- DL manuals

- ConMed

- Medical Equipment

- 1000 SES

- Service Manual

ConMed 1000 SES Service Manual

Summary of 1000 SES

Page 1

Service manual english version smoke evacuation system 60-6852-eng (-).Qxd 2/1/99 12:40 pm page 1.

Page 2

Limited warranty for a period of two years following the date of delivery, conmed corporation warrants the conmed 1000ses tm smoke evacuation system against any defects in material or workmanship and will repair or replace (at conmed’s option) the same without charge, provided that routine maintenan...

Page 3: Table of Contents

Table of contents & list of illustrations 1.0 system description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1 1.1 introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.1 1.2 inspection . . ....

Page 4

1 control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1 2 back view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4 3 front view . . . . . . . . . . . . . . . . ....

Page 5: System Description

1.1 introduction the conmed 1000ses tm smoke evacuation system is designed to remove smoke and noxious odors produced by surgical smoke during laser and electrosurgical procedures. The conmed 1000ses tm has been designed with a high suction, high flow rate centrifugal action pump. The ultra-quiet mo...

Page 6

Caution - before connecting, read instructions. Type cf equipment class 1 protect against dripping water. Alternating current 1-2 • the conmed 1000ses tm filters are com- pletely disposable. Please handle these dispos- able filters according to your local codes or regulations and hospital policy. Th...

Page 7: Operating Instructions

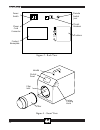

2.1 system controls the electronic system controls on the conmed 1000ses tm are easy to understand and simple to use. The membrane control panel contains the power on/off switch, suction power adjustment, remote activation indicator, filter reset button, fil- ter life indicator, and service indicato...

Page 8

2-2 reading the filter life indicator install a conmed 1000ses tm filter into the system per the installation instructions contained in this operator’s manual. When the system is turned on, the filter life indicator will light up all the green, amber and red led’s. This indicates full filter life. T...

Page 9

2-3 2. Attach unit power cord to the receptacle on the rear panel of the machine. Plug the three prong power connector into an appropriate power out- let. 3. Optional: attach either remote activator switch or footswitch by inserting the male footswitch plug into remote switch recep- tacle on rear of...

Page 10

2-4 figure 3 - front view figure 2 - back view power switch power cord connector circuit breakers remote switch jack cautions product nameplate i 0 ipx1 control panel filter inlet filter conmed 1000ses handle cooling vents power switch remote switch jack circuit breakers cautions power cord connecto...

Page 11: Maintenance

3.1 general maintenance information this section contains information for ordinary maintenance of the conmed 1000ses tm smoke evacuation system. While the unit has been designed and manufactured to high industry standards, it is recommended that periodic inspec- tion and performance testing be perfo...

Page 12

3-2 potential cause 1. Filter not seated completely. 2. Filter clogged. 3. Vacuum hose clogged. 4. Motor/blower obstructed. 1. Not plugged into electrical outlet. 2. Circuit breaker(s) tripped. 3. Footswitch plugged in. 4. Electronic system failure. 5. Main power switch in off position. Corrective a...

Page 13: Customer Service

Customer service section 4.0 4-1 4.1 equipment return for the quickest response to your service needs, please follow these procedures: step 1: write down the serial number of the conmed 1000ses tm . Step 2: call technical services at the numbers listed on the inside front cover of this manual and de...

Page 14

4-2 this page intentionally left blank. 60-6852-eng (-).Qxd 2/1/99 12:40 pm page 4-2.

Page 15: Theory of Operation

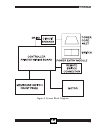

The conmed 1000 ses smoke evacuation filtration system is designed to remove smoke and noxious odors from the smoke plume gener- ated during the course of laser and electrosurgical procedures. The conmed 1000 ses is designed with a high suction and high flow rate centrifugal action pump. The ultra-q...

Page 16

5-2 ed at the factory. This approach allows quick repair with a minimum of downtime. The motor/blower is a specially designed high suction/high flow rate centrifugal air pump. This motor/blower is controlled by a triac on the con- troller pwb and runs on mains power. This motor/blower is rated at 11...

Page 17

5-3 figure 5 system block diagram 60-6852-eng (-).Qxd 2/1/99 12:40 pm page 5-3.

Page 18

5-4 this page intentionally left blank. 60-6852-eng (-).Qxd 2/1/99 12:40 pm page 5-4.

Page 19: Maintenance

6.1 cleaning after each procedure, clean the exterior of the conmed 1000 ses with an appropriate germi- cide. Avoid the use of abrasive cleaners. Also clean the inlet port of the filter with an appropriate germicide after each procedure and recap the filter inlet port. Replace vacuum hose and all si...

Page 20

6-2 nents which may point to the source of the prob- lem. Verify that all connections are clean and seat- ed properly and that all harness connections are sound and not shorting. Check the power cord and all other wiring for evidence of mechanical damage. Check the mains voltage against the nameplat...

Page 21

6-3 6.6 disassembly warning: service should only be attempted by qualified service personnel. Refer to section 4.0 for instructions on returning the unit to conmed for factory service. Caution: this device contains components which will be damaged by static electricity. Proper handling by a grounded...

Page 22

6-4 unscrew the remote switch jack using a socket wrench. Caution: for the next few steps, you will need to be electrically grounded. Remove the 6 screws from the circuit board using a screwdriver. Carefully remove the circuit board and place it in an anti-static holder. If necessary, using a chip p...

Page 23

6-5 figure 6 exploded view 60-6852-eng (-).Qxd 2/1/99 12:40 pm page 6-5.

Page 24

6-6 figure 7 insulation assembly 60-6852-eng (-).Qxd 2/1/99 12:40 pm page 6-6.

Page 25

6-7 figure 8 electrical schematic 60-6852-eng (-).Qxd 2/1/99 12:40 pm page 6-7.

Page 26

6-8 6.7 replacement parts lists # part number description qty. 1. Housing conm housing assembly 1 2. Motorcon120 motor #763-13 (100/120v versions only) 1 2. Motor220/240 motor 220/240 international (220/240v versions only) 1 3. Gskt mm con top 1/4", bottom 1/2", sc-42 silicone motor mount gaskets 1 ...