- DL manuals

- DAELIM

- Other

- S2-250

- Service Manual

DAELIM S2-250 Service Manual - Serial Number Location

Summary of S2-250

Page 2: Contents

How to use this manual this manual describes effective maintenance procedure for the s2-250 manufactured by daelim motor co., ltd. To ensure safety and optimal operating conditions of the vehicle, carry out regular inspections according to the maintenance schedule (section 2). Sections 1 through 2 p...

Page 4: 1. Service Information

1. Service information general safety 1-1 service rules 1-1 caution when wiring 1-5 serial number location 1-9 specifications 1-10 torque values 1-12 standard torque values 1-13 symbols 1-13 lubrication oil 1-14 wiring diagram 1-15 general safety 1. Do not run the engine for a long time in closed or...

Page 5

1-2 service information 9. Check to see if the rubber part is worn out when removing it and replace it if necessary. Some rubber part is weak to gasoline and kerosene, so pay attention not to soak with gasoline or oils. 10. Recommended grease must be applied to or filled in the specified place. 7. A...

Page 6

1-3 service information 11. Maintenance needed to use the specialized tools must be performed with the right tool. 12. Never reuse the ball bearing removed with the ball applied pressure when removing press-fitted the bearing. 13. Check the smooth rotation of inner or outer race of the ball bearing ...

Page 7

1-4 service information 21. Keep the pneumatic system interior or the engine interior from the infiltration of dust. 22. Install the gasket mounted in the contact surface of each case of the engine while removing gasket material completely. Remove damaged contact surface by wiping with the oil stone...

Page 8: Caution When Wiring

1-5 service information •each cord must be connected depending on its color. When connecting different cord, attach color tube around the connector. Connect the coupler to the connector with same color and same pin number. •identify the two-colored cord by main color first and then spriped color . •...

Page 9

1-6 service information •insert the lock of the coupler until the lock is fully secured. •turn off the main switch before connecting/dis- connecting. •release the lock to disconnect the lock of the coupler. •the lock of the coupler has two types according to releasing method(press type and pull type...

Page 10

1-7 service information •wire band must be secured firmly in the specified location of the frame. In case of aluminium band, secure the wire harness to the coated part. •secure the wire harness firmly using the clamp. •insert the connector until the vinyl cover is fully inserted into the terminal. •...

Page 11

1-8 service information •if necessary, lock the wire harness properly. •when mounting parts, make sure that the wire harness is not pressed by the parts. •in case that the wire harness is contacted with the end or the sharp edge, protect both parts with tube or tape. •the wire must not hang down or ...

Page 12: Serial Number Location

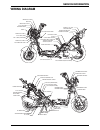

1-9 service information serial number location engine serial number location frame serial number location.

Page 13: Specifications

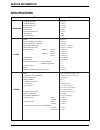

1-10 service information specifications item specifications 2,110 mm 745 mm 1,356 mm 1,481 mm 760 mm 121 mm 164 kg 294 kg underbone telescopic swing arm 120 / 70 - 12 / tubeless 140 / 60 - 13 / tubeless 2.00 kgf / ㎠ 2.00 kgf / ㎠ 2.00 kgf / ㎠ 2.25 kgf / ㎠ hydraulic disk hydraulic disk 11ℓ 2.8ℓ 27。 87...

Page 14

1-11 service information item specifications cvk type/30 mm butterfly # 102 2 ½ 18.5 mm 1,700±100 rpm automatic transmission 2.8 (42/15) 2.79 (39/14) full-transistor btdc 5。/ 1,700 ( rpm ) 12v 10ah (mf type) ngk dpr 7ea-9 0.9 mm starter motor 55/ 55w 5w 10w × 2/10w × 2 5/21w 3w 1.7w × 2 3w × 2 1.4w ...

Page 15: Torque Values

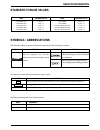

1-12 service information item reference torque value thread dia (mm) q’ty 3.0 kgf·m 3.0 kgf·m 1.47 kgf·m 2.2 kgf·m 2.45 kgf·m 1.1 kgf·m 1.0 kgf·m 1.27 kgf·m 5.5 kgf·m 5.5 kgf·m 5.88 kgf·m 0.5 kgf·m 1.18 kgf·m 1.72 kgf·m 1.18 kgf·m 1.18 kgf·m 2.8 kgf·m 4.0 kgf·m 8 8 30 8 8 5 6 12 12 12 14 5 6 10 6 8 ...

Page 16: Standard Torque Values

1-13 service information standard torque values item item torque value torque value 0.5 kgf·m 1.0 kgf·m 2.2 kgf·m 3.5 kgf·m 5.5 kgf·m 0.4 kgf·m 0.9 kgf·m 1.2 kgf·m 2.7 kgf·m 4.0 kgf·m 5mm bolt, nut 6mm bolt, nut 8mm bolt, nut 10mm bolt, nut 12mm bolt, nut 5mm screw 6mm screw 6mm flange bolt, nut 8mm...

Page 17: Lubrication Oil

1-14 service information lubrication oil lubrication points reference sae15w-40 or sae10w 30# api se, sf or sg heat-resistant grease loctite applies glue valve guide/valve stem operating parts cam shaft contact area cam shaft drive chain cylinder lock bolt and nut piston around and piston ring groov...

Page 18: Wiring Diagram

1-15 service information wiring diagram water pass tube a fuel neck earth wire battery (12v 10ah) resister comp. Heater controller ignition unit comp. L. Seat lock cable throttle position senser coupler i.G coil trank lamp wire fuel unit coupler air cleaner tube(air cleaner) drain tube auto chock co...

Page 19

1-16 service information fuel tube (insulator) fuel tube (insulator) fuel tube fuel strainer comp. Fuel water pass tube b fuel tube (fuel tank) tube clip rr. Stay water hose b water hose a water hose clamp water pipe a water pipe b rr. Brake hose pipe water pass tube b e.M.I. Unit comp. Water pass t...

Page 20

1-17 service information head light controller regulator rectifier start magnetic switch battery earth cable headlight controller code regulator coupler 2ea head light relay thermo switch relay winker relay earth cable battery box coupler *note - white color : export use only - black color : domesti...

Page 21

1-18 service information headlight relay battery earth cable reserve fuse battery box fuse box winker relay thermo switch relay headlight relay fuse box ass'y battery box.

Page 22

1-19 service information start magnetic switch start motor cable fuel pump fuel tube (insulator) fuel tube (fuel tank) fuel tube (carburetor) trunk lamp wire thermo sensor wire noise suppressor cap auto chock cord i.G. Coil side stand switch coupler throttle position coupler rr. Brake hose water hos...

Page 23: Memo

Memo.

Page 24: 2. Inspections/adjustments

2-1 2. Inspections/adjustments service information •the exhaust gas contains poisonous substance. Do not keep engine idling in a closed or poorly ventilated place for a long period of time. •refer to 2~3, 2~4 with respect to engine oil and oil filter. •stand the main stand prior to beginning work. S...

Page 25

2-2 inspections / adjustments tires cold tire pressure tire size driver only driver and a passenger front tire rear tire front tire rear tire front tire rear tire 2.00kgf/ ㎠ ㎠ 2.00kgf/ ㎠ ㎠ 2.00kgf/ ㎠ ㎠ 2.25kgf/ ㎠ ㎠ 120/70 - 12 (tubeless) 140/60 - 13 (tubeless).

Page 26: Maintenance Schedule

2-3 inspections / adjustments maintenance schedule ● carry out pre-operation check at each scheduled maintenance period based on the information described in the owner’s manual. I : inspect and clean, adjust, lubricate or replace if necessary. R : replace l : lubricate c : clean * if there are no ap...

Page 27: Fuel Line(Fuel Tube)

2-4 inspections / adjustments fuel line(fuel tube) ● remove the luggage box . ● check the fuel tube of the fuel auto cock connected to the fuel tank and carburetor. If the fuel tube is cranked, damaged or leaks, replace it. Throttle grip operation ● check if the throttle grip operates smoothly in an...

Page 28: Air Cleaner

2-5 inspections / adjustments air cleaner ● loosen the 6 screws securing the air cleaner case cover, remove it. ● loosen the 2 screws securing the air cleaner element holder, remove it. Valve clearance ● remove the cylinder head cover. Spark plug ● remove the plug maintenance cover. ● remove the spa...

Page 29

2-6 inspections / adjustments ● loosen the lock nut with a valve wrench, and set valve clearance to a prescribed level by turning the adjusting screw with a valve adjusting wrench. ● after setting clearance to the prescribed level, hold the adjuster screw with a valve adjusting wrench, and tighten t...

Page 30: Carburetor Idle Speed

2-7 inspections / adjustments carburetor idle speed ● remove the plug maintenance cover. Gear oil replacement ● remove the oil check bolt. ● remove oil drain bolt and drain oil completely. ● install and tighten the oil drain bolt. Torque value : 0.98kgf · m drive belt ● remove the l.Crankcase cover....

Page 31: Coolant Level Inspection

2-8 inspections / adjustments coolant level inspection ● erect the main stand prior to beginning work. ● check the coolant level of the reserve tank. ● the level should be between the “upper” and “lower” level lines. ● fill the coolant with the reserve tank up to the “f” (upper level). •unless the c...

Page 32: Brake Fluid

2-9 inspections / adjustments brake fluid ● remove the brake fluid cover. ● check the oil level inside the front brake reservoir. If the oil level is near the lower limit line, remove the reservoir diaphragm and fill dot 3 and dot 4 brake fluid to the top limit line. ● if the brake fluid reaches the...

Page 33: Suspension

Suspension front wheel ● hold the brake lever, and compress the front cushion up and down several times to check the operating conditions. ● check the front fork for oil leakage, parts damage or looseness. Rear wheel ● compress the near cushion up and down several times to check the operating condit...

Page 34: Wheels/tires

2-11 inspections / adjustments wheels/tires standard pressure •check the tire pressure when the tires have been cooled off. Check the tread (the part making contact with the road surface) and side for wear, cracks or damage. Replace damaged tires. ● check the tread depth at the tire center. ● if the...

Page 35: Memo

Memo.

Page 36: Service Information

Service information ● this section describes external parts removal/installation. ● do not apply unreasonable force when disassembling covers, to prevent possible damage. ● a muffler is hot. Do not service it immediately after the engine is stopped. 3-1 3. External parts 3 service information · ·· ·...

Page 37: Seat

3-2 external parts seat ● release the seat lock by turning the main switch key to open the seat. ● loosen the flange nuts and remove the seat. ● install in the reverse order of removal. Rear grip ● remove the rear grip cap (r.L) ● loosen the 4 special bolts. ● install in the reverse order of removal...

Page 38: Luggage Box

3-3 external parts luggage box ● remove the seat. ● remove the pillion seat. ● remove the luggage box top cover. ● loosen the screws on the seat catch. ● loosen the open stay nuts. ● loosen the washer bolts. ● remove the wire for the trunk lamp. ● install in the reverse order of removal. Center cove...

Page 39: Body Cover

3-4 external parts body cover ● remove the rr. Grip r/l ● remove the following parts - seat - luggage box - center cover - body side cover ● loosen the special screw ● loosen the body cover clip (r/l) ● remove the wire for the tail light and pull the body cover backward. ● install in the reverse ord...

Page 40: Front Cover

3-5 external parts front cover ● loosen the 2 tapping screws securing the fornt cover ● loosen the 2 tapping screws securing the inner cover ● install in the reverse order of removal under cover ● loosen the 4 special screws (r/l, 2ea for each) to remove the under cover ● install in the reverse orde...

Page 41: Windscreen

3-6 external parts windscreen ● remove the front cover ● loosen the 4 washer bolts and remove the windscreen ● install in the reverse order of removal front under cover a ● remove the front cover and windscreen ● loosen the 7 tapping screws securing the inner cover ● install in the reverse order of ...

Page 42: Inner Cover

3-7 external parts ● loosen the 4 tapping screws securing the inner cover inner cover ● remove the front cover and windscreen ● remove the coolant reserve tank ● remove the fuel tube clip ● remove the breather tube ● loosen the 3 screws securing the inner cover ● remove the bag holder ● loosen the 2...

Page 43: Front Fender

3-8 external parts front fender ● loosen the 4 screws (r/l, 2ea for each) ● install in the reverse order of removal ex. Pipe ● loosen the 2 cap nuts securing the cylinder comp. ● pull the ex. Pipe comp. Downward to remove it ● install in the reverse order of removal muffler ● loosen the muffler flan...

Page 44: Memo

Memo.

Page 45

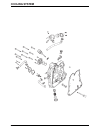

4-0 lubrication system rocker arm shaft crank shaft oil filter screen oil pump.

Page 46: 4. Lubrication System

4-1 4. Lubrication system 4 service information · ·· ·· ·· · 4-1 troubleshooting · ·· ·· ·· ·· · 4-2 engine oil level inspection · · 4-3 engine oil change · ·· ·· ·· ·· · 4-3 oil pump · ·· ·· ·· ·· ·· ·· ·· ·· ·· ·· · 4-4 oil pump ass’y assembly · · 4-6 service information general safety 1. The exha...

Page 47: Troubleshooting

4-2 lubrication system 4-2 troubleshooting oil level low •oil consumption. •external oil leaks. •worn piston ring or incorrect piston ring installation. •worn valve guide or seal. Oil contamination •oil or filter not changed often enough. •faulty head gasket. •worn piston rings. Low or no oil pressu...

Page 48: Engine Oil Level Inspection

4-3 lubrication system engine oil level inspection ● erect the motorcycle on the main stand. ● warm up the engine to heat the engine oil to an appropriate level. ● stop the engine, and check the oil level line on the sight-glass installed on the lh. Crank case cover. ● if the oil level is between th...

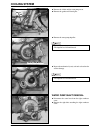

Page 49: Oil Pump

4-4 lubrication system oil pump removal ● drain cooling water. ● remove the following parts. - rh. Crank case cover - a.C generator - starting clutch gear comp - oil seperator cover and attaching bolt oil pump disassembly ●loosen the screw securing the oil pump plate. ●remove the oil pump body and t...

Page 50

4-5 lubrication system oil pump inspection ●assemble the inner and outer rotors to the oil pump body. ●measure the pump body clearance. Service limit : 0.25mm tool : feeler gauge ●measure the rotor tip clearance. Service limit : 0.20mm ●measure the pump side clearance. Service limit : 0.12mm oil pum...

Page 51

4-6 lubrication system ● install in accordance with the hole of the dowel pin and pump cover. ● tighten the pan screw. ●install the oil separetor cover. ●install the starting clutch gear comp. ●install the pump chain on the oil pump drive sprocket. ●install the circlip aroud the pump shaft. Oil pump...

Page 52: Memo

Memo.

Page 53

5-0 fuel system.

Page 54: Service Information

5-1 service information general safety ● gasoline is extremely flammable. Avoid fire in the work place, also paying particular attention to sparks. Furthermore, the evaporated (gasified) gasoline is highly explosive. Work in a well-ventilated areas. ● exhaust gas contains poisonous substance. Do not...

Page 55: Troubleshooting

5-2 fuel system troubleshooting the vehicle does not start. ● no gasoline in fuel tank. ● fuel is not coming out of carburetor. ● too much fuel is flowing into cylinder. ● no spark emitted from spark plug. ● air cleaner is blocked. ● suction system is experiencing secondary intake of air. ● using lo...

Page 56: Fuel Tank

5-3 fuel system fuel tank removal ● release the seat lock by turning the main switch key to open the seat. ● remove the following parts. - luggage box . ( ⇨ 4-4) - floor panel leg . - center cover. - rear center cover. - rear carrier/back rest . - body cover. ● remove the fuel tube from the fuel tan...

Page 57: Vacuum Chamber Removal

● loosen the throttle cable lock nut, and remove the throttle cable from the carburetor. ● loosen the air cleaner connecting tube band and the carburetor intake manifold band. ● remove the carburetor ● remove the two vacuum chamber cover screws and the cover. ● remove the compression spring and vacu...

Page 58: Vacuum Piston Inspection

5-5 fuel system ● remove the needle holder, spring and jet needle from the piston. Vacuum piston inspection ● inspect the vacuum piston and jet needle for wear or damage. ● inspect the diaphragm for deterioration and tears. Float chamber disassembly ● remove the three float chamber screws and the fl...

Page 59: Float Valve Inspection

Float valve inspection ● inspect the float valve seat contact area for wear. Jets/screws removal ● inspect the float valve seat contact area for wear. ● remove the main jet, needle jet holder and needle jet. ● remove the slow jet. ● clean the removed the main jet, needle jet holder, needle jet and s...

Page 60: Auto Bystarter

Auto bystarter inspection/removal auto bystarter inspection ● measure the resistance between the auto bystarter wire terminals. Resistance : 10Ω(minutes minimum after stopping the engine) auto bystarter removal ● remove the one set plate screw and set plate and then remove the auto bystarter from th...

Page 61: Air Cut-Off Valve (A.C.V)

5-8 fuel system air cut-off valve (a.C.V) a.C.V removal ● remove the two screws and the air cut-off valve cover. ● remove the spring, diaphragm and o-rings. ● inspect the diaphragm and spring for wear or damage. ● install the o-ring onto the air-cut-off valve body securely. ● install the diaphragm, ...

Page 62: Accelerating Pump

5-9 fuel system ● install and tighten the two screws attaching the air cut- off valve cover. ● connect the hose. •insert the auto bystarter into the carburetor body until it bottoms and position the set plate into the upper groove in the bystarter. •install the set plate with its round face facing d...

Page 63: Float Level Inspection

5-10 fuel system float level inspection ● install the float valve, float and float fin. ● measure the float level at the location of the main jet (just contacting the float valve) float level : 18.5 ±1.0mm ● replace the float if the level is incorrect. ● check the operation of the float and then rei...

Page 64: Fuel Pump

Fuel pump removal ● remove the frane center cover. ● disconnect the fuel pump inlet, outlet and vacuum tubes. ● remove the two fuel pump attaching bolts and the fuel pump. Carburetor installation ● tighten the drain screw. ● install the carburetor onto the intake manifold and tighten the band. ● ins...

Page 65

5-12 fuel system ● disassemble the fuel pump. ● inspect the fuel pump diaphragms a and b for damage. ● inspect each gasket for damage. ● inspect the suction valve, outlet valve and relief valve in the fuel pump body for damage, cracks or foreign matters. ● install in the reverse order of removal. Ou...

Page 66: Memo

Memo.

Page 67: Cooling System

6-0 cooling system.

Page 68: 6. Cooling System

6-1 6. Cooling system service information ● do not remove the radiator cap except to refill or drain the cooling system after servicing the cooling system. ● avoid spilling coolant on painted surfaces. If contaminated, wash in water immediately. ● after disassembling or servicing the cooling system,...

Page 69: Cooling System

6-2 cooling system troubleshooting engine temperature too high ● faulty temperature gauge or thermo sensor ● air in cooling system ● faulty thermostat stuck (thermostat stuck closed) ● passages blocked in radiator, hoses or water jacket ● faulty fan motor switch ● faulty water pump engine temperatur...

Page 70: Cooling System

6-3 cooling system 5 10 15 20 25 30 35 40 45 50 55 60 0 1.009 1.018 1.028 1.036 1.045 1.053 1.063 1.072 1.080 1.086 1.095 1.100 1.009 1.017 1.027 1.035 1.044 1.052 1.062 1.070 1.078 1.084 1.093 1.098 1.008 1.017 1.026 1.034 1.043 1.051 1.060 1.068 1.076 1.082 1.091 1.095 1.009 1.016 1.025 1.033 1.04...

Page 71: Cooling System

6-4 cooling system cooling system test ● install the redicator cap onto the radiator tester. ● press it with specified pressure and it must keep the pressure for at least six seconds. Radiator inspection ● remove the front cover. ● remove the under cover a. Radiator cap relief pressure : 0.9 ± 0.15k...

Page 72: Cooling System

6-5 cooling system ● loosen the hose band and disconnect the upper hose and lower hose from the radiator. ● disconnect the thermostatic switch wire coupler. ● disconnect the fan motor wire coupler. ● remove the 2 bolts and 1nut on the radiator. ● remove the 3bolts and then remove the fan/shround fro...

Page 73: Cooling System

6-6 cooling system check thermostatic switch ● when coolant temperature lower then 83~87° c the thermostatic switch off. ● when coolant temperature over 88~92°c the thermostatic switch on. Radiator installation ● install the radiator on the radiator bracket with the 2 bolts and 1 nut. ● connect the ...

Page 74: Cooling System

6-7 cooling system ● connect the overflow tube and secure with the tube clamp. ● fill the radiator with coolant. ● connect the vent tube to the radiator filler. ● after installation, check for coolant leaks. ● install the front cover. Water pump mechanical seal (water seal) inspection ● inspect the ...

Page 75: Cooling System

6-8 cooling system ● remove the 4 bolts and the water pump cover. ● remove the gasket and 2 dowel pins. ● remove the water pump impeller. ·the impeller has left hand threads. ● inspect the mechanical (water) seal and seal washer for wear or damage. ·the impeller has left hand threads. Water pump sha...

Page 76: Cooling System

6-9 cooling system ● remove the water pump bearing snap ring from the water pump assembly. ● remove the water pump shaft and inner bearing. ● remove the water pump shaft outer bearing. ·apply sealant to the right crankcase cover fitting surface of a new mechanical seal and then drive in the mechanic...

Page 77: Cooling System

6-10 cooling system ·when installing the water pump assembly, aligning the groove on the water pump shaft with the tab on the oil pump shaft. Water pump shaft installation ● drive a new water pump shaft outer bearing into the water pump assembly from the inside. Water pump / impeller installation ● ...

Page 78: Cooling System

6-11 cooling system thermosensor removal ● remove the seat, met-in box and center cover. ● drain the coolant. ● disconnect the thermosensor wire. ● remove the thermosensor. ·the impeller has left hand thread. ● install the impeller onto the water pump shaft. Torque value : 0.98~1.37kgf · m ● install...

Page 79: Cooling System

6-12 cooling system 120 16 100 27 80 52 50 154 temperature(° c) resistance( Ω ) inspection ● suspen the thermosensor in a pan of water over a burner and measure the resistance through the sensor as the water heats up. Installation ● apply a sealant to the themosensor threads and install it into the ...

Page 80: Cooling System

6-13 cooling system 80 2 c 90 c 3.5~4.5mm begins to open full-open valve lift installation ● install in the reverse order of removal. Inspection ● suspend the thermostat in a pan of water over a burner and gradually raise the water temperature to check its operation. Technical data ·do not let the t...

Page 81: Memo

Memo.

Page 82: Service Information

7-1 7. Engine removal/installation service information general safety •use a jack to remove or install the engine. Support the motorcycle with a jack firmly, taking precautions not to damage the frame, engine, cable or harness. •attach tape to the frame to protect it during the engine removal or ins...

Page 83: Engine Removal

7-2 engine removal/installation engine removal ● disconnect the battery ⊖ cable. ● remove the frame body cover. ● disconnect the engine ⊖ cable. ● disconnect the a.C generator, auto bystarter, spark plug, thermosensor wire couplers and connectors. ● disconnect the engine fuel tube. ● drain the coola...

Page 84: Engine Installation

7-3 engine removal/installation engine installation ● tighten the engine mounting nut. Torque value : 4.9kgf · m ● remove the r/l rear shock absorber upper mount bolts. ● remove the engine mounting bolt and pull out the engine. ● remove the engine hanger bolts to remove the engine hanger. ● inspect ...

Page 85

7-4 engine removal/installation ● tighten the rear shock absorber upper mount bolts. Torque value : 3.92kgf · m after installation, inspect and adjust the following: ● throttle grip free play. ● fill the rear brake reservoir with brake fluid and bleed air from the rear brake. ● fill the cooling syst...

Page 86: Memo

Memo.

Page 87

8-0 lh. Crankcase cover/continuously variable transmission.

Page 88: Variable Transmission

8-1 8. Lh. Crankcase cover/continuously variable transmission service information ● do not allow oil to contact the drive belt or the pulley face. The transmission rate of driving force is reduced with oil contact. ● do not operate starter motor while the l. Crank case front cover is removed. Specif...

Page 89: Lh. Crankcase Cover

8-2 lh. Crankcase cover/continuously variable transmission lh. Crankcase cover removal ● remove the bolts securing lh. Side cover. ● loosen the air tube screw. ● remove the air tube. ● loosen the lh. Cover bolts. ● remove the lh. Crankcase cover. ● remove the and dowel pin. Installation ● install th...

Page 90: Drive Fulley

8-3 lh. Crankcase cover/continuously variable transmission drive fulley removal ● remove the lh. Crankcase cover. ● loosen the drive face flange nut with the drive face holder. ● remove the drive face. ● remove the drive bolt from the movable drive face. ● remove the movable drive face assembly. ● r...

Page 91

8-4 lh. Crankcase cover/continuously variable transmission disassembly ● remove the ramp plate. ● remove the weight rollers. ● check the weight roller for wear or damage. ● measure the weight roller o.D. Service limit : 22mm replace if below ● measure the movable drive face bushing i.D. Service limi...

Page 92

8-5 lh. Crankcase cover/continuously variable transmission ● check the drive pully collar for damage or wear. ● measure the o.D of the drive pully collar sliding surface. Service limit : 26.9mm replace if below ● install the ramp plate. ● install the weight rollers into the movable face. Assembly ra...

Page 93

8-6 lh. Crankcase cover/continuously variable transmission ● insert the drive pulley collar into the movable drive face. ● install the movable drive face onto the crankshaft. ● lay the drive belt on the driven pulley. ● set the drive belt on the drive pulley collar. ● install the washer and drive nu...

Page 94

8-7 lh. Crankcase cover/continuously variable transmission ● hold the dirve pulley with the drive face holder and tighten the drive face nut. Torque value : 8.82~9.8kgf · m clutch/driven pulley ● remove the left crankcase cover. ● remove the drive pulley and drive belt. ● hold the clutch outer with ...

Page 95: Clutch/driven Pulley

8-8 lh. Crankcase cover/continuously variable transmission clutch/driven pulley disassembly ● hold the clutch/driven pulley assembly with the clutch spring compressor. ● set the tool in a vise and remove the clutch drive plate nut. (39mm) ● loosen the clutch spring compressor and disassemlble the cl...

Page 96

8-9 lh. Crankcase cover/continuously variable transmission ● check the driven face assembly for wear or damage. ● measure the driven face o.D. Service limit : 39.85mm replace if below ● check the movable driven face for wear or damage. ● measure the movable driven face i.D. Service limit : 40.06mm r...

Page 97

8-10 lh. Crankcase cover/continuously variable transmission ● press a new needle bearing into the driven face. Clutch disassembly ● remove the circlips and retainer plate to disassemble the clutch. Clutch assembly ● install the damper rubbers on the drive plate pins. ● install the clutch weights/sho...

Page 98

8-11 lh. Crankcase cover/continuously variable transmission clutch/driven pulley assembly ● clean the pulley faces and remove any grease from them. ● apply frease to the o-ring and install them onto the moveable driven face. ● install the movable driven face onto the driven face. ● apply grease to t...

Page 99

8-12 lh. Crankcase cover/continuously variable transmission ●install the clutch/driven pulley onto the drive shaft. ● install the clutch outer. ● hold the clutch outer with the universal holder. ● install and tighten the clutch outer nut. Torque value : 4.9~5.88kgf · m ● install the drive belt. ● in...

Page 100: Memo

Memo.

Page 101

9-0 a.C generator/starter clutch.

Page 102: Service Information

9-1 9. A.C generator / starter clutch service information ● drain the coolant before removing the right crankcase cover. ● be careful not to drain the coolant when the engine temperature in high. (perform this operation when the engine is cold.) ● drain the engine oil into a clean container before r...

Page 103: Right Crankcase Cover

9-2 a.C generator/starter clutch stator removal ● remove the three a.C. Generator stator bolts and the stator. Flywheel removal ● hold the flywheel with a flywheel holder and remove the flywheel nut. Right crankcase cover removal ● disconnect the water hoses from the right crankcase cover. ● remove ...

Page 104: Starter Clutch

9-3 a.C generator/starter clutch starter clutch removal ● remove the starter clutch gear comp. Inspection ● inspect the starter clutch gear comp for wear or damage. ● measure the starter clutch gear comp i.D. And o.D. Service limits: i.D. : 22.15mm replace if over o.D.: 41.50mm replace if below ● in...

Page 105: Flywheel Installation

9-4 a.C generator/starter clutch ● remove the starter one-way clutch rollers, plungers and springs. Installation ● install the starting clutch gear comp onto the crankshaft. ● install the starter reduction gear and shaft. Flywheel installation ● install the flywheel onto the crankshaft by aligning t...

Page 106: Stator Installation

9-5 a.C generator/starter clutch stator installation ● install the a.C. Generator stator on the rh. Crankcase cover and secure it with the 3 bolts. ● install the pulse coil on the rh. Crankcase cover and secure it with the 2 scerws. ● install the wire grommet in the groove in the rh. Crankcase cover...

Page 107

10-0 cylinder head / valve.

Page 108: Service Information

10-1 10. Cylinder head/cylinder/piston service information ● drain the coolart from the radiator and water. ● apply oil to valve guide and valve arm when assemblying. Specifications 10 services information · ·· ·· ·· ·· ·· ·· ·· · 10-1 cylinder head cover · ·· ·· ·· ·· ·· ·· ·· · 10-1 cam shaft · ··...

Page 109: Camshaft

10-2 cylinder head / valve camshaft removal ● turn the a.C. Generator flywheel so that the “t” mark on the flywheel aligns with the index mark on the crankcase. ● hold the round hole on the camshaft gear facing up and the location is the top dead center on the compression stroke. ● remove the 2 bolt...

Page 110

10-3 cylinder head / valve ● remove the camshaft gear from the cam chain to remove the camshaft. Inspection ● check each cam lobe for wear or damage. ● measure the cam lobe height. Service limits: in : 34.14mm replace if below ex: 34.02mm replace if below ● check each camshaft bearing for play or da...

Page 111: Cylinder Head

10-4 cylinder head / valve ● measure the i.D. Of each valve rocket arm. Service limits: in : 10.10mm replace if over ex: 10.10mm replace if over ● measure each rocker arm shaft o.D. Service limits: in : 9.90mm replace if below ex: 9.90mm replace if below cylinder head removal ● first drain the coola...

Page 112

10-5 cylinder head / valve ·be careful not to damage the cylinder head mating surface. ·be sure to compress the valve springs with a valve spring compressor. ·mark all disassembled parts to ensure correct reassembly. ● remove carbon deposits fron the exhaust port and combustion chamber. Disassembly ...

Page 113

10-6 cylinder head / valve ● inspect each valve for bending, burning, scratches or abnormal stem wear. ● check valve movenment in the guide. ● measure each valve stem o.D. Service limits: in : 4.925mm replace if below ex : 4.925mm replace if below assembly ● install the valve spring seats and stem s...

Page 114

10-7 cylinder head / valve ● install the cylinder head and take out the cam chain. ● assemble the camshaft holder. ● first install the intake and exhaust valve ● rocker arms ; then install the rocker arm shafts. Camshaft installation ● turn the a.C. Generator flywheel so that the “t” mark on the fly...

Page 115

10-8 cylinder head / valve ● install the camshaft holder, washers and nuts on the cylinder head. ● tighten the 4 cylinder head nuts and the 2 bolts between the cylinder head and cylinder. Torque : cylinder head cap nut : 2.45kgf · m cylinder & cylinder head bolt : 0.78~1.18kgf · m ● turn the cam cha...

Page 116: Memo

Memo.

Page 117

11-0 cylinder/piston.

Page 118: 11. Cylinder / Piston

11-1 11. Cylinder / piston service information general safety ● be careful not to damage the mating surfaces by using a screwdriver when disassembling the cylinder. Do not strike the cylinder too hard during disassembly, even with a rubber or plastic mallet, to prevent the possibility of damage to t...

Page 119: Cylinder Removal

11-2 cylinder/piston ·place a clean shop towel in the crankcase to keep the piston pin clip from falling into the crankcase. Cylinder removal ● remove the cylinder head. ● remove the water hose from the cylinder. Pistion removal ● remove the piston pin clip. ● remove the piston pin out of the piston...

Page 120

11-3 cylinder/piston ·take care not to damage or break the piston rings during removal. ● install the piston, piston pin and piston rings. ● remove the piston rings. ·use the piston head to push each piston ring into the cylinder. ● remove the piston rings and insert each piston ring into the cylind...

Page 121

11-4 cylinder/piston ·take measurement at 9mm from the bottom and 90° to the piston pin hole. ● measure the piston pin o.D. Service limits : 16.96mm replace if below service limits : 72.60mm replace if below ● measure the piston-to-piston pin clearance. Service limits : 0.02mm replace if over cylind...

Page 122: Pistion Ring Installation

11-5 cylinder/piston ·be careful not to damage the piston and piston rings during assembly. ·all rings should be installed with the markings facing up. ·after installing the rings, they should rotate freely withlout sticking. ·stagger the ring end gaps as the figure shown. ● inspect the top of the c...

Page 123: Pistion Installation

11-6 cylinder/piston ·be careful not to drop foreign matters into the crankcase. Pistion installation ● remove any gasket material from the crankcase surface. Cylinder installation ● install the dowel pins and a new cylinder gasket on the crankcase. ·position the piston “in” mark on the intake valve...

Page 124

11-7 cylinder/piston ● install the cam chain guide. ● install the cylinder gasket and dowel pins. ● connect the water hohse to the cylinder. ● install the cylinder head. ● tighten the cylinder base bolt. Dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel pin dowel ...

Page 125

12-0 crankshaft/crankcase.

Page 126: 12. Crankshaft/crankcase

12-1 12. Crankshaft/crankcase service information general safety ● this section covers crankcase separation to service the crankshaft. The engine must be removed for this operation. ● when separating the crankcase, never use a driver to pry the crankcase mating surfaces apart forcedly to prevent dam...

Page 127: Troubleshooting

12-2 crankshaft/crankcase tool universal bearing puller bearing remover set remover ass’y remover shaft remover head slieding weight assembly shaft troubleshooting excessive engine noise ● excessive bearing play ● excessive crankpin bearing play ● worn piston pin and piston pin hole.

Page 128: Crankcase Removal

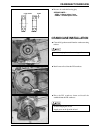

12-3 crankshaft/crankcase crankcase removal ● remove the cam chain tensioner slipper bolt. ● remove the cam chain tensioner slipper and cam chain. ● loosen the 3 bolts securing the rh. Crankcase. ● remove the lh. Crankcase. ● place the crankcase with the lh. Crankcase down and remove the rh. Crankca...

Page 129: Crankcase Inspection

12-4 crankshaft/crankcase ● remove the oil seal from the lh. Crankcase. ● install a new drive shaft oil seal. Crankcase inspection ● measure the connecting rod big end sied clearance. Service limits : 0.6mm replace if over ● measure the connecting rod small end i.D. Service limits : 17.06mm replace ...

Page 130: Crankcase Installation

12-5 crankshaft/crankcase ● install a new oil seal into the lh. Crankcase. ● measure the crankshaft bearing play. Service limits : axial : 0.20mm replace if over radial : 0.05mm replace if over crankcase installation ● clean off all gasket material from the crankcase mating surfaces. ● place the lh....

Page 131

12-6 crankshaft/crankcase ● place the rh. Crankcase over the crankshaft and onto the lh. Crankcase. ● install and tighten the r/l and left crankcase bolts. Torque value : 0.78~1.08kgf · m ● install the cam chain. ● install the cam chain tensioner slipper. ● install the tighten the cam chain tensione...

Page 132: Memo

Memo.

Page 133

13-0 final reduction.

Page 134: 13. Final Reduction

13-1 13. Final reduction service information specifications specified oil : sae 90# oil capacity: at disassembly : 0.2 liter at change : 0.18 liter torque values transmission case cover bolt : 1.17~2.16kgf·m cam chain tensioner : 0.78~1.18kgf·m special tools bearing remover, 12mm bearing remover, 15...

Page 135: Final Reduction

13-2 final reduction final reduction disassembly ● remove the exhaust muffler. ● remove the rear brake caliper. ● remove the rh. Rear shock absorber. ● remove the rear fork. ● remove the rear wheel. ● remove the left crankcase cover. ● remove the clutch/driven pulleys. ● drain the transmission gear ...

Page 136

13-3 final reduction ● check the lh. Crankcase bearings for excessive play and inspect the oil seal for wear or damage. ● inspect the drive shaft and gear for wear or damage. ● check the transmission case covers bearings for excessive play and inspect the final shaft bearing oil seal for wear or dam...

Page 137: Final Reduction

13-4 final reduction bearing replacement (transmission case cover) ● remove the transmission case cover bearings using the bearing remover. ● remove the final shaft oil seal. ● install the final gear and final shaft into the left crankcase. Final reduction assembly ● install the drive shaft into the...

Page 138

13-5 final reduction ● install the countershaft and gear into the left crankcase. ● install the resin washer onto the counter-shaft. ● install the dowel pins and a new gasket. ● after installation, fill the ransmission case with the specified oil. ● after installation, fill the ransmission case with...

Page 139

14-0 front wheel/front fork/steering/brake.

Page 140: Service Information

14-1 14. Front wheel/front fork/steering/brake service information general safety ● keep oil or brake fluid off the brake disk and pad because the contaminated brake disk and pad reduces the braking performance. If contaminated, replace the pad with a new one, and clean the disk. ● use special tire ...

Page 141: Troubleshooting

14-2 front wheel/front fork/steering/brake troubleshooting hard steering ● steering bearing adjustment nut too tight. ● faulty steering stem bearings. ● damaged steering stem bearings. ● insufficient tire pressure. Steers to one side or does not track straight ● unevenly adjusted right and left shoc...

Page 142: Steering Handle

14-3 front wheel/front fork/steering/brake steering handle removal ● remove the upper handle cover and the under handle cover from the handle bar. ● loosen the bolts securing the front and rear break master cylinder. ● remove the front cover, front under cover and speedometer cover. ● loosen the 4 s...

Page 143: Front Wheel

14-4 front wheel/front fork/steering/brake ● lubricate the throttle grip front end with grease and then install the throttle grip. ● connect the throttle cable to the throttle grip. ● install the right and left handlebar switches and tighten the screws. ● install the front and rear brake master cyli...

Page 144: Front Wheel Bearing

Wheel rim ● check the wheel rim runout. Service limit : radial : 2.0mm replace if over axial : 2.0mm replace if over front wheel bearing inspection ● turn the inner race of each bearing with your finger to see if they turn smoothly and quietly also check if the outer race fits tightly in the hub. ● ...

Page 145

14-6 front wheel/front fork/steering/brake speedometer gear replacement ● remove the speedometer gear and washer from the speedometer gear box. ● check the gear for wear or damage. ● install the washer. ● apply grease to the speedometer gear prior to assembling. ● install the washer. ● apply grease ...

Page 146: Front Wheel

● apply grease to the dust seal rim. ● install the dust seal, and align the tangs of the speedometer gear retainer with the gear groove to assemble the speedometer gear box. Front wheel installation ● insert the front wheel between the front forks. ● insert the disk, taking precautions not to damage...

Page 147

Disassembly ● remove the fr/rr stop switch. ● take out the boot and circlip from the master cylinder. Tools : snap ring pliers ● remove the washer, piston, spring from the master cylinder. ● clean the master cylinder, reserve, master piston with the recommended brake fluid. Inspection ● check the pi...

Page 148

● check the master cylinder for scores, scratches or nicks and replace if necessary. Assembly installation ● coat the piston, cup with the fresh brake fluid and install it on the piston. Install the spring with its larger diameter end toward the master cylinder. 14-9 front wheel/front fork/steering/...

Page 149: Brake Fluid

● install the brake hose to the master cylinder with 2 new sealing washers and the hose bolt. Torque value : 2.5~3.5 kgf · m ● loosen the 2 flat screws, remove the oil cup cap, diaphragm plate and diaphragm. ● fill the brake fluid, and bleed air. ● install the diaphragm, diaphragm plate and the oil ...

Page 150

● repeat the above procedures until no air bubbles appear in the bleeder hose. ● squeeze the bleeder valve and operate the brake lever to check the ingress of air. When the brake bleeder is not available > ● fill the brake fluid up to the upper limit line. ● connect the transparent bleeder hose to t...

Page 151: Brake Caliper

● disassemble the piston seal and the dust seal ● clean the piston and the inside of the caliper and remove the oil from the seal groove. Brake caliper removal ● first drain the brake fluid from the hydraulic brake system. ● remove the brake fluid tube bolt. ● remove the two bolts securing the brake...

Page 152

Inspection ● check the caliper cylinder bore for scoring, scratches or other damage. ● measure the caliper i.D. Service limit : 25.42mm ● check the piston for scratches or wear. ● measure the piston o.D. With a micrometer gauge. Service limit : 25.27mm ● clean the piston seal and the dust seal with ...

Page 153: Front Fork

● apply the silicone grease to the boot. ● connect the boot to the portion of the caliper. ● install the pad spring in the caliper. ● install the caliper pin bolt and the slide pin in the caliper. ● install the brake pad and the hanger pin in the caliper. ● install the front caliper to the front for...

Page 154

Disassembly ● remove the fork pipe bolt. ● wrap the bottom case with a piece of cloth, and remove the socket bolt. ● remove the dust seal. 14-15 front wheel/front fork/steering/brake ·if the screw is completely loosened, the fork tube cap bolt may spring out by the force of the spring. Take due prec...

Page 155

● remove the oil seal stop ring. ● remove the oil seal. ● remove the fork tube from the bottom case. ● remove the piston and rebound spring from the fork tube. Front fork inspection ● place the fork spring on a level place, and measure the free length. ● if the free length deviates from the service ...

Page 156

● check the slider bush contact face. ● if the slider bush is extensively damaged, replace the bottom case. Front fork assembly ● wash parts with clean oil prior to assembling. ● assemble the rebound spring and thd fork piston to the fork tube. ● assemble the fork tube to the bottom case. ● wrap the...

Page 157

● install the dust seal. ● fill a prescribed amount of automatic transmission fluid(atf) into the fork tube. Capacity : 90cm 3 ● slowly press the fork tube 2-3 times to discharge air. ● install the oil seal stopper ring ● accurately assemble the oil seal stop ring to the bottom case. ● assemble the ...

Page 158: Steering Stem

14-19 front wheel/front fork/steering/brake ● remove the steering stem nut using the steering stem nut socket. Tool : steering stem nut socket ● remove the steering top thread nut using the steering stem socket. Tool : steering stem socket ● remove the top cone race. ● check the upper ball assembly,...

Page 159

● remove the steering top ball race from the head pipe. ● remove the steering bottom race. Installation ● install the steering head dust seal washer and dust seal onto the steering stem. ● press in the steering bottom cone race using the steering stem driver. ● install the under ball ass’y into the ...

Page 160: Memo

Memo.

Page 161

15-0 rear wheel / brake / suspension / rear swing arm.

Page 162: Service Information

15-1 15. Rear wheel/brake/suspension/swing arm service information ● during servicing, keep oil or grease off the brake pads and brake disk. ● inhaled asbestos fibers have been found to cause respiratory disease and cancer. Never use an air hose or dry brush to clean brake assemblies. Use a brake cl...

Page 163: Troubleshooting

15-2 rear wheel / brake / suspension / swing arm troubleshooting wobble or vibration in motorcycle ● tire pressure incorrect ● faulty tire ● bent rim ● loose wheel bearing ● swing arm bushing worn ● wheel out of balance soft suspension ● weak springs ● rear damper improperly adjusted, oil leakage ha...

Page 164: Rear Brake

Rear brake removal ● remove the muffler. ● loosen the rear break tube bolt and remove the break tube. ● loosen 2 bolts and remove rear break caliper. ● wind the caliper facing down with cloth to prevent the piston or break fluid from leaking. ● remove the piston from the caliper while blowing the lo...

Page 165

● disassemble the piston seal and the dust seal. ● clean the piston and inside of caliper with break fluid. ● apply the silicone grease to the pin bush. ● connect the pin bush to the portion of the caliper. ● install the pad spring in the caliper. ● install the caliper pin bolt and the caliper brack...

Page 166: Rear Wheel

Installation ● install the brack caliper to the front fork and tighten the bolt to specified torque. Torque value : 3.0kgf · m ● connect the brcakhose to the caliper body and tighten 2 oil bolts and washers to specified torque. Torque value : 3.4kgf · m ● fill the break fluid to te upper limit line ...

Page 167: Rear Cushion Adjust

Inspection ● measure the rear wheel rim runout. Service limit : radial : 1.0mm replace if over axial : 1.0mm replace if over assembly ● install in the reverse order of removal. Torque value rear cushion lower bolt: 1.96~2.94kgf · m rear axle nut: 7.84~9.8kgf · m rear cushion adjust ● adjust the cush...

Page 168

Installation ● install in the reverse order of removal. Torque value : 3.92kgf · m 15-7 rear wheel / brake / suspension / swing arm.

Page 169

16-0 charging system regulator rectifier main switch a.C. Generator.

Page 170: 16. Charging System

16-1 16. Charging system service information ·do not place flammable materials near battery when charging. This can be a fire hazard as hydrogen gas is created during charging battery. ·do not allow battery acid to come into contact with clothes, skin or eyes. Battery acid contact can cause burns or...

Page 171: Troubleshooting

16-2 charging system troubleshooting no power (key turned on) low power (engine running) ● dead battery. ● battery undercharged. -low fluid level. ● battery is failing. -low specific gravity. ● charging system failure. -charging system failure. ● disconnected battery cable. Intermittent power ● main...

Page 172: Battery

16-3 charging system battery charger battery ● remove the seat and luggage box. ● loosen the screws secuning the battery cover and remove the battery cover. ● remove the battery. ● first disconnect the negative “⊖” battery cable, and then disconnect the positive “⊕” cable. ● the installation sequenc...

Page 173: Charging System Inspection

16-4 charging system ● remove the frame center cover. ● disconnect the a.C. Generator connector. ● measure the resistance between the yellow wires. ● replece the stator if resistance value is high or there is continuity between each yellow wire and ground. ● resistance : yellow~yellow 0.6~1.6Ω charg...

Page 174

16-5 charging system regulator rectifier inspection ● remove the luggage box. ● remove the regulator rectifier coupler. ● measure each terminal. ● replace the regulator rectifier unit if the resistance value between the terminals is abnormal. Resistance value tester ⊕ tester ⊖ unit : ㏀, ( 20 ℃) r b ...

Page 175

17-0 ignition system battery regulator rectifier ignition unit a.C. Generator main switch ignition unit.

Page 176: 17. Ignition System

17-1 17. Ignition system service information general safety ● follow the steps described in the troubleshooting flow chart when servicing the ignition system. ● the cdi unit may be damage if dropped. Also, if the connector is disconnected when current is flowing, the excessive voltage may damage the...

Page 177: Troubleshooting

17-2 ignition system troubleshooting no spark at plug. Unusual condition probable cause (check in numerical order) 1. The multitester impedance is too low. 2. Cranking speed is too slow. - battery is undercharged (or operating force of the kick starter is weak). 3. The sample timing of the tester an...

Page 178: Ignition Coil Inspection

17-3 ignition system ignition coil inspection ● remove the seat lock with the main key. ● remove the luggage box. ● remove the center cover. ● remove the primary wire. ● measure the resistance between the two terminals of the ignition primary coil. ● if the resistance value is within the specified r...

Page 179: A.C. Generator Inspection

17-4 ignition system a.C. Generator inspection exciter/puise coil inspection ● remove the luggage box. ● disconnect the a.C. Generator connector. ● measure the exciter coil resistance between the black/white wire terminal and ground. Ignition unit inspection ● measure the resistance between terminal...

Page 180: Memo

Memo.

Page 181

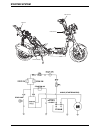

18-0 starter system battery main switch starter motor stop switch cable (starter motor) stop lamp battery + cable.

Page 182: 18. Starter System

18-1 18. Starter system service information general safety ● the starter motor can be maintained without removing the engine from the vehicle. ● a weak battery may be unable to turn the starter motor quickly enough, or, supply adequate ignition current. ● the starter motor may be damaged if current ...

Page 183: Troubleshooting

18-2 starter system troubleshooting starter motor will not turn. ● check for a blown main fuse before servicing. ● check that the stop light is correctly adjusted. ● check that the side stand is positioned in the condition under which the engine can be started. With the ignition switch “on”and squee...

Page 184: Starter Motor

18-3 starter system disassembly ● release the two starter motor case screws, front cover, rear cover, motor case and other parts. Inspection ● inspect the removed parts for wear, damage or discooration. Replace if necessary. ● clean the commutator if there is metal powder between the seaments. ● che...

Page 185

18-4 starter system ● measure the length of the brushes. Service limit : 8.5m replace if below ● check the continuity between brush ⊕and cord terminal. - normal if there is continuity. ● check the continuity between cord terminal and case. - normal if there is no continuity. ● make a continuity chec...

Page 186: Starter Magnetic Switch

18-5 starter system assembly ● apply grease to the dust seal in the front cover. ● install the brushes onto the brush holders. ● apply a thin coat of grease to the two ends of the armature shaft. ● insert the commutator into the front cover. ● install a new o-ring to the front cover. ● install the s...

Page 187

18-6 starter system starter magnetic switch voltage ● measure the voltage between the yellow / red wire (+) and ground at the starter magnetic switch connector. ● if battery voltage appears only when the starter switch is pressed, it is normal. Starter magnetic switch ground line ● disconnect the wi...

Page 188: Memo

Memo.

Page 189: Memo

Memo.

Page 190: 19. Lights/switchs/horn

19-1 19. Lights/switchs/horn troubleshooting light not turned on when the main switch is on ● faulty light bulb ● faulty switch ● faulty or disconnected wiring ● fuse cut ● battery discharged dim headlight ● battery discharged ● wiring and switch resistance high headlight hi-low bean cannot be charg...

Page 191: Main Switch

19-2 lights/switch/horn main switch ● remove the front covers. ● disconnect the ignition switch wire couplers. ● check for continuity between the wire terminals. Handle switch ● remove the headlight. ● disconnect the connector of handle switch. ● check for continuity between teminals. ● remove the f...

Page 192: Horn

19-3 lights/switch/horn horn ● remove the horn from the wire connector. ● connect the horn terminal with 12v battery. ● normal if it sounds. Fuel unit ● remove the foor panel. ● be cover full not to be damaged for the wire. ● check the base packing for damage. ● measure the resistance between the fu...

Page 193: Thermostatic Switch

19-4 lights/switch/horn thermostatic switch ● remove the front covers. ● start and run engine to make the water temperature reaches 85° c~90° c and check if the cooling fan motor operates. ● lower the water temperature to 85° c and check if the fan motor stops. Heater controller unit ● open ignition...

Page 194: Headlight Controller

19-5 lights/switch/horn a terminal : earth b terminal : none c terminal : none d terminal : sw. 1 e terminal : battery f terminal : pulser(input) cord sz1-lc headlight controller ● when the main switch turns on, the headlight (low), meter illumination, taillight, position light and license light tur...

Page 195: Headlight Bulb Replacement

19-6 lights/switch/horn headlight bulb replacement ● remove the front cover. ● remove the headlight coupler and winker coupler. ● remove the bulb socket of rubber boots. ● remove the rubber boots. ● replace the headlight bulb. Front winker bulb replacement ● loosen the 2 screws, remove the winker le...

Page 196: Fuse Capacity

19-7 lights/switch/horn head light relay thermo switch relay winker relay earth cable main wire harness battery box domestic use only (coupler color : black) export use only (coupler color : white "export" marked) coupler connection ● connect the coupler corefully according to the type of vehicle. ●...

Page 197: Memo

Memo.

Page 198: 20. Wiring Diagram

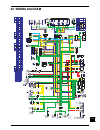

20-1 sky blue pink gray light green color comb : ground/marking red blue green white orange brown yellow violet black g g bat lighting comp comb. Sw. Color b lock color off r/w color push y/r color haz gg r o sb n l push color b gr sb o push color lg (n) color lo br/w lw b b l stand color b/l r colo...

Page 199: Memo

Memo.

Page 200

Service manual 2004. 9. Printed 2004. 9. Publication no copy.

Page 201

Sm50-0409-01e head office (factory) #58, sung san-dong, changwon, kyungnam, korea tel : (82-55) 239-7000 / fax : (82-55) 239-7524 overseas sales office #13-5, sung soo 1dong 1ga, sung dong gu, seoul, korea tel : (82-2) 498-6465 / fax : (82-2) 467-9997.