- DL manuals

- Condair

- Humidifier

- EL

- Installation Manual

Condair EL Installation Manual

Summary of EL

Page 1

En 1603 humidification and evaporative cooling planning- and installation manual steam humidifier condair el.

Page 2

Thank you for choosing condair installation date (mm/dd/yyyy): commissioning date (mm/dd/yyyy): site: model: serial number: manufacturer condair group ag talstrasse 35-37, ch-8808 pfäffikon ph. +41 55 416 61 11, fax +41 55 416 62 62 info@condair.Com, www.Condair.Com proprietary notice this document ...

Page 3: Contents

3 contents contents 1 introduction 5 1.1 to the very beginning 5 1.2 notes on the installation manual 5 2 for your safety 7 3 product overview 9 3.1 calculating the maximum required steam capacity 9 3.2 models overview 10 3.2.1 single units small ("s"), el 5...15 and medium ("m"), el 20...45 10 3.2....

Page 4

4 contents 5.6 notes on humidity control systems/humidity control 52 5.6.1 system 1 – room humidity control 52 5.6.2 system 2 – room humidity control with continuous limitation of the supply air humidity 52 5.6.3 system 3 – supply air humidity control with continuous output limit ation 53 5.6.4 whic...

Page 5: Introduction

5 introduction 1 introduction 1.1 to the very beginning we thank you for having purchased the condair el steam humidifier. The condair el steam humidifier incorporates the latest technical ad van ces and meets all recognized safety standards. Nevertheless, improper use of the condair el steam humidi...

Page 6

6 introduction symbols used in this manual caution! The catchword "caution" used in conjunction with the caution symbol in the circle designates notes in this installation manual that, if neglected, may cause damage and/or malfunction of the unit or damage to property. Warning! The catchword "warnin...

Page 7: For Your Safety

7 for your safety 2 for your safety general every person, who is in charge of the installation work on the condair el must have read and understood this installation manual and the condair el operation manual before carrying out any work. Knowing and understanding the contents of the installation ma...

Page 8

8 for your safety preventing unsafe operation all persons working with the condair el are obliged to report any alterations to the unit that may affect safety to the owner without delay and to secure the condair el against accidental power-up. Prohibited modifications to the unit no modifications mu...

Page 9: Product Overview

9 product overview m d = • (x 2 -x 1 ) v • p 1000 m d = • (x 2 -x 1 ) v 1000 • ε oder 3 product overview 3.1 calculating the maximum required steam capacity the maximum required steam capacity must be calculated based on one of the following formulas: m d : maximum steam demand in kg/h v: volume of ...

Page 10

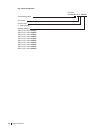

10 product overview 3.2 models overview condair el steam humidifiers are available as single units with different housing sizes (s, m and l), as double units (2 x "m") and as linkup systems (3 x "m" or 4 x "m") with different heating voltages and steam capacities ranging from 5 kg/h up to a maximum ...

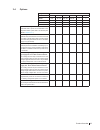

Page 11

11 product overview 3.2.2 single units large ("l"), el 50...90 housing size condair el 200v/1~ 230v/1~ 240v/1~ 200v/3~ 230v/3~ 400v/3~ 415v/3~ 440v/3~ 460v/3~ 480v/3~ 500v/3~ 600v/3~ kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h l ...50... –– –– –– –– –– 50.0 50.0 –– –– –– –– –– ...60....

Page 12

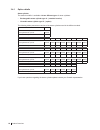

12 product overview 3.2.3 double units (2 x "m"), el 35...90 housing size condair el 200v/1~ 230v/1~ 240v/1~ 200v/3~ 230v/3~ 400v/3~ 415v/3~ 440v/3~ 460v/3~ 480v/3~ 500v/3~ 600v/3~ kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h 2*m ...35... –– –– –– 2*17.5 2*17.5 –– –– –– –– –– –– –– .....

Page 13

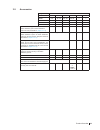

13 product overview 3.2.4 linkup systems (3 x "m"), el 70...135 housing size condair el 200v/1~ 230v/1~ 240v/1~ 200v/3~ 230v/3~ 400v/3~ 415v/3~ 440v/3~ 460v/3~ 480v/3~ 500v/3~ 600v/3~ kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h 3*m ...70... –– –– –– –– 3*23.3 –– –– –– –– –– –– –– ......

Page 14

14 product overview 3.2.5 linkup systems (4 x "m"), el 105...180 housing size condair el 200v/1~ 230v/1~ 240v/1~ 200v/3~ 230v/3~ 400v/3~ 415v/3~ 440v/3~ 460v/3~ 480v/3~ 500v/3~ 600v/3~ kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h kg/h 4*m ...105... –– –– –– –– 4*26.3 –– –– –– –– –– –– –– ....

Page 15

15 product overview 3.3 product designation the identification of the unit is found on the specification label. Fig. 6: location of the specification label condair ltd, talstrasse 35-37, ch-8808 pfäffikon type: condair el 400v3 serial: xxxxxxx 07.15 voltage: 400v 3~ / 50...60hz el. Power: 30.0 kw / ...

Page 16

16 product overview key model designation example: condair el 50 l 400v/3~ product designation unit model: housing size: l: large housing heating voltage: 230v/1~/50...60hz: 230v/1~ 200v/3~/50...60hz: 200v/3~ 230v/3~/50...60hz: 230v/3~ 400v/3~/50...60hz: 400v/3~ 415v/3~/50...60hz: 415v/3~ 440v/3~/50...

Page 17

17 product overview 3.4 options voltage condair el 200...240v/1~ 5...8 10 --- --- --- --- 200v/3~ 5...8 10...15 20...30 35...60 --- --- 230v/3~ 5...8 10...15 20...30 35...60 70...90 105...120 400...415v/3~ 5...8 10...15 20...30 50...90 105...135 152...180 440...600v/3~ 5...8 10...15 20...45 50...90 ...

Page 18

18 product overview 3.4.1 option details steam cylinder the steam humidifier is available with two different types of steam cylin ders: – exchangeable steam cylinder type a... (standard version) – cleanable steam cylinder type d... (option) the following tables present an overview of the steam cylin...

Page 19

19 product overview 3.5 accessories voltage condair el 200...240v/1~ 5...8 10 --- --- --- --- 200v/3~ 5...8 10...15 20...30 35...60 --- --- 230v/3~ 5...8 10...15 20...30 35...60 70...90 105...120 400...415v/3~ 5...8 10...15 20...30 50...90 105...135 152...180 440...600v/3~ 5...8 10...15 20...45 50.....

Page 20

20 product overview 3.5.1 accessory details 3.5.1.1 dv41-..., dv61-... And dv81-... Steam distribution pipes the steam distribution pipes are selected on the basis of the duct width "b" (for horizontal installation) or the duct height "h" (for vertical installation) and the capacity of the steam hum...

Page 21

21 product overview 3.5.1.2 optisorp steam distribution system the optisorp steam distribution system is used in ventilation ducts with a short humidification distance (for the calculation of the humidification distance refer to chapter 5.4.2 ). When ordering an optisorp system the duct dimension mu...

Page 22

22 product overview 3.5.1.3 blower pack the blower packs – in combination with the steam humidifiers condair el – are used for direct room humidification. The blower packs are mounted directly on the humidifier or separately above the humidifier to the wall. Note: further information on the blower p...

Page 23: Receiving and Storage

23 receiving and storage 4 receiving and storage 4.1 inspection after receiving: – inspect shipping boxes for damage. Any damages of the shipping boxes must be reported to the shipping company without delay. – check packing slip to ensure all parts has been delivered. All material shortages are to b...

Page 24

24 receiving and storage 4.2 storage and transportation storing until installation store the condair el in its original packaging in a protected area meeting the following requirements: – room temperature: 5 ... 40 °c – room humidity: 10 ... 75 %rh transportation for optimum protection always transp...

Page 25

25 mounting and installation work 5 mounting and installation work 5.1 safety notes on mounting and installation work qualification of personnel all mounting and installation work must be carried out only by well qualified personnel authorised by the owner. It is the owner’s responsibility to verify...

Page 26

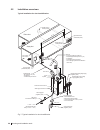

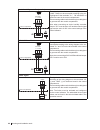

26 mounting and installation work 5.2 installation overviews typical installation for duct humidification fig. 7: typical installation for duct humidification z261 dv41 dv61 dv81 ks10 ds80 ds60 ds22 humidity sensor or humidity controller return duct supply duct humidity sensor or humidity controller...

Page 27

27 mounting and installation work typical installation for room humidification fig. 8: typical installation for room humidification z261 bp bp ds80 ks10 humidity sensor or humidity controller steam line – as short as possible (max. Length 4 m) – adequate upslope/downslope min.15 % (8.5°) – no restri...

Page 28

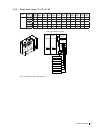

28 mounting and installation work y x z min. 50 mm * min. 600 mm min. 50 mm * min. 400 mm min. 600 mm * recommended.: 250 mm 50 mm 50 mm 50 mm 50 mm 50 mm 50 mm extension a extension a extension b main b main b main a main a modul b modul a 5.3 mounting the unit 5.3.1 notes on locating the unit fig....

Page 29

29 mounting and installation work the installation location of the condair el depends largely on the location of the steam distributor (see chapter 5.4.2 ). To ensure proper functioning of the steam humidifier and to obtain an optimal efficiency, the following points must be considered and observed ...

Page 30

30 mounting and installation work dimension housing size el 5...15 ("s") el 20...45 ("m") "a" in mm 193.5 193.5 "b" in mm 304.8 406.4 "c" in mm 57.6 61.8 weights housing size el 5...15 ("s") el 20...45 ("m") netweight in kg 24.1 34.5 operating weight in kg 34.1 58.6 5.3.2 mounting the humidifier ove...

Page 31

31 mounting and installation work dimension housing size el 50...90 ("l") "a" in mm 243.5 "b" in mm 406.4 "c" in mm 117.2 weights housing size el 50...90 ("l") netweight in kg 57.3 operating weight in kg 105.0 overview wall mounting single units large ("l") fig. 11: overview wall support mounting si...

Page 32

32 mounting and installation work procedure 1. Mark the attachment points "a" for the wall support at the desired position with the help of a spirit level. Then, drill holes diameter: 10 mm, depth: 50 mm. 2. Insert the supplied plastic plugs, and fix the wall support to the wall with the screws and ...

Page 33

33 mounting and installation work 5.4 steam installation 5.4.1 overview steam installation for duct humidification fig. 12: overview steam installation for duct humidification dv41 ks10 ds80 ds60 ds22 dv61 dv81 steam line – as short as possible (max. Length 4 m) – adequate upslope/downslope min.15 %...

Page 34

34 mounting and installation work fig. 13: overview steam for room humidification ks10 ds80 bp bp steam line – as short as possible (max. Length 4 m) – adequate upslope/downslope min.15 % (8.5°) – no restrictions – condensate trap at the lowest point – hose or fixed pipe (with same inner diameter as...

Page 35

35 mounting and installation work 5.4.2 positioning of the steam distributor the location of the steam distributor should be determined at the time of dimensioning the air condition- ing system. Please note the following instructions to ensure proper humidification of the duct air. Calculating the a...

Page 36

36 mounting and installation work example given φ 1= 30 %rh, φ 2= 70 %rh absorption distance b n : 1,4 m (0.36 m for steam distribution system optisorp) note: if the absorption distance has to be reduced for technical reasons, the amount of steam per unit must be divided between several steam distri...

Page 37

37 mounting and installation work before diffuser before humidity limit controller / sensor 1 x b n 5 x b n before/after filter/heater + 1.5 x b n * (1.97") 50 mm 2,5 x b n before aerosol filter before/after fan, zone exit (1.97") 50 mm 1 x b n 1 x b n.

Page 38

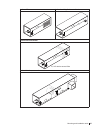

38 mounting and installation work installation notes the steam distribution pipes are designed for either horizontal installation (on the duct wall) or, with ac- cessories, for vertical installation (in the duct floor). The outlet orifices should always point upwards and at right angles to the airfl...

Page 39

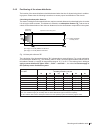

39 mounting and installation work h 1/5 1/5 1/5 2/5 h min.= 600 mm h 1/5 1/5 1/5 2/5 gmin gmin h min.= 500 mm g min.= 150 mm h 1/4 1/4 1/4 1/4 h min.= 400 mm h min.= 720 mm h 1/6 1/6 1/6 1/6 2/6 h min.= 600 mm g min.= 150 mm h 1/6 1/6 1/6 1/6 2/6 gmin gmin gmin h min.= 500 mm h 1/5 1/5 1/5 1/5 1/5 n...

Page 40

40 mounting and installation work guidelines for dimensioning the ventilation ducts – to facilitate the installation of the steam distribution pipes and for control purposes, a sufficiently sized control opening should be planned. – within the range of the absorption distance, the ventilation duct s...

Page 41

41 mounting and installation work 5.4.4 positioning and mounting of the blower packs (accessory bp) the blower packs can either be mounted directly on the humidifier or separately above the humidifier to the wall. To allow the steam coming from the blower pack to spread out evenly, without condensin...

Page 42

42 mounting and installation work 5.4.5 installing the steam and condensate lines installations notes – use original steam and condensate hose from your condair representative or solid steam pipes from copper or stainless steel (min. Din 1.4301) exclusively. Steam and condensate lines from other mat...

Page 43

43 mounting and installation work installation examples fig. 15: steam distributor mounted more than 500 mm above the top edge of the humidifier Ømin. 200 mm Ømin. 200 mm rmin. 300 mm rmin. 300 mm min. 300 mm min. 300 mm max. 4 m max. 4 m min. 300 mm min. 300 mm accessory: vs-dv....

Page 44

44 mounting and installation work fig. 16: steam distributor mounted less than 500 mm above the top edge of the humidifier obstacle install condensate drain (full size t) at the lowest point Ømin. 200 mm rmin. 300 mm min. 300 mm max. 4 m min. 300 mm Ømin. 200 mm Ømin. 200 mm rmin. 300 mm rmin. 300 m...

Page 45

45 mounting and installation work fig. 17: steam line with solid piping and insulation steam line must be insolated over the entire length! Max. 4 m Ømin. 200 mm rmin. 5 x d min. 300 mm min. 300 mm.

Page 46

46 mounting and installation work 5.4.6 common steam and condensate line errors wrong correct 1 steam line not led at least 11.81" (300 mm) perpendicularly upwards before first bend (forming of condensate). Lead steam line at least 11.81" (300 mm) perpendicularly upwards before first bend. 2 minimum...

Page 47

47 mounting and installation work 5.4.7 inspecting the steam installation use the following check list to ensure that the steam installation was performed correctly: – steam distributor steam distributors (steam distribution pipe or optisorp steam distribution system) correctly positioned and secure...

Page 48

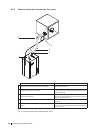

48 mounting and installation work 5.5 water installation 5.5.1 overview water installation fig. 19: overview water installation for single units small ("s") and medium ("m") fig. 20: overview water installation for single units large ("l") filter valve (accessory) or shut-off valve and filter 5µm wa...

Page 49

49 mounting and installation work fig. 21: overview water installation for double units medium ("m ") filter valve (accessory) or shut-off valve and filter 5µm water drain connector ø30 mm water supply connector g 3/4" water supply pipe (supplied by others) drain hose (supplied) – internal diameter ...

Page 50

50 mounting and installation work 5.5.2 notes on water installation water supply the water supply is to be carried out according to the figure found in chapter 5.5.1 and the applicable local regulations for water installations. The indicated connection specifications must be observed. – the installa...

Page 51

51 mounting and installation work 5.5.3 inspecting the water installation check the following topics: – water supply has filter valve (accessory "z261") or shut-off valve and 5 µm water filter respectively been installed in supply line to each unit module? Has acceptable water pressure (without drai...

Page 52

52 mounting and installation work 5.6 notes on humidity control systems/humidity control 5.6.1 system 1 – room humidity control system 1 is suited for direct room humidification and air conditioning systems with mainly recir- culated air. The humidity sensor or humidistat respectively is preferably ...

Page 53

53 mounting and installation work a1/2 humidity sensor b1 ventilation interlock b2 airflow monitor b3 safety humidistat pi i internal pi controller pi e external pi controller y input signal from a1 z input signal from a2 5.6.3 system 3 – supply air humidity control with continuous output limit atio...

Page 54

54 mounting and installation work 5.6.5 admissible control signals control with external controller control with internal pi controller control signals humidity sensor signals 0...5 vdc 0...5 vdc 1...5 vdc 1...5 vdc 0...10 vdc (potentiometer 140 Ω ... 10 kΩ) 0...10 vdc (potentiometer 140 Ω ... 10 kΩ...

Page 55

55 mounting and installation work 5.7 electrical installation 5.7.1 notes on electrical installation danger! Danger of electric shock the condair el is mains powered. Live parts may be exposed when the unit is open. Touching live parts may cause severe injury or danger to life. Prevention: the conda...

Page 56

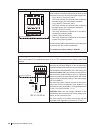

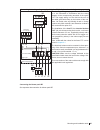

56 mounting and installation work l1 l2 l3 l1 l2 l3 pe q5 f5 200-600 v/3~/50..60 hz 200-240 v/1~/50..60 hz l1 n pe q5 f5 l1 l2 l3 k1 cs cyl. X0 140Ω...10kΩ a2 on/off a3 gnd in v+ in v+ b3 k2 b2 b1 l1 n pe f6 q6 230 v/1~/50..60 hz j3 230v/5a a4 + – + – a1 jp1 24v 10v jp1 24v 10v j1 l1 n pe m l2 l3 l1...

Page 57

57 mounting and installation work pe pe sc2 sc1 n l1 inlet spare/drain conta. Cont. Sign. Gnd in v+ 10v 24v cont. Inlet l1fu l1sw n main supply module b pe p1 n p lim. Sign. Gnd in spare drain switch l1sc nsw l1sc nsw l1sw nsw l1sw f1 (1 at) comm hb ok jp3 jp1 level low 24v gnd sc ok hws blower in 2...

Page 58

58 mounting and installation work pe pe sc2 sc1 n l1 inlet spare/drain conta. Cont. Sign. Gnd in v+ 10v 24v cont. Inlet l1fu l1sw n main supply module b pe p1 n p lim. Sign. Gnd in spare drain switch l1sc nsw l1sc nsw l1sw nsw l1sw f1 (1 at) comm hb ok jp3 jp1 level low 24v gnd sc ok hws blower in 2...

Page 59

59 mounting and installation work pe pe sc2 sc1 n l1 inlet spare/drain conta. Cont. Sign. Gnd in v+ 10v 24v cont. Inlet l1fu l1sw n main supply module b pe p1 n p lim. Sign. Gnd in spare drain switch l1sc nsw l1sc nsw l1sw nsw l1sw f1 (1 at) comm hb ok jp3 jp1 level low 24v gnd sc ok hws blower in 2...

Page 60

60 mounting and installation work legend a1 continuous humidity controller (active) or humidity sensor a2 ohmic humidity ontroller (passive), set jumper jp1 to 10v a3 on/off humidity controller, set jumper jp1 to 24v a4 limiter signal b1 ventilation interlock b2 airflow monitor b3 safety humidistat ...

Page 61

61 mounting and installation work 5.7.6 installation work external connections connecting the external safety chain pe pe sc2 sc1 n l1 main supply k2 j3 b3 b2 b1 control compartment do not apply extraneous voltage via k2! Danger: 230 v the potential-free contacts of external moni t or ing de- vices ...

Page 62

62 mounting and installation work ohmic humidity controller (passive) cont. Sign. Gnd in v+ 10v 24v jp1 140Ω...10kΩ a2 jp1 10v 24v control compartment the signal cable of an ohmic humidity controller (140Ω...10kΩ) is to be connected according to the wir- ing diagram to the terminals "v+", "in" and g...

Page 63

63 mounting and installation work connecting the remote operating and fault indication h1 error 1 2 3 service f1 (100 ma) 4 5 6 steam 7 8 unit on 9 10 control compartment the remote operating and fault indication board contains four potential-free relay contacts for the connection of the following o...

Page 64

64 mounting and installation work connecting the accessory board (option) f1 (100 ma) h2 hyg. Valve a fan b 1 2 3 hyg. Valve b 4 5 6 7 8 fan a 9 10 control compartment the optional accessory board contains four potential-free relay contacts to activate external fans of the ahu and the optional valve...

Page 65

65 mounting and installation work connecting the heating voltage supply l1 l2 l3 l1 l2 l3 pe q5 f5 200-600 v/3~/50..60 hz 200-240 v/1~/50..60 hz l1 n pe q5 f5 l1 l2 l3 k1 x0 control compartment the heating voltage supply (l1, l2, l3 and pe or l1, n and pe) is to be connected in accordance with the w...

Page 66

66 mounting and installation work connecting the heating voltage supply via option tr (for 3 phase single voltage system) pe pe sc2 sc1 n l1 main supply l1 l2 l3 k1 l1 l2 l3 pe q5 f5 l2 l3 l1 l1 n pe 6.3 a, slow acting 500 ma, slow acting option tr control compartment the heating voltage supply (l1,...

Page 67

67 mounting and installation work connecting the heating voltage supply via option cvi (for 3 phase/neutral single voltage system) pe pe sc2 sc1 n l1 main supply l2 l3 l1 n pe l1 l1 l2 l3 n q5 f5 pe l1 l2 l3 k1 6.3 a, slow acting control compartment option cvi the heating voltage supply (l1, l2, l3,...

Page 68

68 mounting and installation work 5.7.7 inspecting the electrical installation check the following points: do the supply voltages for heating and control voltage comply with the relevant voltages stated on the specification label? Are the voltage supplies (heating and control voltage) correctly fuse...

Page 69: Product Specification

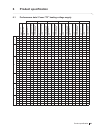

69 product specification 6 product specification 6.1 performance data / fuses "f3" heating voltage supply 200 v/1~/50...60hz 230 v/1~/50...60hz 240 v/1~/50...60hz 200 v/3~/50...60hz 230 v/3~/50...60hz 400 v/3~/50...60hz max. Steam capacity in kg/h nominal power max. In kw nominal current max. In a c...

Page 70

70 product specification 415v/3~/50...60 hz 440v/3~/50...60 hz 460v/3~/50...60 hz 480v/3~/50...60 hz 500v/3~/50...60 hz 600v/3~/50...60 hz max. Steam capacity in kg/h nominal power max. In kw nominal current max. In a cable cross section al min. In mm 2 heating voltage fuse „f5" in a, quick acting (...

Page 71

71 product specification 6.2 operating data control steam output – active 0…5 vdc, 1…5 vdc, 0…10 vdc, 2…10 vdc, 0…20 vdc, 0…16 vdc, 3.2…16 vdc, 0…20 madc, 4…20 madc – passive all potentiometric humidity sensors from 140 Ω…10 kΩ – on/off control off; ≥2.5 vdc…20 vdc --> on duct air pressure -0.8 kpa ...

Page 72: Appendix

72 appendix 7 appendix 7.1 unit dimensions 7.1.1 unit dimensions condair el 5 - 15, unit size "s" fig. 29: unit dimensions condair el 5 - 15, unit size "s" (dimensions in mm) 670 420 72 15.5 54 80.5 35 304.5 57.5 57.5 305 54 193.5 500 71.5 173.5 123 45 82.5 217 370 7 51 211.5 44 97 ø31 g 3/4" ø22 a ...

Page 73

73 appendix fig. 30: unit dimensions condair el 20 - 45 and 35 - 180, unit size "m" (dimensions in mm) 780 530 62 15.5 54 88.5 35 406.5 61.75 61.75 406.5 54 193.5 580 51 321.5 44 97 62 163.5 181.8 44.5 82.5 232 406 7 ø31 g 3/4" ø30 (a4../d4..) ø45 (a6../d6..) a a 2x ø8 (“a”) 36.5 7.1.2 unit dimensio...

Page 74

74 appendix fig. 31: unit dimensions condair el 50 - 90, unit size "l" (dimensions in mm) 406 7 780 1000 15.5 117 70 406.5 406.5 164 243.5 590 51 321.5 407 678 889 44 97 77 179 535.5 61.8 163.5 418 520 44.5 82.5 232 2x g 3/4" 2x ø31 4x ø8 (“a”) 2x ø45 a a a a 36.5 7.1.3 unit dimensions condair el 50...

Page 75

75 appendix 7.2 ec declaration of conformity.

Page 76

76 appendix 7.3 h,x diagram © 1501 • condair gmbh • www.Condair.De für 101325 pa/ meereshöhe.

Page 77

Notes.

Page 78

Notes.

Page 80

01.2016 condair cz / omyly a technické změny sk / omyly a technické zmeny flair, a.S. Flair, a.S., organizační složka slovensko stará vajnorská 37, 831 04 bratislava tel.: +421 244 632 567, fax: +421 244 632 569 info@flair.Sk; www.Flair.Sk flair, a.S. Jihlavská 512/52 140 00 praha 4 - michle tel.: +...