Connoisseur Models GWR Loriot M Instructions Manual

PROTOTYPE. The Great Western Railways designation Loriot, covered a range of

low floored wagons designed to carry agricultural machinery, traction engines and

other heavy road vehicles.

They were designed with a sloping floor so that a vehicle could be driven onto the

wagon from an end loading dock and then sit within the well of the wagon, chained

into place using the securing holes in the wagons side curb rail. This enabled tall

road vehicles to remain within the loading gauge but some traction engines

travelled with their chimneys removed and chained down separately onto batons.

The Loriot M was built by the GWR between 1925 and 1927 to diagram G14. They

carried running numbers 42197-42201 and ran in service well into BR days.

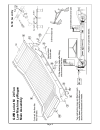

KIT. This is a very straightforward kit. Some push out rivet detail, a few parts

requiring simple folding and a selection of small detail parts make this an interesting

project.

Wheels are required to complete, 3’1”, 3 Hole Disc (Slater's Catalogue Number

7122). Available From Slater's Plastikard, Temple Rd, Matlock Bath, Matlock,

Derbyshire, DE4 3PG, Telephone 01629 583993.

Connoisseur Models, 33 Grampian Road, Penfields, Stourbridge,

DY8 4UE, Telephone 01384 371418

GWR Loriot M

20 Ton Low Machinery Wagon

- 0 Gauge -