- DL manuals

- Daewoo

- Engine

- CIELO EURO III

- Manual

Daewoo CIELO EURO III Manual

DAEWOO T-154 BL2,3

SECTION 1

ENGINE

CIELO EURO III

SECTION 1A

GENERAL ENGINE INFORMATION

TABLE OF CONTENTS

Diagnosis

1A-1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compression Test

1A-1

. . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pressure Test

1A-2

. . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Leak Diagnosis

1A-3

. . . . . . . . . . . . . . . . . . . . . . . .

Knock Diagnosis

1A-4

. . . . . . . . . . . . . . . . . . . . . . . . . .

Noise Diagnosis

1A-8

. . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information

1A-11

. . . . . . . . . . . . . . . . . . . . . . .

Cleanliness and Care

1A-11

. . . . . . . . . . . . . . . . . . . . .

On-Engine Service

1A-11

. . . . . . . . . . . . . . . . . . . . . . .

DIAGNOSIS

COMPRESSION TEST

Important:

Disconnect the Crankshaft Position (CKP)

Sensor connector to disable the fuel and the ignition

systems.

Test the compression pressure for each cylinder. Low

compression pressure may be the fault of the valves or

the pistons. The following conditions should be consid-

ered when you check the cylinder compression:

D

The engine should be at normal operating tempera-

ture.

D

The throttle must be wide open.

D

All the spark plugs should be removed.

D

The battery must be at or near full charge.

1. Place approximately three squirts of oil from a plung-

er-type oiler into each spark plug port.

2. Insert the engine compression gauge into each spark

plug port.

3. Crank test each cylinder with four to five compression

strokes using the starter motor.

4. The lowest reading should not be less than 70% of

the highest reading. The compression gauge reading

should not be less than 689 kPa (100 psi) for any of

the cylinders.

5. Examine the gauge readings obtained after the four

‘‘puffs’’ per cylinder are obtained from cranking the

starter motor. The readings are explained in the follow-

ing descriptions:

D

Normal Condition – Compression builds up quickly

and evenly to the specified compression on each cylin-

der.

D

Piston Rings Faulty – Compression is low on the first

stroke and tends to build up on following strokes, but

the compression pressure does not reach normal. The

compression pressure improves considerably with the

addition of oil into the cylinder.

D

Valves Faulty – Low compression pressure on the

first stroke. The compression pressure does not tend

to build up on the following strokes. The compression

pressure does not improve much with the addition of

oil into the cylinder.

Summary of CIELO EURO III

Page 1

Daewoo t-154 bl2,3 section 1 engine cielo euro iii section 1a general engine information table of contents diagnosis 1a-1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Compression test 1a-1 . . . . . . . . . . . . . . . . . . . . . . . . . Oil pressure test 1a-2 . . . . . . . . ....

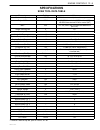

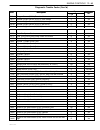

Page 2

1a – 2 general engine information daewoo t-154 bl2,3 oil pressure test ÜÜÜÜ ÜÜÜÜ step ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ action ÜÜÜÜÜ ÜÜÜÜÜ value(s) ÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜ yes ÜÜÜÜÜÜ ÜÜÜÜÜÜ no 1 is low or no oil pressure indicated? – go to step 2 system ok 2 check the oil level in the crankcase. Is the le...

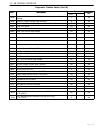

Page 3

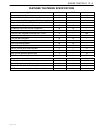

General engine information 1a – 3 daewoo t-154 bl2,3 oil pressure test (cont’d) ÜÜÜÜ ÜÜÜÜ step ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ action ÜÜÜÜÜ ÜÜÜÜÜ value(s) ÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜ yes ÜÜÜÜÜÜ ÜÜÜÜÜÜ no 20 inspect the bearing clearances. Are the bearing clearances more than the specified values? Crankshaft...

Page 4

1a – 4 general engine information daewoo t-154 bl2,3 3. Direct the light toward the suspected area. The dyed fluid will appear as a yellow path leading to the source. Repairing the leak once the origin of the leak has been pinpointed and traced back to its source, the cause of the leak must be deter...

Page 5

General engine information 1a – 5 daewoo t-154 bl2,3 heavy knock hot with torque applied ÜÜÜÜ ÜÜÜÜ step ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ action ÜÜÜÜÜ ÜÜÜÜÜ value(s) ÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜ yes ÜÜÜÜÜÜ ÜÜÜÜÜÜ no ÜÜÜÜ ÜÜÜÜ 1 ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ is there a heavy knock when the engine is hot a...

Page 6

1a – 6 general engine information daewoo t-154 bl2,3 light knock hot ÜÜÜÜ ÜÜÜÜ step ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ action ÜÜÜÜÜ ÜÜÜÜÜ value(s) ÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜ yes ÜÜÜÜÜÜ ÜÜÜÜÜÜ no ÜÜÜÜ ÜÜÜÜ 1 ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ is there a light knock when the engine is hot? ÜÜÜÜÜ ÜÜÜÜÜ – ÜÜÜÜÜÜ...

Page 7

General engine information 1a – 7 daewoo t-154 bl2,3 knocks at idle hot ÜÜÜÜ ÜÜÜÜ step ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ action ÜÜÜÜÜ ÜÜÜÜÜ value(s) ÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜ yes ÜÜÜÜÜÜ ÜÜÜÜÜÜ no 1 does the engine knock at idle when hot? – go to step 2 system ok 2 inspect the drive belts. Are the belts loos...

Page 8

1a – 8 general engine information daewoo t-154 bl2,3 noise diagnosis main bearing noise ÜÜÜÜ ÜÜÜÜ step ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ action ÜÜÜÜÜ ÜÜÜÜÜ value(s) ÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜ yes ÜÜÜÜÜÜ ÜÜÜÜÜÜ no 1 are dull thuds or knocks heard with every engine revolution? – go to step 2 system ok 2 check ...

Page 9

General engine information 1a – 9 daewoo t-154 bl2,3 piston noises ÜÜÜÜ ÜÜÜÜ step ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ action ÜÜÜÜÜ ÜÜÜÜÜ value(s) ÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜ yes ÜÜÜÜÜÜ ÜÜÜÜÜÜ no 1 are any of the following noises heard: a sharp double knock when the engine is idling, a light ticking with no load...

Page 10

1a – 10 general engine information daewoo t-154 bl2,3 valve mechanism or valve train noises ÜÜÜÜ ÜÜÜÜ step ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜÜ action ÜÜÜÜÜ ÜÜÜÜÜ value(s) ÜÜÜÜÜÜÜ ÜÜÜÜÜÜÜ yes ÜÜÜÜÜÜ ÜÜÜÜÜÜ no 1 is a light tapping sound heard from the engine? – go to step 2 system ok 2 inspect the val...

Page 11: General Information

General engine information 1a – 11 daewoo t-154 bl2,3 general information cleanliness and care an automobile engine is a combination of many ma- chined, honed, polished and lapped surfaces with toler- ances that are measured in the ten-thousandths of an inch. When any internal engine parts are servi...

Page 12: Blank

Daewoo t-154 bl2,3 blank.

Page 13: Section 1B

Daewoo t-154 bl2,3 . Section 1b sohc engine mechanical caution: disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal inju...

Page 14: Specifications

1b – 2 sohc engine mechanical daewoo t-154 bl2,3 specifications engine specifications application description (manual and automatic) general data: engine type 4 cylinder (in-line) displacement: 1.5 sohc 1 498 cm 3 (91.44 in 3 ) bore stroke: 1.5 sohc 76.5 x 81.5 mm (3.01 in. X 3.21 in.) compression r...

Page 15

Sohc engine mechanical 1b – 3 daewoo t-154 bl2,3 engine specifications (cont’d) ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ application ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ description (manual and automatic) ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ bearing od: ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁ...

Page 16

1b – 4 sohc engine mechanical daewoo t-154 bl2,3 fastener tightening specifications application n m lb-ft lb-in a/c compressor hose assembly retaining bolt 33 24 – a/c compressor mounting bolts 27 20 – a/c compressor mounting bracket bolts 50 37 – air filter housing bolts 8 – 71 alternator adjusting...

Page 17: Special Tools

Sohc engine mechanical 1b – 5 daewoo t-154 bl2,3 fastener tightening specifications (cont’d) application n m lb-ft lb-in intake manifold support bracket retaining bolts 22 16 – lower timing belt cover bolts 10 – 89 oil pan retaining bolts 10 – 89 oil pan drain plug 55 41 – oil pressure switch 40 30 ...

Page 18

1b – 6 sohc engine mechanical daewoo t-154 bl2,3 special tools table (cont’d) a102b152 km -26 3 -b engine assembly support fixture a102b153 km-427 piston pin service set a102b154 mkm-571-b gauge a102b155 km-253 valve guide reamer a102b155 km-254 valve guide reamer a102b155 km-255 valve guide reamer ...

Page 19

Sohc engine mechanical 1b – 7 daewoo t-154 bl2,3 special tools table (cont’d) a102b158 km-419 distance gauge a102b160 km-635 crankshaft rear oil seal installer a102b159 mkm-412 engine overhaul stand a202b005 km-498-b pressure gauge a102b161 km-470-b angular torque gauge a102c155 j-36972 crankshaft r...

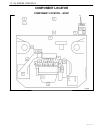

Page 20: Component Locator

1b – 8 sohc engine mechanical daewoo t-154 bl2,3 component locator upper end a402b001.

Page 21

Sohc engine mechanical 1b – 9 daewoo t-154 bl2,3 1 wiring bracket 2 bolt 3 bolt 4 cap, bayonet joint 5 seal, bayonet cap 6 valve cover 7 bolt 8 throttle position sensor 9 idle air control valve 10 throttle body 11 throttle body gasket 12 nut 13 engine coolant temperature sensor 14 intake manifold 15...

Page 22

1b – 10 sohc engine mechanical daewoo t-154 bl2,3 lower end a202b006.

Page 23

Sohc engine mechanical 1b – 11 daewoo t-154 bl2,3 1 piston ring seat 2 piston 3 piston pin 4 connecting rod 5 connecting rod bearing set 6 connecting rod bolt 7 oil level gauge stick 8 gauge stick tube 9 connecting piece 10 oil filter 11 camshaft pulley bolt 12 washer 13 camshaft gear 14 rear cover ...

Page 24: Maintenance And Repair

1b – 12 sohc engine mechanical daewoo t-154 bl2,3 a402b002 maintenance and repair on-vehicle service valve cover removal procedure 1. Disconnect the negative battery cable. 2. Disconnect the breather tube from the valve cover. A402b003 3. Remove the eight bolts from the valve cover. 4. Remove the va...

Page 25

Sohc engine mechanical 1b – 13 daewoo t-154 bl2,3 a402b002 3. Connect the breather tube to the valve cover. 4. Connect the negative battery cable. Cylinder head and gasket tools required j-42492 timing belt adjuster km-470-b angular torque gauge removal procedure 1. Remove the fuel pump fuse. 2. Sta...

Page 26

1b – 14 sohc engine mechanical daewoo t-154 bl2,3 a102b092 9. Disconnect the electronic ignition (ei) system igni- tion coil connector. 10. Disconnect the oxygen (o 2 ) sensor connector. 11. Disconnect the fuel injector harness connectors. A102b016 12. Disconnect the idle air control (iac) valve con...

Page 27

Sohc engine mechanical 1b – 15 daewoo t-154 bl2,3 a102b003 19. Remove the upper timing belt cover bolts. 20. Remove the upper timing belt cover. A102b004 21. Align the camshaft gear timing mark to the notch in the rear timing belt cover. A102b006 22. Remove the right front wheel. Refer to section 2e...

Page 28

1b – 16 sohc engine mechanical daewoo t-154 bl2,3 a102b005 25. Remove the alternator drive belt. 26. Remove the power steering pump pulley bolts, if equipped. 27. Remove the power steering pump pulley, if equipped. A402b009 28. Disconnect the fuel return line at the fuel pressure regulator. 29. Disc...

Page 29

Sohc engine mechanical 1b – 17 daewoo t-154 bl2,3 a102b114 33. Disconnect the upper radiator hose at the thermo- stat housing. 34. Disconnect the brake booster vacuum hose at the intake manifold. 35. Disconnect all of the necessary vacuum hoses. A102b008 36. Remove the crankshaft pulley bolt. 37. Re...

Page 30

1b – 18 sohc engine mechanical daewoo t-154 bl2,3 a402b004 45. Disconnect the crankcase ventilation tube at the camshaft housing. A102b111 46. Remove the valve cover bolts. 47. Remove the valve cover and the valve cover gasket. Notice: take care to prevent any scratches, nicks or damage to the camsh...

Page 31

Sohc engine mechanical 1b – 19 daewoo t-154 bl2,3 taa1f480 54. Disconnect the ignition wires at the spark plugs. 55. Remove the retaining nuts from the auxiliary catalyt- ic converter at the exhaust manifold flange. A102b119 56. Disconnect the heater inlet hose at the coolant dis- tributor. 57. Disc...

Page 32

1b – 20 sohc engine mechanical daewoo t-154 bl2,3 a402b006 60. Gradually loosen all of the cylinder head bolts in the sequence shown. 61. Remove the cylinder head bolts. 62. Remove the camshaft carrier assembly. Notice: prevent any engine oil or coolant from entering the cylinders when removing the ...

Page 33

Sohc engine mechanical 1b – 21 daewoo t-154 bl2,3 a402b008 5. Install the cylinder head bolts in the sequence shown. A102b172 tighten tighten the cylinder head bolts in the sequence pre- viously shown to 25 n m (18 lb-ft) using a torque wrench. Use the angular torque gauge km-470-b to tighten the cy...

Page 34

1b – 22 sohc engine mechanical daewoo t-154 bl2,3 a102b119 8. Connect the surge tank coolant hose at the throttle body. 9. Connect the heater inlet hose to the coolant distribu- tor. Taa1f480 10. Install the auxiliary catalytic converter nuts at the ex- haust manifold flange. Tighten tighten the aux...

Page 35

Sohc engine mechanical 1b – 23 daewoo t-154 bl2,3 a102b111 notice: take extreme care to prevent any scratches, nicks, or damage to the camshaft. Such damage can im- pair vehicle operation. 16. Install the camshaft gear. 17. While holding the camshaft firmly in place, install the camshaft gear bolt. ...

Page 36

1b – 24 sohc engine mechanical daewoo t-154 bl2,3 a102b030 22. Align the mark on the crankshaft gear to the notch at the bottom of the rear timing belt cover. A102b020 23. Install the timing belt. Refer to “timing belt” in this section. 24. Check the timing belt tension. Refer to “timing belt check ...

Page 37

Sohc engine mechanical 1b – 25 daewoo t-154 bl2,3 a102b114 33. Connect all of the vacuum hoses. 34. Connect the brake booster hose at the intake man- ifold. 35. Connect the upper radiator hose at the thermostat housing. A102b118 36. Install the alternator adjusting bracket. 37. Install the alternato...

Page 38

1b – 26 sohc engine mechanical daewoo t-154 bl2,3 a102b003 41. Install the alternator drive belt. Tighten tighten the alternator adjusting bolt to 20 n m (15 lb-ft). 42. Install the upper timing belt cover. 43. Install the upper timing belt cover bolts. Tighten tighten the upper timing belt cover bo...

Page 39

Sohc engine mechanical 1b – 27 daewoo t-154 bl2,3 a402b003 camshaft tools required km-565-a valve spring compressor removal procedure 1. Remove the timing belt. Refer to “timing belt” in this section. 2. Disconnect the air breather tube at the valve cover. 3. Remove the valve cover bolts. 4. Remove ...

Page 40

1b – 28 sohc engine mechanical daewoo t-154 bl2,3 a102c034 10. Disconnect the positive battery cable from the bat- tery. 11. Remove the battery and the battery tray. Refer to section 1e, engine electrical. A102b075 12. Disconnect the electronic ignition (ei) system igni- tion coil connector. 13. Dis...

Page 41

Sohc engine mechanical 1b – 29 daewoo t-154 bl2,3 a102b077 20. Remove the camshaft. A102b076 installation procedure 1. Install the camshaft. 2. Install the camshaft pressure plate. 3. Install the camshaft pressure plate bolts. Tighten tighten the camshaft pressure plate bolts to 10 n m (89 lb-in). A...

Page 42

1b – 30 sohc engine mechanical daewoo t-154 bl2,3 a102c034 11. Install the battery and the battery tray. Refer to sec- tion 1e, engine electrical. 12. Connect the positive battery cable to the battery. A102b111 notice: take extreme care to prevent any scratches, nicks, or damage to the camshaft. Suc...

Page 43

Sohc engine mechanical 1b – 31 daewoo t-154 bl2,3 a402b003 17. Install the valve cover gasket. 18. Install the valve cover. 19. Install the valve cover bolts. Tighten tighten the valve cover bolts to 9 n m (80 lb-in). 20. Connect the air breather tube to the valve cover. 21. Install the timing belt....

Page 44

1b – 32 sohc engine mechanical daewoo t-154 bl2,3 a102b003 9. Remove the a/c compressor drive belt, if equipped. 10. Remove the alternator drive belt. 11. Remove the power steering pump pulley bolts, if equipped. 12. Remove the power steering pump pulley, if equipped. 13. Remove the power steering p...

Page 45

Sohc engine mechanical 1b – 33 daewoo t-154 bl2,3 a102b030 20. Install the crankshaft pulley bolt. 21. Rotate the crankshaft at least one full turn clockwise using the crankshaft pulley bolt. 22. Align the dot on the crankshaft gear to the notch at the bottom of the rear timing belt cover. A102b004 ...

Page 46

1b – 34 sohc engine mechanical daewoo t-154 bl2,3 a102b039 27. Align the adjust arm hole of the timing belt automatic tensioner to the hole in the timing belt automatic ten- sioner bracket. 28. Insert a 4.5 mm driver through the adjust arm hole and the tensioner bracket hole. 29. Rotate the cranksha...

Page 47

Sohc engine mechanical 1b – 35 daewoo t-154 bl2,3 a102b018 38. Install the crankshaft pulley. 39. Install the crankshaft pulley bolt. Tighten tighten the crankshaft pulley bolt to 95 n m (70 lb-ft) using a torque wrench. Use the angular torque gauge km-470-b to tighten the crankshaft pulley bolt ano...

Page 48

1b – 36 sohc engine mechanical daewoo t-154 bl2,3 a102b001 51. Connect the air intake tube to the throttle body. 52. Connect the breather tube to the valve cover. 53. Connect the iat sensor connector. 54. Connect the negative battery cable. A102b001 timing belt tools required j-42492 timing belt adj...

Page 49

Sohc engine mechanical 1b – 37 daewoo t-154 bl2,3 a102b003 9. Remove the a/c compressor drive belt, if equipped. 10. Remove the alternator drive belt. 11. Remove the power steering pump, if equipped. Re- fer to section 6b, power steering pump. 12. Remove the upper timing belt cover bolts. 13. Remove...

Page 50

1b – 38 sohc engine mechanical daewoo t-154 bl2,3 a102b040 20. Slightly loosen the coolant pump retaining bolts. 21. Using the timing belt adjuster j-42492, rotate the coolant pump counterclockwise to release the ten- sion on the timing belt. 22. Remove the timing belt. A102b042 installation procedu...

Page 51

Sohc engine mechanical 1b – 39 daewoo t-154 bl2,3 a102b039 6. Align the adjust arm hole of the timing belt automatic tensioner to the hole in the timing belt automatic ten- sioner bracket. 7. Insert a 4.5 mm driver through the adjust arm hole and the tensioner bracket hole. A102b030 8. Rotate the cr...

Page 52

1b – 40 sohc engine mechanical daewoo t-154 bl2,3 a102b041 13. Rotate the coolant pump until the adjust arm pointer of the timing belt automatic tensioner is aligned with the notch in the timing belt automatic tensioner bracket. 14. Tighten the coolant pump retaining bolts. Tighten tighten the coola...

Page 53

Sohc engine mechanical 1b – 41 daewoo t-154 bl2,3 a102b003 20. Install the upper timing belt cover. 21. Install the upper timing belt cover bolts. Tighten tighten the upper timing belt cover bolts to 10 n m (89 lb-in). A102b006 22. Install the power steering pump, if equipped. Refer to section 6b, p...

Page 54

1b – 42 sohc engine mechanical daewoo t-154 bl2,3 a102b001 29. Connect the air intake tube to the throttle body. 30. Connect the breather tube to the valve cover. 31. Connect the iat sensor connector. 32. Connect the negative battery cable. A102b019 oil pump tools required km-498-b pressure gauge km...

Page 55

Sohc engine mechanical 1b – 43 daewoo t-154 bl2,3 a102b019 7. Install the oil pressure switch. Tighten tighten the oil pressure switch to 40 n m (30 lb-ft). 8. Connect the electrical connector to the oil pressure switch. 9. Install the right-hand wheel well splash shield. 10. Check the oil level and...

Page 56

1b – 44 sohc engine mechanical daewoo t-154 bl2,3 a102b065 11. Remove the oil pump retaining bolts. 12. Carefully separate the oil pump and the gasket from the engine block and the oil pan. 13. Remove the oil pump. A202b002 inspection procedure 1. Clean the oil pump and the engine block gasket mat- ...

Page 57

Sohc engine mechanical 1b – 45 daewoo t-154 bl2,3 a202b001 7. Clean the oil pump housing and all of the parts. 8. Inspect all of the parts for signs of wear. Refer to “engine specifications” in this section. 9. Coat all of the oil pump parts with clean engine oil. 10. Reinstall all of the oil pump p...

Page 58

1b – 46 sohc engine mechanical daewoo t-154 bl2,3 a202b002 5. Install a new oil pump to the crankshaft shaft seal. 6. Coat the lip of the seal with a thin coat of grease. A102b064 7. Coat the threads of the oil pump pickup tube and the support bracket bolts with loctite 573. 8. Install the oil pump ...

Page 59

Sohc engine mechanical 1b – 47 daewoo t-154 bl2,3 taa1f480 oil pan removal procedure 1. Disconnect the negative battery cable. 2. Drain the engine oil from the engine crankcase. 3. Disconnect the post-converter heated oxygen (o 2 ) sensor. 4. Remove the auxiliary catalytic converter upper flange nut...

Page 60

1b – 48 sohc engine mechanical daewoo t-154 bl2,3 a102b043 9. Remove the oil pan retaining bolts. 10. Remove the oil pan from the engine block. A102b044 cleaning procedure 1. Clean the oil pan sealing surface. 2. Clean the engine block sealing surface. 3. Clean the oil pan retaining bolts. 4. Clean ...

Page 61

Sohc engine mechanical 1b – 49 daewoo t-154 bl2,3 a102b021 4. Install the flywheel or flexible plate inspection cover. 5. Install the flywheel or flexible plate inspection cover bolts. Tighten tighten the flywheel inspection cover bolts to 12 n m (106 lb-in) or the flexible plate inspection cover bo...

Page 62

1b – 50 sohc engine mechanical daewoo t-154 bl2,3 a105b012 engine mount tools required km-263-b engine assembly support fixture removal procedure 1. Disconnect the negative battery cable. 2. Support the engine assembly using the engine as- sembly support fixture km-263-b . A102b020 3. Remove the eng...

Page 63

Sohc engine mechanical 1b – 51 daewoo t-154 bl2,3 a102b045 installation procedure 1. Install the engine mount. 2. Install the engine mount attaching nuts. Tighten tighten the engine mount attaching nuts to 40 n m (30 lb-ft). A102b020 3. Install the engine mount bracket retaining bolts. Tighten tight...

Page 64

1b – 52 sohc engine mechanical daewoo t-154 bl2,3 intake manifold removal procedure 1. Remove the fuel pump fuse. 2. Start the engine. After it stalls, crank the engine for 10 seconds to rid the fuel system of fuel pressure. 3. Disconnect the negative battery cable. 4. Disconnect the en gine control...

Page 65

Sohc engine mechanical 1b – 53 daewoo t-154 bl2,3 a102b031 11. Disconnect the heater inlet hose from the coolant distributor beneath the intake manifold. 12. Disconnect the surge tank coolant hose at the throttle body. 13. Disconnect all of the necessary vacuum hoses, in- cluding the vacuum hose at ...

Page 66

1b – 54 sohc engine mechanical daewoo t-154 bl2,3 a102b118 21. Remove the alternator drive belt. 22. Remove the alternator adjusting bracket and the bolts. A102b033 23. Remove the three intake manifold support bracket retaining bolts from the coolant distributor and the engine block. 24. Remove the ...

Page 67

Sohc engine mechanical 1b – 55 daewoo t-154 bl2,3 a102b034 26. Remove the intake manifold. 27. Remove the intake manifold gasket. 28. Clean the sealing surfaces of the intake manifold and the cylinder head. A102b035 installation procedure 1. Install the intake manifold gasket. 2. Install the intake ...

Page 68

1b – 56 sohc engine mechanical daewoo t-154 bl2,3 a402b010 8. Install the fuel rail and the fuel injectors as an assem- bly. Refer to section 1f, engine controls. 9. Install the fuel rail retaining bolts. Tighten tighten the fuel rail retaining bolts to 25 n m (18 lb-ft). A402b005 10. Connect the fu...

Page 69

Sohc engine mechanical 1b – 57 daewoo t-154 bl2,3 a102b001 21. Connect the air intake tube to the throttle body. 22. Connect the iat sensor connector. 23. Connect the ecm ground terminal to the in- take manifold. 24. Connect the negative battery cable. 25. Install the fuel pump fuse. 26. Refill the ...

Page 70

1b – 58 sohc engine mechanical daewoo t-154 bl2,3 a102b038 installation procedure 1. Install the exhaust manifold gasket. 2. Install the exhaust manifold. 3. Install the eight exhaust manifold nuts and torque in the sequence shown. Tighten tighten the exhaust manifold nuts 25 n m (18 lb-ft). Taa1f48...

Page 71

Sohc engine mechanical 1b – 59 daewoo t-154 bl2,3 a102b111 notice: take extreme care to prevent any scratches, nicks, or damage to the camshaft. Such damage can im- pair vehicle operation. 5. While holding the camshaft firmly in place, remove the camshaft gear bolt. 6. Remove the camshaft gear. A102...

Page 72

1b – 60 sohc engine mechanical daewoo t-154 bl2,3 a102b046 rear timing belt cover removal procedure 1. Disconnect the negative battery cable. 2. Remove the timing belt. Refer to “timing belt” in this section. Notice: take extreme care to prevent any scratches, nicks, or damage to the camshaft. Such ...

Page 73

Sohc engine mechanical 1b – 61 daewoo t-154 bl2,3 engine tools required km-470-b angular torque gauge removal procedure important: on vehicles equipped with a manual trans- axle, the manual transaxle must be removed before en- gine removal. Refer to section 5b, five-speed manual transaxle. 1. Remove...

Page 74

1b – 62 sohc engine mechanical daewoo t-154 bl2,3 a102b014 12. Remove the right front wheel. Refer to section 2e, tires and wheels. 13. Remove the right front wheel well splash shield. 14. Remove the a/c compressor drive belt, if equipped. 15. Remove the alternator drive belt. 16. Remove the power s...

Page 75

Sohc engine mechanical 1b – 63 daewoo t-154 bl2,3 a402b009 32. Disconnect the alternator voltage regulator connec- tor. 33. Disconnect all of the necessary vacuum lines, in- cluding the brake booster vacuum hose. 34. Disconnect the fuel return line at the fuel pressure regulator. 35. Disconnect the ...

Page 76

1b – 64 sohc engine mechanical daewoo t-154 bl2,3 taa1f480 51. Remove the auxiliary catalytic converter nuts from the exhaust manifold and the bolts at the bracket. B102g003 52. Remove the nuts from the front muffler pipe to the main catalytic converter. 53. Remove both catalytic converters as a uni...

Page 77

Sohc engine mechanical 1b – 65 daewoo t-154 bl2,3 a102b019 56. Disconnect the vacuum lines at the evaporative (evap) emission canister purge. 57. Disconnect the electrical connector at the evap emission canister purge solenoid and the knock sensor. 58. Disconnect the electrical connector at the oil ...

Page 78

1b – 66 sohc engine mechanical daewoo t-154 bl2,3 a102b020 66. Remove the transaxle bell housing bolts. 67. Support the transaxle with a floor jack. 68. Install the engine lifting device. 69. Disconnect the right engine mount bracket from the rubber engine mount by removing the two retaining bolts. ...

Page 79

Sohc engine mechanical 1b – 67 daewoo t-154 bl2,3 a102b022 9. Install the transaxle torque converter bolts, if the ve- hicle has an automatic transaxle. Tighten tighten the transaxle torque converter bolts to 65 n m (48 lb-ft). A102b024 10. Install the flywheel or the flexible plate inspection cover...

Page 80

1b – 68 sohc engine mechanical daewoo t-154 bl2,3 a102b018 15. Connect the oil pressure switch connector. 16. Install the crankshaft pulley. 17. Install the crankshaft pulley bolt. Tighten tighten the crankshaft pulley bolt to 95 n m (70 lb-ft) using a torque wrench. Using the angular torque gauge k...

Page 81

Sohc engine mechanical 1b – 69 daewoo t-154 bl2,3 a102b015 21. Connect the power steering pressure hose, if equipped. 22. Connect the power steering return hose, if equipped. A102b025 23. Install the a/c compressor mounting bracket, if equipped. 24. Install the a/c compressor mounting bracket bolts,...

Page 82

1b – 70 sohc engine mechanical daewoo t-154 bl2,3 a402b009 33. Install the right front wheel well splash shield. 34. Install the right front wheel. Refer to section 2e, tires and wheels 35. Connect the fuel feed line to the fuel rail. 36. Connect the fuel return line to the fuel pressure reg- ulator...

Page 83

Sohc engine mechanical 1b – 71 daewoo t-154 bl2,3 a102b017 51. Install the cooling system radiator and the engine cooling fans. Refer to section 1d, engine cooling. 52. Connect the lower radiator hose to the coolant pipe. 53. Connect the upper radiator hose to the thermostat housing. 54. Connect the...

Page 84

1b – 72 sohc engine mechanical daewoo t-154 bl2,3 a102b079 5. Move the piston to the bottom of the piston stroke. 6. Mark the connecting rod cap. 7. Remove the connecting rod cap bolts. 8. Remove the connecting rod cap and lower connect- ing rod bearing. 9. Remove the upper piston connecting rod bea...

Page 85

Sohc engine mechanical 1b – 73 daewoo t-154 bl2,3 a102b087 inspection procedure 1. Inspect the connecting rod for bending or twisting. If the connecting rod is bent or twisted, replace the con- necting rod. 2. Inspect the connecting rod bearings. 3. Inspect the connecting rod lower end for wear. 4. ...

Page 86

1b – 74 sohc engine mechanical daewoo t-154 bl2,3 a102b081 installation procedure 1. Align the notch on the piston and connecting rod so that the proper sides will be facing the front of the en- gine. 2. Install the piston pin guide through the piston and the connecting rod. 3. Coat the piston pin w...

Page 87

Sohc engine mechanical 1b – 75 daewoo t-154 bl2,3 a102b086 12. Install a piston oil ring, the expander, and the sec- ond piston oil ring to the bottom ring groove of the piston. 13. Install the second compression ring to the middle ring groove of the piston. 14. Install the top compression ring to t...

Page 88

1b – 76 sohc engine mechanical daewoo t-154 bl2,3 a102c151 20. Install the connecting rod bearing cap bolts. Tighten tighten the connecting rod bearing cap bolts to 25 n m (18 lb-ft). Using the angular torque gauge km-470-b, tighten one turn of 30 degrees. A102b094 21. Install the oil pump/pickup tu...

Page 89: Unit Repair

Sohc engine mechanical 1b – 77 daewoo t-154 bl2,3 a102b049 unit repair cylinder head and valve train components tools required mkm-571-b gauge km-253 valve guide reamer km-254 valve guide reamer km-255 valve guide reamer km-340-0 cutter set km-340-7 guide drift km-340-13 cutter km-340-26 cutter km-3...

Page 90

1b – 78 sohc engine mechanical daewoo t-154 bl2,3 a102b048 10. Remove the intake manifold retaining nuts. 11. Remove the intake manifold. 12. Remove the intake manifold gasket. 13. Remove the intake manifold studs. A102b050 14. Remove the thermostat housing mounting bolts. 15. Remove the thermostat ...

Page 91

Sohc engine mechanical 1b – 79 daewoo t-154 bl2,3 a102b052 cylinder head inspection 1. Clean the sealing surfaces. 2. Inspect the cylinder head gasket and the mating sur- faces for leaks, corrosion, and blowby. 3. Inspect the cylinder head for cracks. 4. Inspect the length and the width of the cylin...

Page 92

1b – 80 sohc engine mechanical daewoo t-154 bl2,3 a102b023 7. Inspect the valve spring. If the valve spring ends are not parallel, replace the valve spring. 8. Measure the valve spring height. Refer to “engine specifications” in this section. If the valve spring height does not match the specificati...

Page 93

Sohc engine mechanical 1b – 81 daewoo t-154 bl2,3 a102b057 3. Check the contact pattern on the valve head and in the cylinder head. 4. Clean the valves, the valve guides, and the cylinder head. A102b066 valve grind 1. Ensure that there are no crater line burns on the valve cone. 2. The valve may be ...

Page 94

1b – 82 sohc engine mechanical daewoo t-154 bl2,3 a102b059 valve guide ream 1. Measure the diameter of the valve guide using the gauge mkm-571-b and a commercially available in- side micrometer. Important: valve oversizes may already have been fitted in production. 2. An oversize code is on the valv...

Page 95

Sohc engine mechanical 1b – 83 daewoo t-154 bl2,3 a102b058 3. Clean the chippings from the cylinder head. 4. Inspect the dimension for the proper valve seat width. Intake: 1.3 to 1.5 mm (0.051 to 0.059 inch) exhaust: 1.6 to 1.8 mm (0.063 to 0.071 inch) 5. Inspect the valve stem projection using the ...

Page 96

1b – 84 sohc engine mechanical daewoo t-154 bl2,3 a102b050 9. Install the thermostat and the gasket. 10. Install the thermostat housing. 11. Install the thermostat housing mounting bolts. Tighten tighten the thermostat housing mounting bolts to 20 n m (15 lb-ft). A102b048 12. Install the intake mani...

Page 97

Sohc engine mechanical 1b – 85 daewoo t-154 bl2,3 a102b049 21. Install the exhaust manifold heat shield. 22. Install the exhaust manifold heat shield bolts. Tighten tighten the exhaust manifold heat shield bolts to 15 n m (11 lb-ft). 23. Install the coolant temperature sensor. Tighten tighten the co...

Page 98

1b – 86 sohc engine mechanical daewoo t-154 bl2,3 a102b096 6. Remove the upper timing belt cover bolts. 7. Remove the upper timing belt cover. 8. Remove the power steering pump mounting bolts. 9. Remove the power steering pump. 10. Remove the lower timing belt cover bolts. 11. Remove the lower timin...

Page 99

Sohc engine mechanical 1b – 87 daewoo t-154 bl2,3 a102b093 19. Remove the timing belt automatic tensioner bolt. 20. Remove the timing belt automatic tensioner. 21. Remove the rear timing belt cover bolts. 22. Remove the rear timing belt cover. 23. Remove the crankshaft timing belt gear. A102b064 24....

Page 100

1b – 88 sohc engine mechanical daewoo t-154 bl2,3 a102b067 31. Mark the order of the rod bearing caps. 32. Remove the connecting rod cap bolts for all of the pistons. 33. Remove the connecting rod bearing caps and the lower connecting rod bearings. 34. Remove the upper connecting rod bearings. A102b...

Page 101

Sohc engine mechanical 1b – 89 daewoo t-154 bl2,3 a102b071 4. With the crankshaft mounted on the front and the rear crankshaft bearings, check the middle crankshaft journal for permissible out-of-round (runout). Refer to ‘‘engine specifications’’ in this section. A102b069 5. Coat the crankshaft bear...

Page 102

1b – 90 sohc engine mechanical daewoo t-154 bl2,3 a102c151 14. Install the connecting rod bearing caps to the con- necting rods. Notice: do not reuse the old connecting rod bearing cap bolts. Damage to the engine could result. 15. Install new connecting rod bearing cap bolts. Tighten tighten the con...

Page 103

Sohc engine mechanical 1b – 91 daewoo t-154 bl2,3 a102b043 20. Install the oil pan gasket to the oil pan. 21. Install the oil pan. Important: install the oil pan within 5 minutes after ap- plying the liquid gasket to the oil pan. 22. Install the oil pan retaining bolts. Tighten tighten the oil pan r...

Page 104

1b – 92 sohc engine mechanical daewoo t-154 bl2,3 a102b008 30. Install the timing belt. 31. Adjust the timing belt tension. Refer to “timing belt check and adjust” in this section. 32. Install the valve cover gasket and the valve cover. 33. Install the valve cover bolts. Tighten tighten the valve co...

Page 105

Sohc engine mechanical 1b – 93 daewoo t-154 bl2,3 a102b070 crankshaft bearings and connecting rod bearings — gauging plastic tools required km-470-b angular torque gauge inspection procedure – crankshaft 1. Coat the crankshaft bearings with engine oil. 2. Install the upper crankshaft bearings into t...

Page 106

1b – 94 sohc engine mechanical daewoo t-154 bl2,3 a102b091 10. Install the crankshaft bearing caps. 11. Install the crankshaft bearing cap bolts. Tighten tighten the crankshaft bearing cap bolts to 50 n m (37 lb-ft). Using the angular torque gauge km-470-b, tighten the crankshaft bearing cap bolts a...

Page 107

Sohc engine mechanical 1b – 95 daewoo t-154 bl2,3 a102c151 5. Cut the plastic gauging threads to the length of the bearing width. Lay them axially between the con- necting rod journals and the connecting rod bear- ings. 6. Install the connecting rod bearing caps. 7. Install the connecting rod bearin...

Page 108: General Description

1b – 96 sohc engine mechanical daewoo t-154 bl2,3 general description and system operation cylinder head and gasket the cylinder head is made of an aluminum alloy. The cylinder head uses crossflow intake and exhaust ports. A spark plug is located in the center of each of the com- bustion chambers. C...

Page 109: Section 1D

Daewoo t-154 bl2,3 section 1d engine cooling caution: disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and dam...

Page 110: Special Tools

1d – 2 engine cooling daewoo t-154 bl2,3 fastener tightening specifications application n m lb-ft lb-in coolant pump mounting bolts 10 – 89 electric cooling fan (main) motor nut 3.2 – 28 electric cooling fan (main) motor retaining screws 4 – 35 electric cooling fan assembly (auxiliary) mounting bolt...

Page 111: Diagnosis

Engine cooling 1d – 3 daewoo t-154 bl2,3 diagnosis thermostat test 1. Remove the thermostat from the vehicle. Refer to “thermostat” in this section. 2. Make sure the valve spring is tight when the thermo- stat is fully closed. If the spring is not tight, replace the thermostat. 3. Suspend the thermo...

Page 112

1d – 4 engine cooling daewoo t-154 bl2,3 cooling system diagnosis engine overheats ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ checks ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ check for a loss of the coolant. ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ add the coolant. Á...

Page 113

Engine cooling 1d – 5 daewoo t-154 bl2,3 engine fails to reach normal operating temperature or cool air from the heater ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ checks ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ check to determine if the thermostat is stuck open, ...

Page 114: Component Locator

Engine cooling 1d – 6 component locator (numai la cvm) (numai la cva) 1. Bridˆ fixare radiator 2. Tampoane amortizare 3. “urub 4. Tampon amortizare 5. Motorul electric al ventilatorului 6. Suport ventilator 7. “urub 8. “urub 9. Termocontact (tura ie scˆzutˆ) 26. Colier 27. Pompˆ de apˆ 28. “urub 29....

Page 115

Engine cooling 1d – 7 daewoo t-154 bl2,3 coolant pump/thermostat (sohc) a102d027 1 thermostat housing bolt 2 thermostat housing 3 seal ring 4 thermostat 5 coolant pump mounting bolts 6 coolant pump 7 o-ring.

Page 116: Maintenance And Repair

1d – 8 engine cooling daewoo t-154 bl2,3 a102d001 maintenance and repair on-vehicle service draining and refilling the cooling system caution: to avoid injury, do not remove the surge tank cap while the engine and the radiator are hot. Scalding fluid and steam may be blown out under pressure. 1. Pla...

Page 117

Engine cooling 1d – 9 daewoo t-154 bl2,3 a102d002 thermostat single overhead cam engine removal procedure caution: to prevent personal injury, do not remove the surge tank cap while the engine and the radiator are hot because the heat causes the system to re- main under pressure. Scalding fluid and ...

Page 118

1d – 10 engine cooling daewoo t-154 bl2,3 a102d003 dual overhead cam engine removal procedure caution: to prevent personal injury, do not remove the surge tank cap while the engine and the radiator are still hot because the heat causes the system to remain under pressure. Scalding fluid and steam ma...

Page 119

Engine cooling 1d – 11 daewoo t-154 bl2,3 a102d003 4. Connect the bypass hose to the thermostat adapter. 5. Secure the bypass hose with a hose clamp. 6. Connect the upper radiator hose to the thermostat housing. 7. Secure the upper radiator hose to the thermostat housing with a hose clamp. 8. Refill...

Page 120

1d – 12 engine cooling daewoo t-154 bl2,3 a102d042 installation procedure 1. Install a new ring seal to the coolant pump. 2. Coat the sealing surface of the ring seal with lubri- plate . 3. Install the coolant pump to the engine block. 4. Secure the coolant pump to the engine block with the mounting...

Page 121

Engine cooling 1d – 13 daewoo t-154 bl2,3 a102d007 installation procedure caution: if a fan blade is bent or damaged in any way, no attempt should be made to repair or reuse the damaged part. A bent or damaged fan assembly must be replaced with a new fan assembly. It is es- sential that fan assembli...

Page 122

Engine cooling 1d – 14 daewoo t-154 bl2,3 a102d017 surge tank removal procedure caution: to prevent personal injury, do not remove the surge tank cap while the engine and the radiator are hot, because the heat causes the system to re- main under pressure. Scalding fluid and steam may be blown out un...

Page 123

1d – 15 engine cooling daewoo t-154 bl2,3 b102d015 radiator removal procedure 1. Disconnect the negative battery cable. 2. Drain the engine cooling system. Refer to “draining and refilling the cooling system” in this section. 3. Remove the main cooling fan. Refer to “electric cool- ing fan-main” in ...

Page 124

Engine cooling 1d – 16 daewoo t-154 bl2,3 a102d012 installation procedure 1. If installing a new radiator, remove the transaxle cooler pipes from the old radiator and install them onto the left tank of the new radiator. Tighten tighten the upper transaxle cooler pipe bolt to 12 n m (106 lb-in). 3. I...

Page 125

1d – 17 engine cooling daewoo t-154 bl2,3 b102d015 12. Connect the surge tank hose to the radiator. 13. Secure the surge tank hose with a hose clamp. 14. Connect the upper radiator hose and the lower ra- diator hose to the radiator. 15. Secure each hose with a hose clamp. 16. Install the main coolin...

Page 126: General Description

1d – 1 9 engine cooling daewoo t-154 bl2,3 general description and system operation general description the cooling system maintains the engine temperature at an efficient level during all engine operating conditions. When the engine is cold, the cooling system cools the engine slowly or not at all....

Page 127

Engine cooling 1d – 20 daewoo t-154 bl2,3 jury. This fan is electric and can turn on whether or not the engine is running. Caution: if a fan blade is bent or damaged in any way, no attempt should be made to repair or reuse the damaged part. A bent or damaged fan assembly should always be replaced wi...

Page 128: Blank

Daewoo t-154 bl2,3 blank.

Page 129: Section 1E

Daewoo t-154 bl2,3 section 1e engine electrical caution: disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and ...

Page 130

1e – 2 engine electrical daewoo t-154 bl2,3 generator specifications ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ application ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ description ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ types ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁ...

Page 132

1e – 4 engine electrical daewoo t-154 bl2,3 a402e002 charging syst em.

Page 133: Diagnosis

Engine electrical 1e – 5 daewoo t-154 bl2,3 diagnosis no crank ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value(s) ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ ÁÁÁÁÁÁ ÁÁÁ...

Page 134

1e – 6 engine electrical daewoo t-154 bl2,3 no crank (cont’d) ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value(s) ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ 14 ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ repair the starter “s” terminal. Is the repair com...

Page 135

1e – 7 engine electrical daewoo t-154 bl2,3 no crank (cont’d) ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value(s) ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁ ÁÁÁÁÁÁ...

Page 136

Engine electrical 1e – 8 daewoo t-154 bl2,3 starter motor noise to correct starter motor noise during starting, use the following procedure : ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ checks ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁ...

Page 137

1e – 9 engine electrical daewoo t-154 bl2,3 generator output test 1. Perform the generator system test. Refer to “gener- ator system check” in this section. 2. Replace the generator if it fails that test. Refer to “generator” in the on-vehicle service section. If it passes the test, perform the on-v...

Page 138: Maintenance And Repair

Engine electrical 1e – 1 0 daewoo t-154 bl2,3 a202e001 maintenance and repair on-vehicle service generator removal procedure 1. Disconnect the negative battery cable. 2. Disconnect the intake air temperature (iat) sensor electrical connector from the air intake tube. A202e002 3. Remove the breather ...

Page 139

1e – 1 1 engine electrical daewoo t-154 bl2,3 a202e003 5. Remove the generator shackle bracket bolt and the washer. 6. Remove the serpentine accessory drive belt. For ve- hicles equipped with power steering and air condition- ing, refer to section 6b, power steering pump. A202e004 7. Remove the bolt...

Page 140

Engine electrical 1e – 1 2 daewoo t-154 bl2,3 a102e254 9. For vehicles with the dohc engine, remove the throttle body. Refer to section 1f, engine controls. 10. Remove the fuel rail mounting bolts. Notice: take extreme care not to damage the fuel injec- tor o-rings to prevent fuel leaks when the fue...

Page 141

1e – 1 3 engine electrical daewoo t-154 bl2,3 a102e232 5. Connect the harness connector to the back of the generator. 6. Install the generator lead to the battery and fasten the lead with the nut. Tighten tighten the generator battery lead nut to 15 n s m (11 lb-ft). 7. Lubricate the injector o-ring...

Page 142

Engine electrical 1e – 1 4 daewoo t-154 bl2,3 a202e001 12. Install the iat electrical connector to the air intake tube. 13. Connect the negative battery cable. A102e235 starter removal procedure 1. Remove the upper and the lower starter mounting bolts. A102e236 2. Remove the starter solenoid nuts to...

Page 143

1e – 1 5 engine electrical daewoo t-154 bl2,3 a102e235 installation procedure 1. Place the starter assembly in position. 2. Install the upper and the lower starter mounting bolts. Tighten tighten the starter mounting bolts to 43 n s m (32 lb- ft). A102e236 3. Position the starter electrical wire on ...

Page 144

Engine electrical 1e – 1 6 daewoo t-154 bl2,3 a202e005 3. Check the battery carrier tray for obvious cracks or damage. Detach the carrier tray if necessary by re- moving the upper and the lower bolts. A202e005 installation procedure 1. Install the battery carrier by fastening the carrier tray upper ...

Page 145

1e – 1 7 engine electrical daewoo t-154 bl2,3 a102e240 4. Connect the negative and the positive battery cables. Tighten tighten the battery cable nuts to 15 n s m (11 lb-ft)..

Page 146: Unit Repair

Engine electrical 1e – 1 8 daewoo t-154 bl2,3 a102e239 unit repair starter motor disassembly procedure 1. Remove the starter. Refer to “starter” in this section. 2. Remove the starter through-bolts. A102e215 3. Remove the commutator end frame/brush holder as- sembly. 4. Inspect the brushes, the pop-...

Page 147

1e – 1 9 engine electrical daewoo t-154 bl2,3 a102e217 6. When testing a series coil for ground, separate the series and the shunt coil strap terminals during the test. 6.1 with the strap terminals not touching the case or the other ground, using a test lamp, place one lead on the grounded brush hol...

Page 148

Engine electrical 1e – 2 0 daewoo t-154 bl2,3 a102e219 notice: complete the testing in a minimum amount of time to prevent overheating and damaging the solenoid. Important: if the specified current draw does not in- clude the solenoid, deduct from the armature reading the specified current draw of t...

Page 149

1e – 2 1 engine electrical daewoo t-154 bl2,3 a102e219 8.3 failure to operate with high current draw indi- cates a direct ground in the terminal or fields, or “frozen” bearings. 8.4 failure to operate with no current draw indi- cates an open field circuit, open armature coils, broken brush springs, ...

Page 150

Engine electrical 1e – 2 2 daewoo t-154 bl2,3 a102e247 11. Rotate the solenoid 90 degrees and remove it along with the plunger return spring. A102e221 important: if the solenoid is not removed from the start- ing motor, the connector strap terminals must be re- moved from the terminal on the solenoi...

Page 151

1e – 2 3 engine electrical daewoo t-154 bl2,3 a102e222 14. Slide the field frame with the enclosed armature as- sembly away from the starter assembly. 15. Remove the shield. A102e242 16. Separate the field frame from the armature. A102e223 17. Inspect the shaft, the bearing, and the pinion for dis- ...

Page 152

Engine electrical 1e – 2 4 daewoo t-154 bl2,3 a202e006 22. Remove the gears, the bushings, and the washer. 23. Remove the cushion and the driveshaft assembly from the starter housing. A102e220 24. Disassemble the driveshaft assembly by first sepa- rating the needle bearing from the driveshaft. 25. R...

Page 153

1e – 2 5 engine electrical daewoo t-154 bl2,3 a102e249 27. Remove the gear support from the driveshaft. A102e226 28. If not done in the previous steps, remove the screws that hold the solenoid assembly into the housing, and remove the nut from the field coil connector. A102e247 29. Rotate the soleno...

Page 154

Engine electrical 1e – 2 6 daewoo t-154 bl2,3 a102e250 30. Remove the plunger with the boot and the shift lever assembly. Test the solenoid windings, if not done in step 12. A102e237 important: the pinion clearance must be correct to pre- vent the buttons on the shift lever yoke from rubbing on the ...

Page 155

1e – 2 7 engine electrical daewoo t-154 bl2,3 a102e249 assembly procedure 1. Clean all of the starter motor parts, but do not use grease-dissolving solvents for cleaning the armature and the field coils. 2. Lubricate the gears with lubricant. (begin at step 7 if proceeding with just the reassembly o...

Page 156

Engine electrical 1e – 2 8 daewoo t-154 bl2,3 a102e250 7. Install the shift lever assembly with the plunger and the boot. A102e224 8. Lubricate the gears with lubricant and install the dri- veshaft assembly with the bushing and the washer on the gear end. 9. Install the cushion and the gears. A102e2...

Page 157

1e – 2 9 engine electrical daewoo t-154 bl2,3 a102e247 11. Position the solenoid assembly and the return spring against the plunger, applying sealer to the solenoid flange. A102e226 12. Fasten the solenoid assembly with the screws. Tighten tighten the starter solenoid assembly screws to 8 n s m (71 ...

Page 158

Engine electrical 1e – 3 0 daewoo t-154 bl2,3 a102e215 17. Position the commutator end frame/brush holder as- sembly, lining up the end frame holes with the through-bolt holes in the housing. A102e239 18. Install the starter through-bolts. 19. Install the starter. Refer to “starter” in this section....

Page 159

1e – 3 1 engine electrical daewoo t-154 bl2,3 a102e258 notice: if the stator connections are not welded, melt the lead. Avoid excessive heating, as it can damage the diodes in the rectifier bridge. 4. Remove the stator connections from the rectifier bridge terminals by cutting the wires. A102e203 5....

Page 160

Engine electrical 1e – 3 2 daewoo t-154 bl2,3 a102e259 7. Remove the pulley and the collars. A102e252 8. Test the rotor for an open circuit by using the ohmme- ter with the drive end frame assembled. The reading should be sufficiently high, or the rotor must be re- placed. A102e205 9. Test the rotor...

Page 161

1e – 3 3 engine electrical daewoo t-154 bl2,3 a102e206 10. Remove the drive end frame from the shaft. 11. For vehicles with an internal generator fan, remove the drive end frame and the fan. A102e207 12. Remove the rotor assembly. A102e208 13. Remove the stator. 14. Test the stator for an open circu...

Page 162

Engine electrical 1e – 3 4 daewoo t-154 bl2,3 a102e256 15. Pry off the baffle. 16. Remove the rectifier/regulator/brush holder assem- bly screws. 17. Remove the brush holder assembly and the regula- tor, cutting the terminal between the regulator and the rectifier bridge. Important: if the brush can...

Page 163

1e – 3 5 engine electrical daewoo t-154 bl2,3 a102e211 20. Replace the rectifier bridge, if each reading is the same. 21. Test the remaining two diodes after the above pro- cedure. Notice: some kinds of digital ohmmeters are not suited for the test of the bridge diode. In this case, consult the manu...

Page 164

Engine electrical 1e – 3 6 daewoo t-154 bl2,3 a102e256 3. Weld the brush holder terminal to the regulator termi- nal, if removed. 4. Fix the brush holder with the retainer pin, and weld the regulator/brush holder assembled terminal to the rectifier terminal. 5. Apply silicone grease between the brid...

Page 165

1e – 3 7 engine electrical daewoo t-154 bl2,3 a102e201 10. Install the outside cover. A102e203 11. Position the rotor assembly shaft with the drive end frame in the slip ring end assembly until the gap be- tween the outer lace and the end frame casting is 1.9 mm (0.075 inch). 12. Install the generat...

Page 166: General Description

Engine electrical 1e – 3 8 daewoo t-154 bl2,3 general description and system operation battery the battery has three major functions in the electrical system. First, the battery provides a source of energy for cranking the engine. Second, the battery acts as a voltage stabilizer for the electrical s...

Page 167

1e – 3 9 engine electrical daewoo t-154 bl2,3 2. When charging sealed-terminal batteries out of the vehicle, install the adapter kit. Make sure all the char- ger connections are clean and tight. For best results, batteries should be charged while the electrolyte and the plates are at room temperatur...

Page 168

Engine electrical 1e – 4 0 daewoo t-154 bl2,3 notice: make sure the cables are not on or near pulleys, fans, or other parts that will move when the engine starts, damaging the parts. 4. Shift an automatic transaxle to park, or a manual transaxle to neutral. Caution: do not use cables that have loose...

Page 169: Section 1F

Daewoo t-154 bl2,3 section 1f engine controls caution: disconnect the negative battery cable before removing or installing any electrical unit or when a tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable will help prevent personal injury and da...

Page 170

1f – 2 engine controls daewoo t-154 bl2,3 dtc p1111 intake air temperature (iat) sensor intermittent high voltage 1f-107 . . . . . . . . Dtc p0112 intake air temperature (iat) sensor low voltage 1f-111 . . . . . . . . . . . . . . . . . . . Dtc p1112 intake air temperature (iat) sensor intermittent l...

Page 171

Engine controls 1f – 3 daewoo t-154 bl2,3 dtc p0406 exhaust gas recirculation (egr) pintle position sensor high voltage 1f-316 . . . . . . Dtc p0420 catalyst (oxygen sensor) low efficiency 1f-320 . . . . . . . . . . . . . . . . . . . . . . . . Dtc p0443 evaporative emission (evap) purge control circ...

Page 172

1f – 4 engine controls daewoo t-154 bl2,3 engine control module (sohc) 1f-408 . . . . . . . . . . . Electronic ignition system ignition coil 1f-409 . . . . . General description and system operation 1f-410 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ignition system operation 1f-410 ....

Page 173: Specifications

Engine controls 1f – 5 daewoo t-154 bl2,3 specifications scan tool data table parameter scaling value desired idle speed rpm ecm idle command (varies with temperature) engine rpm rpm r 50 rpm from desired rpm in drive (a/t) r 50 rpm from desired rpm in neutral (m/t) map kpa 29 – 55 (varies with mani...

Page 174

1f – 6 engine controls daewoo t-154 bl2,3 scan tool data table (cont’d) parameter scaling value fuel pump command on/off on closed loop yes/no yes throttle at idle yes/no no o2 ready (b1–s1) yes/no yes knock present yes/no no fan low on/off on/off fan high on/off on/off park/neutral (only at) p/n an...

Page 175

Engine controls 1f – 7 daewoo t-154 bl2,3 decreases), the voltage signal will decrease and the ecm will interpret the lower voltage as a warm en- gine. Egr desired position the desired exhaust gas recirculation (egr) position is the commanded egr position. The ecm calcu- lates the desired egr positi...

Page 176

1f – 8 engine controls daewoo t-154 bl2,3 sor has mainly been below 450 mv, indicating a lean air/ fuel mixture, short term fuel trim will increase to tell the ecm to add fuel. If the oxygen sensor voltage stays mainly above the threshold, the ecm will re- duce fuel delivery to compensate for the in...

Page 177

Engine controls 1f – 9 daewoo t-154 bl2,3 fastener tightening specifications application n m lb-ft lb-in camshaft position sensor 12 – 106 crankshaft position sensor retaining bolt 10 – 89 electronic ignition system ignition coil retaining bolts 10 – 89 engine control module (ecm) retaining bolt – s...

Page 178

1f – 10 engine controls daewoo t-154 bl2,3 fuel system specifications gasoline all engines are designed to use unleaded fuel only. Un- leaded fuel must be used for proper emission control system operation. Its use will also minimize spark plug fouling and extend engine oil life. Using leaded fuel ca...

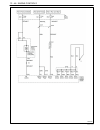

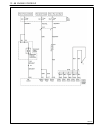

Page 179

Engine controls 1f – 11 daewoo t-154 bl2,3 schematic and routing diagrams ecm wiring diagram ( 1.5l soh c-1o f6) taa1f010

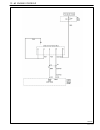

Page 180

1f – 12 engine controls daewoo t-154 bl2,3 taa1f020 ecm wiring diagram ( 1.5l sohc - 2 of 6 ).

Page 181

Engine controls 1f – 13 daewoo t-154 bl2,3 ecm wiring diagram (1.5l soh c-3o f6).

Page 182

1f – 14 engine controls ecm wiring diagram ( 1 .5 l s o h c-4o f6).

Page 183

Engine controls 1f – 15 daewoo t-154 bl2,3 ecm wiring diagram ( 1.5l sohc - 5 of 6 ).

Page 184

Engine controls 1f – 16 daewoo t-154 bl2,3 ecm wiring diagram ( 1.5l sohc - 6 of 6 ).

Page 185

1f –17 engine controls daewoo t-154 bl2,3 connector end view c1f0409a date link connector (dlc) taa1f520 taa1f530

Page 186

Engine controls 1f –18 daewoo t-154 bl2,3 connector end view (cont’d) taa1f550 a402f081 a102f074 taa1f610 ( ) : 1.5l sohc a102f076.

Page 187

1f –19 engine controls daewoo t-154 bl2,3 connector end view (cont’d) taa1f590 ( ) : 1.5l sohc (1) (2) taa1f620 a102f089 a102f082 a102f075 a402f020

Page 188

Engine controls 1f –20 daewoo t-154 bl2,3 connector end view (cont’d) taa1f560 a402f022 a402f017 taa1f570 taa1f600 (a) (b) (c).

Page 189

1f – 21 engine controls daewoo t-154 bl2,3 connector end view (cont’d) taa1f580 ( ) : 1.5l sohc (a) (b) (c) (d) (e) a402f028 a402f019 a102f086.

Page 190: Blank

Engine controls 1f –22 daewoo t-154 bl2,3 blank.

Page 191: Component Locator

1f –2 3 engine controls daewoo t-154 bl2,3 component locator component locator – sohc.

Page 192

Engine controls 1f –24 daewoo t-154 bl2,3 components on ecm harness 11 engine control module (ecm) 12 data link connector (dlc) 13 malfunction indicator lamp 15 fuse panel (2) ecm controlled devices 21 fuel injector (4) 22 idle air control (iac) valve 23 fuel pump relay 24 engine fan relays 25 a/c c...

Page 193: Diagnosis

1f –25 engine controls daewoo t-154 bl2,3 diagnosis system diagnosis diagnostic aids if an intermittent problem is evident, follow the guide- lines below. Preliminary checks before using this section you should have already per- formed the “on-board diagnostic system check.” perform a thorough visua...

Page 194

Engine controls 1f –26 daewoo t-154 bl2,3 tec (tooth error correction) learn procedure when an ecm is reflashed, initialized or replaced, and driveplate of flywheel has been replaced, follow these procedures to relearn the crankshaft position (ckp) system variation: caution: to avoid personal injury...

Page 195: Blank

Daewoo t-154 bl2,3 blank.

Page 196

1f –28 engine controls daewoo t-154 bl2,3 tta1f250

Page 197

Engine controls 1f –29 daewoo t-154 bl2,3 on-board diagnostic (eobd) system check circuit description the on-board diagnostic (eobd) system check is the starting point for any driveability complaint diagnosis. Before using this procedure, perform a careful visual/ physical check of the engine contro...

Page 198

1f – 30 engine controls daewoo t-154 bl2,3 on-board diagnostic (eobd) system check (cont’d) ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value(s) ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no 7 compare the ecm data values displayed on the scan tool to the typical engine scan data val...

Page 199: Blank

Engine controls 1f –31 daewoo t-154 bl2,3 blank.

Page 200

1f –32 engine controls daewoo t-154 bl2,3 multiple ecm information sensor dtcs set system description th e engine control module (ecm) monitors various sensors to determine engine operating conditions. The ecm controls fuel delivery, spark advance, transaxle operation, and emission control device op...

Page 201

Engine controls 1f –33 daewoo t-154 bl2,3 multiple ecm information sensor dtcs set ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no 1 perform an on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to...

Page 202

1f –34 engine controls daewoo t-154 bl2,3 multiple ecm information sensor dtcs set (cont’d) ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no 11 replace the egr valve. Is the repair complete? – go to step 21 – 12 locate and repair short ...

Page 203: Blank

Engine controls 1f –35 daewoo t-154 bl2,3 blank.

Page 204

1f –36 engine controls daewoo t-154 bl2,3 taa1f240

Page 205

Engine controls 1f –37 daewoo t-154 bl2,3 taa1f260

Page 206

1f –38 engine controls daewoo t-154 bl2,3 engine cranks but will not run test description the number(s) below refer to step(s) on the diagnostic table. 1. The on-board diagnostic (eobd) system check prompts the technician to complete some basic checks and store the freeze frame and failure re- cords...

Page 207

Engine controls 1f –39 daewoo t-154 bl2,3 engine cranks but will not run (cont’d) step action value(s) yes no 10 1. Install a scan tool. 2. Turn the ignition on, the engine off and close the throttle. Does the throttle position (tp) sensor read less than the specified value. 1.0 v go to step 11 go t...

Page 208

1f – 40 engine controls daewoo t-154 bl2,3 engine cranks but will not run (cont’d) step action value(s) yes no 22 check for an open or short in the wire between the ckp connector terminal 3 and ground. Is the problem found? – go to step 25 go to step 40 23 check for an open or short in the wire betw...

Page 209

Engine controls 1f –41 daewoo t-154 bl2,3 engine cranks but will not run (cont’d) step action value(s) yes no 33 1. Repair the wiring as needed. 2. Connect the ei system ignition coil connector. 3. Check for the presence of spark from all of the ignition wires. Is spark present from all of the ignit...

Page 210

1f –42 engine controls daewoo t-154 bl2,3 engine cranks but will not run (cont’d) step action value(s) yes no 45 1. Check the fuel filter for a restriction. 2. Inspect the fuel lines for kinks and restrictions. Is the problem found? – go to step 46 go to step 47 46 1. Replace the fuel filter and/or ...

Page 211

Engine controls 1f –43 daewoo t-154 bl2,3 engine cranks but will not run (cont’d) step action value(s) yes no 56 1. Turn the ignition off. 2. Connect a test light between the fuel pump relay connector terminal 85 and battery positive. 3. Turn the ignition on. 4. With the ignition on, the test light ...

Page 212

1f – 44 engine controls daewoo t-154 bl2,3 engine cranks but will not run (cont’d) step action value(s) yes no 66 1. Turn the ignition off. 2. Connect a test light between the fuel injector harness connector terminal 2 and battery positive. 3. Crank the engine. 4. Repeat steps two and three for each...

Page 213: Blank

Engine controls 1f –45 daewoo t-154 bl2,3 blank.

Page 214

1f – 4 6 engine controls daewoo t-154 bl2,3 taa1f230

Page 215

Engine controls 1f – 4 7 daewoo t-154 bl2,3 no malfunction indicator lamp circuit description when the ignition is turned on, the malfunction indica- tor lamp (mil) will be turned on and remain on until the engine is running, if no diagnostic trouble codes (dtcs) are stored. Battery voltage is suppl...

Page 216

1f – 4 8 engine controls daewoo t-154 bl2,3 no malfunction indicator lamp step action value yes no 1 perform an on-board diagnostic (eobd) system check. Is the system check complete? – go to step 2 go to “on- board diag- nostic system check” 2 turn the ignition switch on, with the engine off. Is the...

Page 217

Engine controls 1f – 4 9 daewoo t-154 bl2,3 no malfunction indicator lamp (cont’d) step action value yes no 15 with a test light still connected to ground, probe the ignition feed terminal k18. Does the test light illuminate? – go to step 18 go to step 19 16 repair the open battery feed circuit. Is ...

Page 218

1f – 50 engine controls daewoo t-154 bl2,3 tab1f230

Page 219

Engine controls 1f – 51 daewoo t-154 bl2,3 malfunction indicator lamp on steady circuit description when the ignition is turned on, the malfunction indica- tor lamp (mil) will be turned on and remain on until the engine is running, if no diagnostic trouble codes (dtcs) are stored. Battery voltage is...

Page 220

1f – 52 engine controls daewoo t-154 bl2,3 fuel system diagnosis system description the fuel pump is an in-tank fuel pump mounted to a fuel sender assembly. The fuel pump will remain on as long as the engine is cranking or running and the engine control module (ecm) is receiving reference pulses fro...

Page 221

Engine controls 1f – 53 daewoo t-154 bl2,3 fuel system diagnosis (cont’d) step action value(s) yes no 5 1. Relieve the fuel system pressure. 2. Install a fuel pressure gauge. 3. Turn the ignition on. Is the fuel pressure within the values specified but not holding steady? 284-325 kpa (41-47 psi) go ...

Page 222

1f – 54 engine controls daewoo t-154 bl2,3 fuel system diagnosis (cont’d) step action value(s) yes no 16 1. Replace the fuel pressure regulator. 2. Disconnect the fuel pressure regulator vacuum hose. 3. Start the engine. 4. Allow the engine to idle. 5. Connect the fuel pressure regulator vacuum hose...

Page 223: Blank

Engine controls 1f – 55 daewoo t-154 bl2,3 blank.

Page 224

1f – 5 6 engine controls daewoo t-154 bl2,3 taa1f330 fuel pump relay circuit check circuit description when the ignition switch is turned on, the engine control module ecm will activate the fuel pump relay and run the in-tank fuel pump. The fuel pump will operate as long as the engine is cranking or...

Page 225

Engine controls 1f – 57 daewoo t-154 bl2,3 fuel pump relay circuit check step action value(s) yes no 1 1. Turn the ignition off for 10 seconds. 2. Turn the ignition on. 3. Listen for in-tank fuel pump operation. Does the fuel pump operate for the time specified? 2 sec system ok go to step 2 2 1. Tur...

Page 226

1f – 58 engine controls daewoo t-154 bl2,3 fuel pump relay circuit check (cont’d) step action value(s) yes no 10 1. Repair the wire between the fuel pump relay connector terminal 86 to the ecm connector terminal k54. 2. Install the fuel pump relay. 3. Turn the ignition off for 10 seconds. 4. Turn th...

Page 227: Blank

Engine controls 1f – 59 daewoo t-154 bl2,3 blank.

Page 228

1f – 60 engine controls daewoo t-154 bl2,3 taa1f140 manifold absolute pressure check circuit description the manifold absolute pressure (map) sensor mea- sures the changes in the intake manifold pressure which result from engine load (intake manifold vacuum) and rpm changes. The map sensor converts ...

Page 229

Engine controls 1f – 61 daewoo t-154 bl2,3 manifold absolute pressure check step action value(s) yes no 1 1. Turn the ignition off. 2. Connect a scan tool to the data link connector (dlc). 3. Turn the ignition on. 4. Compare the manifold absolute pressure (map) sensor voltage reading from the scanne...

Page 230

1f – 62 engine controls daewoo t-154 bl2,3 taa1f360 idle air control system check circuit description the e ngine control module (ecm) controls the engine idle speed with the idle air control (iac) valve. To increase the idle speed, the ecm pulls the iac pintle away from its seat, allowing more air ...

Page 231

Engine controls 1f – 63 daewoo t-154 bl2,3 idle air control system check step action value(s) yes no 1 perform an on-board diagnostic (eobd) system check. Is the check completed? – go to step 2 go to “on-board diagnostic system check” 2 1. Turn the ignition off. 2. Connect the idle air control drive...

Page 232

1f – 64 engine controls daewoo t-154 bl2,3 idle air control system check (cont’d) step action value(s) yes no 11 check for an open or short in the wire between the iac connector terminal b and the engine control module (ecm) con- nector terminal m30. Is the problem found? – go to step 15 go to step ...

Page 233: Blank

Engine controls 1f – 65 daewoo t-154 bl2,3 blank.

Page 234

1f – 66 engine controls daewoo t-154 bl2,3 taa1f240

Page 235

Engine controls 1f – 6 7 daewoo t-154 bl2,3 ignition system check circuit description the electronic ignition (ei) system uses a waste spark method of spark distribution. In this type of ei system, the crankshaft position (ckp) sensor is mounted to the oil pump near a slotted wheel that is a part of...

Page 236

1f – 68 engine controls daewoo t-154 bl2,3 ignition system check (cont’d) step action value(s) yes no 5 1. Turn the ignition off. 2. Disconnect the electronic ignition (ei) system ignition coil connector. 3. While cranking the engine, measure the voltage at the ei system ignition coil connector term...

Page 237

Engine controls 1f – 69 daewoo t-154 bl2,3 ignition system check (cont’d) step action value(s) yes no 14 1. Turn the ignition on. 2. Measure the voltage between the ckp sensor connector terminals 1 and 3. Is the voltage within the value specified? 2.4-2.7 v go to step 20 go to step 15 15 measure the...

Page 238

1f – 70 engine controls daewoo t-154 bl2,3 taa1f430 engine cooling fan circuit check – without a/c circuit description the engine cooling fan circuit operates the cooling fan. The cooling fan is controlled by the engine control module (ecm) based on input from the engine coolant temperature (ect) se...

Page 239

Engine controls 1f – 71 daewoo t-154 bl2,3 (199 f). The ecm will turn the cooling fans off when the coolant temperature is 90 c (194 f). The ecm will turn the cooling fans on at high speed when the coolant temperature is 97 c (207 f). The ecm will change the cooling fans from high speed to low speed...

Page 240

1f – 7 2 engine controls daewoo t-154 bl2,3 engine cooling fan circuit check – without a/c (cont’d) ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value(s) ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ 8 ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁ...

Page 241

Engine controls 1f – 73 daewoo t-154 bl2,3 engine cooling fan circuit check – without a/c (cont’d) step action value(s) yes no 21 replace the ecm. Is the repair complete? – system ok – 22 1. Turn the ignition off. 2. Disconnect the ecm connector 2 3. Connect a fused jumper between the ecm connector ...

Page 242

1f – 7 4 engine controls daewoo t-154 bl2,3 f41f013 engine cooling fan circuit check – with a/c circuit description the engine cooling fan circuit operates the main cooling fan and the auxiliary cooling fan. The cooling fans are controlled by the en gine control module (ecm) based on inputs from the...

Page 243

Engine controls 1f – 7 5 daewoo t-154 bl2,3 short to ground in the wiring of the appropriate circuit. If the fuses become open (blown) when the cooling fans are to be turned on by the ecm, suspect a faulty cooling fan motor. The ecm will turn the cooling fans on at low speed when the coolant tempera...

Page 244

1f – 7 6 engine controls daewoo t-154 bl2,3 engine cooling fan circuit check – with a/c (cont’d) ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value(s) ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ 5 ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁ...

Page 245

Engine controls 1f – 77 daewoo t-154 bl2,3 engine cooling fan circuit check – with a/c (cont’d) step action value(s) yes no 13 1. Turn the ignition off. 2. Connect the cooling fan relay a. 3. Disconnect the engine control module (ecm) white connector. 4. Connect a fused jumper between the ecm connec...

Page 246

1f – 78 engine controls daewoo t-154 bl2,3 engine cooling fan circuit check – with a/c (cont’d) ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value(s) ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ 25 ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁ...

Page 247

Engine controls 1f – 79 daewoo t-154 bl2,3 engine cooling fan circuit check – with a/c (cont’d) step action value(s) yes no 37 1. Connect the main cooling fan connector. 2. Connect the cooling fan relay b. 3. Connect the cooling fan control relay. 4. Disconnect the ecm connector. 5. Connect a fused ...

Page 248

1f – 80 engine controls daewoo t-154 bl2,3 engine cooling fan circuit check – with a/c (cont’d) ÁÁÁÁ ÁÁÁÁ step ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ action ÁÁÁÁÁ ÁÁÁÁÁ value(s) ÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁ yes ÁÁÁÁÁÁ ÁÁÁÁÁÁ no ÁÁÁÁ ÁÁÁÁ ÁÁÁÁ 43 ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ ÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁÁ replace the cool...

Page 249: Blank

Engine controls 1f – 81 daewoo t-154 bl2,3 blank.

Page 250

1f – 82 engine controls daewoo t-154 bl2,3 taa1f250

Page 251

Engine controls 1f – 83 daewoo t-154 bl2,3 data link connector diagnosis circuit description the provision for communicating with the engine control module (ecm) is the data link connector (dlc). It is located under the instrument panel. The dlc is used to connect the scan tool. Battery power and gr...

Page 252

1f – 84 engine controls daewoo t-154 bl2,3 data link connector diagnosis (cont’d) step action value yes no 6 check the serial data circuit for a short to voltage and repair as necessary. Is a repair necessary? – go to step 17 go to step 11 7 with the test light connected to b+, probe the dlc ground ...

Page 253: Blank

Engine controls 1f – 85 daewoo t-154 bl2,3 blank.

Page 254

1f – 86 engine controls daewoo t-154 bl2,3 fuel injector balance test a fuel injector tester is used to energize the injector for a precise amount of time, thus spraying a measured amount of fuel into the intake manifold. This causes a drop in the fuel rail pressure that can be recorded and used to ...

Page 255: Blank

Engine controls 1f – 87 daewoo t-154 bl2,3 blank.

Page 256: Trouble Code Diagnosis

1f – 88 engine controls daewoo t-154 bl2,3 trouble code diagnosis clearing trouble codes notice: to prevent engine control module (ecm) damage, the key must be off when disconnecting or reconnecting the power to the ecm (for example battery cable, ecm pigtail connector, ecm fuse, jumper cables, etc....

Page 257

Engine controls 1f – 89 daewoo t-154 bl2,3 diagnostic trouble codes (cont’d) dtc description type illuminate dtc description 1.5s illuminate mil p1134 oxygen sensor (o2s 1) transition ratio e yes p0137 heated oxygen sensor (ho2s 2) low voltage e yes p0138 heated oxygen sensor (ho2s 2) high voltage e...

Page 258

1f – 90 engine controls daewoo t-154 bl2,3 diagnostic trouble codes (cont’d) dtc description type illuminate dtc description 1.5s illuminate mil p0406 exhaust gas recirculation (egr) pintle position sensor high voltage e yes p0420 catalyst (oxygen sensor) low efficiency a yes p0443 evaporative emiss...

Page 259: Blank

Engine controls 1f – 90 daewoo t-154 bl2,3 blank.

Page 260

1f – 9 1 engine controls daewoo t-154 bl2,3 diagnostic trouble code (dtc) p0106 manifold absolute pressure (map) sensor rationality circuit description the engine control module (ecm) uses the manifold absolute pressure (map) sensor to control the fuel delivery and the ignition timing. The map senso...

Page 261

Engine controls 1f – 92 daewoo t-154 bl2,3 5. This step checks if the reason for no map change was due to a faulty sensor or vacuum source to the sensor. 6. The map sensor vacuum source should be thor- oughly checked for restrictions. A drill bit can be used to clean out any casting flash that may e...

Page 262

1f – 93 engine controls daewoo t-154 bl2,3 dtc p0106 manifold absolute pressure (map) sensor rationality (cont’d) step action value yes no 9 1. Using the scan tool, clear the diagnostic trouble codes (dtcs). 2. Start the engine and idle at normal operating temperature. 3. Operate the vehicle within ...

Page 263: Blank

Engine controls 1f – 94 daewoo t-154 bl2,3 blank.

Page 264