- DL manuals

- Condair

- Humidifier

- DL

- Installation Manual

Condair DL Installation Manual

Summary of DL

Page 1

Installation manual adiabatic air humidification system condair dl 2577868 en 1502 humidification and evaporative cooling.

Page 2

Thank you for choosing condair installation date (mm/dd/yyyy): commissioning date (mm/dd/yyyy): site: model: serial number: manufacturer condair ltd. Talstrasse 35-37, ch-8808 pfäffikon ph. +41 55 416 61 11, fax +41 55 416 62 62 info@condair.Com, www.Condair.Com proprietary notice this document and ...

Page 3: Contents

3 contents contents 1 introduction 4 1.1 to the very beginning 4 1.2 notes on the installation manual 4 2 for your safety 6 3 important notes on installation 8 3.1 delivery 8 3.2 storing/transportation/packaging 8 3.3 product designation 9 4 installation 10 4.1 installation overview 10 4.2 installat...

Page 4: Introduction

4 introduction 1 introduction 1.1 to the very beginning we thank you for having purchased the adiabatic air humidification system condair dl. The adiabatic air humidification system condair dl incorporates the latest technical ad van ces and meets all recognized safety standards. Nevertheless, impro...

Page 5

5 introduction symbols used in this manual caution! The catchword “caution” used in conjunction with the caution symbol in the circle designates notes in this installation manual that, if neglected, may cause damage and/or malfunction of the unit or other material assets. Warning! The catchword “war...

Page 6: For Your Safety

6 for your safety 2 for your safety general every person working with the adiabatic air humidification system condair dl must have read and under- stood this installation manual and the operation manual of the condair dl before carrying out any work. Knowing and understanding the contents of the ins...

Page 7

7 for your safety preventing unsafe operation all persons working with the adiabatic air humidification system condair dl are obliged to report any alterations to the unit that may affect safety to the owner without delay and to secure such systems against accidental power-up. Prohibited modificatio...

Page 8

8 important notes on installation 3 important notes on installation 3.1 delivery after receiving: – inspect shipping boxes for damage. Any damages of the shipping boxes must be reported to the shipping company. – check packing slip to ensure all parts has been delivered. All material shortages are t...

Page 9

9 important notes on installation 3.3 product designation the product designation and the most important unit data are found on the rating plate fixed on the right side of the control unit. Notes regarding the rating plate and the product key can be found in the operation manual of the con- dair dl..

Page 10: Installation

10 installation 4 installation 1 - mounting the post evaporation unit --> see chapter 4.2 – installation of the humidification unit 2 - mounting the nozzle system --> see chapter 4.4 – positioning and mounting the control unit 3 - mounting the control unit --> see chapter 4.4 – positioning and mount...

Page 11

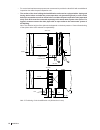

11 installation 4.2 installation of the humidification unit 4.2.1 positioning of the humidification unit usually, the design and dimensioning of the ventilation duct/ahu as well as the location of the humidifi- cation system condair dl inside the duct are determined, recorded and set compulsory when...

Page 12

12 installation – for control and maintenance purposes we recommend to provide the duct/ahu with an additional inspection door after the post-evaporation unit. – the section of the duct holding the humidification unit must be equipped with a sloping tub having drains before and after the post-evapor...

Page 13

13 installation 4.2.2 mounting the post-evaporation unit 1. Marking the positions of the fastening elements inside the duct/ahu: • mark the position of the topmost fastening holes (or welding studs) for the fastening of the lateral supports of the post-evaporation unit “a”, the nozzle system “c” and...

Page 14

14 installation 2. Mount the lateral supports of the post-evaporation unit to the duct walls: • align the lateral supports with the “top” labeled mounting bracket on top with an identical dis- tance to the duct ceiling (target measure ”a”: 65 mm, admissible range: 0...90 mm) and with a distance “b” ...

Page 15

15 installation 3. Mounting the fastening profiles for the upper sealing plates: • if not done already in step 1, mark the position of the outmost fastening holes for the fastening of the leftmost and rightmost fastening profiles for the upper sealing plates “d” on the duct ceiling using the bended ...

Page 16

16 installation 4. Mounting the fastening profiles for the lateral sealing plates: • if not done already with the drilling template in step 1, mark the position of the lateral fastening profiles for the lateral sealing plates on both sides of the duct. Distance between fastening profiles and post-ev...

Page 17

17 installation 5. Mount the cross members: note: this step must be carried out only on air ducts /ahu's with a width >1650 mm. • for air ducts/ahu's with a width >2000 mm the cross members are supplied in sections and must be bolted together on site. Proceed as follows: undo the screw connections o...

Page 18

18 installation 6. Mount the vertical support(s): note: this step must be carried out only on air ducts /ahu's with a width >1650 mm. • for air ducts/ahu's with a height >2000 mm the vertical supports are supplied in sections and must be bolted together on site. Proceed as follows: undo the screw co...

Page 19

19 installation • mark horizontal position(s) of the vertical support(s) on the cross members (one vertical sup- port is always in the middle of the duct, several vertical supports must be evenly allocated over the duct width). From the front (view in air flow direction) attach the vertical support(...

Page 20

20 installation 7. Mounting the lateral sealing plates: • start on the bottom shift the lateral sealing plates with the slightly bent surface behind the fasten- ing profiles. Make sure the sealing plates on top of each other covers and overlaps the subjacent sealing plate. Slightly tighten the self-...

Page 21

21 installation 8. Inserting ceramic support profiles: • insert the ceramic support profiles into the lowest row of holders. Make sure the support profiles are inserted such that the pins on each side of the support profile are outside of the holder. Abb. 10: inserting ceramic support profiles pin p...

Page 22

22 installation 9. Mounting the tub rubber sealing: • fix tub rubber sealing with the clips to the ceramic support profiles as shown below (longer part of the clip is on the side of the rubber sealing). Cut rubber sealing on both sides of the duct to the appropriate length. Make sure rubber sealing ...

Page 23

23 installation 10. Inserting ceramic carrier profiles: • insert the ceramic carrier profiles into holders. Make sure the carrier profiles are inserted such that the pins on each side of the carrier profile are outside of the holder. Abb. 12: inserting ceramic carrier profiles pin pin pin.

Page 24

24 installation 11. Mount the ceramic plates: • start from the bottom left (view in air flow direction) carefully hang the ceramic plates of the bot- tom row onto the carrier profiles, then align the row to the middle of the duct. Important: make sure, the very right and very left ceramic plates hav...

Page 25

25 installation 12. Mount the upper sealing plates: • starting on one side push the upper sealing plates underneath the fastening profiles until the they touch the ceramic plates of the topmost row. • carefully shift the very right and the very left sealing plate against the lateral sealing plates w...

Page 26

26 installation 4.2.3 mounting the nozzle system 1. Mount the lateral supports of the nozzle system to the duct walls: • align the lateral supports with the “top” labeled mounting bracket on top with an identical dis- tance to the duct ceiling (target measure ”a”: 65 mm, admissible range: 0...90 mm)...

Page 27

27 installation 2. Mount the cross members: note: this step must be carried out only on systems with two nozzle grids in the width. • for air ducts/ahu's with a width >2000 mm the cross members are supplied in sections and must be bolted together on site. Proceed as follows: undo the screw connectio...

Page 28

28 installation 3. Mount vertical support(s): note: this step must be carried out only on air ducts /ahu's with a width >2000 mm. • mark horizontal position(s) of the vertical support(s) on the cross members. From the back (view in air flow direction) attach the vertical support(s) with the same dis...

Page 29

29 installation 4. Hang up nozzle grid(s): • hang up nozzle grid into the holders, then push nozzle grid downwards until its comes to a stop. Repeat step for additional nozzle grid(s) if necessary. Abb. 18: hang up nozzle grid.

Page 30

30 installation 5. Mount housing feed throughs: • drill holes ø19 mm for the housing feed throughs at the desired position (distance between axes min. 55 mm) into the duct wall, then deburr the holes. Important: it is mandatory that the holes of the housing lead-throughs are below the lowest hose co...

Page 31

31 installation 6. Connect spray circuits to the housing feed throughs: • interconnect the spray circuits of the different nozzle grids (if more than on grid is present). Interconnect spray circuits with same colour only. • connect spray circuits to the appropriate housing feed throughs. Abb. 20: co...

Page 32

32 installation 4.3 positioning and mounting the central unit positioning the central unit – the central unit is designed for wall-mounting in interior spaces. Make sure that the construction (duct wall, pillar, etc.) to which the central unit is to be mounted, offers a sufficiently high load-bearin...

Page 33

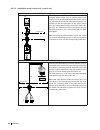

33 installation mounting the central unit abb. 21: mounting the central unit - dimensions in mm (inch) procedure 1. Mark the attachment points “a” for the two wall supports at the desired position with the help of a spirit level. 2. Fix the wall supports with the self-tapping screws 6.3 x 25 mm supp...

Page 34

34 installation 4.4 positioning and mounting the control unit positioning the control unit – the control unit is designed for wall-mounting in interior spaces. Make sure that the construction (duct wall, pillar, etc.) to which the control unit is to be mounted, offers a sufficiently high load-bearin...

Page 35

35 installation 210 52.5 52.5 (8.3 ") (2.1 ") (2.1 ") 315 (12.4 ") max. 1000 (max. 39.4 ") 64.5 (2.5") 450 (17.7") 300 (1 1.8") min. 200 (min. 7.9 ") min. 200 (min. 7.9 ") min. 600 (min. 23.6 ") a a a a b b mounting the control unit electrical isolator the electrical isolator (included in the delive...

Page 36

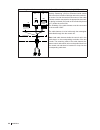

36 installation 4.5 water installation 4.5.1 overview water installation abb. 23: overview water installation ** for hygiene reasons it is not allowed to guide the drain water hose into a drain pipe equipped with a bore! Tundish with drain trap drain hose with constant downslope (min. 2%) to open tu...

Page 37

37 installation 4.5.2 notes on water installation general notes on installation of the hoses – use the supplied black plastic hoses ø10/8 mm and ø12/10 mm only. For hygienic reasons do not use other hoses (except products supplied by your condair distributor). Caution! Fully demineralised water is a...

Page 38

38 installation – if the conduit length between the water conditioning unit and the central unit of the condair dl exceeds 20 m, the supply conduit must be equipped with a suitable pressure damper (overflow valve, surge tank, etc.). Furthermore, the supply conduit must be properly fastened according...

Page 39

39 installation 4.6 electrical installation 4.6.1 notes on electrical installation danger! Danger of electric shock the control unit of the adiabatic air humidification system condair dl is mains powered. Live parts may be exposed when the control unit is open. Touching live parts may cause severe i...

Page 40

40 installation 4.6.2 wiring diagram condair dl 3v cr2032 x1 x2 j1 rj45 bat sd x3 x4 x19 x5 x6 x7 f1 (6.3 at) f2 (630 mat) x9 x8 x10 x20 x11 x12 x13 x14 x15.1 x15.2 x16 j6 j10 j12 j14 j2 jp5: 10v jp4: 24v jp/tr b7 k1 b6 b5 s2 pe n/gnd l/24v p gnd 24v p d– gnd d+ 24v e gnd gnd 24v e 24v 3 gnd gnd gnd...

Page 41

41 installation 4.6.3 electrical connections between central unit and control unit 4.6.3.1 wiring diagram central unit - control unit 3v cr2032 rj45 bat sd a2 j7 j4 x1 x2 x3 x4 x19 x5 x6 x7 f1 (6.3 at) f2 (630 mat) x9 x8 x10 x20 x11 x12 x13 x14 x15.1 x15.2 x16 jp5 : 10v jp4 : 24v jp/tr pe n/gnd l/24...

Page 42

42 installation 4.6.3.2 installation work central unit - control unit connecting the motor cable (mc) to the frequency converter (type a only) u1 pe w v u 3 2 1 m1 mc pe l3 l2 l1 m 3~ z z 3 2 1 control unit central unit ex factory the motor cable is connected to the frequency converter inside contro...

Page 43

43 installation connecting the cable harness “valves” (ch2) x3 x4 x5 x6 24v scb gnd 24v p 24v p 24v sca y2 y1 y10 y9 y8 y7 y6 y5 ps1 ps2 ps3 level/t gnd 24v p 24v p y11 y4 y3 y8 braun / grün y9 weiss / gelb y7 weiss / g rü n y6 rot / blau y5 grau / p ink y10 gelb / braun y1 weiss / grau y5 weiss y6 ...

Page 44

44 installation connecting the cable harness “ag-ionisation” and ”conductivity measuring” (ch3) x2 24v 3 gnd gnd gnd 24v 1 24v 2 ag+ ag– cnd w1 cnd w2 tmp w1 tmp w2 gnd t1 b1 x18 x17 ch3 gelb grün braun weiss braun weiss gelb grün ag+ lf control unit central unit ex factory the cable harness “ag-ion...

Page 45

45 installation 4.6.4 external electrical connections 4.6.4.1 wiring diagram external electrical connections b7 k1 b6 b5 s2 + – y b4 linkup rs485 bms rs485 rj45 etnernet 3v cr2032 x1 x2 j1 rj45 bat sd x3 x4 x19 x5 x6 x7 f1 (6.3 at) f2 (630 mat) x9 x8 x10 x20 x11 x12 x13 x14 x15.1 x15.2 x16 j6 j10 j1...

Page 46

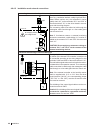

46 installation 4.6.4.2 installation work external connections connecting the external safety chain x1 b7 k1 b6 b5 sc2 sc1 j3 control unit do not apply extrane- ous voltage via k1! The potential-free contacts of external moni t or ing de- vices (e.G. Ventilation interlock, safety high limit humi- di...

Page 47

47 installation connecting the external enable switch x16 j1 s2 24/10v tmp gnd hum 24v e enable control unit do not apply extraneous voltage via s2! The potential-free contact of external enable contact is connected to the terminals “24v” and “enable” of the terminal block “x16” on the driver board ...

Page 48

48 installation connecting the mains voltage supply l n pe pe l n f3 q sf control unit snap ferrite: lead wires twice through bore of snap ferrite high leakage current! Connect 2x protective earthing conductor the mains voltage supply (l1, n and 2xpe) is to be connected to terminals xe1 in accordanc...

Page 49

Notes.

Page 50

Notes.

Page 52

Condair ltd. Talstrasse 35-37, ch-8808 pfäffikon phone +41 55 416 61 11, fax +41 55 416 62 62 info@condair.Com, www.Condair.Com consulting, sales and service:.