- DL manuals

- Condair

- Humidifier

- CP3

- Installation And Operating Instructions Manual

Condair CP3 Installation And Operating Instructions Manual

Summary of CP3

Page 1

Installation and operating instructions electrode humidifiers 2529291 e n 1401 condair cp3.

Page 3

3 1 introduction 4 1.1 to the very beginning 4 1.2 notes on the installation and operating instructions 4 2 for your safety 6 3 product overview 8 3.1 models overview 8 3.2 identification of the unit 9 3.3 steam humidifier construction 10 3.4 functional description 11 3.5 humidification system overv...

Page 4: 1 Introduction

4 limitation the subject of these installation and operating instructions are the steam humidifier condair cp3 in its versions “basic” and “pro”. The various accessories (e.G. Steam distributor, steam distribution system, etc.) are only described insofar as this is necessary for proper operation of ...

Page 5

5 symbols used in this manual caution! The catchword “caution” designates notes in this documentation that, if neglected, may cause damage and/or malfunction of the unit or other material assets. Warning! The catchword “warning” used in conjunction with the general caution symbol designates safety a...

Page 6: For Your Safety

6 2 for your safety general every person working with the condair cp3 must have read and understood the present installation and operating instructions before carrying out any work. Knowing and understanding the contents of the present installation and operating instructions is a basic requirement f...

Page 7

7 danger that may arise from the unit danger! Danger of electrical shock! The condair cp3 is mains powered. One may get in touch with live parts when the unit is open. Touching live parts may cause severe injury or danger to life. Prevention: before carrying out any work set the condair cp3 out of o...

Page 8: Product Overview

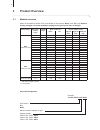

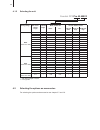

8 3 product overview 3.1 models overview steam air humidifiers condair cp3 are available in the versions “ basic" and “pro” with different heating voltages and steam capacities ranging from 5 kg/h up to a max. Of 180 kg/h. Heating voltage * max. Steam capacity in kg/h graduation in kg/h model condai...

Page 9

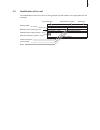

9 3.2 identification of the unit the identification of the unit is found on the type plate (for the location of the type plate see unit overview): condair ag, ch-8808 pfäffikon type: cp3 pro 45 ser.Nr.: xxxxxxx 11.06 heating voltage: 400v / 3~ / 50...60hz power: 33.8 kw steam capacity: 45.0 kg/h ctr...

Page 10

10 3.3 steam humidifier construction 1 housing (small, large) 2 cable openings, top side 3 main contactor 4 power board 5 control board with cp3 card 6 display and control unit 7 remote operating and fault indication board 8 operation status indicators 9 cable openings, bottom side 10 drain key 11 u...

Page 11

11 3.4 functional description the steam humidifier condair cp3 is a pressureless steam generator that utilizes an electrode heating. The steam humidifier condair cp3 is designed for air humidification via a steam distributor (steam distribution pipe, ventilation unit or steam distribution system opt...

Page 12

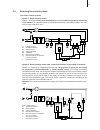

12 3.5 humidification system overview 1 steam humidifier 2 steam connection 3 water drain connection 4 water supply connection 5 filter valve (accessory “z261”) 6 manometer (installation recommended) 7 funnel with siphon (building side) 8 water drain hose (accessory “ds80” 9 control voltage supply 1...

Page 13

13 3.6 overview unit interconnection single unit (cp3 5...45) i/o i/o i/o i/o main unit, module a (cp3 5 ... 45) power board control board heating voltage control voltage control signal remote indication rfi main unit, module b (cp3 46 ... 90) power board heating voltage main unit, module a (cp3 5 ....

Page 14

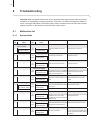

14 3.7 options 3.7.1 options overview condair cp3 basic... / condair cp3 pro... 230v1 5...8 400v3 5...8 9...15 16...45 52/60/70/80/90 105/120/135 152/160/180 230v3 5...8 9...15 16...30 44/50/60 75/90 100/120 d... Cleanable steam cylinder cleanable steam cylinder as an alternative to the disposable s...

Page 15

15 3.7.2 option details steam cylinder the steam humidifier is available with two different types of steam cylin ders: – exchangeable steam cylinder type a... (standard version) – cleanable steam cylinder type d... (option) the following tables present an overview of the steam cylinders used in the ...

Page 16

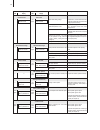

16 3.8 accessories 3.8.1 accessories overview accessories for water installation condair cp3 basic... / condair cp3 pro... 230v1 5...8 400v3 5...8 9...15 16...45 52/60/70/80/90 105/120/135 152/160/180 230v3 5...8 9...15 16...30 44/50/60 75/90 100/120 filter valve z261 (1 pcs. Per system) accessories...

Page 17

17 the steam distribution pipes are selected on the basis of the duct width (for horizontal installation) or the duct height (for vertical installation) and the capacity of the steam humidifier. Important! Always select the longest possible steam distribution pipe (opti mum humidification distance)....

Page 18

18 3.9 standard delivery the standard delivery includes: – steam humidifier condair cp3 equipped with the options ordered according to chapter 3.7, fixing set and installation and operating instructions (this document), packaged in cardboard box – unit small (wxhxd): 456 mm x 620 mm x 280 mm, shippi...

Page 19

19 4.1 selecting the unit version the maximum required steam capacity must be calculated based on one of the following formulas: v • ρ m d = • (x 2 - x 1 ) 1000 or v m d = • (x 2 - x 1 ) 1000 • ε m d : maximum steam demand in kg/h v: volume of supply air portion per hour in m 3 /h (for indirect room...

Page 20

20 condair cp3 pro 45 400v3 4.1.2 selecting the unit heating voltage * max. Steam capacity in kg/h graduation in kg/h model condair cp3 unit size / number of units basic... Pro... Single unit small single unit large double unit large 400v3 (400v/3~/50...60hz) 5...15 1 5...15 5...15 1 16...45 1 16......

Page 21

21 4.3 selecting the control system the various control systems – system 1: room humidity control system 1 is suited for direct room humidification and air conditioning systems with mainly recirculated air. The humidity sensor or humidistat respectively is preferably located in the room itself or in...

Page 22

22 – system 3: supply air humidity control with continuous output limitation supply air humidity control (humidity sensor installed in supply air duct) should be used only where room humidity control is impracticable for technical reasons. Such systems always require a pi-controller. The humidity se...

Page 23

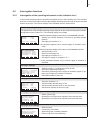

23 input signals control with external controller control with internal pi controller control signals humidity sensor signals 0...5 vdc (potentiometer 135 Ω ... 10 kΩ) 0...5 vdc (potentiometer 135 Ω ... 10 kΩ) 1...5 vdc 1...5 vdc 0...10 vdc 0...10 vdc 2...10 vdc 2...10 vdc 0...16 vdc 0...16 vdc 3.2....

Page 24

24 5 mounting and installation work qualification of personnel all mounting and installation work must be carried out only by well qualified personnel authorised by the owner. It is the owner’s responsibility to verify proper qualification of the personnel. General note strictly observe and comply w...

Page 25

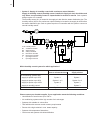

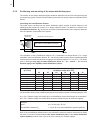

25 min. 400 mm b min. 600 mm h min. 250 mm min. 400 mm min. 600 mm 50 mm 60...70 °c 1 ... 40 °c max. 75 %rh ip20 t 5.2 mounting the unit 5.2.1 notes on locating the unit condair cp3 ... 230v1 basic pro 5...8 condair cp3 ... 230v3 basic pro basic pro basic pro basic pro basic pro pro pro 5...8 9...15...

Page 26

26 the installation site of the steam humidifier depends largely on the location of the steam distributor (see chapter 5.3). To ensure proper functioning of the steam humidifier and to obtain an optimal efficiency, the following points must be considered and observed when choosing the location for t...

Page 27

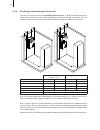

27 5.2.2 mounting the humidifier procedure 1. Mark the attachment point “a” on the wall. 2. Drill hole for attachment point “a” (diameter: 8 mm, depth: 40 mm). 3. Insert the supplied plastic plug, and tighten the screw until the distance between the wall and the screw head is 4 mm. 4. Unlock the two...

Page 28

28 5.2.3 inspecting the installed unit check the following points: is the unit installed in the correct place (see chapter 5.2.1)? Is the supporting surface stable enough? Is the unit correctly aligned, vertically and horizontally? Is the unit properly secured (see chapter 5.2.2)? Has the front pane...

Page 29

29 5.3 steam installation 5.3.1 overview steam installation fan3s cp basic m fan3s cp basic l fan3s cp pro m fc fan3s cp pro m fan3s cp pro l basic fan3s cp basic m fc basic pro ds60 ds80 rmin. 300 mm Ømin. 200 mm max. 4 m ds60 ds22 ds80 61-... 81-... 61-... 41-... 41-... 81-... Max. 4 m min. 5 % – ...

Page 30

30 the calculation of the humidification distance “b n ” is dependent on several factors. For a rough estimation of the humidification distance “b n ”, the following table is useful. Recommended standard values listed in this table are based on a supply-air temperature range of 15 °c to 30 °c. The v...

Page 31

31 minimum distances to be observed to prevent the water vapour, that is emitting from the steam distribution pipe, from condensing on downstream system components, a minimum distance to the steam distribution pipe must be observed (depends on the humidification distance “b n ”). Before/after constr...

Page 32

32 in positioning the steam distribution pipes, the following dimensions should be observed: note: when locating the optisorp steam distribution system please note the instructions in the separate documentation for this product. H min h min h min h min h min h min 1/2 h 1/2 h h 1/3 2/3 h 1/5 1/5 2/5...

Page 33

33 5.3.3 installing the steam distributors detailed information on the installation of steam distribution pipes 41-.., 61-.../81-... And optisorp steam distribution system can be found in the separate “mounting instructions” for this products. Guidelines for dimensioning the ventilation ducts – to f...

Page 34

34 5.3.4 positioning and mounting of the fan unit fan3s cp ... M fan3s cp ... M fc fan3s cp ... L m d max. 8 kg/h 15 kg/h 30 kg/h 45 kg/h a min. 4.0 m 6.0 m 8.0 m 10.0 m b min. 1.0 m 1.0 m 1.0 m 1.5 m c min. 2.2 m 2.2 m 2.2 m 2.2 m d min. 1.0 m 1.0 m 1.0 m 1.5 m e min. 0.15 m e max. (max. Steam hose...

Page 35

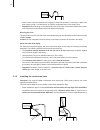

35 5.3.5 installing the steam hose important! Use original condair steam hose exclusively. Other types of steam hoses can cause undesired operational malfunctions. Instructions for the hose layout the hose layout depends on the position of the steam distribution pipe: – steam distribution pipe is mo...

Page 36

36 – steam hoses must be prevented from sagging (condensate pockets); if necessary, support with pipe clamps, trough, or wall brackets, or install a condensate drain in the steam hose. – important! When deciding on the length and layout of the hose, it should be noted that the steam hose may become ...

Page 37

37 – steam distribution pipe is mounted less than 300 mm above the top edge of the humidifier: condensate hose is led down with a minimum slope of 20 %, in the form of a siphon (min. Hose bend diameter Ø200 mm), directly into a discharge funnel. Note: if your unit feeds a number of steam distributio...

Page 38

38 ds80 125...1250 µs/cm 1...10 bar 1...40 °c ø40 mm ø10/8 mm g 1/2" z261 ≥ 40 mm g 1/2" min. 50 cm min. 10 % – min. 10 % – 5.4 water installation 5.4.1 overview water installation.

Page 39

39 water supply the water supply is to be carried out according to the figure found in chapter 5.4.1 and the applicable local regulations for water installations. The indicated connection specifications must be observed. – the installation of the filter valve (accessory “z261”, alternatively a shut-...

Page 40

40 5.4.3 inspecting the water installation check the following topics: – water supply has filter valve (accessory “z261”) or shut-off valve and 5 µm water filter respectively been installed in supply line? Have admissible water pressure (1 – 10 bar) and admissible temperature (1 – 40 °c) been observ...

Page 41

41 5.5 electric installation 5.5.1 wiring diagram condair cp3 basic/pro a1 controller (active) o r humidity sensor a2 controller (passive), set jp3 to position 5v a3 on/of f controller , set jp3 to position 24v a4 limitation signal ba t backup battery cp3 pro (cr2032, lithium 3v) b1 ventilation inte...

Page 42

42 5.5.2 wiring diagram cp3 pro link up systems a1 controller (active) o r humidity sensor a2 controller (passive), set jp3 to position 5v a3 on/of f controller , set jp3 to position 24v a4 limitation signal ba t backup battery cp3 pro (cr2032, lithium 3v) b1 ventilation interlock b2 safety humidist...

Page 43

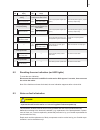

43 5.5.4 fuses f5 for heating voltage supply heating voltage max. Steam capacity [kg/h] model condair cp3 unit design ** nominal power [kw] nominal current [a] main fuses f5 [a] basic... Pro... 400v3 (400v/3~/50...60hz) 5...8 5...8 5...8 ek 6.0 8.7 3x 10 9...12 9...12 9...12 ek 9.0 13.0 3x 16 13...1...

Page 44

44 5.5.5 inserting the cp3 card all important operating parameters such as the maximum steam capacity, the heating voltage, the number of base units as well as the differentiation between main and extension unit are permanently stored on the cp3 card. Before you start the electrical installation, ch...

Page 45: 6 Operation

45 6 operation display and control unit function: configuration of the condair cp3. Indication of operating parameters. Reset of maintenance counter and error indication. Red led “error” function: the led lights in case of a malfunction of the unit. The type of malfunction is shown in the display, s...

Page 46

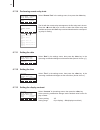

46 startup: cp3 pro init module xxxxxxxxxxxxxxxxxxxx menu set the steam humidifier carries out a system test, during which all the leds light up and the opposite display is shown. If a failure occurs on the system test, a corresponding error message is shown in the display. After the system test the...

Page 47

47 6.3.3 inspections during operation during operation the condair cp3 and the humidification system have to be inspected weekly. On this occasion check the following: • the water and steam installation for any leakage. • the steam humidifier and the other system components for correct fixing and an...

Page 48

48 demand :50% cp3 p90 400v3 xxxxxxxxxxxxxxxxxxxx xxxxxxxxxxxxxxxxxxxx 2014-01-21 12:00:00 menu set software :1.14la02 cp3 p90 400v3 controlsign.:0-10v limitsignal :0-10v modbus addr.:1 menu set power limit :100% cp3 p90 400v3 request a :50% request b :50% ∑ steam :45kg/h menu set cylindertype:a644 ...

Page 49

49 6.6 interrogation functions 6.6.1 interrogation of the operating information in the indication level in the normal operating mode the operating and display unit is in the indication level. The indication level forms a loop that includes several pages holding operating information which can be acc...

Page 50

50 6.6.2 interrogation of unit information select the list with the unit information: path: main menu > info > unit status press and keys, in order to select the unit information available in the list: 1 total operating hours since the initial commissioning. 2 actual current unit a (and b) 3 actual ...

Page 51

51 6.6.3 interrogation of the malfunction list select the error history list: path: main menu > info > errorhistory the last error that occurred is shown with: – running number of the error – date and time of occurrence (version pro only) – error code (warning: w..., error: e...) – error message – a...

Page 52

52 6.7 unit settings 6.7.1 launching the unit settings menu select the unit settings menu: path: main menu > user > password entry: 8808 > settings press the and keys in order to select the individual settings in the settings menu. Detailed information on the different settings are found in the foll...

Page 53

53 – hum.Control: selecting the control type. Factory setting: extern options: extern (external continuous controller), 24von/off (external on/off humidistat), int. (p) (internal p controller) int. (pi) (internal pi controller) – controlsign.: selecting the control signal. Note: this setting is avai...

Page 54

54 6.7.4 cylinder settings settings controls :set cylinder :set power limit :set language :english on/off timer :set esc set cylinder cyl. Number :644 cyl. Line :dispos esc set select “ cylinder” in the settings menu, then press the key. The cylinder settings appear. Press the and keys in order to s...

Page 55

55 settings cylinder :set power limit :set on/off timer :set controls :set gfci-mode :on esc set 6.7.5 setting the capacity limitation select “ power limit” in the settings menu, then press the key. With the parameters in the “power limit” submenu you determine whether the condair cp3 is to be opera...

Page 56

56 6.7.7 activating/deactivating fault current relay operation settings on/off timer :set gfci-mode :on multi-mode :sequence power limit :set water manag.:set esc set select “ gfci-mode” in the settings menu, then press the key. In the upcoming modification dialogue select whether or not the condair...

Page 57

57 6.7.9 water management settings select “ water manag.” in the settings menu, then press the key. The water management settings menu appears. Press the and keys in order to select the individual settings and press the key to call up the modification dialogue for the selected setting. Settings mult...

Page 58

58 6.7.10 performing remote relay tests settings water manag.:set remote test :set date :19.10.07 multi-mode :sequence time :12:00 esc set select “ remote test” in the settings menu, then press the key. The list with the remote relay tests appears, the first relay test is shown. Press the and keys i...

Page 59

59 6.8 modbus settings select the modbus menu: path: main menu > user > password entry: 8808 > modbus the modbus menu appears. In the modbus menu you can set the com- munication parameters for the modbus interface on the control board (network) and for the modbus interface on the power board (remote...

Page 60: 7 Maintenance

60 7 maintenance qualification of personnel all maintenance work must be carried out only by well qualified and trained personnel authorised by the owner. It is the owner’s responsibility to verify proper qualification of the personnel. General note the instructions and details for maintenance work ...

Page 61

61 7.2 maintenance list to maintain operational safety the condair cp3 steam humidifier must be maintained at regular in- tervals. This is differentiated between the f irst maintenance after approx. 500 operating hours (i), steam cylinder maintenance after the yellow led lights (ii) and annual maint...

Page 62

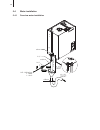

62 7.3 removing and installing parts for maintenance 7.3.1 removal and installation of the steam cylinder 1. Use a screwdriver to undo the two screws fixing the front panel to the unit, then remove the front panel. 2. Units with steam hose connector in housing top: release the two hose clamps on the...

Page 63

63 5. Carefully lift steam cylinder away from the cylinder receptacle, then remove it to the front. Caution! Put steam cylinder down carefully to avoid damage to the lower connection piece! Installation of the steam cylinder follows the reverse sequence. Observe the following: – before installing th...

Page 64

64 7.3.2 disassembly and assembly of the cleanable steam cylinder type d... 1. Fasten electrode snap fastenings and push electrodes approx. 2 cm downwards into the steam cylinder. 2. Release clamp clips of the cylinder cover and raise cover. 3. Remove carefully electrodes by lifting upwards. 4. Remo...

Page 65

65 7.3.3 removal and installation of the water cup and the water hoses to improve accessibility for removing the water cup and the water hoses we recommend to remove the steam cylinder first (see chapter 7.3.1). 1. Release hose clamps using pliers, then disconnect all hoses from the corresponding co...

Page 66

66 7.3.4 removal and installation of the drain pump the steam cylinder does not need to be removed when removing the drain pump. 1. Detach electric cables (polarity of the cables must not be observed). 2. Release hose clamps and remove the hoses from the connectors. 3. Pull the drain pump off the ho...

Page 67

67 7.4 notes on cleaning the unit components unit component what to clean and how to clean steam cylinder cover steam cylinder body cylinder strainer • knock off or brush away any limescale as much as pos- sible (do not use a wire brush). If the parts are heavily calcified, place them in an 8% formi...

Page 68

68 unit component what to clean and how to clean drain pump o-ring pump wheel • use a brush to remove any limscale from the pump hous- ing and the pump wheel (do not use a wire brush). • then, wipe pump wheel with a damp cloth. Wash the pump housing with a lukewarm soap solution and rinse well with ...

Page 69

69 7.5 notes on cleaning agents only use cleaning agents stated in the table above. The use of disinfectants is only permitted if they do not leave any toxic residues. In any case the parts must be thoroughly rinsed with water after cleaning. Warning! Formic acid is indeed harmless to the skin, but ...

Page 70: 8 Troubleshooting

70 8 troubleshooting important! Most operational malfunctions are not caused by faulty equipment but rather by improper installation or disregarding of planning guidelines. Therefore, a complete fault diagnosis always in- volves a thorough examination of the entire system. Often, the steam hose conn...

Page 71

71 warning error cause remedy led display led display hardware fault ––– ––– red lights error e10: flash r/w fault control board defective. Replace control board. ––– ––– error e11: clock r/w fault backup battery on control board discharged. Let have the backup battery be replaced (see chapter 8.4)....

Page 72

72 warning error cause remedy led display led display no electrode current for more than 20 minutes no electrode current for more than 4 hours ––– warning w23a: no current red lights error e23a: no current phase failure heating voltage. Inspect/turn on service switch of the mains supply line. Inspec...

Page 73

73 8.2 resetting the error indication (red led lights) to reset the error indication: disconnect the steam air humidifier from the mains. Wait approx. 5 seconds, then reconnect the unit to the mains. Note: if the fault has not been eliminated, the error indication reappears after a short while. 8.3 ...

Page 74

74 8.4 replacing the backup battery on the control board of the condair cp3 pro 1. Set the condair cp3 out of operation as described in chapter 6.4, disconnect it from the mains and secure the unit against inadvertent power-up. 2. Undo the two screws of the front cover, then remove the front cover. ...

Page 75

75 9 taking out of service/disposal 9.1 taking out of service if the condair cp3 must be replaced or if the humidification system is not needed any more, proceed as follows: 1. Take the unit out of operation as described in chapter 6.4. 2. Have the unit (and all other system components, if necessary...

Page 76: 10 Product Specifications

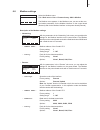

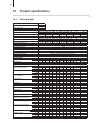

76 10 product specifications 10.1 technical data heating voltage 230v/1~/50..60hz unit model: basic pro 5...8 steam capacity in kg/h: 5...8 max. Power consumption in kw 3.8...6.0 heating voltage 230v/3~/50..60hz unit model: basic pro basic pro basic pro basic pro basic pro pro pro 5...8 9...15 16......

Page 77

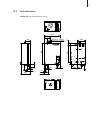

77 10.2 unit dimensions condair cp3 5...15 (dimensions in mm) 456 178 177 73 28 105 71 93 34 40 280 150 228 51 180 90 500 620 28 ø22.5 (5...8 kg/h) ø30.0 (9...15 kg/h).

Page 78

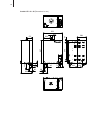

78 condair cp3 16...45 (dimensions in mm) 559 228 ø45 667 40 28 105 71 175 34 93 350 73 177 284 51 216 144 545 32.

Page 79

© condair ltd., printed in switzerland technical modifications reserved.

Page 80

Consulting, sales and service: manufacturer: condair ltd. Member of the walter meier group talstrasse 35-37, 8808 pfäffikon, switzerland ph. +41 55 416 61 11, fax +41 55 416 62 62 info@condair.Com, www.Condair.Com reg.No. 40002-2.