual

Conair EARTHSMART ECM Series User Manual

Summary of EARTHSMART ECM Series

Page 1

Earthsmart tm ecm series, 0.50 to 0.75 ton models corporate office: 724-584-5500 l instant access 24/7 (parts and service): 800.458.1960 l parts and service: 814.437.6861 u s e r g u i d e u g h 0 3 1 - 0 2 0 9 www.Conairgroup.Com.

Page 2

Please record your equipment’s model and serial number(s) and the date you received it in the spaces provided. It’s a good idea to record the model and serial number(s) of your equipment and the date you received it in the user guide. Our service department uses this infor- mation, along with the ma...

Page 3: 1-1

Ta b l e o f c o n t e n t s 1-1 i n t r o d u c t i o n purpose of the user guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 how the guide is organized . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2 your responsibilities as a user . . . . . . . . . . . . . ...

Page 4: 5-1

Stopping the chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4 changing temperature units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5 chiller operation sequence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6 resetting the hig...

Page 5

B a p p e n d i x safety adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1 c a p p e n d i x water quality control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1 d a p p e n d i x chiller capacity and derate chart . . . . . . . . ....

Page 6

I v l ta b l e o f c o n t e n t s.

Page 7

I n t r o d u c t i o n p u r p o s e o f t h e u s e r g u i d e . . . . . . . . . . . . . . 1 - 2 h o w t h e g u i d e i s o r g a n i z e d . . . . . . . . . . . . . 1 - 2 yo u r r e s p o n s i b i l i t i e s a s a u s e r . . . . . . . . . . . 1 - 3 at t e n t i o n : r e a d t h i s s o n o ...

Page 8

✐ p u r p o s e o f t h e u s e r g u i d e this user guide describes the earthsmart ecm series chiller and explains step-by-step how to install, operate, maintain and repair this equipment. Before installing this product, please take a few moments to read the user guide and review the diagrams and ...

Page 9

I n t r o d u c t i o n l 1 - 3 yo u r r e s p o n s i b i l i t y a s a u s e r you must be familiar with all safety procedures concerning installation, opera- tion and maintenance of this equipment. Responsible safety procedures include: • thorough review of this user guide, paying particular atte...

Page 10: At T E N T I O N :

At t e n t i o n : r e a d t h i s s o n o o n e g e t s h u r t we design equipment with the user’s safety in mind. You can avoid the potential hazards identified on this machine by following the procedures outlined below and elsewhere in the user guide. W a r n i n g : i m p r o p e r i n s t a l ...

Page 11: At T E N T I O N :

1 introduction i n t r o d u c t i o n l 1 - 5 c a u t i o n : h o t s u r f a c e s always protect yourself from hot surfaces when working on the chiller, especially when working on or around the compressor and condenser. These devices can be over 160°f {71°c}. Allow these devices to cool before pe...

Page 12

1 - 6 l i n t r o d u c t i o n.

Page 13

D e s c r i p t i o n l 2 - 1 d e s c r i p t i o n w h a t i s t h e e a r t h s m a r t e c m s e r i e s c h i l l e r ? . . 2 - 2 ty p i c a l a p p l i c a t i o n s . . . . . . . . . . . . . . . . . . 2 - 2 l i m i t a t i o n s . . . . . . . . . . . . . . . . . . . . . . . . 2 - 3 h o w i t w...

Page 14: C H I L L E R ?

W h a t i s t h e e a r t h s m a r t e c m s e r i e s c h i l l e r ? The conair earthsmart ecm series chillers provide self-contained sources of chilled water and are available with compressor ranges of 0.5 hp or 0.75 hp (nominal capacities of 0.41 tons or 0.70 tons of refrigeration). Important: ...

Page 15

D e s c r i p t i o n l 2 - 3 2 description l i m i t a t i o n s conair earthsmart ecm series chillers are chosen based on the cooling load, ambient temperature and cooling temperature. ● cooling load - choose a chiller that has 0 - 10% more cooling capacity than the process load to be chilled. ● a...

Page 16

2 - 4 l d e s c r i p t i o n h o w i t w o r k s : p r o c e s s c i r c u l a t i o n hot fluid from the process enters the chiller through the “from process” inlet into the chiller’s reservoir. Pump moves fluid from the reservoir through evaporator where it is chilled. Fluid is chilled in the eva...

Page 17

2 description d e s c r i p t i o n l 2 - 5 h o w i t w o r k s : r e f r i g e r a n t c i r c u l a t i o n the evaporator extracts heat from the process fluid, causing the refrigerant to vaporize (evaporate) into a gas. Vaporized refrigerant travels to the compressor, where the low-pressure vapor...

Page 18

H o w i t w o r k s : c o m p o n e n t l i s t i n g water system • motor/pump assembly - the motor/pump assembly circulates chilled coolant through the process loop. The pump assembly is built with brass to maintain water quality. Refrigeration system • compressor - hermetic compressor takes low-p...

Page 19

• evaporator - the evaporator is a brazed plate heat exchanger where the liquid refrigerant is allowed to evaporate (boil off) to absorb the heat (btu) from the process fluid. As the heat is absorbed, the process fluid is chilled. • high/low pressure switches: the high/low pressure switches protect ...

Page 20: E C M

2 - 8 l d e s c r i p t i o n s p e c i f i c a t i o n s : e a r t h s m a r t t m e c m s e r i e s c h i l l e r s a b c tphs039-1208 model ecm-0.5 ecm-0.75 performance characteristics capacity* tons 0.41 0.70 compressor hp {kw}✝ 0.5 {0.37} 0.75 {0.56} pump hp {kw} 0.25 {0.19} 0.5 {0.37} chilled ...

Page 21: E C M

D e s c r i p t i o n l 2 - 9 2 description p u m p c u r v e : e a r t h s m a r t t m e c m s e r i e s c h i l l e r s 25 50 75 100 125 150 175 200 225 250 25 20 30 40 50 60 70 80 90 100 110 120 130 140 10 0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.50 0.55 0.60 0.65 outlet pressure* (psi...

Page 22

2 - 1 0 l d e s c r i p t i o n.

Page 23

I n s t a l l a t i o n l 3 - 1 i n s t a l l a t i o n u n p a c k i n g t h e b o x e s . . . . . . . . . . . . . . . . . 3 - 2 w a r n i n g s a n d c a u t i o n s . . . . . . . . . . . . . . . . 3 - 3 p r e p a r i n g f o r i n s t a l l a t i o n . . . . . . . . . . . . . . 3 - 4 m a k i n g ...

Page 24

3 - 2 l i n s t a l l a t i o n u n p a c k i n g t h e b o x e s the earthsmart ecm series chiller comes fully assembled in a single crate. Units are shipped with the casters attached. 1 carefully uncrate the chiller and its components. 2 remove all packing material, protective paper, tape and plas...

Page 25

I n s t a l l a t i o n l 3 - 3 3 installa tion w a r n i n g s a n d c a u t i o n s w a r n i n g : i m p r o p e r i n s t a l l a t i o n , o p e r a t i o n , o r s e r v i c i n g m a y r e s u l t i n e q u i p m e n t d a m a g e o r p e r s o n a l i n j u r y. This equipment should only be...

Page 26

P r e p a r i n g f o r i n s t a l l a t i o n plan the location for the chiller and prepare the area properly. Position the chiller as close to the process machine as possible. Place the chiller in position near the process machine so that coolant lines can be connected from the process machine to...

Page 27

I n s t a l l a t i o n l 3 - 5 3 installa tion m a k i n g p r o c e s s p l u m b i n g c o n n e c t i o n s all process piping materials (such as hoses, rigid piping, valves or filters) used with process water piping circuitry must be rated for 100°f {37.8°c} minimum temperature and 150 psi {10....

Page 28

3 - 6 l i n s t a l l a t i o n f i l l i n g t h e c h i l l e r the chiller is shipped without coolant. The chiller is manually filled during instal- lation using water as its coolant. For atypical process temperatures below 45°f {7.2°c}, use the table below to determine the percentage (by volume)...

Page 29

I n s t a l l a t i o n l 3 - 7 3 installa tion d r a i n c o n n e c t i o n to drain the chiller for storage or transport: 1 rotate the chiller’s drain valve counterclockwise. If using chemicals or additives with your process coolant, observe local disposal laws and regulations. 2 close the chille...

Page 30

3 - 8 l i n s t a l l a t i o n c h e c k i n g t h e r e f r i g e r a n t c h a r g e warning: refrigerant hazard only certified refrigerant technicians should examine and correct problems involving the refrigerant circuit. All chillers are fully charged with r-134a refrigerant from conair. Your c...

Page 31

C o n n e c t i n g t h e m a i n p o w e r the conair earthsmart ecm chiller uses standard 115 volt, 60 hz or 220 volt, 60hz single-phase power, depending on model. To connect the the main power to the chiller: 1 connect the chiller’s plug into a properly-sized and rated electrical outlet. Importan...

Page 32

3 - 1 0 l i n s t a l l a t i o n.

Page 33: O P E R A T I O N

S e c t i o n 4 4 opera tion o p e r a t i o n e a r t h s m a r t e c m s e r i e s c h i l l e r : c o n t r o l d e s c r i p t i o n s . . . . . . . . . . . . . . . 4 - 2 s t a r t i n g t h e c h i l l e r . . . . . . . . . . . . . . . . . . 4 - 3 s t o p p i n g t h e c h i l l e r . . . . . ....

Page 34

1 2 % sd e a r t h s m a r t e c m c h i l l e r : c o n t r o l d e s c r i p t i o n s h o t - g a s b y p a s s s t a t u s indicates the status of the hot-gas bypass valve. A c t u a l c h i l l e r te m p e r a t u r e shows the (process) actual temperature value. O n / o f f to g g l e s w i t...

Page 35

4 opera tion o p e r a t i o n l 4 - 3 s t a r t i n g t h e c h i l l e r to start the chiller: 1 toggle the power switch to the on or “ i” position. The control display will illuminate. Facing the chiller’s control, the “to process” actual temperature will be on the left, the setpoint temperature ...

Page 36

4 - 4 l o p e r a t i o n s t o p p i n g t h e c h i l l e r to stop the chiller: 1 toggle the power switch to the off or “o” position. Off position 12 % sd important: do not rapidly cycle the chiller’s power on and off (short cycle). Once the power has been turned off, wait at least three (3) minu...

Page 37

4 opera tion o p e r a t i o n l 4 - 5 c h a n g i n g te m p e r a t u r e u n i t to stop the chiller: 1 press the green “return” button once to access the temperature units selection screen. Press the ▲ or ▼ buttons to toggle between fahrenheit and celsius temperature units. 2 press the “infinity...

Page 38

4 - 6 l o p e r a t i o n c h i l l e r o p e r a t i o n s e q u e n c e the earthsmart ecm series chiller has a unique user interface that controls the process temperature and prevents refrigeration migration during compressor off times. When the main power is connected: 1 depending on the state o...

Page 39

O p e r a t i o n l 4 - 7 4 opera tion c h i l l e r o p e r a t i o n s e q u e n c e ( c o n t i n u e d ) 5 the condenser fan can energize anytime the toggle switch is in the “on” or “ i” position. The fan is controlled by the fan cycling (high refrigeration) pressure switch. This switch maintain...

Page 40

4 - 8 l o p e r a t i o n r e s e t t i n g t h e h i g h p r e s s u r e s w i t c h o f t h e c o m p r e s s o r the high refrigeration safety pressure switch shuts off the compressor immediately when the high refrigeration pressure reaches 230 psi {15.9 bar} without going through pump down durin...

Page 41

M a i n t e n a n c e p r e v e n t a t i v e m a i n t e n a n c e s c h e d u l e . . . . . . . 5 - 2 c h e c k i n g e l e c t r i c a l c o n n e c t i o n s . . . . . . . . . . 5 - 4 c l e a n i n g t h e b r a z e d p l a t e a d a p t e r . . . . . . . . 5 - 5 c l e a n i n g t h e a i r- c o...

Page 42

5 - 2 l m a i n t e n a n c e p r e v e n t a t i v e m a i n t e n a n c e s c h e d u l e daily, or as often as needed ❒ checking process fluid level in the pump tank check the process fluid level in the water level gauge on the back of the chiller. If low, see maintenance section entitled, checki...

Page 43

M a i n t e n a n c e l 5 - 3 p r e v e n t a t i v e m a i n t e n a n c e s c h e d u l e ( c o n t i n u e d ) monthly ❒ inspecting cooling water treatment system if your chiller uses a cooling water treatment system, maintain proper chemi- cal levels and follow the recommendations of your water ...

Page 44

5 - 4 l m a i n t e n a n c e c h e c k i n g e l e c t r i c a l c o n n e c t i o n s warning: electrical hazard before performing any work on this item, disconnect and lock out electrical power sources to prevent injury from unexpected energization or startup. Be sure that power to the chiller is...

Page 45

C l e a n i n g t h e b r a z e d p l a t e e v a p o r a t o r minerals and other contaminants produce deposits, scales, slime or algae on the heat transfer surfaces exposed to water. Fouled surfaces could result in decreased cooling capacity. Implement a water treatment program to slow the fouling...

Page 46

5 - 6 l m a i n t e n a n c e c l e a n i n g t h e b r a z e d p l a t e e v a p o r a t o r ( c o n t i n u e d ) 5 remove rtd from bottom of evaporator. 6 connect 3/8-inch tubing to the 3/8-inch connections of the heat exchanger. See below to install customer-supplied chemical pump and solution f...

Page 47

5 maintenance c l e a n i n g t h e a i r- c o o l e d c o n d e n s e r warning: electrical hazard before performing any work on this item, disconnect and lock out electrical power sources to prevent injury from unexpected energization or startup. Be sure that power to the chiller is off when doing...

Page 48

C l e a n i n g t h e a i r- c o o l e d c o n d e n s e r ( c o n t i n u e d ) 7 check the air filter. If the filter is blinded or torn, replace the filter. 8 replace the chiller’s side panels and then the top lid by replacing the four (4) retaining bolts. 9 reapply main power. Caution: wear eye p...

Page 49

M a i n t e n a n c e l 5 - 9 c h e c k i n g r e s e r v o i r l e v e l warning: electrical hazard before performing any work on the chiller, disconnect and lock out electrical power sources to prevent injury from unexpected energization or startup. Be sure that power to the chiller is off when do...

Page 50

C l e a n i n g t h e p u m p s t r a i n e r earthsmart chillers use a rotary pump to flow process coolant through their internal piping and to the process. A strainer on the pump may periodically need cleaning, depending upon the quality of the process coolant. Warning: electrical hazard before pe...

Page 51

C l e a n i n g t h e p u m p s t r a i n e r ( c o n t i n u e d ) 6 remove the strainer from its housing. 7 inspect the strainer for holes or blinding, clean or replace as necessary. 8 re-install the strainer and strainer cap. Properly seal all piping with approved teflon tape or pipe dope. 9 chec...

Page 52: Q U A L I T Y

5 - 1 2 l m a i n t e n a n c e c h e c k i n g t h e r e f r i g e r a n t c h a r g e a n d q u a l i t y warning: refrigerant hazard only certified refrigerant technicians should examine and correct problems involving the refrigerant circuit. All chillers are fully charged with r-134a refrigerant...

Page 53

Tr o u b l e s h o o t i n g b e f o r e b e g i n n i n g . . . . . . . . . . . . . . . . . . . . 6 - 2 a f e w w o r d s o f c a u t i o n . . . . . . . . . . . . . . 6 - 3 d i a g n o s t i c s h o w t o i d e n t i f y t h e c a u s e o f a p r o b l e m . . . . 6 - 3 a l a r m s . . . . . . . ....

Page 54

B e f o r e b e g i n n i n g you can avoid most problems by following the recommended installation and maintenance procedures outlined in this user guide. If you do have a problem, this section will help you determine what caused it and how to fix it. ❏ diagnose causes from the control panel. 1 not...

Page 55: P R O B L E M

6 troubleshooting a f e w w o r d s o f c a u t i o n improper corrective actions can lead to hazardous conditions and should never be attempted to sustain production. Warning: only a qualified electrical technician should examine and correct problems that require opening the chiller’s electrical en...

Page 56: A L A R M S

6 - 4 l tr o u b l e s h o o t i n g a l a r m s if the red alarm led is illuminated, an alarm is activated. The chiller has automat- ically pumped down because it has detected a serious problem that could damage your process or chiller. Note that the alarm must be acknowledged before the con- trol ...

Page 57: Problem

Tr o u b l e s h o o t i n g l 6 - 5 6 troubleshooting tr o u b l e s h o o t i n g problem the chiller will not start. (control not illuminated) pump will not start. Possible cause tripped circuit breaker. Incorrect incoming voltage. The power toggle switch is not turned to the “on” or “i” position...

Page 58: Problem

Tr o u b l e s h o o t i n g ( c o n t i n u e d ) problem compressor will not start. Possible cause high pressure switch has been tripped. Circuit breaker has been tripped. Loose wire connection or defective start capacitor. The actual “to process” temperature is below the setpoint. Damaged or defe...

Page 59: Problem

Tr o u b l e s h o o t i n g ( c o n t i n u e d ) problem chiller shuts down due to a high pressure switch alarm. Chiller shuts down due to a low pressure switch. Possible cause low air flow across the condenser. Fan not operating. High ambient temperature. Insufficient clear space around unit. Clo...

Page 60

C h e c k i n g o r r e p l a c i n g t h e te m p e r a t u r e s e n s o r the earthsmart ecm series chiller uses a rtd sensor to monitor the temperature of the process coolant. To check or replace an rtd sensor: 1 disconnect and/or lockout the main power supply. 2 locate the rtd sensor. 3 check t...

Page 61: B R E A K E R S

Tr o u b l e s h o o t i n g l 6 - 9 c h e c k i n g o r r e s e t t i n g t h e c i r c u i t b r e a k e r s the earthsmart ecm series chiller uses electrical circuit breaker to protect the chiller from overloads or improper operating conditions. To check or reset the chiller’s circuit breakers: 1...

Page 62

A - 1 l a p p e n d i x w e ’ r e h e r e t o h e l p conair has made the largest investment in customer support in the plastics indus- try. Our service experts are available to help with any problem you might have installing and operating your equipment. Your conair sales representative also can he...

Page 63

A p p e n d i x l a - 2 e q u i p m e n t g u a r a n t e e conair guarantees the machinery and equipment on this order, for a period as defined in the quotation from date of shipment, against defects in material and workmanship under the normal use and service for which it was recommended (except f...

Page 64

B - 1 l a p p e n d i x s a f e t y a d j u s t m e n t s to ensure safe and efficient operation at lower setpoints, adjustments of the low pressure switch from factory settings is required. The table below lists the appropriate settings. The low pressure switch serves as the mainline defense agains...

Page 65

A p p e n d i x l c - 1 w a t e r q u a l i t y c o n t r o l insufficient or improper water treatment can damage the earthsmart ecm chiller. A certified water treatment specialist should be consulted for your particular application. It is the owner’s responsibility to prevent damage from foreign ma...

Page 66

D - 1 l a p p e n d i x c h i l l e r c a p a c i t y a n d d e r a t e c h a r t if operation of the chiller is less than 45°f {7.2°c}, a glycol and water mixture is required. See operation section entitled, filling the chiller. Ambient conditions affect air-cooled chiller operation and capacity. S...

Page 67

A p p e n d i x l e - 1 p r e s s u r e - te m p e r a t u r e c h a r t f o r r - 1 3 4 a r e f r i g e r a n t refrigerant pressure (psig) 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 105 110 115 120 125 130 135 140 145 150 155 160 170 180 190 200 210 220 230 saturated temperature -...

Page 68

F - 1 l a p p e n d i x r t d r e s i s t a n c e c h a r t you can use the following chart to determine if you need to replace your rtd..

Page 69

A p p e n d i x l g - 1 o v e r h e a d p l u m b i n g d e t a i l s overhead piping installations above process connections require installing a check valve in the “to process” line and a 12 inch {305 mm} riser with a check valve and vacuum break in the “from process” line to prevent siphoning whe...

Page 70

H - 1 l a p p e n d i x e l e c t r i c a l s c h e m a t i c 9.009 .0 0 8.008 .0 0 4.044 .0 4 1tc1t c 1enc1e n c 1cab1c a b 1sw1s w 2cb2 c b 1cb1c b 1tb1t b 1gb1g b 1 2 2 2 2 3 4 6 7 7 8 9 10 10 2enc2 e n c 1tc1t c 1sw1s w 7.887 .8 8 1pl1p l 2pl2 p l 3pl3 p l 2cab2 c a b 4pl4 p l 5pl5 p l 7pl7 p l ...

Page 71

A p p e n d i x l i - 1 c o n t r o l s e t u p 1/32 din watlow sd controller setup sheet enter the following parameters menu parameter description setting set up page sen input sensor type rtd up & down for c-f temperature units (degrees) f 3 seconds s.Dec temperature decimal places 0 is.En infosen...

Page 72

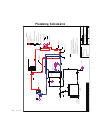

P l u m b i n g s c h e m a t i c from process 1 2 " to process 1 2 " level wa te r ta n k 1 psl fs 1 e v apora to r (1/4" schraeder valv e) pi 1 range= 40 to 65 °f ta h h 1 s te 1 ta ll tic 11 s to process temp (1/4" gauge por t) tx v fil ter/dr y e r sight glass no tes: k or l -t ype c opper tubin...