- DL manuals

- DAELIM

- Switch

- VL125E - SERVICE

- Service Manual

DAELIM VL125E - SERVICE Service Manual

How to use this manual

This manual explains how to maintain the Daystar of the

DAELIM MOTOR CO., LTD.

Follow the maintenance schedule (Section 3) recommen-

dations to ensure that the vehicle is in peak operating

condition.

Section 1 through 3 apply to the whole motorcycle, while

sections 4 through 18 describe parts of the motorcycle,

grouped according to location.

Most sections start with an assembly or system

illustration, service information and trouble shooting for

the section. The subsequent pages give detailed

procedures.

If you don’t know the source of the trouble, go to section

20, trouble shooting.

All information, illustrations, directions and

specificiations included in this publication are based

on the latest product information avaliable at the time

of approval for printing.

DAELIM reserves the right to make changes at any

time without notice and without incurring any

obligation whatever.

No part of this publication may be reproduced wihtout

written permission.

Some drawings of this manual can be slightly different

from actual specification of model.

General Information

Lubrication

Maintenance

Fuel System

EMS(Engine Management System)

Engine Removal / Installation

Clutch / Gearshift

A.C. Generator / Starter Clutch

Cylinder Head / Valve

Cylinder / Piston

Crankcase / Transmission /

Crankshaft

Cooling System

Front Wheel / Front Fork

/ Steering

Rear Wheel / Rear Brake /

Suspension

Hydraulic Brake

Charging System / Battery

Ignition System

Electric Starter

Lights / Switches / Horn / Fuel Unit

Wiring diagram

Troubleshooting

Contents

Engine

Frame

Electrical

General

Seat / Exhaust Muffler

Summary of VL125E - SERVICE

Page 1

How to use this manual this manual explains how to maintain the daystar of the daelim motor co., ltd. Follow the maintenance schedule (section 3) recommen- dations to ensure that the vehicle is in peak operating condition. Section 1 through 3 apply to the whole motorcycle, while sections 4 through 1...

Page 2: Service Rules

1. If the engine must be running to do some work, make sure the area is well-ventilated. Never run the engine in an enclosed area. The exhaust contains poisonous carbon monoxide gas that may cause loss of consciousness and lead to death. 2. The battery contains sulfuric acid(electrolyte) contact wit...

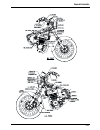

Page 3: Model Identification

1-2 general information model identification frame no frame no frame no frame no frame no frame no frame no frame no frame no frame no frame no frame no engine no engine no engine no engine no engine no engine no engine no engine no engine no engine no engine no engine no.

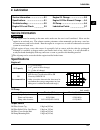

Page 4: Specifications

1-3 general information item specifications overall length 2,240mm overall width 860mm overall height 1,140mm dimensions wheel base 1,505mm seat height 720mm ground clearance 135mm dry weight 147.5kgf curb weight 344.9kgf type double cradle front suspension stroke telescopic fork 140mm rear suspensi...

Page 5

1-4 general information item specifications clutch hydraulic, multi-plate transmission type constant mesh transmission primary reduction 3.650(73/20) secondary reduction 3.214(45/14) gear ratio 1st 3.083(37/12) drive train gear ratio 2nd 1.882(32/17) gear ratio 3rd 1.380(29/21) gear ratio 4th 1.095(...

Page 6: Torque Values

1-5 general information item q’ty thread dia torque remark oil filter screen cap 1 36 1.5(15) oil filter relief valve oval screw 1 10 1.2(12) oil filter cover socket bolt 3 6 1.1(11) oil pump mounting bolt 2 6 1.1(11) valve adjusting screw lock nut 4 5 1.1(11) drive sprocket 2 6 1.2(12) engine hange...

Page 7

1-6 general information torque specifications listed above are for important fastener. Other should be tighten to the standard torque values below. Sh(small head): 6mm bolt of 8mm flange head. Type torque type torque kgf-m n.M kgf-m n.M 1 5mm bolt, nut 0.45~6 4.5~6 5mm screw 0.35~0.5 3.5~5 1 6mm bol...

Page 8: Safety Notices

1-7 general information ! Warning safety notices following marks indicate some warnings and caution against some specific service methods. The following symbols indicate needed lubrication steps, the changing of parts, and required specialized tools, etc. When performing maintenance special greases,...

Page 9: Tools

1-8 general information tools special common description reference section description reference section clutch center holder 6 wrench, 8 9mm 3 flywheel puller 7 adjusting wrench, b 3 lock pin puller set 8 float level gauge 4 sliding shaft 8 lock nut wrench, 20 24mm 6 sliding weight 8 extension bar ...

Page 10: Tester, Gauge

1-9 general information tester, gauge compression gauge digital circuit tester circuit tester inspecion adapter spark adapter 3 16, 17 16, 17 17 17 remark description reference section valve seat cut valve seat cutter 45 valve seat cutter 35 valve seat cutter 35 valve seat cutter 60 cutter holder 5m...

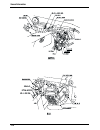

Page 11: Cable & Harness Routing

1-10 general information cable & harness routing note the following when routing cables and wire harnesses: a loose wire, harness or cable can be safety hazard. After clamping, check each wire to be sure it is secure. Do not squeeze wires against the weld or its clamp. Secure wires and wire harnesse...

Page 12

1-11 general information.

Page 13

1-12 general information.

Page 14

1-13 general information.

Page 15

Memo.

Page 16: Service Information

2-1 lubrication service information if the engine must be running to do some work, make sure the area is well ventilated. Never run the engine in an enclosed area. The exhaust contains poisonous carbon monoxide gas that may cause loss of consciousness and lead to death. Run the engine in an open are...

Page 17: Troubleshooting

2-2 lubrication troubleshooting low oil pressure oil level low pressure relief valve stuck open plugged oil pick-up screen oil pump worm external oil leaks high oil pressure pressure relief valve stuck closed plugged oil filter, gallery, or metering orifice in correct oil being used no oil pressure ...

Page 18: Engine Oil Level Check

2-3 lubrication engine oil level check run the engine and allow it to idle for few minutes. Stop the engine and place the motorcycle on its center stand. After 2-3 minutes, check the oil level with the filler cap/dipstick. Do not screw it in when making this check. If the oil level is below or near ...

Page 19: Oil Pump

2-4 lubrication engine oil filter element change remove the drain plug and drain the oil. ( 2-3) remove the oil filter cover bolt, filter cover, filter element and spring. Replace the oil filter element with a new oil filter. Check the operation of the relief valve. If the relief valve is fully open...

Page 20

2-5 lubrication measure the rotor end clearance. Service limit : 0.20mm(0.008 in) disassembly / assembly remove the inner and outer rotor from pump body. Remove the setting ring, spacer, oil seal and pump shaft. Clean each parts with cleaning solvent. Measure the pump side clearance. Service limit :...

Page 21

2-6 lubrication remove the oval screw, sealing washer, spring and relief valve from oil filter cover. Remove the oil filter element from r. Crank case cover. Blow the oil path way of crank case cover with compressed air, and clean. Torque oil filter cover : 1.1kgf-m(11n.M) oval screw: 1.2kgf-m(12n.M...

Page 22: Lubrication Points

2-7 lubrication lubrication points if there is no specific indication of oil, use general grease to lubricate the lubrication parts. Lubricate the other operation parts which are not shown below with oil or grease. Control cable lubrication periodically, disconnect the throttle cables at their upper...

Page 23

Memo.

Page 24: Service Information

3-1 maintenance service information if the engine must be running to do some work, make sure the area is well ventilated. Never run the engine in an enclosed area. The exhaust contains poisonous carbon monoxide gas that may cause loss of consciousness and lead to death. Run the engine in an open are...

Page 25

3-2 maintenance torque values spark plug 1.1 kgf-m( 11n.M) cylinder head cover bolt 1.0 kgf-m( 10n.M) valve adjusting nut 1.1 kgf-m( 11n.M) timing hole cap 0.6 kgf-m( 6n.M) crankshaft hole cap 0.8 kgf-m( 8n.M) rear axle nut 8.8kgf-m(88n.M) tools common tool wrench, 8 9 mm adjuster wrench compression...

Page 26: Maintenance Schedule

3-3 maintenance fuel line i i i i 3-4 throttle grip operation i i i 3-4 air cleaner r r r 3-5 note 2 spark plug i r i 3-6 valve clearance i i i i 3-6 engine oil r r r r 2-3 engine oil filter element r r r r 2-4 drive chain 1,000km : i,l 3-8 brake fluid i i i 3-10 note 3 brake shoe/pad i i i 3-10 bra...

Page 27: Fuel Line

3-4 maintenance fuel line check the fuel lines for deterioration, damage, or leakage. Replace the fuel lines. Throttle grip operation check the throttle grip for smooth operation. Complete opening and automatic closing in all steering positions. Lubricate the throttle cables if throttle operation is...

Page 28: Air Cleaner

3-5 maintenance air cleaner loosen the four screw, and remove the air cleaner case cover. Loosen the three screw, and remove the air cleaner element..

Page 29: Spark Plug

3-6 maintenance make sure if there is no deterioration and damage in the air cleaner element. Replace damaged parts. The element is a viscous type which contains oil. Therefore do not use compressed air to clean the air cleaner element. Assemble the air cleaner element in the reverse order of remova...

Page 30

3-7 maintenance measure the valve clearance with filler gauge. Valve clearance: intake: 0.12 0.02mm(0.05 0.001in) exhaust: 0.12 0.02mm(0.05 0.001in) loosen the lock nut with a valve wrench, and adjust the adjuster screw to the standard clearance using a valve adjusting wrench. When the standard clea...

Page 31: Drive Chain

3-8 maintenance drive chain stop the engine to inspect the drive chain, otherwise fingers can be caught in the drive chain while the drive chain is operating. Chain free play adjustment stop the engine and shaft the gear into neutral, support the motorcycle on a level surfase. Remove the chain tensi...

Page 32

3-9 maintenance installation after assembling the chain tensioner, keep the upper part of bracket which is holding chain tensioner-roller to the underline of rear swing arm under pipe. Install the drive chain with the closed area of the clip facing to the proceeding direction. While driving, master ...

Page 33: Brake Pad/shoe

3-10 maintenance brake pad/shoe brake pad replacement check the brake pads for wear. Replace the brake. If the red marks in the pads reach to the brake.( 15-4) always replace the brake pads as a set to assure even disc pressure. Brake fluid check the fluid level of the front brake reservoir. If the ...

Page 34: Brake System

3-11 maintenance brake shoe replacement replace the brake shoes if the arrow on the brake arm aligns with the reference mark on full application of the rear brake pedal. Brake system inspect the front brake hoses for deterioration, cracks. If there are signs of leakage, replace them as soon as possi...

Page 35: Headlight Adjustment

3-12 maintenance headlight adjustment adjust the headlight beam by turning the case adjustment screw. Adjust the headlight beam as specified by local laws and regulations. An improperly adjusted headlight may blind on coming drivers, or it may fail to light a road for a safe distance. Height adjustm...

Page 36: Suspension

3-13 maintenance suspension do not ride a vehicle with a faulty suspension. Loose, worn or damaged suspension parts impair vehicle stability and control. Front check the action of the fork by compressing the front suspension several times. Check the entire fork assembly for leaks, damage, or loosene...

Page 37: Bolts, Nuts Fasteners

3-14 maintenance rear check the action of the rear cushion by compressing them several times. Check the rear cushion for leaks, damage, or looseness. Support the motorcycle with a main stand. Check for worn rear fork bush by attempting to move the wheel side to side. Replace the bearings if any loos...

Page 38: Steering Head Bearings

3-15 maintenance measure the tread depth at the center of the tire. Replace the tire when the tread depth reaches the following limits: minimum tread depth: 4mm (0.16 in) 8.5mm (0.3 in) steering head bearings check that the control cables do not interfere with handle bar rotation. Raise the front wh...

Page 39

Fuel system 4-0

Page 40: Service Information

4-1 fuel system service information general gasoline is extremely flammable and is explosive under certain conditions. Work in a well ventilated area with the engine stopped. Do not smoke or allow flames or sparks in the area where gasoline is drained or stored and where the fuel tank is refuelled. ...

Page 41: Troubleshooting

4-2 fuel system troubleshooting engine cranks but won t start no fuel in tank engine flooded with fuel clogged air cleaner no spark at plug(ignition system faulty) rough idle, hard starting or stalling starting incorrect idle ring adjustment lean mixture, rich mixture clogged air cleaner faulty air ...

Page 42: Fuel Tank

4-3 fuel system fuel tank removal gasoline is extremely flammable and is explosive under certain conditions. Work in a well ventilated area with the engine stopped. Do not smoke or allow flames or sparks in the area where gasoline is drained or stored and where the fuel tank is refueled. Loosen the ...

Page 43: Air Cleaner Case

4-4 fuel system air cleaner case removal remove the l. Side cover. Remove the air cleaner connecting tube band out of the air cleaner side. Remove the battery. Remove the air cleaner mounting bolt. Remove the air cleaner case. Installation installation is essentially the reverse order of removal. In...

Page 44

5-4-5 ems(engine management system) 5. Ems(engine management system) 1. Caution when repairing the ems parts 5-2 2. The component parts of the ems 5-3 3.Terminal arrangement of the ecu 5-4 4. Wiring diagram of the ecu 5-4 5. Self-diagnostic function by mil(malfunction indicator lamp) 5-5 - self diag...

Page 45

5-2 ems(engine management system) 1.Caution when repairing the ems parts. If the fuse is short-circuited, findout the cause and repair. Replace with the fuse having the specified capacity. Do not use the electlic wires or others instead of the fuse. Do not drop or throw the ems parts because these p...

Page 46

5-3 ems(engine management system) 2.The component parts of the ems ems consists of intake and fule, ignition and control system. 1) intake system as a system which controls and measures air to be necessary for combustion in engine, the intake system is composed of pressure sensor of intake parts, in...

Page 47: 4. Wiring Diagram of The Ecu

5-4 ems(engine management system) 3. Terminal arrangement of the ecu remarks ecu pin no. 6,7,8,11,13,14,15,16,36,38 were not connected. 4. Wiring diagram of the ecu.

Page 48

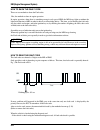

5-5 ems(engine management system) 5. Self-diagnostic function by mil (malfunction indicator lamp) self-diagnostic function the ems is equipped with self-diagnostic function in order to ensure that the engine control system is operation normally. If this function detects a malfunction in the system, ...

Page 49

5-6 ems(engine management system) fail-safe function if the ecu checks something wrong , the vehicle can be driven by its fail safe function. However, if there are something wrong in fuel pump, injector, crank position sensor, the engine operation can be impossible. If there is something wrong in th...

Page 50

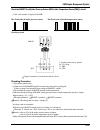

5-7 ems(engine management system) how to check the fault code there are two methods of checking the fault codes. 1) use the mil in the speedometer. 2) the diagnostic tool. First) use the mil in the speedometer(refer to how to read the fault codes and fault codes table and diagnostic methods for each...

Page 51

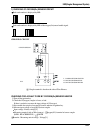

5-8 ems(engine management system) how to show the fault code there are two methods to show the fault codes. First, the methods to show in engine operation in engine operation, when there is something wrong in each part of ems, the mil keeps light on without the light on/off function of mil in order ...

Page 52

5-9 ems(engine management system) fault codes table no failure injection valve failure(iv) idle speed actuator failure (isa) electrical fuel pump failure (efp) intake manifold absolute pressure signal failure (imp) throttle position signal failure (tps) o2 sensor heater output failure (lsh) lambda s...

Page 53

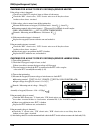

5-10 ems(engine management system) how to remove the fault code remove the fault codes in two ways; first) full warm up 1. Starting the engine. - the mil blinks continuously because the ecu memorized the fault code yet. 2. Full warm up the engine (keep idling five minutes) 3. Turn off the ignition k...

Page 54: 6.Injector

5-11 ems(engine management system) remove connector connector bolt injector and injector cap. Replace the injector 6.Injector be sure to check the engine is cooling because a little gasoline remains. It could be still hot. ! Caution before disassemble, the key is off. ! Caution.

Page 55

5-12 ems(engine management system) checking methods by fault codes checking of the injector circuit the fault code is displayed by mil checking circuit coupler terminal is based on wire harness. Checking procedure 1) turn off the ignition key. 2) check to see if the injector coupler has come loose o...

Page 56

5-13 ems(engine management system) 7) if the measured voltage is normal, check the ‘blue/yellow’ electric wire to see if they have been broken or have short-circuited or if the wire-harness coupler and the ecu coupler are a bad contact (ecu terminal no. 40) if there is no problem in the electric wir...

Page 57: Sensor, Temperature Sensor)

5-14 ems(engine management system) 7. Mapat(manifold air pressure sensor, temperature sensor) remove mapat connector (push by hand and pull to the front-side) loosen the flange bolt 2ea. Be sure to check the coupler is toward upside. ! Caution it is located on the left side of the throttle body befo...

Page 58

5-15 ems(engine management system) check the mapat circuit(intake pressure sensor (imp)+intake temperature sensor(tba))’s circuit fault code number is displayed by mil the fault code of intake pressure sensor the fault code of intake temperature sensor checking circuit coupler terminal is based on t...

Page 59

5-16 ems(engine management system) checking of the intake pressure sensor 1) if voltage value is normal, turn off the ignition key. Connect the mapat(intake pressure sensor + intake temperature sensor) coupler 2) the wire-harness to check the ecu is connected with the ecu with a wire-harness coupler...

Page 60

5-17 ems(engine management system) checking of intake temperature sensor 4) turn on the ignition key. Start the engine and idling. 5) measure the voltage of intake pressure sensor for ecu check. Measuring the voltage of intake pressure sensor - measuring terminal: ecu no.28(tba) ~ ecu no.3(imp groun...

Page 61

5-18 ems(engine management system) checking the tps(throttle position sensor) circuit diagram fault code number is displayed by mil checking circuit the coupler terminal is based on the side of wire-harness checking procedure 1) turn off ignition key . 2) check the tps(throttle position sensor) coup...

Page 62

Checking procedure 6) check continuty between the sensor ground terminal of tps and earth. The continuty tps : 0[ ],20±1 measuring terminal : ecu no. 4 (w/r : white/red) ~ earth remarks : measuring unit for resistance : resistance ‘ r ‘ [ ] 7) if not problem, measure the resistance of tps. By turnin...

Page 63

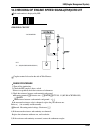

5-20 ems(engine management system) 9.Ets(engine temperature sensor) remove rh.Shroud comp connector by hand ets replace the ets install in reverse order of removal it is located on the left-hand side of cylinder head before disassembly, the key is off. Ets torque:3±0.3[kgf m] ! Caution ! Caution.

Page 64

5-21 ems(engine management system) 1)checking the circuit diagram of ets(engine temperature sensor) fault code number is displayed by mil checking circuit coupler terminal is based on the side of wire-harness checking procedure 1) turn off the ignition key . 2) check to see if the ets(throttle posit...

Page 65

5-22 ems(engine management system) 6-1) if the measured value is not normal, replace the ets with the new one, recheck. If the measured value is normal, check the g/l electric wire, w/r electric wire to see if they have been broken or have short-circuited or if the ecu coupler is a bad contact ( no....

Page 66: 10.Isa(Idle Speed Actuator)

5-23 ems(engine management system) 10.Isa(idle speed actuator) remove lh.Side cover air cleaner isa connector tps connector throttle cable throttle body (loosen the throttle body bolt) loosen the isa screw replace the isa it is located upwards on the throttle body before disassembly, the key is off....

Page 67

5-24 ems(engine management system) 1)check the isa(idel speed actuator) circuit. Showing of defects codes by mil checking circuit coupler terminal is based on the side of the wire-harness check procedure 1) turn off ignition key . 2) check to see if the isa(throttle position sensor) coupler is loose...

Page 68

5-25 ems(engine management system) check procedure 5) if the measured resistance and continuty is abnormal. Replace isa with the new one, and recheck. 6) if resistance and continuty is normal, connect the coupler of isa. 7) turn on ignition key 8) measure isa voltage of wire-harness to check ecu. Me...

Page 69: 11.O2(Oxygen) Sensor

5-26 ems(engine management system) remove rh.Side cover rh.Lower cover o2 sensor connector muffler o2 sensorr located on the exhaust pipe before disassembly, the key is off. Beware of muffler after driving as it is still hot to be burnt 11.O2(oxygen) sensor rh side cover rh side cover rh side cover ...

Page 70

5-27 ems(engine management system) 1) checking of oxygen(o 2 ) sensor circuit fault code number is displayed by mil fault code number is displayed by mil of the oxygen(o 2 )sensor lambda signal. Checking circuit coupler terminal is based on the side of wire-harness. Checking for a fault code by oxyg...

Page 71

5-28 ems(engine management system) checking for a fault code by oxygen(o 2 )sensor heater if the voltage value is abnormal, check to see if the ecu coupler is loose or if there is bad contact. Check the ‘b/b’’ electric wire, ‘g/w’ electric wire to see if they have been broken or have short- circuite...

Page 72

5-29 ems(engine management system) 12.Checking of engine speed signal(ess)circuit fault code number is displayed by mil checking circuit coupler terminal is based on the side of wire-harness. Check procedure 1) turn off the ignition key . 2) check the ess coupler is loose, or bad. If there is no pro...

Page 73

5-30 ems(engine management system) 6)turn on the ignition key. 7) measure the voltage or tachometer of wire harness for ecu check. Measuring terminal: b electric wire ~ g electric wire => output voltage: battery voltage measuring terminal: ecu no. 32(b/y: black/yellow) ~ g electric wire =>output vol...

Page 74

5-31 ems(engine management system) 12.Checking of mil(malfunction indicator lamp)circuit fault code number is displayed by mil checking circuit check procedure 1) turn off ignition key. 2) check the ess coupler is loose, or bad. If there is no problem. 3) turn on the ignition key. 4) check the mil o...

Page 75

5-32 ems(engine management system) remove lh.Side cover connector (a display portion is pulled behind) flange bolt 4 ea replace the ecu install in the reverse order of removal. Replace the ecu it is located inside of the lh. Side cover before disassembly, the key is off. Be sure to assemble the ecu ...

Page 76

5-33 ems(engine management system) remove seat head light unit ass’y fuel unit coupler fuel pump connector ignition coil -connector -spark plug cap -ignition coil bolt 2ea -ignition coil locate on bottom of the fuel tank be sure to check the engine is cooling. Because a little gasoline remains, it i...

Page 77

5-34 ems(engine management system) remove lh. Side cover lh. Lower cover gear shift drum drive chain cuide connector - cps connector(blue, light green) - acg connector(yellow) - neutral s/w (black coupler) eng. Lh.Cover(loosen the bolt 8ea) stator screw cps screw replace the cps located on lh.Crank ...

Page 78: 17.Fuel Pump

5-35 ems(engine management system) remove fuel pump nut 4ea replace the fuel pump do not push the fuel pump base under the fuel tank when the fuel tank is stored. Always replace the packing when the fuel pump is removed. Before disconnecting the fuel hose, release the fuel pressure by loosing the fu...

Page 79: 17.Fuel Pump

5-36 ems(engine management system) the terminal arrangement of the fuel pump (the following color chart is the internal color of the fuel pump) 17.Fuel pump.

Page 80

5-37 ems(engine management system) remove the fuel level gauge (19-10) measure the resistance between terminals. The float position is based on the tank bottom plate after assemble. Measure the resistance between y/w (yellow/white) wire and g(ground) wire of fuel unit terminal remark : measuring uni...

Page 81: 18.Throttle Body

5-38 ems(engine management system) 18.Throttle body throttle body insulator throttle body insulator throttle body insulator throttle body insulator throttle body insulator throttle body insulator throttle body insulator throttle body insulator throttle body insulator throttle body insulator throttle...

Page 82: Disconnect The Throttle Body

5-39 ems(engine management system) disconnect: - fuel tank and air cleaner - gasoline in the fuel tube. - fuel tube connected to the injector cap. - tps, isa, mapat, injector coupler. - throttle cable do not disconnect both the throttle adjust screw and adjusting nut disconnect the insulator mountin...

Page 83: Disconnect The Throttle Body

5-40 ems(engine management system) disconnect: - injector cap bolt - injector and injector cap at the same time from the insulator - injector and injector cap. - mapat sensor disconnect the throttle body insulator checking the insulator check: - o-ring - inner side of insulator - inner side of injec...

Page 84: And Insulator

5-41 ems(engine management system) assembly of the throttle body and insulator assemble the insulator into the throttle body. Torque: 1.0 kgf m installation of insulator and throttle body installation of insulator and throttle body is the reverse order of removal check the o-ring when the insulator ...

Page 85: Supplement

5-42 ems(engine management system) adjustment of throttle adjust screw a vehicle is assembled in the state which engine operation is possible. Loosen the fuel tank, and the adjust-screw is makes possible to adjust.. Disconnect the rh. Side cover. The couper to check the malfunction of vehicle is con...

Page 86: Ecu Is Initialized

The coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. Turn the lgnition key on. Press the power button of the diagnostic tool. Press the enter button in the initial screen. Press the enter in the vehicle diagnosis screen. Press the enter button on the resett...

Page 87

5-44 ems(engine management system) press the enter button when it is ready when the ecu was initialized. Turn off the lgnition key and then turn on the ignition key..

Page 88: Isa Pwm Is Adjusting

The coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. Turn the lgnition key on. Press the power button of the diagnosis tool. Press the enter button on the initial screen. Press the button at the vehicle diagnostic screen. Press the enter button on the curre...

Page 89: 21.The Usage of Scan When

5-46 ems(engine management system) the coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. Turn the lgnition key on. Press the power button of the diagnosis tool. Press the enter button on the initial screen. Press the enter button on the vehicle diagnosis scr...

Page 90: Engine Revolution Is Check

The coupler to check the malfunction of vehicle is connected to the coupler of diagnostic tool. Start the engine. Press the power button of the diagnosis tool. Press the enter button on the initial screen. Press the enter button on the vehicle diagnosis screen. Press the enter button on the current ...

Page 91

Memo.

Page 92

Service infor 6-1 engine removal/installation 6. Engine removal/installation service information 6-2 engine removal 6-3 engine installation 6-4.

Page 93: Service Information

6-2 engine removal / installation service information general a floor jack or other adjustable support is required to support and maneuver the engine. Be careful not to damage the frame, engine body, cables, wire system. The following parts or components can not be served with the engine installed i...

Page 94: Engine Removal

6-3 engine removal / installation engine removal drain the engine oil.( 2-3) remove the following - side cover( 12-2) - seat( 12-2) - fuel tank( 4-3) - mufflers( 12-3) disconnect the connector of the starter motor cable, ac generator wire, gear change switch wire. Remove the battery negative cable, ...

Page 95: Engine Installation

6-4 engine removal / installation engine installation engine installation is essentially the reverse order of removal. Carefully align mounting points with the jack to prevent damage from mounting bolt threads and wire harness and cables. Be careful not to damage any part of the frame and bolt nuts....

Page 96

Memo.

Page 97

7-0 clutch, gearshift.

Page 98: 7. Clutch / Gearshift

7-1 clutch, gearshift 7. Clutch / gearshift service information 7-1 troubleshooting 7-2 r. Crankcase cover dissembly 7-3 clutch disassembly 7-4 gearshift linkage 7- 7 clutch installation 7- 9 primary drive gear 7-10 r. Crank case cover 7-11 service information the clutch, gearshift linkage can be se...

Page 99: Troubleshooting

7-2 clutch, gearshift troubleshooting clutch operation problem can be corrected by adjusting a cable free play. Clutch lever pull too hard damaged, clogged or sticking clutch cable damaged lifter mechanism damaged clutch lifter plate bearing incorrect wiring of clutch cable clutch slips too big clut...

Page 100: R. Crankcase Cover

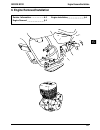

7-3 clutch, gearshift r. Crankcase cover disassembly drain the engine oil( 2-3) remove the clutch adjusting lock nut and adjusting nut. Separate the clutch cable from the clutch arm. Remove the cable out of the cable holder. Remove the right crank case cover bolt and remove the cover. Remove the dow...

Page 101: Clutch Disassembly

7-4 clutch, gearshift separate the clutch arm spring and o-ring from the clutch arm/lift shaft. Inspect the wear and damage of the lifter rod and clutch arm/lift shaft. Inspect the wear and damage of the clutch arm spring. Clutch arm/lifter shaft assembly coat the new o-ring with grease, and assembl...

Page 102

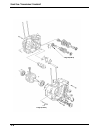

7-5 clutch, gearshift press the clutch center using the clutch center holder and remove the clutch lock nut. Tools: clutch center holder lock nut wrench, 20 24mm extension bar remove the lock washer. Remove the clutch center, disk, plate, and pressure plate. Remove the spline washer and clutch outer...

Page 103

7-6 clutch, gearshift inspection inspect the lifter plate bearing for scoring and other damage. Inspect the lifter plate for damage. If necessary, replace them. Measure the clutch spring free height. Service limit:34.2mm(1.35in) check the clutch disk. If necessary, replace it. Measure the disk ampli...

Page 104: Gear Shift Linkager

7-7 clutch, gearshift check the slots in the clutch outer for nicks or indentations made by the clutch discs. If necessary replace them. Measure the clutch outer inside diameter. Service limit:28.030mm(1.1035in) measure the clutch outer guide outsider diameter. Service limit:27.950mm(1.1004in) insta...

Page 105

Gear shift cam gear shift cam gear shift cam gear shift cam gear shift cam gear shift cam gear shift cam gear shift cam gear shift cam gear shift cam gear shift cam gear shift cam gear shift cam bolt bolt bolt bolt bolt bolt bolt bolt bolt bolt bolt bolt bolt spring spring spring spring spring sprin...

Page 106

7-9 clutch, gearshift clutch assembly coat the clutch outer guide with clean engine oil. Install the trust washer and outer guide into the main shaft. Install the following: - clutch assy. - r. Crank case cover install the gear shift arm into the gear shift spindle install the clutch outer and splin...

Page 107: Primary Drive Gear

7-10 clutch, gearshift install the lock nut by pressing clutch center into the clutch center holder. Torque : 6.5kgf-m (65n.M) tools: clutch center holder lock nut wrench, 20 24mm extension bar install the clutch spring, lifter plate and clutch spring bolt diagonally several times. Check if the pres...

Page 108

7-11 clutch, gearshift remove the lock nut, primary drive gear, and woodruff key installation install the woodruff key into the key groove of the crankshaft. Align the primary drive gear key groove with the crankshaft key and install the gear. Install the washer. Coat the nut with clean engine oil, ...

Page 109: R. Crankcase Cover

7-12 clutch, gearshift r. Crankcase cover installation remove the gasket from the crank case surface. Install the dowel pins and a new gasket. Install the right crank case cover, aligning the spline of the crank shaft and with the oil pump shaft spline. If any difficulty is encountered in joining th...

Page 110

Memo.

Page 111

8-0 a.C generator / starter clutch.

Page 112: Service Information

8-1 a.C generator / starter clutch 8. A.C generator / starter clutch service information 8-1 a.C generator 8-2 starter clutch 8-7 service information general this section covers removal and installation of the a.C. Generator. Refer to section 16 for inspection of the a.C. Generator. The a.C. Generat...

Page 113: A.C Generator

8-2 a.C generator / starter clutch loosen the one bolt attaching a.C. Generator and remove the a.C. Generator wire clamp. A.C generator removal remove the gear change pedal. Remove the l. Lower cover. Disconnect the coupler of the a.C. Generator wire, gear change switch wire coupler. Loosen the 3 bo...

Page 114

8-3 a.C generator / starter clutch remove the starter reduction gear shaft and starter reduction gear. Loosen the left crank case cover adjusting bolt and remove the left crank cover. Remove the gasket and the dowel pins. Remove the starter idle gear shaft and starter idle gear. Hold the flywheel ro...

Page 115

8-4 a.C generator / starter clutch remove the woodruff key from the crank shaft. Remove the starter driven gear collar. After installing the flywheel puller on the rotor, remove the rotor. Tool: flywheel puller stator removal/installation loosen the pulse generator mounting screw and remove the puls...

Page 116

8-5 a.C generator / starter clutch starter idle gear inspection inspect the wear and damage of starter ldle gear. Measure the gear inside diameter. Service limit : 10.100mm(0.393in) measure the gear shaft inside diameter. Service limit : 9.97mm(0.393in) reduction gear inspection inspect the wear and...

Page 117

8-6 a.C generator / starter clutch install the starter idle gear and shaft. Install the new gasket and dowel pin. Install the l. Crankcase cover and tighten the bolt. Torque : 1.1kgf-m(11n.M) install the starter gear and shaft. Install the new o-ring. Starter idle gear starter idle gear starter idle...

Page 118: Starter Clutch

8-7 a.C generator / starter clutch connect the ac generator wire and gear position light switch wire coupler, and install the wire clamp. Install the l. Lower cover and gear change pedal bolt. Tighten the gear change pedal bolt. Starter clutch remove the flywheel( 7-4) if the starter driven gear tur...

Page 119

8-8 a.C generator / starter clutch check the starter driven gear for damage and wear. Measure the driven gear i.D. And o.D. Service limit: o.D. : 39.607mm(1.5566in) i.D. : 22.100mm(0.870in) assembly inspect the one way clutch for wear and damage. Install the way clutch fringe onto the clutch outer. ...

Page 120

Memo.

Page 121

9-0 cylinder head / valve.

Page 122: Service Information

9-1 cylinder head / valve service information general rocker arm and cam shaft can be serviced with the engine installed in the frame. To service the cylinder heads. The engine must be removed from the frame. Cam shaft lubrication oil is fed through an oil pipe. Be sure that the oil pipes and orific...

Page 123: Troubleshooting

9-2 cylinder head / valve torque values cam chain tensioner pivot bolt 1.1kgf-m(11n.M) spark plug 1.1kgf-m(11n.M)-apply engine oil camshaft holder 8mm nut 2.0kgf-m(20n.M)-apply engine oil cam chain tensioner mounting bolt 1.2kgf-m(12n.M) cam chain tensioner sealing screw 0.4kgf-m(4n.M) cylinder head...

Page 124: Camshaft Removal

9-3 cylinder head / valve camshaft removal remove the fuel tank( 4-3) remove the cylinder head cover bolts and cover. Remove the timing hole cap and crank shaft hole cap out of the left crankcase cover. Rotate the crankshaft clockwise, place the flywheel t mark on the left crankcase cover index mark...

Page 125

9-4 cylinder head / valve remove the cam chain from camshaft. In order to separate the cam chain from the crank case, bind it with the thread or a string. Remove the camshaft. Camshaft holder disassembly remove the end of the rocker arm spring from the dowel pins. Remove the dowel pins from the cams...

Page 126: Cylinder Head Removal

9-5 cylinder head / valve inspection inspect the rocker arm and rocker arm shaft for wear and damage. Measure the rocker arm i.D. Service limit : 12.060mm(0.4748in) measure the rocker arm o.D. Service limit : 11.950mm(0.4505in) inspect the cam lobe of the camshaft for wear and damage. Measure the he...

Page 127: Cylinder Head Disassembly

9-6 cylinder head / valve remove the valve spring, valve cotter, retainer, spring, and valve. Tool: valve spring compressor to prevent the loss of tension, do not compress the valve springs more than necessary to remove the cotters. Mark all parts during disassembly so they can be placed back in the...

Page 128

9-7 cylinder head / valve inspect the spark plug assembly hole and the crack of near valve seat. Check for the warp of the cylinder head with a square and filler gauge. Service limit : 0.1mm(0.004in) valve spring measure the free field of valve spring. Service limit : 40.0mm(1.57in) if any valve spr...

Page 129: Valve Guide Replacement

9-8 cylinder head / valve valve guide replacement when replacing the valve guide, valve seat must be amended. Heat the cylinder head equally to 130-140 . Avoid heating over 150 avoid performing the unskilled work. It is caused a burn. When heating the cylinder head, do not heat it sectionally using ...

Page 130: Valve Seat Inspection

9-9 cylinder head / valve trim the reamer not to lean. If cutting the reamer by leaning, the valve hole is inclined, the step seal is leaked, and the around of valve seat is enlarged. So the around of seat is not amended. The entrance of reamer is always performed by turning the reamer to the right....

Page 131

9-10 cylinder head / valve valve seat amendment if the seat part is damaged or rough, cut them using 45 cutter. After replacing the valve guide, cut the seat part. Amend the flat using a 35 cutter side by side. Amend the inside using a 60 cutter side by side. Amend the seat part with a standard widt...

Page 132: Cylinder Head Assembly

9-11 cylinder head / valve coat the valve seat with the compound. Use the valve guide reamer without turning the valve, check the attached state by hitting against lightly. If the position of contacting side is high, cut it using a 35 cutter, and then cut it using a 45 cutter according to the standa...

Page 133

9-12 cylinder head / valve install the valve springs. The springs tightly would coils should face toward the cylinder head. Install the springs retainer. Compress the valve spring and install the valve cotters. To prevent the loss of tension, do not compress the valve springs more than necessary to ...

Page 134: Cylinder Head Installation

9-13 cylinder head / valve cylinder head installation clean the cylinder head surface of any gasket materials. Install the cam chain guide into the cylinder. Install the dowel pins and a new gasket. Install the cylinder head. Install the cam shaft. Install the engine into the frame( 5) camshaft inst...

Page 135

9-14 cylinder head / valve insert the dowel pins into the camshaft holder thoroughly. Align the teeth of the rocker arm spring with the dowel pins as shown. Check the camshaft ass y for wear or damage, and install the cylinder head install the cam chain on the cam sprocket. Rotate the crankshaft to ...

Page 136

9-15 cylinder head / valve install the dowel pin into the cylinder head. Install the camshaft holder. Apply engine oil to the nut part, install and tighten the cam shaft holder nut and bolt in two or three steps as shown torque : 2.0kgf-m(29n.M) remove the screw and o-ring from the cam chain tension...

Page 137

9-16 cylinder head / valve hold the tensioner shaft with the light clip as shown install a new gasket into the tensioner lifter, then install the tensioner lifter into the cylinder. Install the tensioner mounting bolt. Torque:1.2kgf-m(12n.M) from the tensioner lifter, remove the clip which holds the...

Page 138

Memo.

Page 139

10-0 cylinder / piston.

Page 140: 10. Cylinder / Piston

10-1 cylinder / piston 10. Cylinder / piston service information 10-1 trouble shootint 10-1 cylinder 10-2 piston 10-3 piston/cylinder installation 10-5 service information geaneral when removing the cylinder, avoid damaging the cylinder joint part with a driver or cooling pin by hitting the cylinder...

Page 141: Cylinder

10-2 cylinder / piston cylinder removal remove the cylinder head(section 8). Remove the cam chain guide from the cylinder. Loosen the cylinder mounting bolt, and remove the cylinder. Remove the gasket and dowel pins. Remove the gasket from the cylinder. Avoid damaging the gasket surface. Inspection ...

Page 142: Piston

10-3 cylinder / piston nspect the twist of cylinder. Service limit:0.1mm(0.004in) piston removal remove the piston pin clips. Do not let the clips fall into the crankcase. Push the piston pin out and remove the piston. Check the piston ring for damage or deterioration. Remove the piston rings. Be ca...

Page 143

10-4 cylinder / piston insert the piston ring into the cylinder inside, and inspect the piston ring clearance. Insert the piston ring horizontally using a piston head. Service limit: top/second:0.5mm(0.02in) oil(side rail):1.1mm(0.04in) measure the piston outside diameter at 10mm position in piston ...

Page 144: Piston/cylinder Installation

10-5 cylinder / piston piston/cylinder installation remove the gasket from the crankcase surface. Be careful not to damage the gasket surface. Place a shop towel over the crankcase opening to prevent piston pin clips from falling into the crankcase. Note top ring mark top ring second ring side rail ...

Page 145

10-6 cylinder / piston install the piston, piston pin on the connecting rod. Install new piston pin clips. Install the piston with the in mark facing towards the intake side. Place a shop towel over the opening to prevent piston pin clips from falling into the crankcase. Make sure that the piston cl...

Page 146

10-7 cylinder / piston install the lower part of the cam chain into the slot of the crankcase. Install the cam chain guide, aligning the tang of the crankcase with the slot of the cylinder. Install the cylinder head(refer to section 8). Cam chain guide cam chain guide cam chain guide cam chain guide...

Page 147

11-0 crank case / transmission / crankshaft 1.2kgf-m(12n-m) 1.1kgf-m(11n-m).

Page 148: Service Information

11-1 crank case / transmission / crankshaft service information general to service the transmission, crank shaft and kick starter, the crank case must be separated. - clutch, gear shift linkage ( section 6) - a.C. Generator, starter clutch ( section 7) - cylinder head ( section 8) - cylinder, piston...

Page 149: Trouble Shooting

11-2 crank case / transmission / crankshaft torque values main shaft bearing setting plate 1.2kgf-m(12n.M) crank case bolt 1.1kgf-m(11n.M) tools special universal bearing puller bearing remover set, 15mm remover ass'y 15mm remover shaft remover head sliding weight thread adapter assembly shaft crank...

Page 150: Crankcase Disassembly

11-3 crank case / transmission / crankshaft crankcase disassembly the engine must be separated from the frame ( section 5) refer to the service information for removal of necessary parts before disassembling the crankcase. Remove the cam chain set plate and cam chain. Remove the gear change switch. ...

Page 151: Transmission Disassembly

11-4 crank case / transmission / crankshaft inspection inspect the shift fork for wear and damaging. Measure the shift fork inside diameter and projecting parts thickness in shift fork. Service limit: inside diameter: 12.05mm(0.474in) projecting parts thickness: 4.5mm(0.18in) inspect the shift fork ...

Page 152

11-5 crank case / transmission / crankshaft inspect the shift drum for wear and damaging. Inspect the shift drum guide groove for partial wear and damaging. Measure the main shaft and counter shaft outside diameter. Service limit: m3, m5:19.930mm(0.7486in) c1:16.440mm(0.6472in) c2:19.940mm(0.7850in)...

Page 153: Crankshaft Disassembly

11-6 crank case / transmission / crankshaft inspection install the crank shaft into the stand or v-block and measure the vibration of journal part. Service limit:right: 0.1mm(0.004in) left: 0.1mm(0.004in) measure the side gap of connecting rod end and crank weight. Service limit: 0.6mm(0.02in) crank...

Page 154: Crankcase Bearing

11-7 crank case / transmission / crankshaft measure the state of vertical flux of the connecting rod end by x and y direction. Service limit:0.05mm(0.002in) crankcase bearing remove the transmission and crank shaft. Inspection turn the inner race of bearing with fingers and inspect for smooth turnin...

Page 155: Crankshaft Installation

11-8 crank case / transmission / crankshaft r. Crank case remove the main shaft bearing set plate. Separate the main shaft bearing, counter shaft bearing and crank shaft bearing form crank case. Coat the new bearing with clean engine oil and install it into crank case. Insert closely the cooling jet...

Page 156: Transmission Assembly

11-9 crank case / transmission / crankshaft transmission assembly coat the gear and gear bush with clean engine oil and install the mainshaft and counter shaft. Check the gears for freedom of movement or rotation on the shaft. Note the installation direction of each snap ring. Do not use the worn sn...

Page 157: Crankcase Assembly

11-10 crank case / transmission / crankshaft check the marks on the shift forks. - left fork: l. Mark - center fork: c. Mark - right fork: r. Mark install the shift fork into the shift fork shaft, then install the shift fork into the left crankcase assembling hole. With the left fork mark and center...

Page 158

11-11 tighten the left crankcase bolt in crisscross pattern in 2-3 steps. Torque: 1.1kgf-m(11n.M) install the cam chain install the disassembled parts. Install the engine on the frame. ( section 5) after replacing the o-ring of the gear change switch to a new one, coat the new o-ring with engine oil...

Page 159

12-0 memo.

Page 160: 12. Cooling System

12-1 cooling system 12. Cooling system service information 12-1 radiator 12-2 service information general the engine must be cool before servicing the cooling system..

Page 161: Radiator

12-2 cooling system radiator hose inspection check if the radiator core is choked up or bended when bend of pin adjust the driver. Inspect the hose or clamp of damage. Radiator removal remove the radiator grill remove the radiator from the frame. Loosen the oil through bolt from the cylinder, and re...

Page 162: 13. Seat/exhaust Muffler

13-1 seat/exhaust muffler 13. Seat/exhaust muffler service information 13-1 side cover, seat 13-2 grab rail 13-2 rear fender 13-3 muffler 13-3 tool box 13-4 service information muffler is very hot after engine stops. Avoid inspection right after engine stop. ! Caution.

Page 163: Side Cover/seat

13-2 seat/exhaust muffler side cover/seat side cover removal remove the r.Side cover. (removing with a lock key) loosen the screw with a “+” driver separate the side cover hook from grommet of frame. (when removing, remove the side cover with pushing toward the down.) seat removal remove 3 flange bo...

Page 164: Rear Fender

13-3 seat/exhaust muffler rear fender removal separate the seat and remove the code connection. Remove the grab rail. (after removing, push the stay connecting bolt toward the inside.) remove the rear fender. (tail light is attached.) loosen the inside screws of rear fender. After removing the green...

Page 165: Tool Box

13-4 seat/exhaust muffler tool box remove the r. Front cover (removing with a key.) loosen the tool box stay pinch bolt. Assembly is done in reverse of disassembly. Muffler removal/assembly loosen the 3 pan screw of muffler protector and remove the protector. Loosen the upper/low muffler band. Loose...

Page 166

13-5 memo.

Page 167

14-0 front wheel/front fork/steering.

Page 168: Service Information

14-1 front wheel/front fork/steering service information 14-1 troubleshooting 14-2 handle bar 14-3 front wheel 14-6 front fork 14-11 steering stem 14-18 14. Front wheel/front fork/steering service information general contaminated brake disk and pad reduce stopping power. Keep grease off the brake di...

Page 169: Troubleshooting

14-2 front wheel/front fork/steering tools special ball race driver steering stem driver fork seal driver steering stem socket common extension bar driver fork seal driver body lock nut wrench 30 32mm bearing remover shaft remover head attachment 42 47mm attachment 37 40mm pilot 12mm troubleshooting...

Page 170: Handle Bar

14-3 front wheel/front fork/steering handle bar removal loosen the cable guide bolt and remove the guide. Remove the starter switch, throttle cable and throttle grip. Remove the master cylinder holder socket bolt with l.Wrench. Remove the master cylinder holder. Remove the master cylinder from the h...

Page 171

14-4 front wheel/front fork/steering assembly install the handle into the top bridge connecting hole. Tighten the handle washer and nut. Torque: 2.6kgf-m(26n.M) install the master cylinder into the handle bar with the “up” mark on the holder facing up. Align the mating surface of the master cylinder...

Page 172

14-5 front wheel/front fork/steering apply grease to the ends of the throttle cable. Install the throttle cable into the throttle pipe. Install the lighting start switch housing mounting holder pin onto the handlebar hole and tighten the mounting holder pin. Tighten the forward screws first, then ti...

Page 173: Front Wheel

14-6 front wheel/front fork/steering tighten the forward screws first, then tighten the rear screws. After installing the brake hose, kill switch cable, winker switch code into the cable guide, tighten the guide. Inspection inspect the front axle for bent. Install the front axle into v-block, and me...

Page 174

14-7 front wheel/front fork/steering check the rim runout by placing the wheel in a truing stand. Spin the wheel slowly and read the runout using a dial indicator. Service limit: radial runout: 2.0mm(0.08in) axial runout: 2.0mm(0.08in) wheel bearing inspection turn the inner race of each bearing wit...

Page 175

14-8 front wheel/front fork/steering remove the bust seal of r. Side. Remove the brake disc of l. Side. Inspection for the problems of disk. ( section 15-6) wheel bearing replacement install the bearing remover head and remover shaft into the wheel. Remove the distance collar and drive out other bea...

Page 176

14-9 front wheel/front fork/steering assembly apply grease to the dust seal rim. Install the dust seal, brake disk. Install the brake disk. Torque: 4.2kgf-m(42n.M) install the right side collar. Dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust seal dust ...

Page 177

14-10 front wheel/front fork/steering loosen the brake disc by the disk bolt. Align the speedometer gear retainer hole with the slot of the wheel hub. Apply grease the dust seal rim. Install the dust seal. Install the speedometer box, aligning the tangs in the speedometer gear retainer with the slot...

Page 178: Front Fork

14-11 front wheel/front fork/steering loosen the fork tube cap bolt when disassem- bling the front fork. Don’t remove the fork tube cap bolt, but loosen it. Loosen the fork top socket bolt. Loosen the steering stem pinch flange bolt. Loosen the front fender pinch socket bolt. Remove the front fork. ...

Page 179

14-12 front wheel/front fork/steering cover the bottom case with cloth, and remove the socket bolt. If nto removing the socket bolt with turning, assemble temporarily the spring and fork tube cap bolt. Support the bottom case by vise strongly, preventing it from transformation or damaging. Remove th...

Page 180

14-13 front wheel/front fork/steering remove the set ring. Remove the oil seal. Prevent the around of bottom case inside and outside from damaging. Inspection place the fork spring in flat place, and measure the fork spring free length. Replace the new one if it is under the service limit. Inspect e...

Page 181

14-14 front wheel/front fork/steering install the fork tube into v-block, and measure the bent with a dial gauge. Service limit: replacement if over 0.2mm inspect the contacted part of slider bush. Bottom case must be replaced if the copper portion is shown over three of quarter in teflon coating pa...

Page 182

14-15 front wheel/front fork/steering connect the rebound spring and fork piston into the fork tube. Connect the oil lock piece into the piston top end part, and install the fork tube into the bottom case. Cover the bottom case with cloth, and fix it into the vise. Coat the bolt part of socket bolt ...

Page 183

14-16 front wheel/front fork/steering install the set ring. Install the set ring to bottom case exactly. Install the dust seal. Fill the auto-transmission fluid (aft) into the fork tube according to standard amount. Capacity: 280cm 3 pull out the air by pressing the fork tube 2-3 times slowly. Check...

Page 184

14-17 front wheel/front fork/steering install the new o-ring to frok tube cap bolt. Install the fork tube cap bolt to fork tube. Do not install the fork tube cap bolt again. Installation install the front fork into the steering stem, top bridge. Align the top end of the fork tube with the upper surf...

Page 185: Steering Stem

14-18 front wheel/front fork/steering install the following: - brake caliper torque: 3.0kgf-m - front fender - front wheel ( 13-6) steering stem removal remove the parts as following. - handle ( 13-3) - remove the cable guide. - front wheel ( 13-6) - front fender - brake caliper - front fork and for...

Page 186

14-19 front wheel/front fork/steering remove the steering head top thread. Tools: steering stem socket extension bar remove the steering upper bearing. Bearing replacement always replace the bearing and races as a set. Tool: ball race driver to protect the nuts, install the stem nut into the steerin...

Page 187

14-20 front wheel/front fork/steering if the motorcycle had caused an accident, check the steering head pipe for crack of damage. Tighten the top thread. Torque: 1.8kgf tools: steering stem socket extension bar move the steering stem from side to side 4-5 times, and allow the steel ball to operate. ...

Page 188

14-21 front wheel/front fork/steering after arranging the cable, install the cable guide. Install the front fork. ( 13-11) cable guide cable guide cable guide cable guide cable guide cable guide cable guide cable guide cable guide cable guide cable guide cable guide cable guide install the parts as ...

Page 189

15-0 rear wheel/rear brake/suspension.

Page 190: Service Information

15-1 rear wheel/rear brake/suspension service information 15-1 troubleshooting 15-2 rear wheel 15-3 rear brake 15-6 rear brake pedal 15-8 rear cushion 15-8 rear fork 15-10 15. Rear wheel/rear brake/suspension service information general note the assembling direction of the bolts. Specifications torq...

Page 191: Troubleshooting

15-2 rear wheel/rear brake/suspension tools common rear cushion compressor rear cushion compressor attachment attachment, 32 35mm attatchment, 42 47mm pilot, 15mm driver bearing remover shaft remover head, 15mm troubleshooting wobble or vibration in motorcycle bent rim worn rear wheel bearings fault...

Page 192: Rear Wheel

15-3 rear wheel/rear brake/suspension rear wheel removal raise and support the motorcycle with main stand. Loosen the rear brake adjuster, remove the brake rod. Loosen the chain adjusting nut. Remove the axle nut, then disconnect the axle shaft. Remove the drive chain by pressing the rear wheel forw...

Page 193

15-4 rear wheel/rear brake/suspension check the teeth of the final driven sprocket. Replace the worn, damaged final driven sprocket. Check the drive chain and drive sprocket at the same time. Check the damper rubber. Replace the faulty, damaged, worn damper rubber. Remove the dust seal if it is dama...

Page 194

15-5 rear wheel/rear brake/suspension coat the bearing with the grease. Insert the new bearing in parallel with the seal side facing outside. After inserting the distance collar, insert the bearing of the right side with the seal side facing outside. Tools: driver attachment pilot, 15mm make the par...

Page 195: Rear Brake

15-6 rear wheel/rear brake/suspension install the chain adjuster, insert the axle shaft from the left side. Install the chain case b. Install the brake rod, brake adjusting nut. Check the drive chain operation. Install the lock washer and axle nut. Torque: 8.8kgf-m adjust the brake pedal operation. ...

Page 196

15-7 rear wheel/rear brake/suspension assembly apply grease a little to the anchor pins and brake cam. Assemble the brake cam. Apply engine oil the dust seal, install it onto the brake panel. Install the wear indicator, aligning the punch mark on the brake cam with the gap. Assemble the brake arm wi...

Page 197: Rear Brake Pedal

15-8 rear wheel/rear brake/suspension rear brake pedal disassembly remove the bolts and brake pedal. Loosen the rear brake adjusting nut and remove the brake rod from the brake arm. Separate the stop switch spring from the return spring. Tilt the motorcycle body to the left, remove the pedal pivot s...

Page 198

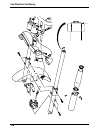

15-9 rear wheel/rear brake/suspension disassembly install the rear cushion compressor and attachment. Tools: rear cushion compressor rear cushion attachment avoid the upper joint from damage. Fix the upper joint, and remove the upper joint by loosening the lock nut. Remove the case, spring, lock nut...

Page 199: Rear Fork

15-10 rear wheel/rear brake/suspension coat the lock nut with oil to the thread, and install the rear cushion compressor attachment into the damper rod. Coat the upper joint with oil to the thread and install it into the damper rod. Fix the upper joint and tighten the lock nut. Torque: 3.8kgf-m (38n...

Page 200

15-11 rear wheel/rear brake/suspension disassembly disassemble the rear sub fender. Disassemble the chain slider. Disassemble the rear fork pivot bearing. Disassemble the dust seal and center collar. Disassemble the pivot bush. Inspect the center collar pivot bush for wear, damage, and defect. Check...

Page 201

16-0 hydraulic brake.

Page 202: 16. Hydraulic Brake

16-1 hydraulic brake service information 16-1 troubleshooting 16-2 brake fluid/bleeding 16-3 brake pad 16-4 brake disk 16-6 brake caliper 16-7 master cylinder 16-9 16. Hydraulic brake service information general do not allow foreign material to enter the system when filling the reservoir. Do not mix...

Page 203: Troubleshooting

16-2 hydraulic brake tools special snap ring pliers troubleshooting brake lever soft or too hard air bubbles in hydraulic system. Moisture in brake fluid. Brake pad and disk contaminated. Caliper piston worn. Master cylinder piston worn. Brake pad worn. Contaminated caliper inner part. Incorrectly i...

Page 204: Brake Fluid / Bleeding

16-3 hydraulic brake brake fluid / bleeding brake fluid replacement a contaminated brake disk or pad reduces stopping power. Discard contaminated pads and clean the disk with a high quality brake degreasing agent. Check the fluid level often while filling the reservoir. Avoid spilling fluid on paint...

Page 205: Brake Pad

16-4 hydraulic brake if the brake bleeder is not available, use the following procedure. Fill the master cylinder reservoir to the upper level mark. Connect the bleeder hose to the bleed valve and bleed the system as follows. 1. Squeeze the brake lever, open the bleed valve 1/2 turn and then close t...

Page 206

16-5 hydraulic brake remove the brake caliper from the left front fork. After removing the hanger pin(1pin) using by l. Lench, remove the piston. Remove the brake pad. Make sure that the pad spring is installed in the position shown. Install a new brake pad, pad pin retainer, hanger pins. Brake cali...

Page 207: Brake Disk

16-6 hydraulic brake install the brake caliper into the left front fork. Be careful not to damage the brake pad. Tighten the caliper bracket bolt. Torque: 3.0kgf-m tighten the hanger pin. Torque: 1.8kgf-m measure the brake disk for warpage. Service limit:0.3mm brake disk inspection measure the thick...

Page 208: Brake Caliper

16-7 hydraulic brake brake caliper removal remove the brake hose bolt and brake hose from the brake caliper. Remove the caliper from the front fork, then remove the pad pin bolt, brake pad. ( 14-4) avoid spilling brake fluid on painted, plastic, or rubber parts. A contaminated brake disk or pad redu...

Page 209

16-8 hydraulic brake inspection inspect the caliper friction surface for damaging or crack. Measure the caliper inside diameter. Service limit: 34.02mm (1.339in) inspect the piston outside for damaging or crack. Measure the piston outside diameter. Service limit: 33.87mm (1.333in) assembly clean the...

Page 210: Master Cylinder

16-9 hydraulic brake installation connect the brake hose to the caliper, and install the 2 sheets of sealing washer and brake hose bolt. Torque: 3.4kgf-m install the slide pin cap. Fill the brake fluid and bleed the mixed air. ( 15-3) master cylinder removal disconnect the brake light switch wires f...

Page 211

16-10 hydraulic brake remove the washer, piston, spring from the master cylinder. Clean the master cylinder inside, resorber, master piston with brake fluid. Inspection inspect the piston circumference for damaging or crack. Inspect th primary cope and secondary cope for damaging and wear. Measure t...

Page 212

16-11 hydraulic brake installation place the master cylinder into the handle bar. Install the holder with the “up” mark facing up. Align the end of master cylinder with the punch mark on the handle bar. Tighten the upper bolt first, then tighten the lower bolt. Install the brake hose to the master c...

Page 213

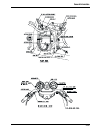

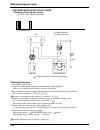

17-0 charging system/battery regulator rectifier fuse battery ac generator.

Page 214: Service Information

17-1 charging system/battery service information 17-1 troubleshooting 17-2 battery 17-3 charging system inspection 17-5 regulator/rectifier 17-6 a.C generator inspection 17-7 17. Charging system / battery service information general the battery contains sulfuric acid (electrolyte). Contact with skin...

Page 215: Troubleshooting

17-2 charging system/battery troubleshooting no power (main switch turned “on”) dead battery - charging system failure disconnected battery cable main fuse burned out faulty ignition switch low power (main switch turned “on”) weak battery - charging system failure charging system failure loose batte...

Page 216: Battery

17-3 charging system/battery battery removal remove the right side cover. Disassemble the battery holder. Remove the battery cable from the battery terminal. Remove the battery negative cable from the battery first, then the positive cable. ! Caution + terminal + terminal + terminal + terminal + ter...

Page 217

17-4 charging system/battery charging connect the charger positive cable to the battery positive terminal. Connect the charger negative cable to the battery negative terminal. Turn power on/off at the charger, not at the battery terminals to prevent spark. Discontinue charging if the electrolyte tem...

Page 218: Charging System Inspection

17-5 charging system/battery charging system inspection leakage inspection turn the ignition switch off. Remove the negative cable from the battery. Connect the voltmeters between the negative cable and battery negative terminal. Measure the leakage current with the main switch off. When measuring m...

Page 219: Regulator/rectifier

17-6 charging system/battery regulator/rectifier inspection of the harness circuit remove the seat. Disconnect the voltage regulator / rectifier coupler. Check for continuity between each terminal and ground. Inspection regulator/rectifier inspection if there is no problem in the starter inspection....

Page 220: A.C Generator Inspection

17-7 charging system/battery replace the regulator / rectifier if the resistance is out of specification. ‘ epresent more than 1[mg] replacement remove the seat. Disconnect the wire coupler of the regulator/rectifier connectors. Remove the voltage regulator/rectifier by removing the two flange bolts...

Page 221

18-0 ignition system a.C generator spark plug ignition coil ecu.

Page 222: 18. Ignition System

18-1 ignition system service information 18-1 troubleshooting 18-2 ignition coil inspection 18-3 pulse generator 18-4 18. Ignition system service information general inspect the ignition system in proper sequence based on the troubleshooting. Dropping or giving a shock to the ecu unit causes a troub...

Page 223: Troubleshooting

18-2 ignition system troubleshooting no spark at plug poorly connected, broken or shorted wires - between a.C. Generator and ecu unit - between ecu unit and ignition coil - between ignition coil and plug faulty main switch faulty ignition coil faulty ecu unit faulty a.C. Generator faulty crank posit...

Page 224: Ignition Coil Inspection

18-3 ignition system ignition coil inspection remove the seat remove the fuel tank disconnect the primary circuit. Measure the ignition coil primary coil resistance between the ignition coil terminal and ground. Standard: (resistance) 0.73 0.08 23 5 (voltage) over 100v disconnect the spark plug caps...

Page 225: Crank Position Sensor

18-4 ignition system performance test measure it using the daelim pva multi- tester. - pva multi-tester well read the instruction manual of tester and handle it. Crank position sensor disconnect the ac generator 2p coupler blue/green wire connector. Measure the resistance between blue and green. Sta...

Page 226

18-5 ignition system.

Page 227

18-6 memo.

Page 228

19-0 electric starter starter motor battery starter magnetic switch.

Page 229: 19. Electric Starter

19-1 electric starter service information 19-1 troubleshooting 19-1 starter motor 19-2 starter magnetic switch 19-5 19. Electric starter service information general the starter motor can be serviced with the engine in the frame. Specification troubleshooting starter motor will not turn battery disch...

Page 230: Starter Motor

19-2 electric starter starter motor removal turn the main switch off before servicing the starter motor. The main switch on brings about an injury. Remove the starter motor cable from the motor. Remove the starter motor mounting bolt, and starter motor. Disassembly remove the following parts - motor...

Page 231

19-3 electric starter inspect the continuity between cable terminal and case. Inspect the continuity between the terminal and brush. If it doesn’t have continuity between cable terminal and case, it is ok. If it doesn’t have continuity between the cable terminal and brush (case side), it is ok. Repl...

Page 232

19-4 electric starter assembly when removing the shim, install it by recorded order. Install the lock washer. Align the groove of front cover with the pin of brush holder and install them. Insert the armature into the brush holder center with driving each brush into the brush holder inside. Install ...

Page 233: Starter Magnetic Switch

19-5 electric starter starter magnetic switch inspection turn the main ignition switch “on”. There should be phonic signal in battery voltage while the starter magnetic switch is depressed. Tighten the two mounting bolts securely. Install the starter motor cable, tighten the terminal nuts securely. ...

Page 234

19-6 electric starter operation inspection disconnect the wire connector of the magnetic switch. Connect the positive wire to the yellow/red wire terminal and the negative wire to the green/red wire terminal and shown. There should be continuity. Ground circuit inspection disconnect the green/red wi...

Page 235

Memo.

Page 236

20-0 service lights/switches/horn.

Page 237: 20. Lights/switches/horn

20-1 lights/switches/horn service information 20-1 troubleshooting 20-1 headlight 20-2 speedometer/tachometer/fuel meter 20-2 tail/brake light 20-4 winker bulb 20-5 winker ass y removal 20-6 main switch 20-7 handle switch 20-8 gear change switch 20-9 brake light switch 20-9 horn 20-9 fuel unit 20-10...

Page 238: Headlight

20-2 lights/switches/horn speedometer/tachometer/fuelmeter removal loosen the speedometer cable nut and remove the cable from the meter. Remove the cable guide and meterstay from top bridge. Remove the seat and fuel tank, and separate the meter code from wire harness. Bulb replacement remove the hea...

Page 239

20-3 lights/switches/horn meter bulb replacement loosen the 2 screw, and remove the speedometer. Loosen the 2 screw, and remove the tachometer. Take off the bulb socket, and replace the bulb. Remove the combination switch upper/ undercover. Remove the meter installation install the meter in the reve...

Page 240: Tail/brake Light

20-4 lights/switches/horn tail/brake light loosen the 2 screw remove the tail/brake light lens take off the bulb socket, and replace the bulb fuel mete removal remove the headlight and remove the individual code from the case. Loosen the 4 screw and remove the fuel meter from meter cover. Assembly i...

Page 241: Winker Bulb

20-5 lights/switches/horn pull out the bulb and replace. Assembly is done in the reverse order of disassembly. Winker bulb loosen the screw and remove the winker unit. Remove the bulb in bulb socket by turning toward anti-clockwise take off the bulb by turning toward anti- clockwise, and replace it....

Page 242: Winker Ass’Y Removal

20-6 lights/switches/horn winker ass’y removal front loosen the head light case screw (2 screws) remove the winker connector connection in state of inclining for ward the head light lens. Remove the winker. Place the wiring and cables exactly according to a wiring diagram. Installation is done in th...

Page 243: Main Switch

20-7 lights/switches/horn main switch inspection remove the fuel tank. Disconnect the main switch code coupler connection. Check for continuity between terminals in each switch position. There should be a continuity between the colour coded wire. ( removal remove the combination switch upper/under c...

Page 244: Handle Switch

20-8 lights/switches/horn handle switch remove the headlight case. Disconnect the handle bar switch couplers /connectors. Check for continuity between wire terminals. Continuity should exist between the colour coded wires o-o in each switch position. If the continuity is between o-o, it is correct. ...

Page 245: Gear Chain Switch

20-9 lights/switches/horn gear chain switch disconnect the gear change switch wire coupler. Check for the continuity between the terminal and engine ground. Brake light switch front remove the headlight case. Disconnect the front brake light switch wire connectors and check for continuity between th...

Page 246: Fuel Unit

20-10 lights/switches/horn the horn should sound when a fully charge 12v battery is connected across he horn terminals. Fuel unit remove the fuel tank. Drain fuel out of tank at clean container. Loosen the 4 nuts and remove the fuel unit from tank. Be careful float arm is not bended unit inspection ...

Page 247

Memo.

Page 248: 21. Wiring Diagram

21-1 wiring diagram 21. Wiring diagram.

Page 249

21-2.

Page 250: 22. Troubleshooting

22-1 troubleshooting engine does not starter is hard to start 22-1 engine lacks power 22-2 poor performance(at low and idle speeds) 22-3 poor performance (at high speed) 22-4 poor handling 22-4 22. Troubleshooting engine doesn’t start or is hard to start 1. Check fuel flow to fuel tube. Not reaching...

Page 251: Engine Lacks Power

22-2 troubleshooting engine lacks power 1. Raise wheels off ground wheel don’t brake dragging and spin by hands. Spin freely. Worn or damaged wheel bearings wheel bearings need lubrication 2. Check tire pressure. Pressure low. Punctured tire faulty tire valve 3. Check clutch slipping. Engine speed n...

Page 252

22-3 service infor troubleshooting 10. Check oil level. Incorrect. Oil level too high. Oil level too low. Contaminated oil. 11. Remove cylinder head cover valve train clogged oil passage. And inspect lubrication. Lubricated clogged oil filter element. Properly. 12. Check for engine overheating exces...

Page 253

22-4 service troubleshooting poor performance(at high speed) 1. Check the ignition timing and incorrect. Faulty valve clearance adjustment. Valve clearance. Faulty ecu. Faulty crank position sensor. Flywheel not installed properly. 2. Disconnect fuel tube at fuel flows clogged fuel tube. Fule pump. ...