- DL manuals

- DAELIM

- Other

- BESBI -

- Owner's Manual

DAELIM BESBI - Owner's Manual

Summary of BESBI -

Page 1

Head office(factory) #58, sung san-dong, chang won, kyungnam, korea tel: (82-55) 239-7000 / fax: (82-2) 467-9997 owner s manual.

Page 2: Important Notice

Welcome thank you for purchasing an daelim vehicle. We hope you enjoy safe riding. Operator and passenger this motorcycle is designed to carry the operator and one passenger. Attempting to change the pre-set maximum speed may cause danger and will void the daelim warranty. On-road use this motorcycl...

Page 3: Contents

Specification operation instruction safety precautions prior to starting vehicle for safe driving operation correct attire cargo modification attachment muffler parts location meter reading and usage meter indicator lamps switch operation main switch start button headlight winker switch horn button ...

Page 4

Maintenance maintenance schedule maintenance precautions brakes brake hose, pipe leakage, damage, assembly state brake pad wear changing engine oil spark plug battery inspection fuse replacement air cleaner element inspection side stand inspection cable rubber part cleaning general cleaning / import...

Page 5: Specification

3 specification length width height(mm) wheel base(mm) ground clearance(mm) seat height(mm) dry weight(kgf) passenger engine type piston displacement(cc) bore and stroke(mm) starting system transmission type 1,820 685 1,060 1,300 135 746 105 2 air- cooled 4 stroke 2valve 124.0 52.4 57.8 start motor ...

Page 6: Operation Instruction

This manual describes matters pertaining to correct operation, safe operation and simple maintenance of the vehicle you purchased. To ensure more comfortable and safer operation, make sure to read this manual carefully prior to operation. The photographs and drawings shown in this manual may differ ...

Page 7

Do not ride on a motorcycle over 2 persons because this vehicle is designed to carry the operator and one passeger. Performing daily inspection. Putting on protective gears(helmet, glove, goggles, etc.) bring the driver’s licence. Determinating the path to the desired destination. Always hold the ha...

Page 8

6 operation gasoline is extremely flammable. Avoid fire in the work place, also paying particular attention to spark. Furthermore the evaporated(gasified) gasoline is highly explosive. Make sure to stop engine and stay away from fire when fueling. Operators should naturally fix bodies to keep smooth...

Page 9

7 be sure to wear helmet and gloves at all time for seafty. Wear shirts or jackets with tight in the wheel driving. Otherwise it can be caught in the wheel to cause serious damage by overturn of vehicle. Many automobile/motorcycle accidents happen because the automobile driver does not “look” the mo...

Page 10

8 modification of vehicle structure of function deteriorates manipulatability or causes exhaust noise to become louder shortening the vehicle life. These modifications are not only prohibited by law but also are the acts harmful to other people. Modifications are not covered by warranty. Except desi...

Page 11

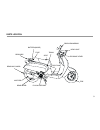

9 parts location pillion step bar rear wheel muffler battery(inside) seat trunk rear grip read mud guard fuse fr. Brake lever head light rear view mirror tire fuel tank lid.

Page 12

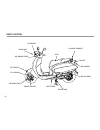

10 parts location headlight fr. Winker fr. Fender fr. Cushion side stand main stand fr. Brake disk brake caliper rr. Brake lever seat luggage carrier tailight rr. Winker air cleaner.

Page 13

11 indicates driving speed. Keep the law speed limits to ensure safe operation. Indicates total distance in kilometers travelled by the vehicle. The fuel meter indicates the gasoline level inside the fuel tank. Gasoline should be put in the fuel tank as soon as possible if the needle is resting in t...

Page 14

12 main switch switch operation p u s h p u s h on off lock 1. On.... Starts engine. Key can not be pulled out.(headlight on) 2. Off....Stops engine. Key can be placed in or taken out of the main switch. 3. Lock....Locks handle bars. Key can be placed in or taken out of the main switch. 4. Open....W...

Page 15

13 the engine is started pressing this button when pressed in a state where the main switch key is placed to an on position and the brake lever is pulled. Put main switch key in “on” position and turn on headlight switch. High beam or low beam can be operated by the use of dimmer switch. High beam ....

Page 16

14 if this switch is turned on when the main switch is in an on position, the winker will operate. (r)....Used when making a right turn. (l)....Used when making a left turn. The horn is sounded if the horn button is pressed when the main switch is in an on position. Caution the winker switch does no...

Page 17

15 to lock the steering, turn the handlebars all the way to the left, turn the key to lock while pushing in. Remove the key. To unlock the steering, turn the key to the off position. The seat automatically locks when the seat is pushed in its downward position, lightly pull upward on the seat to mak...

Page 18

16 there is a trunk under the seat. The seat is opened to gain access to the trunk by using the main switch key on the seat lock. Turn the main switch from off position to open position slightly. Store the owner’s manual and the maintenance notebook in this area. Trunk maximum load:10kg for ease in ...

Page 19

17 make sure to check the oil, gasoline, etc., before starting the engine. Please ensure that the main stand is in a down position when starting the engine. Drive with care for both safety reasons and longer vehicle life. For 1 month (or 1,000km) after pur- chasing the vehicle, drive moderately avoi...

Page 20

18 press the starter button without rotating the starter grip (opening the throttle). If engine is not started with throttle grip closed, press starter button and open throttle grip approximately 1/8 to 1/4. Warning never run the engine in an enclosed area. The exhaust contains poisonous carbon mono...

Page 21

19 it is possible that starting will be more difficult if the vehicle has not been used for a long period of time or if the fuel hole is plugged up(starting problems even when there is sufficient fuel in the fuel tank may be an indication of a plugged fuel hole). When this happens, do not rotate the...

Page 22

20 fold the main stand. Push the vehicle forward to fold the main stand and make sure that the brake lever does not become released during this operation. Get on the vehicle. Mounting should be done from the left side, and you should sit squarely on the seat. Leave either one foot or both feet plant...

Page 23

21 before entering traffic, use the correct turn signal to foreward other drivers of your intentions. The throttle grip.> if the throttle grip is rotated........ The speed of the vehicle increases. Please rotate the throttle grip slowly. When climbing a hill, the throttle grip need to be rotated fur...

Page 24

22 suddenly applied and the handle bars should never be suddenly turned.> sudden braking or turning can cause the vehicle to slide and tip over. It is especially dangerous to perform sudden braking on wet roads or in rainy weather as the tires can lose traction and slip easily. Taken during rainy we...

Page 25

23 after the vehicle has come to a complete stop. Return the winker switch to the center position and turn the main switch to off. This will turn the engine off. Dismount on the left side and lower the main stand on a flat surface. Be sure to park in an area that is free of traffic. Also, the vehicl...

Page 26

24 self inspect the vehicle and have regular maintenance inspections for increased safety and the prevention of accidents. Regular maintenance inspections should be performed even if the vehicle has not been used for a long period of time. Self inspections before operation should be performed on a d...

Page 27

25 check areas which caused for concern when last operating the vehicle. If happened, contact authorized mainte- nance shops for necessary inspection and repairs. Lightly squeeze the brake levers until tension is felt to check for an appropriate amount of free play. No free play in the brake levers ...

Page 28

26 check gasoline to see if there is a sufficient amount of gasoline to reach your destination. Place the main switch to “on” position. If the fuel meter needle indicates e mark (red portion), fill fuel tank with gasoline as soon as possible. Reserve fuel capacity : 1.0 open the key cover on fuel ta...

Page 29

27 check for an appropriate level of air pressure by examining how the tire sits on the ground. If you notice any abnormalities in the shape of the tire with regard to the area contacting the ground, use a tire gauge to check tire pressure and adjust the tire pressure to the appropriate level. Check...

Page 30

28 check the engine oil level each day before riding the motorcycle. The oil level must be maintained between the upper and lower level marks on the sight-glass stand the motorcycle on the main stand on level ground. Start the engine and let it idle for approximately 5~10 minutes. Check the engine o...

Page 31

29 turn a main switch “on”. Check the lamp for proper operation (front/rear and right/left) and sound by operating the switch, and also a lens for damage or contamination. Turn a main switch “on”. Check a stop lamp for proper operation by operating the front wheel and the rear wheel brakes, and also...

Page 32

30 replace with new bulb. Install in the reverse order of removal. Front winker bulb remove the upper handle cover and rotate it to counterclockwise to disassemble it. Do not rotate the bulb, pull as it is to dissamble it. Replace it with new bulb. Install in the reverse order of removal. Front wink...

Page 33

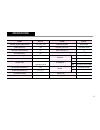

31 perform the self inspections before operation at each scheduled maintenance period. I : inspect and, clean, adjust, lubricate or replace if necessary r: replace l: lubricate c: clean maintenance schedule i i i i i r r r r r i i i i i c c c c i i i i i i i i i i r r r r r c c c c c r i r i i i i i...

Page 34

32 item frequency odometer reading(note 1) remark notes : (1) at higher odometer readings(16,000km), repeat at the frequency interval established here. (2) service more frequently when riding in unusually wet or dusty areas. (3) replace every 2 years, or at indicated odometer interval, whichever com...

Page 35

33 the following is an explanation of correct inspection methods, cleaning and parts replacing. Please always refer to this section when wanting to inspect or repair your vehicle. Both the front and rear brakes are the hydraulic disk type. As the brake pads wear, the brake fluid level drops. There a...

Page 36

34 check that the fluid level is above the lower level mark with the motor- cycle in an upright position. Brake fluid must be added to the reservoir whenever the fluid level begins to reach the lower level mark. 1. Remove the screws. 2. Clean dust and other foreign materials around reserve tank to p...

Page 37

35 visually check for fluid leaks or damage and, using a spanner, check joints and clamps for clearance. Also, check hose and pipe protective parts to see if they contact other parts when turning the handle bars or due to vibration when driving. (bent, distorted, tear) brake pad wear depends upon th...

Page 38

36 when the engine oil is contaminated, the life of engine will be remarkably shortened. Keep the proper oil level, kind and replacing period. Place the vehicle on a flat surface, and idle (warm up) the engine 2~3 minutes. Stop the engine, separate the oil level gauge, place a vessel under the engin...

Page 39

37 if electrode is stained or clearance is not right, satisfactory spark is not produced. Clean and make adjustment. Remove the spark plug cap. Clean around the plug. Using a plug wrench, remove the plug. Clean plug with plug cleaner. Check electrode for wear and corrosion. If the ends become round,...

Page 40

38 when removing the pillion seat and open the battery box cover, you can find the battery. If the battery terminal is polluted or in-rust, separate battery and clean it. Battery terminal in rust with white powder should be cleaned with warm water. In case of serious rust of battery terminal, disass...

Page 41

39 turn off the main switch to see if the fuse is severed. If the fuse is severed, exchange the fuse into a fuse with same capacity. Fuse is installed in fuse box around the battery. To change a fuse, first take off fuse cover. Then, remove the disconnected fuse, and insert the reserved fuse with sa...

Page 42

40 loosen the 6 washer screws and 1 flange bolt, and remove the tube clip and air cleaner case cover. Inspect the air cleaner element. If the air cleaner element is excessively dirt or damaged, replace it with a new one. Air cleaner element inspection caution if the air cleaner element is inadequate...

Page 43

41 erect main stand and place vehicle in upright position on level ground. Check the spring for damage or loss of tension and the side stand assembly for freedom of movement. Check the side stand ignition cut-off system; put the side stand up. Start the engine. Lower the side stand. The engine shoul...

Page 44

42 remove the battery. Store in an area protected from freezing temperatures and direct sunlight. Slow charge the battery once a month. W ash and dry the motorcycle. Wax all painted surfaces. Inflate the tires to their recommended pressures. Place the motorcycle on blocks to raise both tires off the...

Page 45

43 make sure to stop the engine prior to car washing. Be careful not to allow water to enter the muffler during the washing.Water inside the muffler may cause an improper engine starting or rust occurrence. Do not let water get inside the braking system during the washing, as water inside the brake ...

Page 46

44 the frame number is stamped on the front central part of the frame. The engine number is stamped on the lower part of the left crankcase. The frame and engine numbers will be used as the basis of recovering the vehicle when is stolen. Record the frame and engine numbers along with the vehicle lic...

Page 47

45 the appropriate driving position is most important thing to driving safely. Eyes : look at the front direction widely. Shoulders : relieve the tension. Arms : relieve the tension and bend arms to inside and let them act as the spring. Hands : grip the handle the position away from the inside end ...

Page 48

46 taking pose of fellow passenger hands: hold the rear grip. Feet and knees: put the feet on pillion step, and adhere the knees closely to body. Warning if the fellow passenger doesn’t hold the rear grip or put the step on the pillion step, it may lead death or serious injury due to falling from th...

Page 49

47 secure the safe distance. Drive protectively. Do not obstruct the traffic. Do not drive on the pedestrian way or walkway. Drive on the left driveway when passing away. Make sure that you can apply the brake anytime. Always apply the brake when stopping temporarily. Do not drive excessively long d...

Page 50

48 prior to starting always look around to avoid accident. Get on the vehicle after pulling back the stand. Start driving slowly after turning on the winker and releasing the brake while ensuring the safety around the vehicle. Starting caution return the side stand to its original position. Keep dri...

Page 51: Turning Method

49 the basic principle of turn is balancing using the centrifugal force which makes vehicle go outside and the gravity which makes vehicle fall inside. The centrifugal force increases in inverse portion to the radius of a curve and in portion to the square speed. Decelerate prior to entering the cur...

Page 52

50 the basic principle of turn is balancing using combined force of the centrifugal force and the gravity. All 3 positions require straightening the head and keeping the eyes horizontally. This is a turning position with motorcycle and driver in a line. This position is the most natural and exact, s...

Page 53

51 this is a turning position with motorcycle leaned inside more than driver, which is opposite to the lean-in position. With this position, quick turn is well performed and driver can obtain wide front visual field adequate to drive on the rained or slippy road because it has best road holding. How...

Page 54

52 do not drive inside of large truck's turn circle. Dead angle zone is the sight range which cannot be identified by driver and increases in proportion to the width of the vehicle. It is distance between path of the front and rear wheel and increases in proportion to the length of the vehicle. Prec...

Page 55: Braking Method

53 vehicle is braked using friction between road surface and tires. Braking distance increases 1.5 times on wet road and 3 times on icy road because friction force of road surface is decreased. Due to the inertia, vehicle does not stop immediately after applying the brake. Basic principle of brake (...

Page 56

54 turn the throttle grip to its original position and decelerate using the engine brake. Erect the vehicle straight. Brake using both front and rear brakes. Vehicle speed : 50 km/h learn the proper braking method to prevent accident. Impact increases in proportion to the speed and weight. The impac...

Page 57: Wiring Diagram

55 lg g lh.Fr.Winker(1 2v16w) lg lg gr b g o gr l l/w lb o w l lb o g w horn lg b l rh.Fr.Winker(1 2v16w) head light (12v,35/35w) (12v,1.7w) high beam fuel meter g w g lb l o b l/w (12v,1.7w) (12v,3.4w) meter illum. Combination merer ass'y. Lb g g g br br b g/y w g l b y/r b/w b r g b g/y b g/y brak...

Page 58

56 memo :.

Page 59

57 memo :.

Page 60

58 memo :.

Page 61

59 memo :.

Page 62

60 memo :.

Page 63

61 memo :.

Page 64

62 memo :.

Page 65

63 memo :.

Page 66

64 memo :.

Page 67

2007. 06 printed 2007. 06 publication n no o c co op py y.

Page 68: Owner S Manual

Head office(factory) #58, sung san-dong, chang won, kyungnam, korea tel: (82-55) 239-7000 / fax: (82-2) 467-9997 owner s manual.