Service manual built-in dishwasher.

T able of c ontents section 1 - safe servicing practices ............................. 1-1 section 2 - operation ...................................................2-1 static fill ..............................................................................2-1 dynamic fill ............................

Page 1-1 s ection 1 - s afe s ervicing p ractices to avoid personal injury and/or property damage, it is important that safe servicing practices be observed. The following are some limited examples of safe practices: do not attempt a product repair if you have any doubts as to your ability to comple...

Page 2-1 d acor b uilt -i n d ishwasher s ervice m anual in order to address service issues with the dacor built-in dishwasher, the primary elements of its operation are described below, as well as its physical components. Static fill the cycle begins by activating the drain pump, ensuring the sump ...

Page 2-2 s ection 2 - o peration wash system once filling is complete, the dishwasher enters the pre-wash phase. The pre-wash phase conditions the soil with water and detergent to prepare it for removal in the main wash phase. Once water enters the tub, the pump draws the water into the sump through...

Page 2-3 d acor b uilt -i n d ishwasher s ervice m anual main wash/temp assure after the final reading by the soil sensor, the unit drains before starting to fill for the main wash. The tub fills, with the wash motor starting after the low level pressure switch is activated. The detergent dispenser ...

Rinse phases the first rinse phase follows the pre-wash portion of a wash cycle. During this rinse phase, the motor ramps up by 100rpm/second to full speed (2800rpm). Once at full speed, however, the motor will cycle between 1600rpm and 2800 rpm throughout the rest of this rinse phase. This motor ac...

Knowledge of the dishwasher’s cycles and systems is necessary in diagnosing any potential operational problems. Methods for diagnosing these problems, such as taking resistance readings and testing for closed circuits are outlined in the following section as well. Dishwasher control all of the funct...

Page 3-2 s ection 3 - c ycle , s ystems & c omponents component function test (continued) entering the water/service test from power failure while the control displays power failure or flashing lights, press and hold the short wash and the rinse & hold pads simultaneously for one second. The dishwas...

Component function test (continued) soil sensor test mode this tests the sensor for proper operation as well as the value that the sensor is detecting. To activate the test you must press and hold the heavy and start pads simultaneously. When the test mode is activated, the digit display will show t...

Inlet water valve (continued) to check inlet water valve disconnect dishwasher from power supply. To access electrical connections to valve, remove lower front panel. Using ohmmeter, check between p3-5 (yellow wire) and p3-8 (white wire). The resistance reading of the solenoid coil should be 1126 oh...

Low water level switch (continued) checking low water level switch disconnect power to dishwasher. Gain access to electronic control and check between p3-9 (orange wire) and p3-8 (white wire). This should be an open contact. These wires are connected to center terminal #1 and terminal to the right o...

High water level switch (continued) checking high water level switch checking continuity through the high water level switch is easier at the control. Disconnect power to dishwasher. Gain access to electronic control and check for continuity between the l1 black wire and p3-6 (brown wire). This cont...

Page 3-7 d acor b uilt -i n d ishwasher s ervice m anual heater the heater in this dishwasher is inline between the wash motor and the delivery tube. The 1200w heater wraps around a stainless steel core tube. The heater can only be energized, during a wash cycle, while the wash pump is running after...

Page 3-8 s ection 3 - c ycle , s ystems & c omponents checking the soil sensor while in idle mode, simultaneously press and hold heavy wash and start/cancel buttons. • this activates the sensor value test. • if a number does not display, continue with the test. Disconnect dishwasher from power suppl...

Page 3-9 d acor b uilt -i n d ishwasher s ervice m anual dispenser the dispenser consists of two dispensers in one housing, controlled by the use of one wax motor actuator. The first time the actuator is energized in the cycle, detergent is dispensed. The second time the actuator is energized, rinse...

Page 3-10 s ection 3 - c ycle , s ystems & c omponents fan dry unit dishes are dried with a fan driven condensate system. This system is made up of (refer to figures 20, 21): fan dry motor air intake condensate duct condensate vent as the dishwasher completes its final drain, the fan dry motor force...

Page 4-1 d acor b uilt -i n d ishwasher s ervice m anual safety precautions always turn off the electric power supply before servicing electrical components, testing with an ohmmeter, or replacing parts. Refer to safe servicing procedures at the front of this manual before servicing the dishwasher. ...

Page 4-2 s ection 4 - s ervice & d isassembly dispenser disconnect dishwasher from power supply. Remove outer door panel (see previous section for detailed instructions). Remove six screws securing dispenser assembly to inner door panel. Retainer brackets on the top and bottom may also need to be re...

Page 4-3 d acor b uilt -i n d ishwasher s ervice m anual upper spray arm the center of the upper spray arm is a locking mount. Turn upper spray arm and mount counterclockwise to remove. (see figure 28) to reinstall upper spray arm, line up locking posts in center mount with locking tabs on upper spr...

Page 4-4 s ection 4 - s ervice & d isassembly center spray arm and upper rack manifold remove upper rack and place rack upside down on a flat surface. Place blade of a very thin putty knife between retaining ring and center spray arm. Lightly twist knife to lift arm from retaining ring. (see figure ...

Page 4-5 d acor b uilt -i n d ishwasher s ervice m anual upper spray arm mount replacing upper spray arm mount requires removal of cabinet. See section on cabinet removal for detailed instructions. Set dishwasher upright and remove upper spray arm. The mount pushes into the top of the tub with a rub...

Page 4-6 s ection 4 - s ervice & d isassembly water valve disconnect dishwasher from power supply. Turn off water supply to dishwasher. Remove kick plate and lower access panel. Removal of outer door panel may be needed to gain access to necessary parts. Remove wire connect and water supply line. Re...

Page 4-7 d acor b uilt -i n d ishwasher s ervice m anual door spring remove dishwasher cabinet. See previous section detailed instructions. Raise spring support rod out of mounting hole of “c” arm. (see figure 38) reinstall door spring using reverse procedure. Hinge “c” arm remove dishwasher cabinet...

Page 4-8 s ection 4 - s ervice & d isassembly door seal retainer remove dishwasher cabinet. See cabinet removal for detailed instructions. Place dishwasher in an upright position and remove door seal. See previous section for detailed directions. Remove screws (across the top and on both sides of th...

Page 4-9 d acor b uilt -i n d ishwasher s ervice m anual thermistor/soil sensor disconnect dishwasher from power and water supplies. Remove drain line. Remove dishwasher from countertop. Lay dishwasher on its back on a protective pad. Remove wire plug from sensor by lifting lock to release plug. Pus...

Page 4-10 s ection 4 - s ervice & d isassembly drain pump disconnect dishwasher from power and water supplies. Remove drain line. Remove dishwasher from countertop. Lay dishwasher on its back on a protective pad. Remove wires from drain pump. Removing coupling hose with drain pump aids in pump remov...

Page 4-11 d acor b uilt -i n d ishwasher s ervice m anual wash motor (continued) capacitor disconnect dishwasher from power and water supplies. Remove drain line. Remove dishwasher from countertop. Lay dishwasher on its back on a protective pad. Capacitor is mounted to back frame of the unit using a...

Page 4-12 s ection 4 - s ervice & d isassembly blower assembly remove dishwasher cabinet. See cabinet removal for detailed instructions. After cabinet is removed, set unit upright. From inside of the tub, depress retaining clips. (see figure 54) blower assembly is removed from top outside of tub. Re...

Page 4-13 d acor b uilt -i n d ishwasher s ervice m anual side vent and fill hose remove dishwasher cabinet. See cabinet removal for detailed instructions. With cabinet removed, set unit upright. Remove fill hose from side vent by removing hose clamp. Unscrew (counterclockwise) vent grate from left ...

Page 5-1 s ection 5 - t roubleshooting t ips symptom check the following remedy dishwasher will not operate when turned on. 1. Fuse (blown or tripped). 2. 120 vac supply wiring connection faulty. 3. Electronic control board faulty. 4. Motor (inoperative, check resistances). 5. Door switch (open cont...

Page 5-2 d acor b uilt -i n d ishwasher s ervice m anual symptom check the following remedy dishwasher will not pump out. 1. Drain restricted. 2. Defective drain pump. 3. Air lock in drain hose. 4. Blocked impeller. 5. Open windings. 6. Wiring or terminal defective. 7. Electronic control board defec...

Page 6-1 s ection 6 - p arts b reakdown door and control panel.

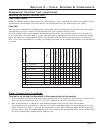

Mdw24 dishwasher component connector locations and display codes technical service 800-353-2267 component name component connector locations resistance (Ω) wash motor p3-4 & p1 14 wash motor tachometer p3-10 & p3-11 246 drain pump p3-6 & p3-8 26 inlet valve p3-5 & p3-8 1126 dispenser p3-2 & p3-8 166...