- DL manuals

- DAB

- Water Filtration Systems

- DAB E.SYBOX

- Instruction For Installation And Maintenance

DAB DAB E.SYBOX Instruction For Installation And Maintenance

Summary of DAB E.SYBOX

Page 1

Instructions for installation and maintenance.

Page 2

Manual valid for firmware versions 4.X-1.X.

Page 3

English gb 37 index key 40 warnings 40 responsibility 41 1. General 41 1.1 description of the integrated inverter 42 1.2 integrated expansion vessel 42 1.3 integrated electropump 43 1.4 technical characteristics 44 2. Installation 44 2.1 vertical configuration 45 2.1.1 hydraulic connections 45 2.1.2...

Page 4

English gb 38 6.2 manual reset of error conditions 63 6.3 self-reset of error conditions 63 7. Reset and factory settings 64 7.1 general system reset 64 7.2 factory settings 64 7.3 restoring the factory settings 64 8. Particular installations 65 8.1 inhibiting self-priming 65 8.2 wall installation 6...

Page 5

English gb 40 the appliance may be used by children over 8 years old and by persons with reduced physical, sensory or mental capacities, or who lack experience or knowledge, on condition that they are under supervision or after they have received instructions con - cerning the safe use of the applia...

Page 6

English gb 41 responsibility the manufacturer does not vouch for correct operation of the electropumps or answer for any damage that they may cause if they have been tampered with, modified and/or run outside the recommended work range or in contrast with other indications given in this manual. The ...

Page 7

English gb 42 face f: as indicated by the label to be removed, the 1” cap next to the word “in” on face c has a dual function: in the case of horizontal installa - tion, the outlet that is closed by the cap acts as the system’s loading door (see below “loading operations”, par. 2.2.3); in the case o...

Page 8

English gb 43 the expansion vessel is preloaded with pressurised air through the valve accessible from the special maintenance compartment (fig.1, face f). The preload value with which the expansion vessel is supplied by the man - ufacturer is in agreement with the parameters sp and rp set as defaul...

Page 9

English gb 44 as the suction depth increases, the performance of the electro - pump decreases. 1.4 technical characteristics topic parameter e.Sybox mini electric power supply voltage 1 ~ 110-127 vac 1 ~ 220-240 vac frequency 50/60 hz maximum power 850 w structural characteri- stics overall dimensio...

Page 10

English gb 45 • the electrical connection is made in a dry place, far from any possible flooding. • the electrical system is provvided with a differential switch with i Δn ≤ 30 ma and that the earth system is efficient. If you are not sure of the absence of foreign bodies in the water to be pumped, ...

Page 11

English gb 46 the brass threads are housed in technopolymer seats. When making the connection watertight by adding material (e.G. Teflon, hemp,...) ensure that the gasket is not too thick: under the action of an adequate tightening torque (e.G. Long handled pipe wrench), the excess material could ex...

Page 12

English gb 47 • disengage the 4 screws at the corners of the panel using the acces - • do not remove the screws completely, just disengage them from thread on the product body. • be careful not to drop the screws into the system. • move the panel away, taking care not to pull on the signal transmis ...

Page 13

English gb 48 2.2.3 loading operation installation above head and below head with reference to its position with respect to the water to be pumped, the instal - lation of the system may be defined “above head” or “below head”. In particular the installation is defined “above head” when the pump is p...

Page 14

English gb 49 the thermal magnetic circuit breaker must be correctly sized (see electrical characteristics). 3.2 configuration of the integrated inverter the system is configured by the manufacturer to satisfy most installation cases operating at constant pressure. The main parameters set in the fac...

Page 15

English gb 50 4 - the keypad and the display the user interface is composed of a keypad with 128x240 pixel lcd dis - play and with power, comm, alarm warning leds as can be seen in figure 12. The display shows the values and the statuses of the device, with indica - tions on the functionality of the...

Page 16

English gb 51 access to the menus the various menus can be accessed from the main menu in two ways: 1 - direct access with a combination of keys. 2 - access by name with a drop-down menu. 4.1 direct access with a combination of keys the desired menu can be accessed directly by pressing simultaneousl...

Page 17

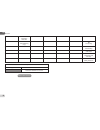

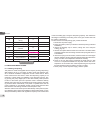

English gb 52 reduced menu (visible) extended menu (direct access or password) main menu user menu mode monitor menu set-minus setpoint menu mode-set manual menu set-minus-plus installer menu mode-set-minus tech. Assist. Menu mode-set-plus main (main page) status rs revs per minute vp pressure vf di...

Page 18

English gb 53 ve information hw e sw ff fault & warning (log) ay anti cycling ae anti-blocking af antifreeze rf reset faults and warnings pw modify password key identifying colours parameters available in version k. Table 3: menu structure.

Page 19

English gb 54 4.2 - access by name with a drop-down menu the selection of the various menus is accessed by name. From the main menu you access menu selection by pressing either of the + or – keys. The names of the menus that can be accessed appear on the menu selec - tion page and one of the menus i...

Page 20

English gb 55 if the case occurs the following may appear: fault indications warning indications specific icons the error conditions are indicated in table 8. The other displays are indi - cated in table 4. Error or status conditions shown on the main page identifying code description go motor runni...

Page 21

English gb 56 5 - meaning of the individual parameters the inverter makes the system work at constant pressure. This regulation is appreciated if the hydraulic plant downstream from the system is suitably sized. Plants made with pipes with too small a section introduce load losses that the equipment...

Page 22

English gb 57 5.1.11- ff: fault log display chronological display of the faults that have occurred during system op - eration. Under the symbol ff appear two numbers x/y indicating respectively the ault displayed and the total number of faults present; to the right of these numbers is an indication ...

Page 23

English gb 58 setting a pressure (sp) that is too high for the pump performance may cause false water lack errors bl; in these cases lower the set pressure. 5.4 - manual menu in manual operation, the sum of the input pressure and the max - imum pressure that can be supplied must not be greater than ...

Page 24

English gb 59 display (or use the selection menu pressing + or -). The menu allows you to view and modify various configuration parameters: the mode key al - lows you to scroll through the menu pages, the + and – keys allow you re - spectively to increase and decrease the value of the parameter conc...

Page 25

English gb 60 5.5.6 - t1: low pressure delay (function detecting low pressure on suction) sets the time when the inverter switches off after detecting low pressure on suction (see setting low pressure detection on suction par. 7.6.15.5). T1 can be set between 0 and 12 s. The factory setting is 2 s. ...

Page 26

English gb 61 each change of the password takes effect when mode or set is pressed and each subsequent change of a parameter implies typing in the new password again (e.G. The installer makes all the settings with the default pw value = 0 and lastly sets the pw so as to be sure that the machine is a...

Page 27

English gb 62 6.1 - description of blockages 6.1.1 - “bl” anti dry-run (protection against dry running) in the case of lack of water the pump is stopped automatically after the time tb. This is indicated by the red “alarm” led and by the letters “bl” on the display. After having restored the correct...

Page 28

English gb 63 full of water with temperatures close to freezing point, to avoid breakages of the system. This is the reason why it is recommended to empty any elec - tropump that is going to remain unused during the winter. However, this system has a protection that prevents ice formation inside by ...

Page 29

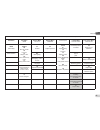

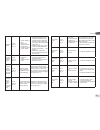

English gb 64 7.2 - factory settings the device leaves the factory with a series of preset parameters which may be changed according to the user’s requirements. Each change of the settings is automatically saved in the memory and, if desired, it is always possible to restore the factory conditions (...

Page 30

English gb 65 ms measuring system 0 (international) tb blockage time for water lack [s] 10 t1 low pr. Delay [s] 2 t2 delay in switching off [s] 10 gp proportional gain coefficient 0,5 gi integral gain coefficient 1,2 ae anti-blocking function 1(enable) af antifreeze 0 pw change password 0 (disabled)...

Page 31

English gb 66 9. Maintenance disconnect the power supply before starting any work on the sys - tem. The system requires no routine maintenance operations. However, below are the instructions for performing the special mainte - nance operations that may be necessary in particular cases (e.G. Emptying...

Page 32

English gb 67 9.2 - emptying the system if you want to drain the water out of the system, proceed as follows: 1. Disconnect the power supply; 2. Turn on the delivery tap closes to the system so as to remove pressure from the system and empty it as much as possible; 3. F there is a check valve immedi...

Page 33

English gb 68 drained, the salts dissolved in the water could have settled and formed calcification between the moving part (motor shaft) and the fixed part of the pump, thus increasing the resistance on starting. In this case it may be sufficient to help the motor shaft by hand to detach itself fro...

Page 34

English gb 69 9.5 - expansion vessel see paragraph 1.2 for the operations to check and adjust the air pressure in the expansion vessel and to replace it if it is broken. To access the valve of the expansion vessel, proceed as follows: 1. Remove the access door to the special maintenance compartment ...

Page 35

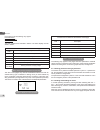

English gb 70 insufficient delivery red: off white: on blue: off 1. Suction depth too high. 2. Suction pipe clogged or diame - ter insufficient. 3. Impeller or hydrau - lic part clogged. 1. As the suction depth increases the hydraulic performance of the product decreases. Check whether the suction d...

Page 36

English gb 71 11 - disposal this product or its parts must be disposed of in an environment-friendly manner and in compliance with the local regulations concerning the envi - ronment; use public or private local waste collection systems. 12 - guarantee any use of faulty material or manufacturing def...