Technical manual.

Technical manual - page 2 policies policies and and procedures procedures product ul label location cabp3 ul marking is on the serial number label attached to the housing cover next to the access plate. Dmo ul marking is on the serial number label inside the oven against the left wall. To view, open...

Technical manual - page 3 erc failure codes -f0- shorted or jammed input device this failure will appear if a shorted or jammed input device is defective. Possible causes include shorted wires or a defective membrane switch. -f1- alarm “system watchdog circuit” the system will detect a failure in th...

Technical manual - page 4 failure codes (continued) -f5- this code is not used -f6- alarm eeprom checksum error the brain of this oven (so to speak) operates a series of software commands. These commands control the various features and functions of the oven. A numerical value has been assigned to e...

Technical manual - page 5 policies policies and and procedures procedures dacor model number designations cps convection plus – single oven, convection 127 – single oven 27 inch 227 – double 27 inch, top only convection cpd double convection ovens pcs/d mcs/d ecs/d dmo microwave oven ecps epicure se...

Technical manual - page 6 policies policies and and procedures procedures serial number format 2 letters followed by 7 numbers ex: ca6520001 is an electric cooktop made in the last week of 1996 first letter a accessories b blowers c electric cooktops d displays e electric modules f ranges h hoods m ...

Serial number format in 2002 dacor changed the serial number format slightly to accommodate additional product line growth by adding two (2) characters each for product code and revision and two (2) digits for the year of manufacture. Prior to the 38th week of 2002 the serial number format was: a da...

Technical manual - page 7 policies policies and and procedures procedures to the authorized service company our mission is to ensure that dacor customers receive prompt, courteous and professional service. We are here to provide support to the servicer with technical information and replacement part...

Technical manual - page 8 policies policies and and procedures procedures labor rate structure a warranty claim shall be defi ned as charges allowed, based upon a previously approved labor rate, accepted by dacor and the authorized service agency to make necessary repairs as specifi ed under the terms...

Technical manual - page 9 policies policies and and procedures procedures governmental agency. Submitting fraudulent claims is grounds for immediate termination of the service agreement. The consumer audit program will also include a customer satisfaction survey. Consumer complaints, comments, sugge...

Technical manual - page 10 policies policies and and procedures procedures parts return policy effective march 1, 2000 dacor implemented a factory direct parts return policy. Each part to be returned should be shipped back in the original container with the shipping label enclosed in the replacement...

Dacor contacts main offi ce dacor 1440 bridge gate drive diamond bar, ca 91765 city of industry - parts shipments dacor 14425 clark street city of industry, ca 91745 626-961-6406 director, technical service – kevin leedom national technical manager - thom tompkins 800-793-0093 x3602 director, custome...

Ul label ul label and and serial tag serial tag location location technical manual - page 12 serial tag location cabp3 serial tag is attached to the housing cover next to the access plate. Dmo serial tag is inside the oven against the left wall. To view, open the oven door. Ehd serial tag is located...

Technical manual - page 13 electrode detection of a gas flame theory of operation if you look closely at a fi nger of burner fl ame you will see that it is clearly made up of three separate elements: (see fi gure 1) 1. Inner fuel rich cone 2. *ionized blue outer cone with current carrying capabilities ...

Technical manual - page 14 the fl ame also plays a very important role in this process. Because the fl ame is conductive, it allows the voltage to pass through its body like a bridge to the burner spreader ring. This {bridge} allows the built up spark voltage to bleed off of the igniter tip and move t...

Technical manual - page 15 cracked ceramic spark electrode itʼs important to determine whether the spark electrode is faulty. Physical impacts and high heat can cause the ceramic post to fracture or crack. If this occurs the spark can shoot through the ceramic insulation and will normally go to grou...

Technical manual - page 16 excessive failures: diagnosis on a spark system can be confusing. For some, diagnosing spark failure is diffi cult while for others it is pure luck to get it right. Often you can eliminate a problem by disassembling the cooktop and putting it back together. In the process m...

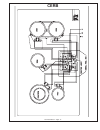

Technical manual - page 17 test point 16 erc connector output voltage check points on erc/clock control all ranges and wall ovens when programming the oven into a cooking cycle, you fi rst select the desired mode on the touch membrane. Pressing this key sends a message to the erc/clock control, which...

Technical manual - page 18 1. Check incoming voltage. Appliances must have 240 volts with a neutral. 2. Check voltage at main relay board at l1 and n just in front of the low voltage transformer. Should read 120 volts. Refer to picture for voltage test points. 3. If you do not have the voltage at l1...

Technical manual - page 19 1. Check the incoming voltage to the unit. There should be 240 volts with a neutral. 2. Check power at the dbl (double line relay) from (com) to neutral. There should be 120 volts incoming to the dbl. Refer to picture for testpoints. If voltage is ok, move to step 3. 3. Pr...

Technical manual - page 20 1. Check the incoming voltage to the unit. There should be 240 volts with a neutral. 2. Check power at the dbl (double line relay) from (com) to neutral. There should be 120 volts incoming to the dbl. Refer to picture for testpoints. If voltage is ok, move to step 3. 3. Pr...

Technical manual - page 21 1. Check the incoming voltage to the unit. There should be 240 volts with a neutral. 2. Program the unit into pure convection. Check power at the dbl (double line relay) from (com) to neutral. There should be 120 volts incoming to the dbl. Refer to picture for test points....

Technical manual - page 22 door latch not running (all models) 1. Check voltage at l2 just to the left of the drlk relay. (door lock relay) you should have 120v present. See picture for test points. If there is no voltage present, check wiring from l2 back to terminal block. If you have voltage at l...

Technical manual - page 23 oven light pcs, mcs, ecs 1. Check input voltage to the light transformer at the primary side across terminal 1 and 5. Should read 240 volts. (see picture) if you do not have 240 volts across 1 and 5, check wiring back to the terminal block. If there is 240 volts present at...

Technical manual - page 24 no cooling fan all ranges and wall ovens 1. Program unit into a cooking cycle. The cooling fan should come on right away. ** if cooling fan doesn’t come on, check voltage at cvf or clf relay (cooling fan relay) side to neutral. Should read 120 vac. If voltage is not presen...

Technical manual - page 25 no bake/broil pgr here is a list of functional parts that should be working for the bake/broil to light.. Main relay board cooling blower air switch (sail switch) dual gas valve bake igniter all of these elements must be working in order for the bake or broil burner to fun...

Technical manual - page 26 common no note: erg30’s had a sail switch prior to sn kc1230128. On 6-7-01 the sail switch was replaced with an automatic reset switch. Pgr30’s unit with a serial level kb0000000 and ka0000000 had a sail switch - those with a kc0000000 and above have an automatic limit swi...

Technical manual - page 27 light not working (120v light circuit) 1. Check voltage for light circuit at main relay board at terminal n, just to the left of ol1 (oven light relay one) should have a constant 120 volts. (see picture) if no voltage there check wiring back to terminal block. If you do ha...

Technical manual - page 28 no bake/broil heat: erg30 1. Check for incoming voltage to the main relay board at the dbl (double line relay) no side to neutral. Should have 120 vac present. If no voltage check wiring back to the power terminal block. If voltage is present go to step 2. 2. After program...

Technical manual - page 29 erd30, 36, 48 large oven, no bake 1. Check incoming power to range should have 240 vac with a neutral. Check voltage going into main relay board from l2 (red) to l1 (black) at main relay board. Should have 240 vac. 2. Program unit into bake cycle, the unit will go into a p...

Technical manual - page 30 no broil erd30, 36, 48 1. Program unit into the broil cycle. Take an amp reading at the broiler igniter. You should have 3.1 to 3.3 amps. Or take a voltage reading at the main relay board. At the main relay board take a voltage check from the br (broil relay) to neutral sh...

Technical manual - page 31 erc quick test the process requires two people. To access the program, one person should stand at the oven, while the other is located at the circuit breaker. The person at the circuit breaker turns off the breaker and then the person at the oven depresses and holds the co...

Technical manual - page 32 theory of operation when keypad up/down button is pushed, contacts on the main pcb close between #12 and #13. Closing these contacts activates the triac for the sleeve motor which is connected to terminals l3 and n3 on the main pcb. The motor then raises the intake assembl...

Technical manual - page 33 if the above test does not show a closed circuit, perform the following. - check for grease or any foreign material between the touch buttons and the contact board. Clean with an electronic contact cleaner as described above. - repeat test above. - if the contacts are clea...

Technical manual - page 34 that the molex plug is securely attached to the main pcb. B. Unit will not raise or lower: 1. Check limit switches and the connecting wiring. 2. Check main pcb between l3 and n3 for 120 vac when the up/down key is pressed. If voltage is not present check between terminals ...

Technical manual - page 35 2. Check for possible miswire of the exhaust motor. Quick check – main pcb: if the vent is not working at all: - check the fuse on the main pcb - if the fuse is good check for continuity between the fuse and l3 (drive motor terminal) - if this circuit is open the pcb is ba...

Technical manual - page 36 will be on and both the low and high led will be off. Fan speed -high button pressing and releasing this button will select the high speed for the fan. The high speed led indicator will be on and the low and medium led will be off. Clean filter button when the total number...

Technical manual - page 37 furthermore, the controller will learn the current status of the limit switches and the direction of the sleeve motor. However if both limit switches are closed during any stage of operation, the controller will only be able to operate the sleeve motor. Failure mode, pcb p...

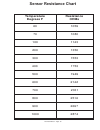

Technical manual - page 38 e r u t a r e p m e t f s e e r g e d e c n a t s i s e r s m h o 0 6 9 5 0 1 0 7 0 8 0 1 0 0 1 3 4 1 1 0 0 2 0 5 3 1 0 0 3 3 5 5 1 0 0 4 3 5 7 1 0 0 5 9 4 9 1 0 0 6 2 4 1 2 0 0 7 1 3 3 2 0 0 8 6 1 5 2 0 0 9 7 9 6 2 0 0 0 1 4 7 8 2 sensor resistance chart.

Technical manual - page 39 cet.

Technical manual - page 40 cer.

Technical manual - page 41 cerb.

Technical manual - page 42 ett304.

Technical manual - page 43 ett365.

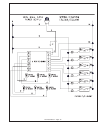

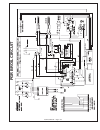

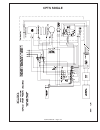

Gr ound grn blk red inner c oil outer c oil 240v a c, 60hz, 50a model number met 365 9500w (39.6a) rl rc met365 wiring dia gr am fl electric al cir cuit required to tal c onnected l o ad p/n 65373 contr ol bo x 5 6 7 2 4 3 1 terminal bl ock j1 j2 e7 e12 e14 e13 e15 e11 e10 e8 e9 e3 e16 e17 e1 e4 e19...

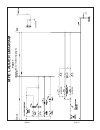

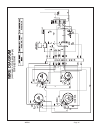

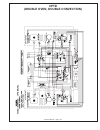

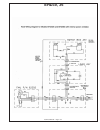

After servicing verify proper operation 120v, 60hz, 0.235a n power supply s1 cause improper and dangerous operation. When servicing controls. Wiring errors can caution: label all wires prior to disconnection wiring diagram pgm365 l ignitor, lr burner cr burner rr burner lf burner diode indicator led...

Technical manual - page 44 ecc.

Technical manual - page 45 ggc.

Technical manual - page 46 sgg304.

Technical manual - page 47.

Technical manual - page 48 sgm304, 364.

Technical manual - page 49 sgm362em.

Technical manual - page 50 sgm464em.

Technical manual - page 51 sgm466.

Technical manual - page 52.

Technical manual - page 53 em4.

Technical manual - page 54 rse.

Technical manual - page 55 rsg.

Technical manual - page 56 ersd30

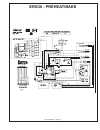

Technical manual - page 57 erd30 prehea t circuit.

Technical manual - page 58 erd30 bake cycle.

Technical manual - page 59 erd30 convection bake.

Technical manual - page 60 erd30 pure convection.

Technical manual - page 61 erd30 broil cycle.

Technical manual - page 62 erd30 self-clean cycle.

Technical manual - page 63 erd light circuit.

Technical manual - page 64 erd36 prehea t cycle.

Technical manual - page 65 erd36 bake circuit.

Technical manual - page 66 erd erd36 pure convection.

Technical manual - page 67 erd36 broil circuit.

Technical manual - page 68 erd36 self clean cycle.

Technical manual - page 69 erd erd36 light circuit.

Technical manual - page 70 18” oven preheat.

Technical manual - page 71 note: c ooling fan turns on betw een 180 and 220 degr ees . 18” oven - bake cycle.

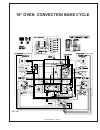

Technical manual - page 72 18” oven convection bake cycle.

Technical manual - page 73 18” oven pure convection cycle.

Technical manual - page 74 note: cooling fan turns on between 180 and 220 degrees 18” oven self clean cycle.

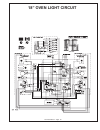

Technical manual - page 75 18” oven light circuit.

Technical manual - page 76 48 range preheat bake cycle large oven.

Technical manual - page 77 48 range conv-bake cycle - large oven.

Technical manual - page 78 48 range - 36” oven - pure convection.

Technical manual - page 79 48 range broil cycle - large oven.

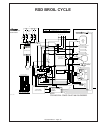

Technical manual - page 80 note: cooling fan turn on temp 180-220 degrees 36” oven - self-clean cycle.

Technical manual - page 81 48 range light cycle - large oven.

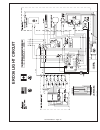

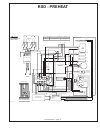

Technical manual - page 82 erg30 prehea t/bake cycle.

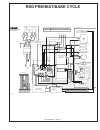

Technical manual - page 83 erg30 convection bake cycle.

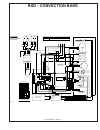

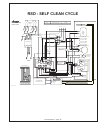

Technical manual - page 84 erg30 self clean cycle.

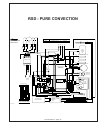

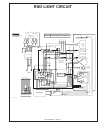

Technical manual - page 85 erg30 light circuit.

Technical manual - page 86 erg36 - preheat/bake.

Technical manual - page 87 erg36 - convection bake.

Technical manual - page 88 erg36 - broil.

Technical manual - page 89 erg36 - light.

Technical manual - page 90 erg36 - self clean.

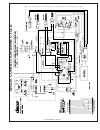

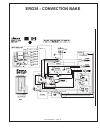

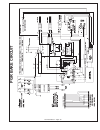

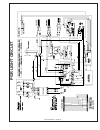

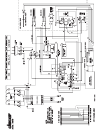

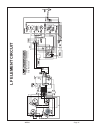

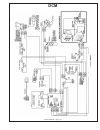

Technical manual - page 91 erc 4800 controller (ref.) oven membrane switch panel (ref.) bk com n.O. Bk bu r y ba l2 br l2 cv l2 drlk l2 cvl l1 n bk oven assembly (ref.) bk w oven light 40w w bk convection element -2200w, 240v bk o bu bk bk y bake element 2200w broil element -3500w, 240v cooling blow...

Technical manual - page 92 erc 4800 controller (ref.) oven membrane switch panel (ref.) bk com n.O. Bk bu r y ba l2 br l2 cv l2 drlk l2 cvl l1 n bk oven assembly (ref.) bk w oven light 40w w bk convection element -2200w, 240v bk o bu bk bk y bake element 2200w broil element -3500w, 240v cooling blow...

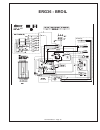

Technical manual - page 93 erc 4800 controller (ref.) oven membrane switch panel (ref.) bk com n.O. Bk bu r y ba l2 br l2 cv l2 drlk l2 cvl l1 n bk oven assembly (ref.) bk w oven light 40w w bk convection element -2200w, 240v bk o bu bk bk y bake element 2200w broil element -3500w, 240v cooling blow...

Technical manual - page 94 erc 4800 controller (ref.) oven membrane switch panel (ref.) bk com n.O. Bk bu r y ba l2 br l2 cv l2 drlk l2 cvl l1 n bk oven assembly (ref.) bk w oven light 40w w bk convection element -2200w, 240v bk o bu bk bk y bake element 2200w broil element -3500w, 240v cooling blow...

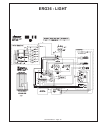

Technical manual - page 95 erc 4800 controller (ref.) oven membrane switch panel (ref.) bk com n.O. Bk bu r y ba l2 br l2 cv l2 drlk l2 cvl l1 n bk oven assembly (ref.) bk w oven light 40w w bk convection element -2200w, 240v bk o bu bk bk y bake element 2200w broil element -3500w, 240v cooling blow...

Technical manual - page 96 erc 4800 controller (ref.) oven membrane switch panel (ref.) bk com n.O. Bk bu r y ba l2 br l2 cv l2 drlk l2 cvl l1 n bk oven assembly (ref.) bk w oven light 40w w bk convection element -2200w, 240v bk o bu bk bk y bake element 2200w broil element -3500w, 240v cooling blow...

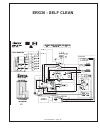

Technical manual - page 97 erc 4800 controller (ref.) oven membrane switch panel (ref.) bk com n.O. Bk bu r y ba l2 br l2 cv l2 drlk l2 cvl l1 n bk oven assembly (ref.) bk w oven light 40w w bk convection element -2200w, 240v bk o bu bk bk y bake element 2200w broil element -3500w, 240v cooling blow...

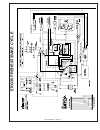

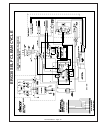

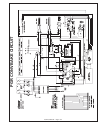

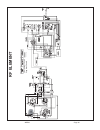

Technical manual - page 98 pgr bake circuit.

Technical manual - page 99 pgr light circuit.

Technical manual - page 100 pgr conv bake circuit.

Technical manual - page 101 pgr prehea t circuit.

Technical manual - page 102 pgr self-clean circuit.

Technical manual - page 103 pgr broil circuit.

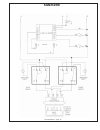

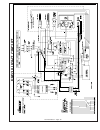

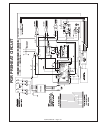

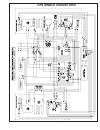

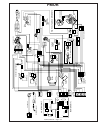

Mre30 page 14 mre ladder diagram pa r t 1 (continued on following page).

Mre30 page 15 mre ladder diagram p art 2.

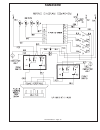

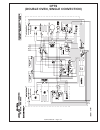

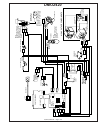

Mre30 page 16 wire diagram (continued on following page) to p s e ction.

Mre30 page 17 wire diagram (continued on following page) bott om section.

Mre30 page 20 s elf clean c y cle self clean cycle.

Mre30 page 21 pu re c o n v ec tion pure convection cycle.

Mre30 service instructions page 22 co nv ec tion f a n convection f an.

Mre30 service instructions page 23 co nv ec tion bak e convection bake cycle.

Mre30 service instructions page 24 co oling f an 180-225 d egr ees cooling f an 180-225 degrees.

Mre30 service instructions page 25 br oil broil cycle.

Mre30 service instructions page 26 bake st andard bake cycle.

Mre30 page 37 lf element cir cuit sta y hot cir cuit - - - - - - - - - lf element circuit.

Mre30 page 38 lr element cir cuit sta y hot cir cuit - - - - - - rf element.

Mre30 page 39 rf element sta y hot cir cuit - - - - - - - rr element.

Mre30 page 40 r/r element - p o w er r/r sta y hot cir cuit - - - - - - - - - rr element.

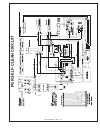

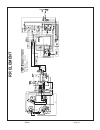

Technical manual - page 104 lower oven bake prehea t.

Technical manual - page 105 lower oven broil.

Technical manual - page 106 lower oven - self clean.

Technical manual - page 107 upper oven preheat.

Technical manual - page 108 upper oven bake cycle.

Technical manual - page 109 upper oven pure convection.

Technical manual - page 110 upper oven broil cycle.

Technical manual - page 111 upper oven self clean cycle.

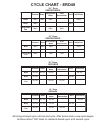

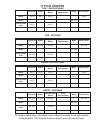

Cycle chart - erd48 36 “oven seconds 18 “ oven seconds 36 “ oven percentages 18“ oven percentages all timing is based upon a 64 second cycle. After 64 seconds a new cycle begins. All times refl ect “on” times for elements based upon a 64 second cycle. T a e h e r p e k a b n o i t c e v n o c e k a b...

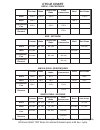

All timing is based upon a 64 second cycle. After 64 seconds a new cycle begins. All times refl ect “on” times for elements based upon a 64 second cycle. Erg36 - seconds erg36 - percentages pgr - seconds cycle charts pgr - percentages t a e h e r p e k a b n o i t c e v n o c e k a b e r u p n o i t ...

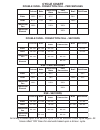

All timing is based upon a 64 second cycle. After 64 seconds a new cycle begins. All times refl ect “on” times for elements based upon a 64 sec. Cycle. Single oven - seconds single oven - percentages erd - seconds cycle chart erd36 - percentages t a e h e r p e k a b n o i t c e v n o c e k a b e r u...

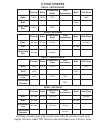

Cycle chart double oven - convection cell - percentages all timing is based upon a 64 second cycle. After 64 seconds a new cycle begins. All times refl ect “on” times for elements based upon a 64 sec. Cycle. Rse - percentages rse - seconds double oven - convection cell - seconds t a e h e r p e k a b...

All timing is based upon a 64 second cycle. After 64 seconds a new cycle begins. All times refl ect “on” times for elements based upon a 64 sec. Cycle. Cycle charts erg30 - percentages erg30 - seconds erd30 - percentages erd30 - seconds t a e h e r p e k a b n o i t c e v n o c e k a b e r u p n o i ...

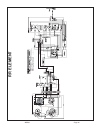

Technical manual - page 117 w305 erciii block l1 n l 2 oven pilot light 2 l light switch upper clean switch com nc no convection fan motor cooling fan terminal board relay 40 watt bulb only lamp holder oven clean temp. Sensor cooling fan switch close open bake temp. Sensor convection element 2200w b...

Technical manual - page 118 cpo.

Technical manual - page 119 cpo.

Technical manual - page 120 cpo.

Technical manual - page 121 cps single convection.

Technical manual - page 122 cpts (double oven, single convection).

Technical manual - page 123 cpts single.

Technical manual - page 124 cptd (double oven, double convection).

Technical manual - page 125 eog36 wiring.

Technical manual - page 126 dwo, edwo, tdwo.

Technical manual - page 127 ewo, mwo, pwo.

Technical manual - page 128 dmo24.

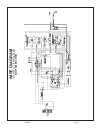

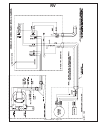

Technical manual - page 129 dmo2420 high voltage capacitor high voltage wire a h.V. Rectifier power supply cord 120v 60hz high voltage components oven lamp and socket magnetron com. Monitor switch com. N.O. N.C. Door sensing switch secondary interlock switch turntable motor note: hot (org) wire must...

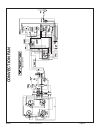

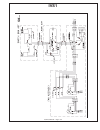

Technical manual - page 130 pmor high voltage components control unit (power unit) (lsi unit) power supply cord 120v 60hz 1 2 3 wht grn blk wht grn blk oven thermal cut-out magnetron temperature fuse wht red blk red blk fan motor turntable motor gry org wht org ylw red wht org blk wht wht hood lamps...

Technical manual - page 131 dcm.

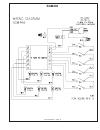

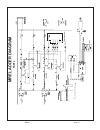

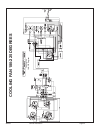

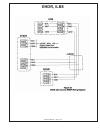

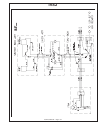

6 45 1 2 3 6 45 1 2 3 a b c d e f g h a b c d e f g h pcor pcor wire diagram high voltage capacitor h.V. Rectifier high voltage components magnetron power transformer f fa power supply cord 120v 60hz grn blk 1 2 3 wht grn blk hood fan thermal cut-out convection motor heating element thermistor tempe...

Technical manual - page 132 ehdr, ilb8.

Technical manual - page 133 ehd30, 36.

Technical manual - page 134 ehd42, 48, 54.

Technical manual - page 135 rv.

Technical manual - page 136 ivs1.

Technical manual - page 137 ivs2.

Technical service 950 s. Raymond ave. Pasadena, ca 91105 part # 95106 rev.8.7.02.