Conair Sure Cut Rotary Knife Cutter SC-5 User Manual

Summary of Sure Cut Rotary Knife Cutter SC-5

Page 1

Sure cut rotary knife cutter instant access parts and service (800) 458-1960 (814) 437-6861 www.Conairnet.Com the conair group, inc. One conair drive pittsburgh, pa 15202 phone: (412) 312-6000 fax: (412)-312-6227 sc-5 servo model uge059/1003 installation operation maintenance troubleshooting.

Page 2

It is important to record the model and serial number(s) of your equipment and the date you received it in the user guide. Our service department uses this information, along with the manual number, to provide help for the specific equipment you installed. Keep this user guide and all manuals, engin...

Page 3: Able Of

Uge059/1003 sc-5 sure cut servo knife cutters t able of c ontents i ntroduction . . . . . . . . . . . . . . . . . . .1-1 purpose of the user guide . . . . . . . . . . . . . . . . . . . . . . . . .1-2 how the guide is organized . . . . . . . . . . . . . . . . . . . . . . .1-2 your responsibilities as...

Page 4

Sc-5 sure cut servo knife cutter uge059/1003 m aintenance . . . . . . . . . . . . . . . . . . . .5-1 maintenance features . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2 warnings and cautions . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2 maintenance overview . . . . . . . . . ....

Page 5: 1-1

1-1 uge059/1003 sc-5 sure cut servo knife cutter ● ● purpose of the user guide . . . .1-2 ● ● how the user guide is organized . . . . . . . . . . . . . . .1-2 ● ● your responsibilities as a user . . . . . . . . . . . . . . . .1-2 ● ● attention: read this so no one gets hurt . . . . . . . . . . .1-3 ...

Page 6: 1-2

Sc-5 sure cut servo knife cutter uge059/1003 1-2 i ntroduction this user guide describes the conair sc-5 sure cut servo knife cutter and explains step-by-step how to install, operate, maintain and repair this equipment. Before installing this product, please take a few moments to read the user guide...

Page 7: 1-3

Warning: improper installation, oper- ation, or servicing may result in equipment damage or personal injury. This equipment should only be installed, adjust- ed, and serviced by qualified technical person- nel who are familiar with the construction, oper- ation, and potential hazards of this type of...

Page 8: 1-4

In order to protect the operator from possible harm from the rotating blade wheel, several safety features are built into this cutter. They include: two electric switches make a contact between the side and the clear polycarbonate sliding blade observation windows such that the windows must be close...

Page 9: Ow To

H ow to u se the l ockout d evice uge059/1003 sc-5 sure cut servo knife cutter i ntroduction 1-5 warning: electrical hazard before performing maintenance or repairs on this product, disconnect and lock out electrical power sources to prevent injury from unexpect- ed energization or start-up. A locka...

Page 11: 2-1

2-1 ● ● what is the sc-5 sure cut knife cutter . . . . . . . . . . . . . . . 2-2 ● ● typical applications . . . . . . . . . . 2-4 ● ● how the sc-5works . . . . . . . . . . . 2-5 ● ● sc-5 features . . . . . . . . . . . . . . . . 2-7 ● ● specifications . . . . . . . . . . . . . . . . 2-7 ● ● optional ...

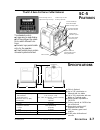

Page 12: Hat Is The

The conair sc-5 sure cut series rotary knife cutter has been designed to be “the most versatile cutter of the industry”. With both capacity to cut small parts at high speeds or large tubes or profiles at low speeds this cutter can eliminate the need for moving cutters in and out of a line per applic...

Page 13: Hat Is The

W hat is the sc-5 s ure c ut ? C ontinued d escription 2-3 uge059/1003 sc-5 sure cut servo knife cutter the larger diameter flywheel used on the servo cutter offers the potential of higher surface speeds at dramatically lower blade rpm’s with high cutting torque. The typical grey area between on-dem...

Page 14: 2-4

Cutting from below the bushing holder the sc-5 sure cut servo cutter housing maximizes versatili- ty and operational ease. Due to the size of the flywheel it was determined best to mount it directly below the bushing holder keeping the center of gravity low and offering the following benefits: ● acc...

Page 15: Ow The

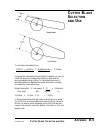

Extruded material that has been sized and cooled enters the cutter from the upstream side (see how the sc-5 sure cut works, section 2, step 1). Typically, a puller is placed just before the cutter; the puller pulls the extrudate through the sizing and/or cooling tanks and feeds it into the cutter. T...

Page 16: 2-6

Sc-5 sure cut servo knife cutter uge059/1003 2-6 d escription the cutter head holds the blade(s) as they rotate and pass between the bushings, cutting the extrudate. Extruded material enters the cutter from the upstream side. 1 cut pieces are collected or carried away on a conveyor. 2 3 h ow the sc-...

Page 17: Sc-5

The sc-5 sure cut servo cutter features: sc-5 f eatures d escription 2-7 uge059/1003 sc-5 sure cut servo knife cutter swivel casters parts discharge chute or optional discharge conveyor optional slide base assembly with position locking mechanism wide range of cutter bushing capacities 24-inch diame...

Page 18: Ptional

O ptional e quipment sc-5 sure cut servo knife cutter uge059/1003 2-8 d escription slide base this option is highly recommended for cutting flexible extru- dates. While the cutter base is fixed and aligned with the puller, the cutter itself is mounted on a set of linear slides that allow as much as ...

Page 19: 2-9

Uge059/1003 sc-5 sure cut servo knife cutter d escription 2-9 tip: conair strongly recom- mends the use of an isolation transformer. Ensuring clean and proper power can help avoid the need for costly ser- vice calls. Discharge conveyor a discharge conveyor facilitates the removal of cut parts. Disch...

Page 21: 3-1

3-1 uge059/1003 sc-5 sure cut servo knife cutter ● ● unpacking the boxes . . . . . . . . .3-2 ● ● preparing for installation . . . . . .3-3 ● ● positioning the sc-5 sure cut . . . . . . . . . . . . . . . . .3-4 ● ● connecting the main power source . . . . . . . . . . . . .3-6 ● ● installing the enco...

Page 22: Npacking The

The sc-5 sure cut series servo knife cutter comes fully assembled in a single crate. U npacking the b oxes sc-5 sure cut servo knife cutter uge059/1003 3-2 i nstallation caution: lifting to avoid personal injury or damage to the cut- ter, lift the cutter using a forklift or hoist with straps that ha...

Page 23: Reparing For

You need these tools for installation: ❒ wire strain relief ❒ 16- or 18-inch adjustable wrench ❒ set of allen wrenches ❒ set of feeler gauges ❒ ½ inch open or box end wrench ❒ flashlight plan the location. Make sure the area where the servo cutter is installed has the following: ● a grounded power s...

Page 24: 3-4

Move the servo cutter into position. Place the servo cutter in position downstream of the belt puller. Determine the best distance from the belt puller to the sc-5 sure cut cutter. ● for flexible products, the cutter should be located as close to the puller as possible to insure a mini- mum amount o...

Page 25: 3-5

Align the cutter with the extrusion line. Measure the centerline height of the extrudate as it exits the extrusion die. Adjust all equipment on the extrusion line (sizing tank, cooling tanks, belt puller, and cutter) to this height. Adjust the cutter's floorlock/caster assembly to the center height ...

Page 26: 3-6

3-6 i nstallation open the servo cutter’s electrical enclosure. Turn the disconnect dial on the door to the off or o position and open the door. Insert the main power wire through the knockout in the side of the enclosure. Secure the wire with a rubber compression fitting or strain relief. Connect t...

Page 27: 3-7

Uge059/1003 sc-5 sure cut servo knife cutter i nstallation 3-7 conair uses bi-directional encoders to ensure that only product that moves forward is counted. Installing the encoder consists of sever- al parts: ● the encoder ● the measuring wheel ● the connecting cable the encoder is fitted with a on...

Page 28: 3-8

Sc-5 sure cut servo knife cutter uge059/1003 3-8 i nstallation i nstalling the c utter b lades danger: sharp blades! Most injuries caused by knife blades occur when the cutter has been turned off. Handle blades with care at all times. ● always lock out power to the cutter before opening the cutting ...

Page 29: 3-9

I nstallation 3-9 uge059/1003 sc-5 sure cut servo knife cutter tip: we recommend that you: ● apply some protective cover on the portion of the blade you are handling, such as masking tape to help prevent getting cut during installation and to leave it on until such time that you will start and check...

Page 30: 3-10

Danger: sharp blades! Always wear cut-resistant gloves when the cut- ting chamber is open and when handling blades. Never open cutting chamber without locking out the cutter power and waiting until the cutter head stops spinning. 3-10 i nstallation sc-5 sure cut servo knife cutter uge059/1003 m ount...

Page 31: 3-11

Uge059/1003 sc-5 sure cut servo knife cutter i nstallation 3-11 c hecking the a lignment of the b ushings for more information about setting and adjusting the gap for the bushings, see about cutter bushings in the appendix c. Checking the alignment of bushing to blade once you are sure that the blad...

Page 32: 3-12

Sc-5 sure cut servo knife cutter uge059/1003 3-12 i nstallation c hecking r epeatability before any conair sc-5’s are shipped, they are tested for cut time repeatability to be sure they are within performance spec- ifications. The repeatability test checks the performance of the rotary knife cutter ...

Page 33: 3-13

Uge059/1003 sc-5 sure cut servo knife cutter i nstallation 3-13 make sure all components are installed according to assembly drawings. Make sure that all bolts on the cut- ter have been tightened. Check that cutter is firmly locked into position with the anchoring screws. Check that all wiring confo...

Page 35: 4-1

4-1 uge059/1003 sc-5 sure cut servo knife cutter ● ● the cutter control . . . . . . . . . . .4-2 ● ● before starting . . . . . . . . . . . . . .4-3 ● ● powering up . . . . . . . . . . . . . . . .4-3 ● ● main screen . . . . . . . . . . . . . . . .4-5 ● ● total screen . . . . . . . . . . . . . . . .4-...

Page 36: 4-2

Sc-5 sure cut servo knife cutter uge059/1003 4-2 o peration o perator c ontrol f eatures the operator control provides an intuitive user-friendly method to interface with the conair servo cutter. Information is viewed and entered at the operator control and is commu- nicated to the servo positional ...

Page 37: 4-3

Uge059/1003 sc-5 sure cut servo knife cutter o peration 4-3 before you start daily operation of the servo cutter, you need to perform preventative maintenance. Necessary maintenance is described in the maintenance section of this users guide, see preventative maintenance, section 5. Daily maintenanc...

Page 38: 4-4

Sc-5 sure cut servo knife cutter uge059/1003 4-4 o peration p owering u p c ontinued open the knife guard. The machine start push button should go out. If the cutter is not working properly at any time, turn it off immediately and refer to the troubleshooting section of this user guide. If you do no...

Page 39: 4-5

Uge059/1003 sc-5 sure cut servo knife cutter o peration 4-5 main screen there are two types of main screens, length or time measure- ment and cuts per minute measurement. The type displayed varies depending on the current cut mode setting. See the mode operator display overviews. The main screen has...

Page 40: 4-6

4-6 o peration menu function key is used to access the menu area. This area can only be accessed from the main display screen for each mode. See the menu area section for more information. Parts select area screen under the current mode on the left side of the bottom line of the display is a soft ke...

Page 41: 4-7

O peration 4-7 reset softkey3 under the counter, on the right is a soft key labeled reset. Pressing this key will zero the counter. Exit or prev, fixed function keys return the display to the parts select screen. Batch screen by pressing softkey3 located under the word batch on the parts select scre...

Page 42: 4-8

Sc-5 sure cut servo knife cutter uge059/1003 4-8 o peration batch select area screen under the batch counter, on the left is a soft key labeled change. Pressing this key displays the select batch area screen. Additional information on how to access this screen can be found in the operator display ov...

Page 43: 4-9

Uge059/1003 sc-5 sure cut servo knife cutter o peration 4-9 numeric keys key in the batch required and press enter. If you require a batch of 50 parts you must key in 50 and then press enter. Enter or delete? If the keyed in number is correct press the enter key for it to be accepted and return to t...

Page 44: 4-10

Sc-5 sure cut servo knife cutter uge059/1003 4-10 o peration exit or prev, if no change is required press exit or prev to return to the main screen. Raise will increase the preset by 0.010 inch. The key can be pressed once for each 0.010 inches increment required or held down to scroll up. Releasing...

Page 45: 4-11

Uge059/1003 sc-5 sure cut servo knife cutter o peration 4-11 exit or prev, if no change is required press exit or prev to return to the previous length screen. Raise will increase the number by 1. The key can be pressed once for each increment of 1 required or held down to scroll up. Releasing the k...

Page 46: 4-12

Sc-5 sure cut servo knife cutter uge059/1003 4-12 o peration raise will increase the preset by 0.010 second. The key can be pressed once for each 0.010 second increment required or held down to scroll up. Releasing the key will freeze the pre- set at the last value then press enter. Lower will decre...

Page 47: 4-13

Uge059/1003 sc-5 sure cut servo knife cutter o peration 4-13 raise will increase the preset by 0.010 second. The key can be pressed once for each 0.010 second increment required or held down to scroll up. Releasing the key will freeze the pre- set at the last value then press enter. Lower will decre...

Page 48: Ontrol

Raise will increase the preset by 1.0. The key can be pressed once for each 1.0 increment required or held down to scroll up. Releasing the key will freeze the preset at the last value then press enter. Lower will decrease the preset by 1.0. The key can be pressed once for each 1.0 decrement require...

Page 49: Ontrol

Raise will increase the preset by 1. The key can be pressed once for each 1 increment required or held down to scroll up. Releasing the key will freeze the preset at the last value then press enter. Lower will decrease the preset by 1. The key can be pressed once for each 1 decrement required or hel...

Page 50: Ontrol

Next or prev, pressing next selects the second function area. Pressing prev returns the display to the first function area screen. Pressing prev from the first function area screen returns the display to the active main mode screen. Menus are a convenient way to access and monitor parameters that do...

Page 51: 4-17

O peration 4-17 uge059/1003 sc-5 sure cut servo knife cutter next, pressing next selects the devcc test if available. If the arrow on the top right hand side of the screen is visible the current mode also supports the devcc test. The devcc repeatability tester also displays total deviation time in m...

Page 52: 4-18

4-18 o peration mode softkey by pressing the soft key located under the word mode, the dif- ferent cut modes are available. There are two cut mode screens. The first screen provides choices for the standard- modes available on all cutters. The second screen displays choices for optional cut modes. T...

Page 53: 4-19

O peration 4-19 uge059/1003 sc-5 sure cut servo knife cutter min softkey by pressing the soft key located under the word min on the second function area screen, the minimum allowable mea- surement value is displayed. The active mode and the cuts per minute limit for the model of cutter determines th...

Page 54: 4-20

4-20 o peration menus are a convenient way to access and monitor parameters that do not need to be altered often, i.E. Home position, encoder direction, scale or unit of measure. In addition, pre- ventive maintenance parameters can be monitored for trouble- shooting and scheduling purposes. Factory ...

Page 55: 4-21

O peration 4-21 uge059/1003 sc-5 sure cut servo knife cutter encdr softkey by pressing the soft key located under the word encdr on the maint. Area screen, there are three sub-menus, drctn, u/m, and scale accessible. Additional information on how to access this screen can be found in the maintenance...

Page 56: 4-22

4-22 o peration if a negative symbol is shown to the left of the count value on the main mode screen the encoder signal is reversed, i.E. Rotat- ing in the wrong direction. The cutter will not function while the encoder is going negative. The direction function corrects this by changing what the ser...

Page 57: 4-23

O peration 4-23 uge059/1003 sc-5 sure cut servo knife cutter c ontrol i nstructions s cale d istance distance softkey by pressing the soft key located under the word dist. On the scale value screen, the scaled distance is available. This value must be set after a u/m change. Additional information o...

Page 58: 4-24

4-24 o peration c ontrol i nstructions s cale c ounts counts softkey by pressing the soft key located under the word counts on the scale value screen, the scaled counts are available. Additional information on how to access this screen can be found in the maintenance area of the operator display ove...

Page 59: 4-25

O peration 4-25 uge059/1003 sc-5 sure cut servo knife cutter c ontrol i nstructions h oming homing a defined home location is required for all servo-positioning applications. After initial power up, emergency stop or guard opened, home position must be found. All motion is relative to this home posi...

Page 60: 4-26

4-26 o peration raise will increase the value by 1.0. The key can be pressed once for each 1.0 increment required or held down to scroll up. Releasing the key will freeze the value at the last value. Lower will decrease the value by 1.0. The key can be pressed once for each 1.0 decrement required or...

Page 61: 4-27

O peration 4-27 uge059/1003 sc-5 sure cut servo knife cutter preventive maintenance softkey pressing the soft key located under the word p/m on the maint. Area screen. Selects the p/m area screen. Three pre- ventive maintenance sub-menus for monitoring inputs, time and cycles are displayed. Addition...

Page 62: 4-28

4-28 o peration c ontrol i nstructions p ower o n t ime time softkey pressing the soft key located under the word time on the p/m area screen, selects the power-on time screen. The power-on time screen displays the total time in hours that the machine has had the power switched on. This infor- matio...

Page 63: 4-29

Uge059/1003 sc-5 sure cut servo knife cutter press the manual cut button and observe the movement of the cutter blade. The cutter head makes a single rotation and the blade moves through the cutter bushings without interference. Insert a piece of extrudate through the cut- ter bushings. Press the ma...

Page 64: Aking

M aking a djustments d uring o peration 4-30 o peration there are several adjustments you can make during normal cutting. These adjustments include: ● in timer mode, adjust the time between cuts ● in encoder and follower modes, adjust the length ● in product mode, adjust the hold-off time ● in flywh...

Page 65: Topping The

Use this procedure to safely stop the servo cutter: press cut on/off soft key to stop cutting (soft key text changes to off). Press stop cutter button to disable the servo motor (start light is off). Turn the rotary disconnect to the off posi- tion. Disconnect the power cord if it is equipped with a...

Page 67: 5-1

5-1 uge059/1003 sc-5 sure cut servo knife cutter ● ● maintenance features . . . . . . . .5-2 ● ● warnings and cautions . . . . . . .5-2 ● ● maintenance overview . . . . . . .5-4 ● ● preventative maintenance schedule . . . . . . . . . . . . . . . . .5-4 ● ● checking the blades . . . . . . . . .5-6 ● ...

Page 68: Arnings And

W arnings and c autions the servo cutter sc-5 sure cut models needs regular, sched- uled maintenance for peak performance. Among the features that require maintenance are: ● cutter blades ● blade mounting hardware ● cutter bushings ● the knife guard hardware ● cutter alignment ● floor locks ● lubric...

Page 69: 5-3

Uge059/1003 sc-5 sure cut servo knife cutter m aintenance 5-3 warning: voltage hazard this equipment is powered by alternating cur- rent, as specified on the machine serial tag and data plate. Do not operate the equipment at power levels other than what is specified on the machine serial tag and dat...

Page 70: 5-4

This section describes the daily, weekly, monthly and semi- annual maintenance schedules that should be performed when changing materials or lines, or when changing equipment, as well as the maintenance procedures to follow. Cutting either flexible or rigid materials generates tremendous shock and v...

Page 71: Reventative

● weekly ❒ ❒ cleaning the blade lubrication tray (if the cutter has this option). See cleaning the blade tray, section 5. ❒ ❒ lubricating shafts on optional slide rail system see cleaning the blade tray, section 5. ● monthly ❒ ❒ checking hardware on the knife guard inspect the hardware on the knife ...

Page 72: Hecking

Blades become dull over time depending on the material being cut, cut rate, blade speed, and blade material and thickness. Check blades regularly for sharpness as well as scratches, nicks, burrs, and material buildup. Clean, sharpen or replace as needed (see installing cutter blades, section 3). C h...

Page 73: 5-7

Uge059/1003 sc-5 sure cut servo knife cutter m aintenance 5-7 check the set screws that secure the cutter bushings. If bush- ings move during cutting, cutting blades and possibly the drive chain could be damaged. I nspecting c utter b ushing s crews c hecking the k nife g uard check the hand knob an...

Page 74: 5-8

Sc-5 sure cut servo knife cutter uge059/1003 5-8 m aintenance this tray is built into the cutter assembly as a simple method of applying lubrication to your blade during cutting cycles. Depending on cut rate and type of material and lubrication, the area will need to be cleaned on a regular basis an...

Page 75: Djusting The

Follow all warnings and cautions listed at the beginning of the maintenance section of this user guide. Be sure the main power is disconnected and the cutter is locked out. Loosen the set screws that hold the cutter bushings. Remove the cutter bushings. Check the depth of the proximity switch face f...

Page 76: Hecking

Be sure the main power is disconnected and the cutter is locked out . Always disconnect and lock out the main power source before opening the unit or servicing. Turn the main power disconnect to the off position before opening the electrical enclosure on the back of the cutter, or the back of the co...

Page 77: 5-11

Open the electrical enclosure. Inspect all wires and connections . Look for loose wires, burned contacts, and signs of over-heated wires. Have a qualified electrician make any necessary repairs or replacements. Close the electrical enclosure door. Inspect the exterior power cords. Cords should not b...

Page 78

B-loc corporation 26 gilbert street monroe, ny 10950 for technical assistance, please call 1-800-865-7756 installation and removal instructions for b-loc™ locking assembly series b112 thank you for purchasing a b-loc™ keyless frictional locking device. B-loc™ keyless connectors provide a high capaci...

Page 79: 6-1

6-1 uge059/1003 sc-5 sure cut servo knife cutter ● ● before beginning . . . . . . . . . . . .6-2 ● ● a few words of caution . . . . . .6-2 ● ● identifying the cause of a problem . . . . . . . . .6-3 ● ● electrical problems . . . . . . . . . .6-4 ● ● product quality problems . . . . .6-8 repair ● ● r...

Page 80: Efore

You can avoid most problems by following the recommended installation, operation and maintenance procedures outlined in this user guide. If you have a problem, this section will help you determine the cause and tell you how to fix it. Find any wiring, parts, and assembly diagrams that were shipped w...

Page 81: Dentifying The

The troubleshooting section covers problems directly related to the operation and maintenance of the servo cutter. This sec- tion does not provide solutions to problems that originate with other equipment. Additional troubleshooting help can be found in manuals supplied with the other equipment. The...

Page 82: 6-4

Sc-5 sure cut servo knife cutter uge059/1003 6-4 t roubleshooting e lectrical p roblems look in this section when you have problems such as lights on the control that are working improperly, buttons that do not execute the function properly, and when information input is not executed properly. Sympt...

Page 83: 6-5

Uge059/1003 sc-5 sure cut servo knife cutter t roubleshooting 6-5 symptom ◆ after pressing start cutter, the cutter head rotates slowly but does not stop. ◆ master safety relay does not ener- gize ◆ while in encoder mode, no count is displayed possible cause the blade home proximi- ty switch failed ...

Page 84: Lectrical

E lectrical p roblems c ontinued sc-5 sure cut servo knife cutter uge059/1003 6-6 t roubleshooting symptom ◆ in encoder or timer modes, the display shows the count which resets, but a cut does not occur at the point of reset. ◆ cutter stops and nothing is displayed possible cause there is a problem ...

Page 85: 6-7

Uge059/1003 sc-5 sure cut servo knife cutter t roubleshooting 6-7 symptom ◆ blade speed does not change when new speed is entered into the control. ◆ cutter mode selec- tion does not change cut mode. ◆ the park (home) position is drifting, i.E. The blade parks further away from the original park sit...

Page 86: 6-8

Sc-5 sure cut servo knife cutter uge059/1003 6-8 t roubleshooting look in this section when the final product does not meet standards: has strings, burrs, cracks, or is misshaped. Symptom ◆ hairs or strings. Possible cause blade speed is too low. The blade is too thick. The blade is wrong for the ap...

Page 87: 6-9

Uge059/1003 sc-5 sure cut servo knife cutter t roubleshooting 6-9 symptom ◆ burrs at cut site. Possible cause the bushings are not pro- viding enough support during cutting. The bushing gap is too wide. The blade speed is too low. Solution change bushing design to make them more supportive. The bush...

Page 88: 6-10

Sc-5 sure cut servo knife cutter uge059/1003 6-10 t roubleshooting symptom ◆ cracks at cut site. Possible cause the extrudate is too cold. The blade speed is too high. The bushings are not pro- viding enough support during cutting. The cutting blade is too sharp. If using nylon, it may be cooling to...

Page 89: 6-11

Uge059/1003 sc-5 sure cut servo knife cutter t roubleshooting 6-11 symptom ◆ cut is not square. Possible cause the blade speed is too low. The blade is misaligned. The cutter bushings are not properly gapped. The knife bevel is not symmetric. For rigid products the puller is too close to the cutter....

Page 90: Eplacing

R eplacing s afety and p roximity s witches sc-5 sure cut servo knife cutter uge059/1003 6-12 t roubleshooting three safety switches are included in sc-5 sure cut cutters: a keyed safety switch on the knife guard, and a proximity switch on each cutter bushing. A failure in any of these switches will...

Page 91: Djusting The

The home position proximity switch should be 0.010 inch from the 5/16 inch thread rod on the cutter head for proper operation. Open the flywheel clear guard window. Locate the 5/16 inch thread rod on the cutter head. It should be 0.010 inch from the proximity switch sensor when it passes that locati...

Page 92: 6-14

6-14 t roubleshooting sc-5 sure cut servo knife cutter uge059/1003 c hecking the e ncoder when the encoder is working properly, the encoder leds on the control panel light or flicker as the encoder wheel moves and generates signals. If the leds do not light when the encoder wheel moves: check all co...

Page 93: Hecking The

C hecking the e ncoder c ontinued encoder mounting and general information the provided encoder is a precision instrument which outputs 3000 bi-directional quadrature pulses per revolution of the shaft. Do not apply excessive axial or radial thrust on encoder shaft (rated for 30lbs. Axial thrust). D...

Page 94: 6-16

Open the flywheel clear guard window. Remove the cutter head by loosening the trantorque assembly. Refer to the manufacturer's guide included with this user guide for information about the trantorque assembly. Locate the four bolts holding the motor/reducer assembly to the cutter. Remove them and ca...

Page 95: Esting

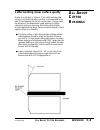

Before any conair puller/cutters are shipped, they are tested for cut time repeatability to be sure they are within perfor- mance specifications. The repeatability test checks the perfor- mance of the rotary knife cutter to return the home park posi- tion after a complete cut. Acceptable repeatabili...

Page 97: A-1

S ervice i nformation a ppendix a-1 conair has made the largest investment in customer support in the plastics industry. Our service experts are available to help with any problem you might have installing and operating your equipment. Your conair sales representative also can help analyze the natur...

Page 98: A-2

W arranty i nformation uge059/1003 a ppendix a-2 e quipment g uarantee p erformance w arranty w arranty l imitations conair guarantees the machinery and equipment on this order, for a period as defined in the quotation from date of shipment, against defects in material and workmanship under the norm...

Page 99: Blade Materials

Cutter blade characteristics such as material, design, and thickness can have a large effect on cut quality. Blade materials blue tempered spring steel is most commonly used because of its cost and availability over a wide range of thicknesses (0.010-0.062 inch). It is a very tough material with an ...

Page 100: Blade Design

Blade design straight-edge knives have a straight cutting surface. A chop- ping action (which has cutting forces parallel to the cut) is typically obtained with straight-edge blades. Because the blade is mounted on a rotary arm, some slicing action (which has additional force vectors at various angl...

Page 101: Blade Thickness

Blade thickness because material is displaced rather than removed in rotary knife cutting, think of the blade as a wedge. The thicker the blade, the greater the displacement. This displacement can cause fracture in rigid profiles and tubing, which is often observed as a whitening on all or a portion...

Page 102: B-4

Calculating blade interruption blade interruption is the length of time which the blade interrupts the extrudate during the cutting process. Knowing blade interruption allows you to optimize blade speed and design for specific applications. You can calculate blade interruption for your application i...

Page 103: B-5

To calculate interruption time: (0.937 in. + 0.250 in.) x 60,000msec/rev = 1.13msec 87.9 in. 718 rpm knowing the interruption time and the line speed, you can cal- culate the amount of production deflection that must be accommodated during cutting. To calculate the amount of extrudate deflection bet...

Page 104: B-6

C onair c utter b lades uge059/1003 b-6 a ppendix part blade bushing blade blade no. Type size thickness material {inches} x length {inches} 0235-30496 straight 4 1/ 4, 5 1/ 4 , 4x10 0.025x9.5 spring steel 3515-30496-1 straight 2 1/ 4 , 2x4, 2x6 0.025x6.48 spring steel 3515-30496-2 straight 3 1/ 4 ,...

Page 105: C-1

Uge059/1003 a ll a bout c utter b ushings a ppendix c-1 rotary knife cutter bushings are probably the most ignored aspect of cutting. Yet, they are probably the most important ingredient to obtaining clean, square, accurate cuts with mini- mal jamming and broken blades. This appendix contains inform...

Page 106: C-2

Supportive bushings become more important if heat is used to minimize whitening (fracturing). ● if you are cutting a square or rectangular profile, whether rigid or flexible, a round bushing bore will not offer proper support and will often lead to an "s" shaped cut. A flat bottomed bushing will off...

Page 107: C-3

A ppendix c-3 cutter bushing shear surface quality similar to a dull pair of scissors, if the cutter bushing shear surface is not sharp the tube or profile is not supported to the side of the blade and the cut will not be clean. In some cases, the entrance of the downstream cutter bushing is slightl...

Page 108: Cutter Bushing Length

Cutter bushing length on flexible extrudates, it is important to minimize the length of the cutter bushings. It is very difficult to push flexible extrudates through since it tends to compress as it is pushed, causing a marginal increase in the tube diameter. For this rea- son, bushing lubrication m...

Page 109: Bout

Adjusting the cutter bushing gap if the bushing gap is too big, material is dragged down between the bushings creating a burr, especially with flexibles. This may lead to jamming within the bushings where the upstream side of the cut extrudate actually hits against the downstream bushing surface. Th...

Page 110: Lade And

Blade and bushing lubrication can nearly always improve the quality of cutting. Description of the cutting process unlike sawing, a rotary knife cutter displaces material rather than removing it. When the knife blade first contacts the extrudate, it pushes it against the opposite side of the cutter ...

Page 111: Common Cutting Lubricants

Common cutting lubricants commonly used general purpose lubricants include: ● tap water ● dish washing liquid (joy, etc) ● glycol (anti-freeze, coolant) ● water-soluble silicone cutting oils ● diesel fuel ● mold release ● mineral oil medical grade lubricants: ● distilled water ● isopropanol (isoprop...

Page 112: Benefits of Using Lubricants

If the blade has a rough surface where the extrudate rubs against it, material will accumulate on the blade in a cheese grater fashion. This scratched material will also be passed from the blade to the next cut and be seen as hairs or flakes. Some of the more flexible materials, such as silicones, s...

Page 113

Select parts area total exit batch length 00000.000 in. Exit total 0,000,000 pcs. Off exit reset batch 000,000 pcs. Change off reset select batch area preset exit alarm preset 000,000 pcs. Exit alarm 000,000 pcs. Exit enc 00000.000 in. Parts off length encoder mode operator display overview or or or...

Page 114

Select parts area total exit batch holdoff 00000.000 sec. Exit total 0,000,000 pcs. Off exit reset batch 000,000 pcs. Change off reset select batch area preset exit alarm preset 000,000 pcs. Exit alarm 000,000 pcs. Exit sns 00000.000 sec. Parts off time end sense mode operator display overview or or...

Page 115

Select parts area total exit batch select blade area speed exit count batch 000,000 pcs. Change off reset total 0,000,000 pcs. Off exit reset preset 000,000 pcs. Exit alarm 000,000 pcs. Exit fly 00000.000 cpm parts off blade flywheel mode operator display overview select batch area preset exit alarm...

Page 116

Select parts area total exit batch time 00000.000 sec exit total 0,000,000 pcs. Off exit reset batch 000,000 pcs. Change off reset select batch area preset exit alarm preset 000,000 pcs. Exit alarm 000,000 pcs. Exit tmr 00000.000 sec parts off time timer mode operator display overview or or or or or...

Page 117

Select parts area total exit batch length 00000.000 in. Exit total 0,000,000 pcs. Off exit reset batch 000,000 pcs. Change off reset select batch area preset exit alarm preset 000,000 pcs. Exit alarm 000,000 pcs. Exit fol 00000.000 cpm parts off length follower mode operator display overview or or o...

Page 118

Select parts area total exit batch length 00000.000 in. Exit total 0,000,000 pcs. Off exit reset batch 000,000 pcs. Change off reset select batch area preset exit alarm preset 000,000 pcs. Exit alarm 000,000 pcs. Exit ato 00000.000 in. Parts off length auto demand mode operator display overview or o...

Page 119

Select parts area total exit batch select length preset length1 length2 next total 0,000,000 pcs. Off exit reset batch#1 000,000 pcs. Change off reset select batch area preset exit alarm preset#1 000,020 pcs. Exit alarm#1 000,015 pcs. Exit 1 enc 00000.000 in. Parts off length multible presets encode...

Page 120

Dependent on mode see mode overviews select function > blade test mode function area 2 operator display overview min parts cpm function area 1 operator display overview (accessed by pressing the menu button) select cut mode > encdr sense flywhl timer follwr auto see mode overviews current min length...

Page 121

Count direction is incorrect change offset +15.0 deg exit select scale value dist. Exit counts select maint. Area encdr home p/m maintainence area display overview (accessed by pressing the menu button from menu area #1 and entering the correct password) or select p/m area inputs time cycles select ...