- DL manuals

- Conair

- Chiller

- VL Series

- User Manual

Conair VL Series User Manual

Summary of VL Series

Page 1

Portable chillers the conair group, inc. One conair drive pittsburgh, pa 15202 phone: (412) 312-6000 fax: (412)-312-6227 vl series air-cooled and water-cooled with capacities from 2 to 40 tons ugh021/0301 installation maintenance operation troubleshooting.

Page 2

It’s a good idea to record the model and serial number(s) of your equipment and the date you received it in the user guide. Our service department uses this information, along with the manual number, to provide help for the specific equipment you installed. Please keep this user guide and all manual...

Page 3

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 3 table of contents 1.0 general 5 1.1 introduction 6 1.2 unit location for air cooled models 6 1.3 unit location for water cooled models 6 1.4 efficiency 6 1.5 safety 7 1.6 clean air act 7 1.7 miscellaneous 7 chiller features identified 8 2...

Page 4

Page: 4 7.0 related drawings 47 7.1 vla-5/7.5/10 mechanical schematic 48 7.2 vla-15/20/25/30 mechanical schematic 49 7.3 vla-5 physical 50 7.4 vla-7.5/10 physical 51 7.5 vla-15/20/25/30 physical 52 7.6 duct schematic for air cooled chillers 53 7.7 vla-5/ 7.5/ 10 electrical 54 7.8 vla-15/ 20/ 25/ 30 ...

Page 5

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 5 1.0 general 1.1 introduction 1.2 unit location for air cooled models 1.3 unit location for water cooled models 1.4 efficiency 1.5 safety 1.6 clean air act 1.7 miscellaneous.

Page 6

Page: 6 vl series portable chillers, 2 to 40 tons ugh021/0301 1.1 introduction a. This manual covers most ‘vl’ series portable chiller models. Most ‘vl’ series portable chillers are basically identical with exception of the type of condenser (air cooled or water cooled). B. All instructions in this ...

Page 7

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 7 quality. Conair recommends filtering where required to prevent solids from plugging critical parts (pumps, heaters, seals for example). Conair highly recommends the services of a competent water treatment specialist be obtained and his re...

Page 8

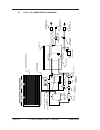

Page: 8 vl series portable chillers, 2 to 40 tons ugh021/0301 to process connection from process connection hot gas bypass valve vla-10 pictured compressor expansion valve liquid line solenoid refrigerant sight glass insulated fiberglass reservoir centrifugal pump electrical cabinet galvanized steel...

Page 9

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 9 2.0 installation 2.1 general 2.2 to and from process connections 2.3 water supply connection 2.4 air cooled condenser 2.5 water cooled condenser connection 2.6 electrical connection.

Page 10

Page: 10 vl series portable chillers, 2 to 40 tons ugh021/0301 2.1 general a. All process piping materials (such as hose, rigid piping, valves or filters) used in process water piping circuitry must be rated for 100°f minimum temperature and 100 psi minimum pressure. B. All such materials must have ...

Page 11

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 11 to process connection: connect to “water in” on process manifold from process connection: connect to “water out” on process manifold water supply connection: (not shown on this unit) connect to city water source figure 2.2b typical proce...

Page 12

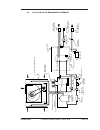

Page: 12 vl series portable chillers, 2 to 40 tons ugh021/0301 b. Air flow is generated by the motor driven fans (figure 2.4a) or centrifugal blowers (figure 2.4b). Air flow is from the outside of the chiller, through the condenser and exhausted through the top of the unit. On centrifugal blowers mo...

Page 13

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 13 2.5 water cooled condenser connection a. Connect the ‘ condenser water in’ port to the plant’s city water supply or tower system supply. 1. Required consumption from a city water source is 1.5 gpm at 65°f per ton of rated capacity. 2. Re...

Page 14

Page: 14 vl series portable chillers, 2 to 40 tons ugh021/0301 cause a significant hazard that may result in serious personal injury and unit damage. 2. A customer supplied, four conductor cable is required for connection to a customer supplied fused disconnecting means. The fused disconnecting mean...

Page 15

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 15 3. Make certain all electrical connections are tightly affixed. Any loose wiring connections must be tighten before engaging the power supply. 4. Make certain no moisture or standing water is present inside the electrical cabinet (figure...

Page 16

Vl series portable chillers, 2 to 40 tons ugh021/0301 page: 16 this page intentionally blank.

Page 17

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 17 3.0 operations 3.1 general 3.2 start up/operations procedure 3.3 instrument/operation 3.4 shut down procedure.

Page 18

Page: 18 vl series portable chillers, 2 to 40 tons ugh021/0301 3.1 general a. Failure to follow the factory required operations procedure may adversely affect the unit’s ability to adequately control process temperature and may create a hazardous operating condition which may result in serious opera...

Page 19

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 19 2. Conair recommends the addition of 20% inhibited propylene glycol to the process fluid. This should help prevent the process fluid from freezing and internal components from rusting. A biocide must be added to the water to prevent orga...

Page 20

Page: 20 vl series portable chillers, 2 to 40 tons ugh021/0301 d. Toggle the chiller on switch. This will quickly cycle the electrical motor “on” and then “off”. E. Observe the motor shaft. When the chiller on switch is turned “on”, the motor shaft will rotate. When the chiller on switch is turned “...

Page 21

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 21 power supply. The operator must reverse the power leads at the disconnect switch only and not at the power entry terminals on the unit’s electrical panel. The unit’s internal electrical system wiring is phased correctly at the factory an...

Page 22

Page: 22 vl series portable chillers, 2 to 40 tons ugh021/0301 4. Excessive flow... Excessive flow can overload the process pump motor and cause eventual failure. This is a result of the process loop’s ability to flow water at a great rate than can be provided by the process pump. This eventually re...

Page 23

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 23 f. The amp meter will display the motor amps. Compare the actual motor amps as displayed on the amp meter to the full load amp rating as listed on the motor name plate. G. If the amp draw is excessive (higher than the listed name plate a...

Page 24

Page: 24 vl series portable chillers, 2 to 40 tons ugh021/0301 determines an indicating light or digit does not illuminate, the instrument must be removed and sent to the factory for repair. When power is supplied to the unit, the power light will illuminated. 3. Toggle ‘on’ the chiller on rocker sw...

Page 25

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 25 b. Instrument operation 1. When the chiller on rocker switch is toggled on, the instrument will begin temperature control operations and the ‘to process’ temperature will begin to drop. 2. When the ‘to process’ temperature drops 1° below...

Page 26

Page: 26 vl series portable chillers, 2 to 40 tons ugh021/0301 the compressor contactor. Engaging the compressor contactor supplies electrical current to the compressor. This action will decrease process water temperature. 4. Capacity control : illuminates when the instrument has engaged the capacit...

Page 27

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 27 4.0 troubleshooting 4.1 sensors 4.2 process pump 4.3 compressor 4.4 blower/fan 4.5 low flow 4.6 high pressure 4.7 low pressure 4.8 freezestat 4.9 oil pressure 4.10 crankcase heater 4.11 electronics.

Page 28

Page: 28 vl series portable chillers, 2 to 40 tons ugh021/0301 4.1 sensors a. The sensor is a solid state temperature transducer which converts temperature input to proportional current output. B. To quickly test for a defective probe, switch connections between the defective probe and a probe known...

Page 29

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 29 4.6 high pressure a. If the refrigerant high pressure safety switch has opened, this switch must be manually reset after the problem has been resolved. B. Refrigerant high pressure will vary with ambient temperature from a minimum of 190...

Page 30

Page: 30 vl series portable chillers, 2 to 40 tons ugh021/0301 port. If the water out temperature of the evaporator reaches the freezestat setting the switch will open and stop the refrigeration compressor. B. Check for restricted water flow and add a bypass line if necessary. C. The setpoint is adj...

Page 31

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 31 5.0 maintenance 5.1 warranty service procedure 5.2 periodic preventative maintenance 5.3 special maintenance 5.4 solenoid valve service 5.5 pump seal service 5.6 checking the refrigerant charge 5.7 proper cleaning procedure for brazed pl...

Page 32

Page: 32 vl series portable chillers, 2 to 40 tons ugh021/0301 5.1 warranty service procedure a. In the event of a problem with a chiller that can not be resolved by normal troubleshooting procedures, the customer is invited to consult the conair service department for assistance. The correct model ...

Page 33

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 33 i. Refrigerant sight glass: check for bubbles when compressor is operating at 100%. Check the moisture indicator for a color other than green. J. Clean unit. 5.3 special maintenance a. Any service of the refrigeration system must be acco...

Page 34

Page: 34 vl series portable chillers, 2 to 40 tons ugh021/0301 5.4 solenoid valve service a. Vla units with the water make-up system use a solenoid valve (figure 5.4a) to regulate the level in the reservoir tank. The solenoid valve is controlled by the float switch. B. Generally, solenoid valves fai...

Page 35

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 35 screen and clean or replace as necessary. 9. Clean the valve body. 10. Reset the mesh screen into the valve body. 11. If a new diaphragm assembly was obtained, continue with step 12. If not, disassemble the diaphragm assembly and note co...

Page 36

5.5 pump seal service a. The vla unit pump seal is a carbon/niresist shaft seal assembly including a stationary member, rotating member and tension spring (figure 5.5a). B. The operator can determine the pump seal is leaking when fluid is identified leaking from the pump case adapter. Generally, a p...

Page 37

6. Locate and remove the pump casing bolts. These bolts secure the motor and motor adapter to the pump casing (figure 5.5d). 7. Separate the motor and motor adapter from the pump casing to expose the pump impeller (figure 5.5e). Remove the motor and motor adapter from the unit and place on a workben...

Page 38

The operator must be certain the stationary seal member is fully squared and seated in cavity. 13. Slide the rotating member onto the lubricated pump shaft (figure 5.5j). The operator must be certain not to damage or tear rubber bellows assembly. 14. Place the spring onto the rotating member. 15. Al...

Page 39

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 39 5.6 checking the refrigerant charge a. All standard conair chillers are manufactured with thermostatic expansion valves as the metering device to the evaporator. B. All conair chillers have a refrigerant sight glass with a moisture indic...

Page 40

Page: 40 vl series portable chillers, 2 to 40 tons ugh021/0301 5.7 proper cleaning procedure for brazed plate evaporators a. The brazed plate evaporator is made of stamped stainless steel plates, furnace brazed together with copper based joints. The complex geometry of the flow passages promotes tur...

Page 41

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 41 c. Backflushing procedure: 1. Turn off all power to the machine. For chillers with a reservoir tank, drain the tank to below the evaporator outlet. For chillers without a reservoir tank, drain total unit. 2. Connect a water supply hose t...

Page 42

Vl series portable chillers, 2 to 40 tons ugh021/0301 page: 42 this page intentionally blank.

Page 43

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 43 6.0 components 6.1 water system 6.2 refrigeration system.

Page 44

Page: 44 vl series portable chillers, 2 to 40 tons ugh021/0301 6.1 water system a. Motor/pump assembly: the motor/pump assembly circulates chilled fluid to the process loop. The pump assembly is built of total stainless steel to maintain water quality (figure 6.1a). B. Freezestat: the freezestat aid...

Page 45

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 45 c. Filter-drier: the filter-drier removes contaminants and moisture from the liquid refrigerant (figure 6.2c). D. Liquid line solenoid valve: controlled by the instrument, this valve closes when the compressor cycles off to prevent refri...

Page 46

H. High/low pressurestats: the high/low pressurestats protect the refrigeration system from unsafe operating levels. The high pressure switch is factory set to open at 325 psi and protects the refrigeration components and personnel from potential damage of injury from excessive high pressure. The hi...

Page 47

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 47 7.0 related drawings 7.1 vla-5/7.5/10 mechanical schematic 7.2 vla-15/20/25/30 mechanical schematic 7.3 vla-5a physical 7.4 vla-7.5/10 physical 7.5 vla-15/20/25/30 physical 7.6 duct schematic for air cooled chillers 7.7 vla-5a/7.5/10 ele...

Page 48

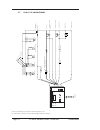

Page: 48 vl series portable chillers, 2 to 40 tons ugh021/0301 7.1 vla-5/7.5/10 mechanical schematic air-cooled condenser w/fans (5-ton model uses single fan) coolant pump to process sensor probe to process port connection make-up port connection (optional) make-up solenoid valve (optional) level sw...

Page 49

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 49 7.2 vla-15/20/25/30 mechanical schematic air-cooled condenser w/blower coolant pump to process sensor probe to process port connection make-up port connection (optional) make-up solenoid valve (optional) level switch (optional) from proc...

Page 50

Page: 50 vl series portable chillers, 2 to 40 tons ugh021/0301 7.3 vla-5 physical 38" 34" 51" 6" 3" po wer pum p compressor hot gas bypass setpoint ch ill er on to process temperature se le ct.

Page 51

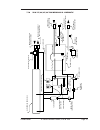

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 51 7.4 vla-7.5/10 physical 54" 34" 51" 6" 3" power pump compressor hot gas bypass setpoint ch ill er on to process temperature se le ct.

Page 52

Page: 52 vl series portable chillers, 2 to 40 tons ugh021/0301 7.5 vla-15/20/25/30 physical 67 1/2" 58" 94" 6" 2" po we r pu mp co mp res so r ho t g as b ypa ss set po int ch ill er on to pr oc ess tem per atu re sel ec t.

Page 53

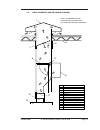

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 53 7.6 duct schematic for air cooled chillers 13 12 11 10 9 8 7 6 5 4 3 2 1 item 1 2 3 4 5 6 7 8 9 10 11 12 13 description weather cap screen flashing to suit roof curb plant roof butterfly with counterbalance separate duct support from roo...

Page 54

Page: 54 vl series portable chillers, 2 to 40 tons ugh021/0301 7.7 vla-5/7.5/10 electrical lo w pressurest a t molex red brn red/yel red/brn red/wht blu org wht 3 1 3 1 3 2 1 3 2 1 19 instr ument gr ound 3 20 19 21 22 22 23 24 25 50 m1 m2 19 19 50 mo t or coil 22 22 22 22 21 21 22 50 50 25 26 26 26 ...

Page 55

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 55 7.8 vla-15/20/25/30 electrical vl chiller control temperature to process setpoint power pump compressor hot gas bypass on off molex red/org blu org wht red/brn red/wht red/yel red/blu red red/blk 29 optional 2 mol 21 t ank flo a t m1 m3 ...

Page 56

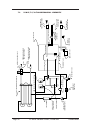

Page: 56 vl series portable chillers, 2 to 40 tons ugh021/0301 7.9 vlw-5/7.5/10 ton mechanical schematic w ater regulator valve coolant pump to process sensor probe to process port connection make-up port connection make-up solenoid valve (optional) level switch (optional) from process port connecti...

Page 57

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 57 7.10 vlw-15/20/25/30 ton mechanical schematic w ater regulator valve coolant pump to process sensor probe to process port connection make-up port connection (optional) make-up solenoid valve (optional) level switch (optional) from proces...

Page 58

Page: 58 vl series portable chillers, 2 to 40 tons ugh021/0301 7.11 vlw 5/7.5/10 ton physical 32" 38" 34" 4" po we r pu mp co mp res so r ho t g as b ypa ss set po int ch ill er on to pr oc ess tem per atu re sel ec t.

Page 59

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 59 7.12 vlw 15/20/25/30 ton physical 54" 34" 51" 6" po we r pu mp co mp res so r ho t g as b ypa ss set po int ch ill er on to pr oc ess tem per atu re sel ec t.

Page 60

Page: 60 vl series portable chillers, 2 to 40 tons ugh021/0301 7.13 vlw 5/7.5/10 ton electrical lo w pressurest a t molex red brn red/yel red/brn red/wht blu org wht 3 1 3 1 3 2 1 3 2 1 19 instr ument gr ound 3 20 19 21 22 22 23 24 25 50 m1 m2 19 50 mo t or coil 22 22 22 22 21 21 22 50 50 25 26 26 2...

Page 61

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 61 7.14 vlw 15/20/25/30 ton electrical molex blu org red/brn red/wht red/yel red br w 21 m1 m2 freezest a t 19 20 19 50 mo t or coil 22 23 23 21 22 22 50 50 27 50 26 26 50 26 24 23 instr ument gr ound ho t gas by -p ass solenoid liq uid lin...

Page 62

Vl series portable chillers, 2 to 40 tons ugh021/0301 page: 62 this page intentionally blank.

Page 63

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 63 8.0 appendix 8.1a ‘vlw’ specifications 8.1b ‘vla’ specifications 8.2 operation below 48°f 8.3 water quality control 8.4 inhibited propylene glycol 8.5 maintaining proper water flow 8.6 low flow bypass circuit 8.7 chiller capacity and der...

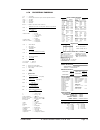

Page 64

Page: 64 vl series portable chillers, 2 to 40 tons ugh021/0301 8.1 specifications model vla-2 vla-4 vla-5 vla-7.5 vla-10 vla-15 vla-20 vla-25 vla-30 performance characteristics capacity * ton 2 4 5 7.5 10 15 18 24 26 compressor hp {kw} ✝ 2 {1.5} 4 {2.9} 5 {3.7} 7.5 {5.6} 10 {7.5} 15 {11} 2x10 {15} 2...

Page 65

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 65 specification notes * ton capacity at 12,000 btu/ton @ 50°f lwt @ 115°f condensing temperature. Capacities may be ± 5% as reserved by the com- pressor manufacturer. Capacity multipliers are: 50°f - 1.00; 40°f - 0.80; 30°f - 0.60; 20°f - ...

Page 66

Page: 66 vl series portable chillers, 2 to 40 tons ugh021/0301 8.2 operation below 48°f a. A chiller typically operates with a setpoint of 50°f or higher. However, if setpoints between 20° - 48°f are required, special precautions must be taken to prevent freezing and possible damage. Attention must ...

Page 67

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 67 decreasing the freeze protecting ability of the solution. Therefore, the water supply source must be disconnected and the connection capped. The operator must monitor the water/glycol level and manually make-up to maintain proper reservo...

Page 68

Page: 68 vl series portable chillers, 2 to 40 tons ugh021/0301 8.3 water quality control a. Lack of, as well as, improper water treatment can damage the chilling unit. The services of a competent water treatment specialist should be obtained and their recommendations followed. It is the equipment ow...

Page 69

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 69 c. Use of plain glycol: 1. Even through they do lower the freeze point, plain glycols are even more corrosive than water. The corrosion rate of plain ethylene glycol on iron, for example, is more than 2.5 times faster than plain water. O...

Page 70

Page: 70 vl series portable chillers, 2 to 40 tons ugh021/0301 8.5 maintaining proper water flow a. The evaporator in a typical water chiller is flow sensitive. That is, the efficiency of operation is directly related to the flow of liquid. Maximum efficiency is obtained at approximately 2.4gpm per ...

Page 71

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 71 8.6 low flow bypass circuits a. In cases of restricted flow or reduced capacity conditions, as an option conair supplies manual or automatic low flow bypass circuits on water cooled or air cooled portable chillers. It is recommended that...

Page 72

Page: 72 vl series portable chillers, 2 to 40 tons ugh021/0301 8.7 overhead piping kit a. Conair portable chillers have between a 4.5 to 60 gallon reservoir capacity (depending on chiller size). When a conair portable chiller is used with overhead piping, the chiller tank will overflow upon shut-dow...

Page 73

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 73 8.8 chiller capacity and derate chart 60 50 45 40 35 30 25 20 15 10 5 0 -5 * * * * * 105% 100% 90% 80% 70% 60% 50% 40% 30% 22% 15% 9% 5% output temperature °f full available % capacity notes: if operation of the chiller at less than 48°f...

Page 74

Page: 74 vl series portable chillers, 2 to 40 tons ugh021/0301 8.9 pressure-temperature chart for r-22 refrigerant saturated temperature 40°f 45°f 50°f 55°f 60°f 65°f 70°f 75°f 80°f 85°f 90°f 95°f 100°f freon pressure 68 76 84 93 100 112 122 132 144 156 168 182 196 these pressure/temperature relatio...

Page 75

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 75 8.10 engineering formulas 1 ton = 12,000 btu btu = material (lbs) x material 's specific heat x temperature difference 1 btu = .293 watts 1 watt = 3.42 btu 1 kw = 1000 watts 1 kw = 3420 btus btu/hr = gpm x t (for water cooled condensers)...

Page 76

Page: 76 vl series portable chillers, 2 to 40 tons ugh021/0301 8.11 spare parts list - water cooled models part # description 820000 caster 4” swivel 830000 caster 4” rigid 1197000 compressor brh2-1000-tfd-219 1515500 condenser 45” x 46 1 / 2 ” 1733700 auxiliary contact cr305x200b (nc) 1825020 conta...

Page 77

Ugh021/0301 vl series portable chillers, 2 to 40 tons page: 77 8.12 spare parts list - air cooled models part # description 820000 caster 4” swivel 830000 caster 4” rigid 1197000 compressor brh2-1000-tfd-219 1515500 condenser 45” x 46 1 / 2 ” 1733700 auxiliary contact cr305x200b (nc) 1825020 contact...

Page 78

Vl series portable chillers, 2 to 40 tons ugh021/0301 page: 78 this page intentionally blank.

Page 79: 814-437-6861

Conair has made the largest investment in customer support in the plastics industry. Our service experts are available to help with any problem you might have installing and operating your equipment. Your conair sales representative also can help analyze the nature of your problem, assuring that it ...

Page 80: Quipment

E quipment g uarantee p erformance w arranty w arranty l imitations conair guarantees the machinery and equipment on this order, for a period as defined in the quotation from date of shipment, against defects in material and workmanship under the normal use and service for which it was recommended (...